air filter CHEVROLET CAMARO 1971 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1971, Model line: CAMARO, Model: CHEVROLET CAMARO 1971 2.GPages: 88, PDF Size: 34.8 MB

Page 36 of 88

Downloaded from www.Manualslib.com manuals search engine SAFETY CHECKS

Your Camaro not only conforms to all U.S. Fed

eral Motor Vehicle

Safety Standards applicable at

time of manufacture, but also incorporates other im

portant General Motors safety features. Even with

these safety features, however, continued safe and

dependable operation depends greatly upon regular

vehicle maintenance.

This section discusses the various components and

systems of your vehicle that should be checked regu-

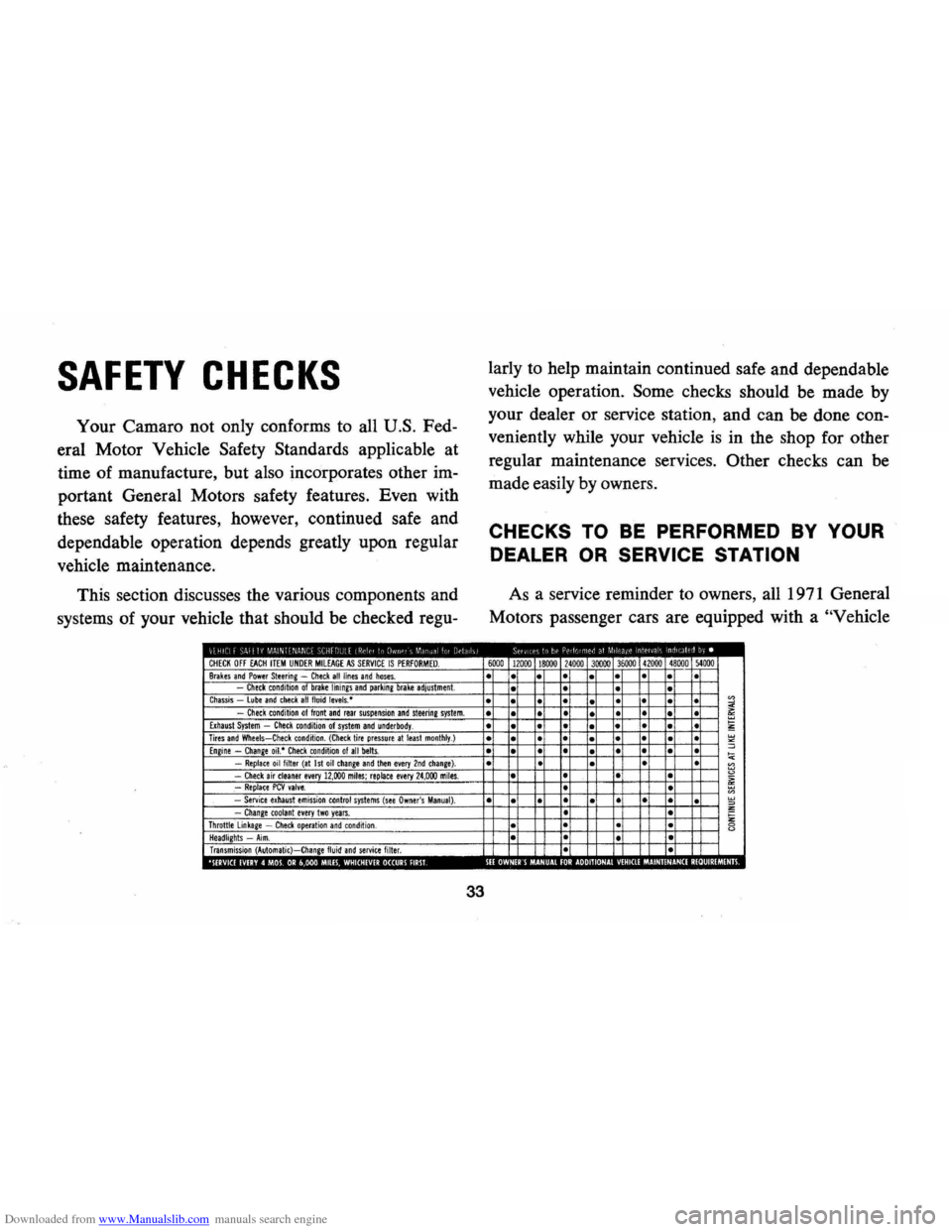

CHECK OFF EACH ITEM UNDER MIlEAGE AS SERVICE IS PERFORMED. Brakes and Power Steering -Check all lines and hoses. Check condition of brake linings and parking brake adjustment. Chassis lube and check all fluid levels,· Check condition of front and rear suspension and steerine system. Exhaust System -Check condition of system and underbody. Tires and Wheels-Check condition. (Check tire pressure at least monthly.) Engine -Change oil.· Check condition 01 all belts. -Replace oil filter (at 1st oil change and tllen every 2nd chanie). -Check air cleaner every 12,000 miles; replace every 24,000 miles. .-Replace PCV valve. -Service exhaust emission control systems (see Owner's Manual). -Change toolanl every Iwo years. Throttle linkage -Check operation and condition . Headlights -Aim. Transmission (Automatic)-Change fluid and service filter. 0 ,', III · 0

33

larly to help maintain continued safe and dependable

vehicle operation.

Some checks should be made by

your dealer or service station, and can be done con

veniently while your vehicle

is in the shop for other

regular maintenance services.

Other checks can be

made easily by owners.

CHECKS TO BE PERFORMED BY YOUR

DEALER OR SERVICE STATION

As a service reminder to owners, all 1971 General

Motors passenger cars are equipped with a

"Vehicle

6000 12000 18000 24000 30000 36000 41000 48000 )4000

• •

• •

• • • •

• • •

• •

• • • • • • •

• • • • • • • • • • •

• • • •

• • •

• •

• • • •

• • • • • • •

• • • • •

• •

• •

• • •

• •

• • • • •

• • • • • •

•

• • •

· • · •

• • • • •

• 0 o· 00 0 ·

0

Page 46 of 88

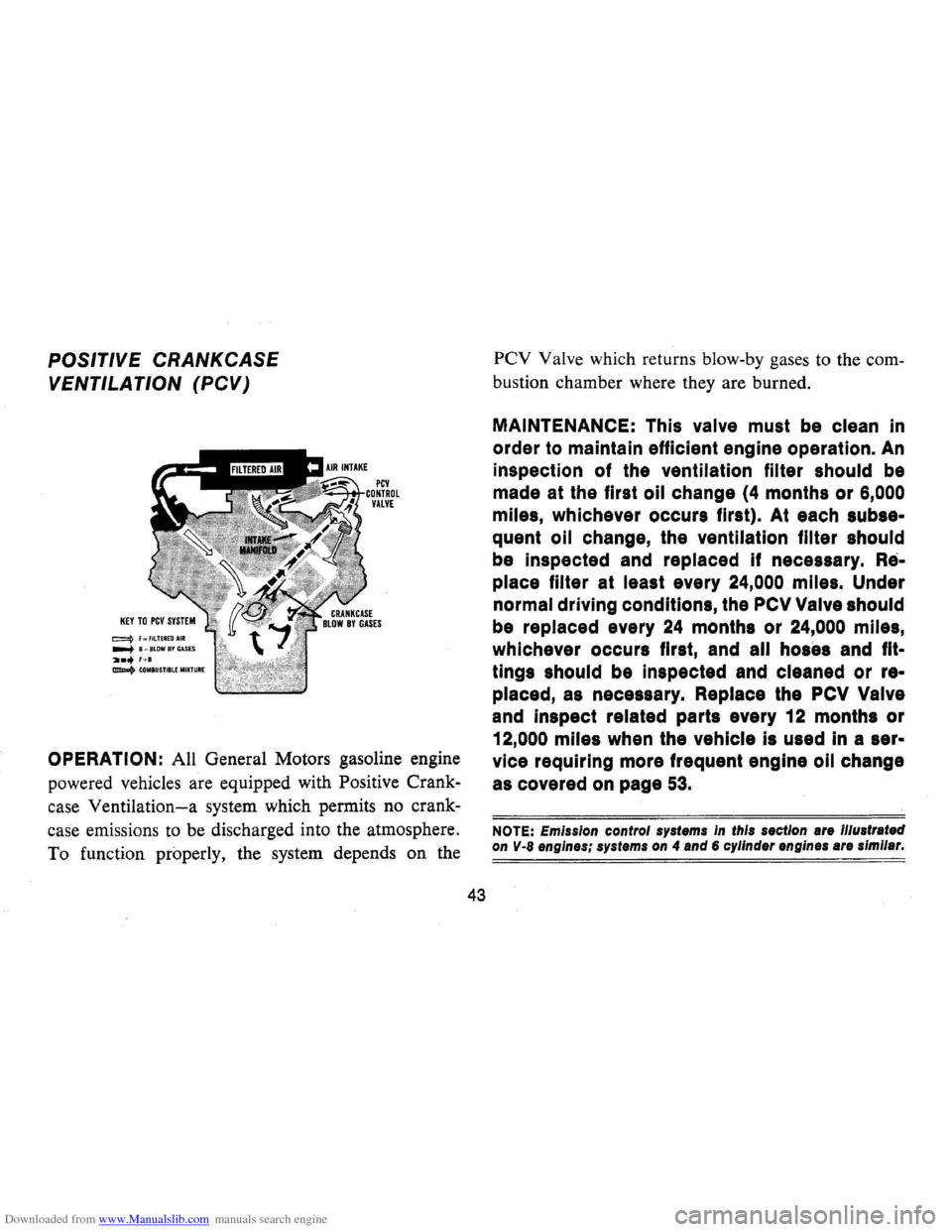

Downloaded from www.Manualslib.com manuals search engine POSITIVE CRANKCASE

VENTILATION (PCV)

~F"'FILnREDAIR --+ B = BLOW BY GASES :lI." HB ~COMBUSTlBlEMIXTURE

pey

VALVE

OPERATION: All General Motors gasoline engine

powered vehicles are equipped with Positive

Crank

case Ventilation-a system which permits no crank

case emissions to be discharged into the atmosphere.

To function properly, the system depends on the

43

PCV Valve which returns blow-by gases to the com

bustion chamber where they are burned.

MAINTENANCE: This valve must be clean in

order to maintain efficient engine operation.

An

inspection of the ventilation filter should be

made at the first oil change

(4 months or 6,000

miles, whichever occurs first). At each subse

quent oil change, the ventilation filter

should

be inspected and replaced if necessary. Re

place filter at least every 24,000 miles. Under

normal driving conditions, the PCV Valve should

be replaced every 24 months or 24,000 miles,

whichever occurs first, and

all hoses and fit·

tings

should be inspected and cleaned or re

placed, as necessary. Replace the PCV Valve

and inspect related parts every 12 months or

12,000 miles when the vehicle is used in a ser

vice requiring more frequent engine oil change

as covered on page 53.

NOTE: Emission control systems in this section are Illustrated on V-8 engines; systems on 4 and 6 cylinder engines are similar.

Page 48 of 88

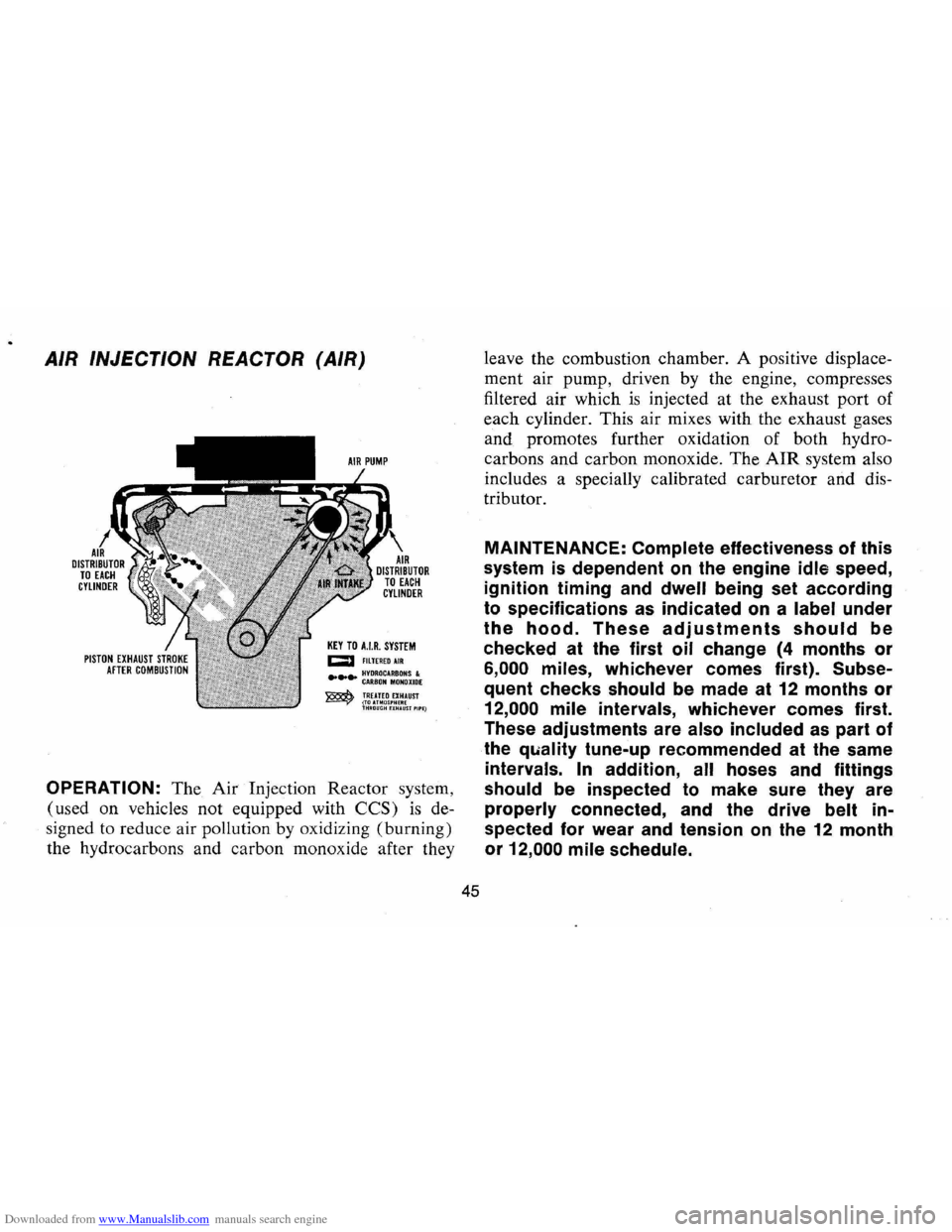

Downloaded from www.Manualslib.com manuals search engine AIR INJECTION REACTOR (AIR)

KEY TO HR. SYSTEM CJ F1LTEREDAIR

.... ~!~:~~A:~~~~I:E ~ TREATED EXHAUST ~(TOUMOS'HERE THMOUGHHHAlIST'II'E)

OPERATION: The Air Injection Reactor system,

(used on vehicles not equipped with

CCS) is de

signed to reduce air pollution by oxidizing (burning)

the hydrocarbons and carbon monoxide after they

45

leave the combustion chamber. A positive displace

ment air pump, driven by the engine, compresses

filtered air which

is injected at the exhaust port of

each cylinder. This air mixes with the exhaust gases

and promotes further oxidation of both hydro

carbons and carbon monoxide. The

AIR system also

includes a specially calibrated carburetor and dis

tributor.

MAINTENANCE: Complete effectiveness of this

system

is dependent on the engine idle speed,

ignition timing and

dwell being set according

to specifications as indicated on a label under

the hood. These adjustments should be

checked at the first oil change (4 months or

6,000 miles, whichever comes first). Subse

quent checks should be made at 12 months or

12,000 mile intervals, whichever comes first.

These adjustments are

also included as part of

the

quality tune-up recommended at the same

intervals. In addition, all hoses and fittings

should be inspected to make sure they are

properly connected, and the drive belt in

spected for wear

and tension on the 12 month

or

12,000 mile schedule.

Page 49 of 88

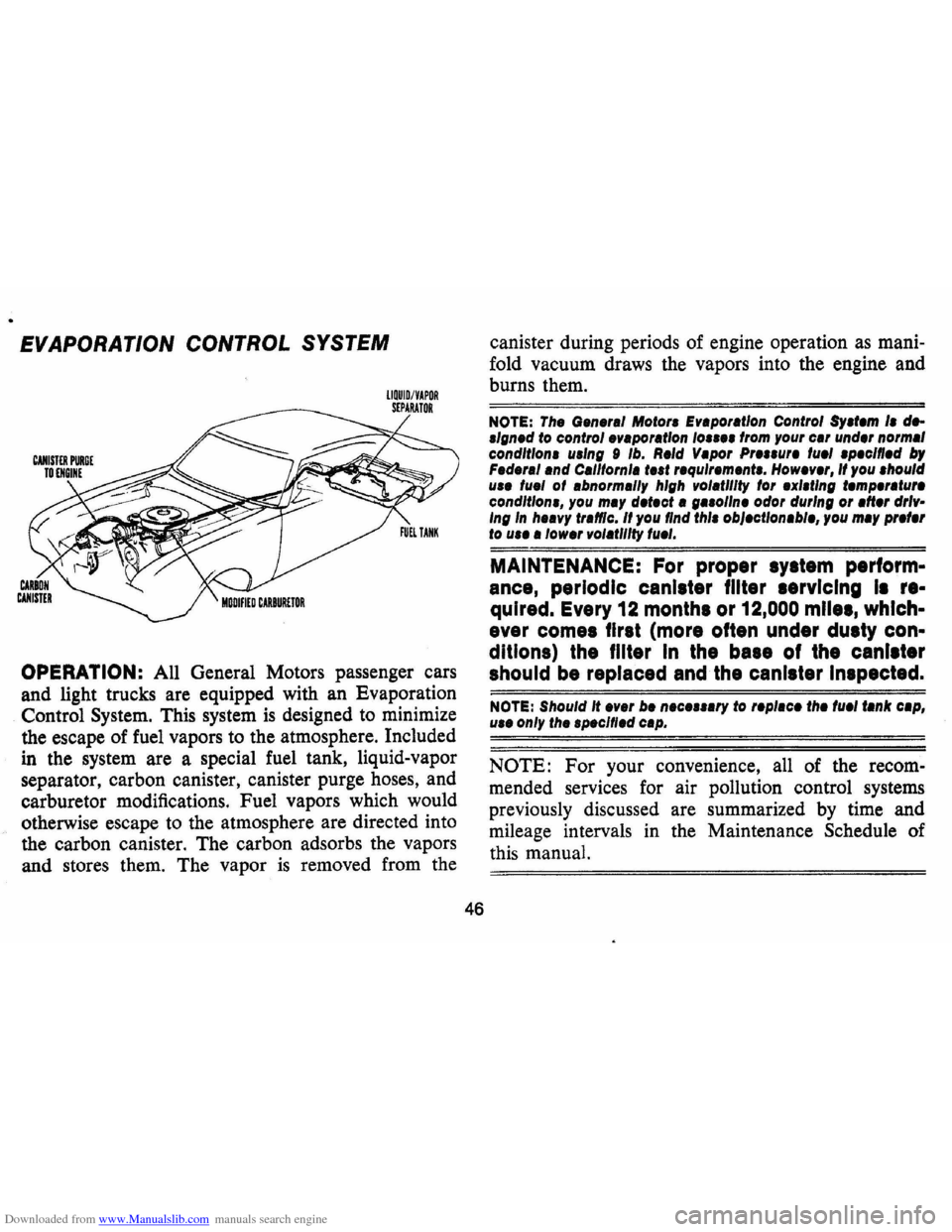

Downloaded from www.Manualslib.com manuals search engine EVAPORATION CONTROL SYSTEM

LIQUID/VAPOR SEPARATOR

OPERATION: All General Motors passenger cars

and light trucks are equipped with an Evaporation

Control

System. This system is designed to minimize

the escape of fuel vapors to the atmosphere. Included

in the system are a special fuel tank, liquid-vapor

separator, carbon canister, canister purge hoses, and

carburetor modifications. Fuel vapors which would

otherwise escape to the atmosphere are directed into

the carbon canister. The carbon adsorbs the vapors

and stores them. The vapor

is removed from the

46

canister during periods of engine operation as mani

fold vacuum draws the vapors into the engine and

burns them.

NOTE: Th. G.n.r.' Motora E".por.tlon Control Sy.t.m I. de.'gn.d to control ."aporatlon 10 •••• trom your c.r und.r normal condition. u.'ng 9 lb. R.ld Vapor Pr ••• ur. tu.' .p.cltl.d by F.d.r.' .nd C.lltorn/a t •• t r.qulr.m.nt •. How.".r, It 'Iou .hould u.. tu.' ot .bnorm.lly high "o/.tlllty tor .x/.tlnll t.mperatur.

condition., you may d.t.ct • ga.olln. odor during or att.r dr/,,· Ing In h •• "y tr.mc. It 'Iou find thl. obJ.ctlonabl., you may pr.t.r to u ••• low.r "o/atlllty tu.'.

MAINTENANCE: For proper system perform

ance, periodic canister tllter servicing II re

quired. Every

12 months or 12,000 miles, which

ever comes first (more often under dusty con

ditions) the filter

In the base of the can liter

should be replaced and the canister Inspected.

NOTE: Should It .".r b. n.c •••• ry to r.pl.c. the tu.' tank cap, u •• only the .peclfl.d c.p.

NOTE: For your convenience, all of the recom

mended services for air pollution control systems

previously discussed are summarized

by time and

mileage intervals in the Maintenance Schedule of

this manual.

Page 58 of 88

Downloaded from www.Manualslib.com manuals search engine the crankcase ventilation valve.

Regular replacement of the PCV

Valve

is recommended at 24-month

or

24,000-mile intervals.

G.M. Evaporation

Control SYltem

The Evaporation Control System

requires only periodic canister filter

servicing.

Every 12 months

or 12,000

miles, whichever occurs first, (more

often under dusty conditions) the

filter in the base of the canister

must be replaced and the canister

inspected.

Drive Beltl

Every 6,000 miles or 4 months

inspect drive belts for wear, fray

ing, cracking, and tension. Belts

which are in poor condition should

be replaced immediately.

Check tension by applying

mod

erate thumb pressure midway be

tween pUlleys. If the center-to

center distance between pulleys

is

13 to 16 inches, the belt should

deflect

lh inch. If the center-to

center distance

is 7 to 10 inches,

the belt should deflect

1;4 inch.

Loose belts should be retensioned

to give the correct deflection.

Air Cleaner

Paper Ellment Type -First

12,000 miles, inspect element for

dust leaks, holes

or other damage,

replace

if necessary. If satisfac

tory, rotate element

1800 from

originally installed position.

Re

place element at 24,000, miles.

Element must not be washed,

oiled, tapped or cleaned with an

air hose.

Crankca.e Ventilation Filter

(located within Air Cleaner)

If so equipped, inspect at every oil

change and replace if necessary.

Replace at least every

24,000

miles; more often under dusty

driving conditions.

Flame Arrester -Every 12,000

55

miles-Clean the arrester (located

in the base of the air cleaner) with

kerosene

or a suitable solvent. Dry

with compressed air.

The engine air cleaner should

be installed at all times unless

temporary removal

is necessary

during repair or maintenance of

the vehicle, because in the absence

of the air cleaner backfiring could

cause

fire in the engine compart

ment.

For maximum protection spe

cify an AC Acron air filter ele

ment.

Fuel Filter

Replace carburetor inlet filter

element every 12 months or

12,000 miles, whichever occurs

first or, if an in-line filter

is also

used, every

24,000 miles.

Replace in-line filter every

24,000 miles.

When replacement

is necessary,

always insist on AC Acron filters.

Page 69 of 88

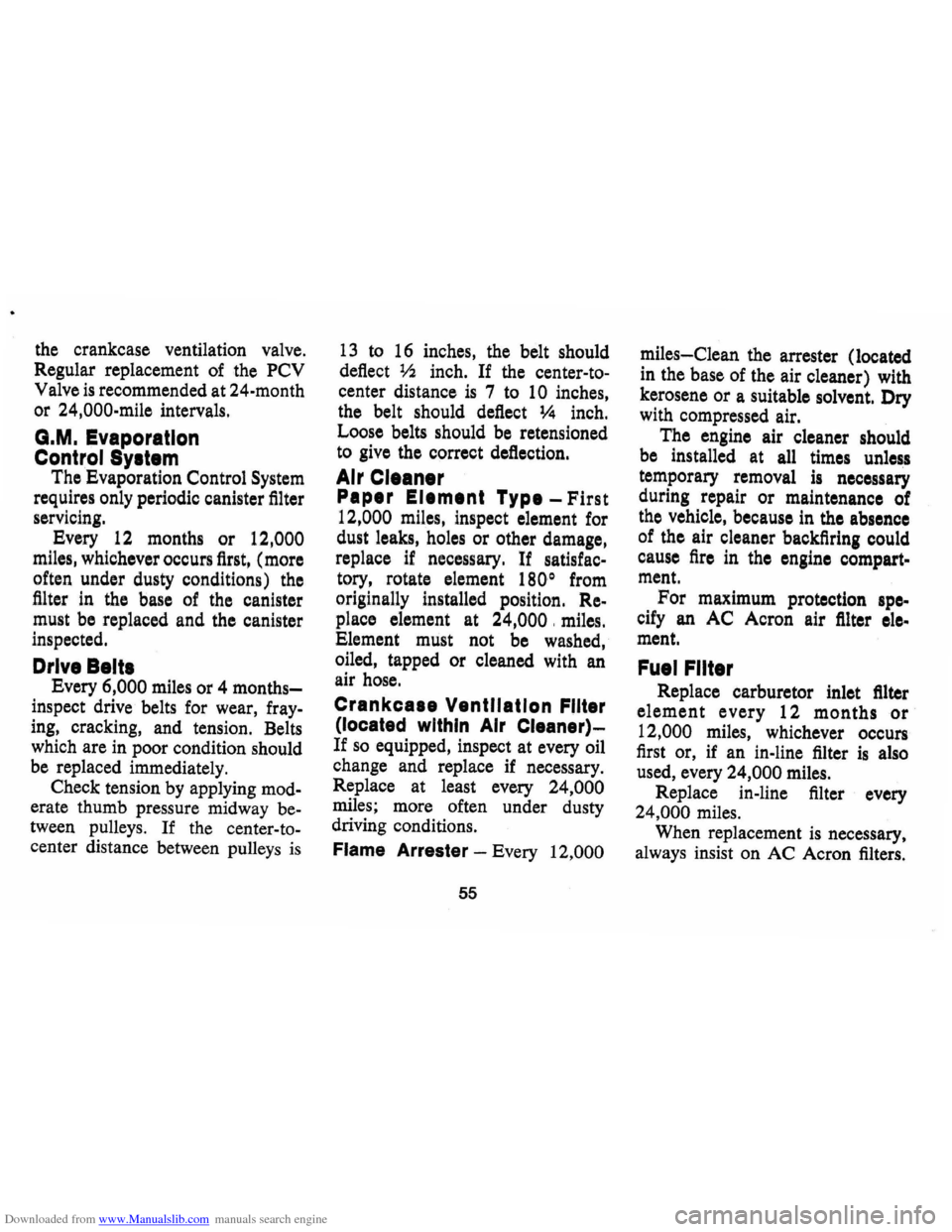

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE SCHEDULE

This section contains a complete summary of the scheduled maintenance recommended for your vehicle.

Intarval

Every 6,000 mile. or 4 month., which· ever occur. flrat

Service To Be Performed

• Change engine oil (normal passenger car serv

ice"). Not to exceed 6,000 miles.

•

Lubricate front suspension and steering linkage.

• Check brake lines and hoses.

• Check all lubricant and fluid levels (power

steering pump, brake master cylinder, transmission, rear axle, radiator, battery).

• Check Power Steering lines and hoses.

• Hood latch lubrication.

• Check manifold

heat control valve.

•

Lubricate transmission floor shift linkage.

• Check

throttle and parking brake linkage and

body parts.

• Check emission control items at first oil

change (adjust engine idle speed, dwell, ignition timing) .

• Check exhaust system for proper mounting , leaks, and missing or damaged parts.

Interval

At first oil change

At first

oil change and

every second

oil change

thereafter

Every

6,000

mlle&

Service To Be Performed

• Check air conditioning system hose connections, refrigerant charge and for refrigerant

leaks.

• Tire and wheel condition inspection.

• Inspect accessory drive belts.

•

Lubricate parking brake pulley, cables and linkage.

Inspect crankcase ventilation filter (located in

air cleaner) and replace if necessary.

• Set idle speed , ignition timing, and dwell to

specifications.

• Change engine oil filter."

•

Rotate ti res • Lubricate parking brake pulley, cables and

linkage .

·Servlce more often during severe operating conditions as outlined under Service and Maintenance.

66

Page 70 of 88

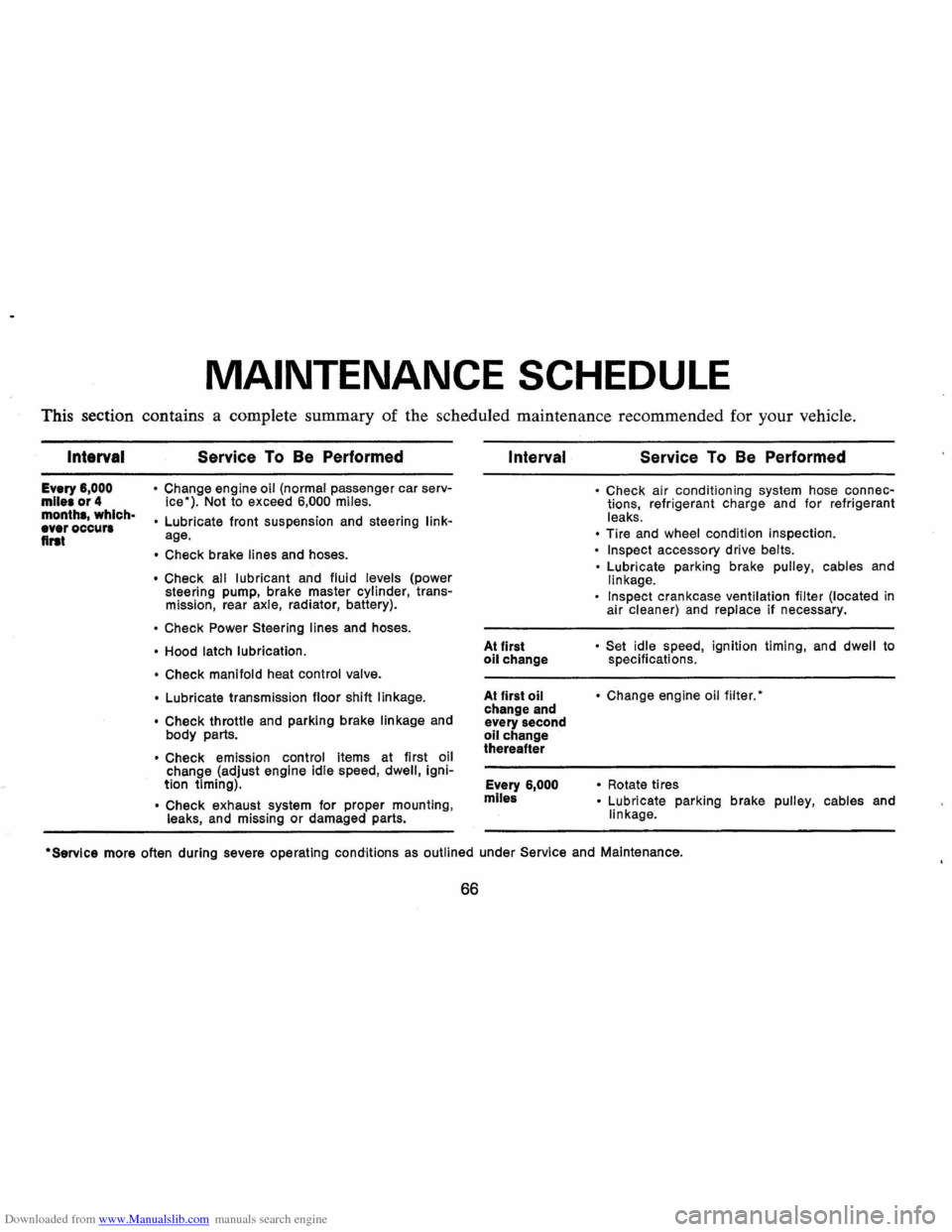

Downloaded from www.Manualslib.com manuals search engine Interval

First 12,000 miles Every 12

months

or 12,000 miles

Every

24,000 miles

Service To Be Performed

• Rotate distributor cam lubricator. See 24,000 mile recommendation.

• Insp .ect air cleaner element, if satisfactory

rotate 1800 from original position and reinstall. See 24,000 mile recommendation.

• Inspect brake linings and check system for

leaks

• Inspect parking brake and throttle linkage. • Engine tune-up.

Replace carburetor 'Inlet fuel filter element. • Check emission control items. • Inspect AIR drive belt.

Evaporation Control System-Replace filter in

base of canister and inspect canister. • Check headlamp aiming.

• Repack front wheel bearings.

• Replace distributor cam lubricator. • Drain automatic transmission sump and add

fresh fluid (normal passenger car service).' Adjust Powerglide low band at first fluid

change.

• Replace crankcase ventilation filter (located

within air cleaner).

• Replace Turbo Hydra-Matic sump filter.

Interval Service To Be Performed

Every 2 years • Drain radiator coolant, flush and refill system.

Every

24 months· Replace PCV Valve. Inspect all hoses and or 24,(100 miles fittings.

Every

36,000 • Check steering gear for seal leakage (actual

miles solid grease-not just oily film).

• Lubricate clutch cross shaft (sooner if necessary), remove plug and install lube fittIng.

During Winter

• Check operation of air conditioning system.

months

Periodically • Check battery liquid leve/.

• Inspect seat belts, buckles, retractors and

anchors.

• Check all lights for proper operation.

As Required

• Check wheel alignment and balancing.

'Service more often during severe operating conditions as outlined under Service and Maintenance.

67

Page 72 of 88

Downloaded from www.Manualslib.com manuals search engine The chart on the previous page, and the information on the pages

which

follow, contains information designed to aid the average

driver to discover, and possibly correct, conditions resulting in minor

mechanical

difficulties in his car. The chart, designed to point out

possible solutions to several of the most common automotive mal

functions and point out a logical checking sequence, will lead step

by step to the most likely causes and corrective procedures. If, after

making the checks and adjustments suggested, the source of the

trouble has not been found and corrected, it is strongly recom

mended that an Authorized Chevrolet Dealer inspect the vehicle and

make whatever repairs

or adjustments are necessary.

FUEL SYSTEM AND ENGINE

If the ignition switch will cause the engine to "turn over" or

"crank" but the car will not start, check Steps A through D below.

NOTE:

If continual "Rooding" of the carburetor is evidenced by a

carbur.tor wet with

fuel or black exhaust smoke, perform the

operation suggested in paragraph D only.

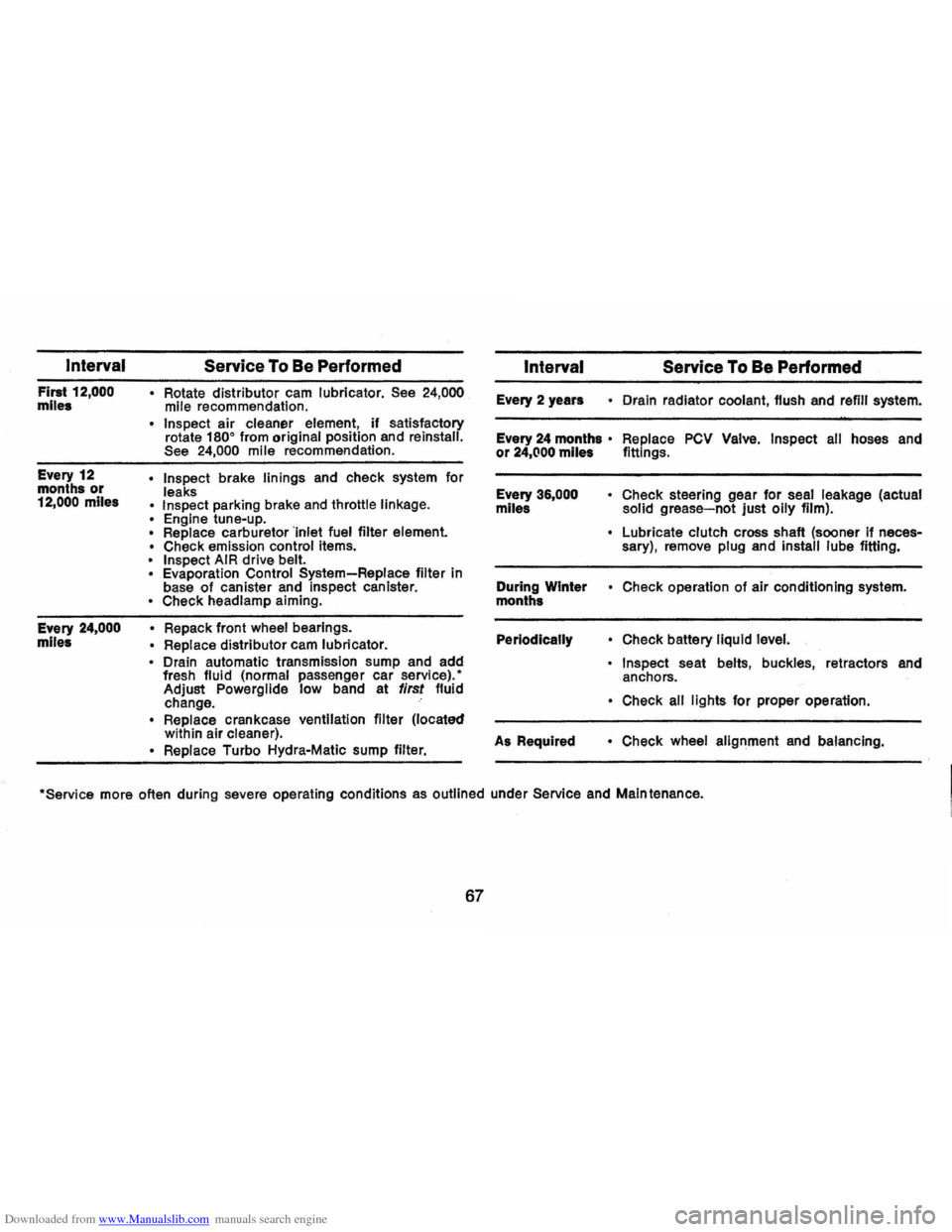

(A) The first and most obvious,

and one of the most frequently overlooked, items to check when

you have difficulty in sta rting you r car is the amount . of fuel in the

tank. Make it a habit to check the FUEL GAUGE regularly and most especially at a time when the engine will "turn over" but will not

start.

(8)

If the fuel tank is noi empty,

you may cheek further to see Checking Fllel Flow

69

whether the fuel is reaching the carburetor. Disconnect the fuel line at the carburetor and remove the center wire (ground the secondary coil terminal or disconnect the primary wire from the coil to the distributor at the coil) from the coil tower. Place a jar or cup under

the open line and briefly "cronk" the engine by means of the

starter. If fuel spurts from the fitting, you may assume that the FUEL LINES are clear and the FUEL PUMP is operating properly. If no fuel leaves the line, either the fuel

lines

or fuel pump are at fault.

See. your Authorized Chevrolet

Dealer.

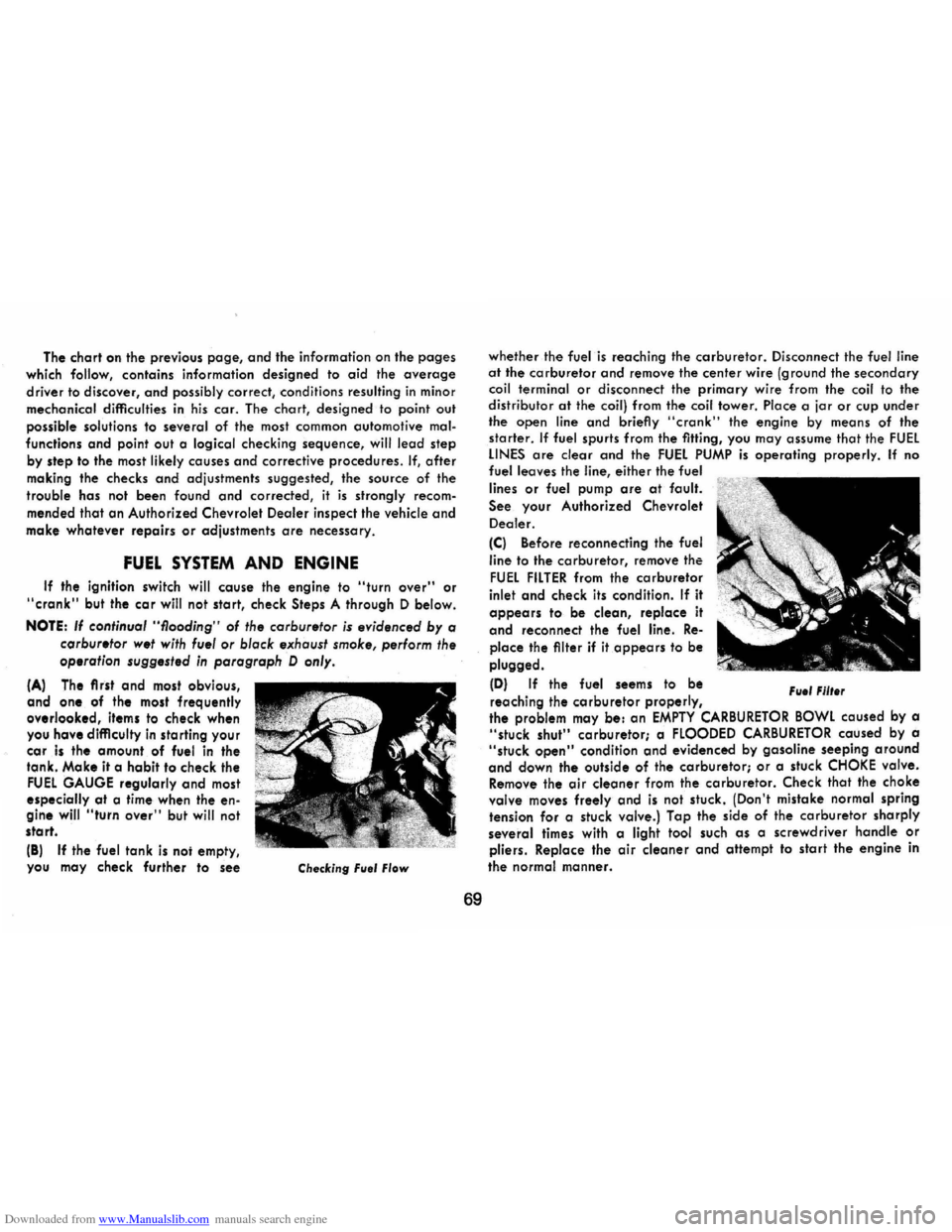

(C) Before reconnecting the fuel

line

to the carburetor, remove the

FUEL FILTER from the carburetor

inlet and check its condition. If it

appears to be clean, replace it

and reconnect the fuel line. Re

place the filter if it appears to be

plugged.

(D) If the fuel seems to be

reaching the

carburetor properly, File' Fllt.r

the problem may be: an EMPTY CARBURETOR BOWL caused by a "stuck shut" carburetor; a FLOODED CARBURETOR caused by a "stuck open" condition and evidenced by gasoline seeping around

and down the outside of the carburetor; or a stuck CHOKE valve. Remove the air cleaner from the carburetor. Check that the choke valve moves freely and is not stuck. (Don't mistake normal spring

tension for a stuck valve.) Tap the side of the carburetor sharply

several times with a light tool such as a screwdriver handle or pliers. Replace the air cleaner and attempt to start the engine in

the

normal manner.

Page 78 of 88

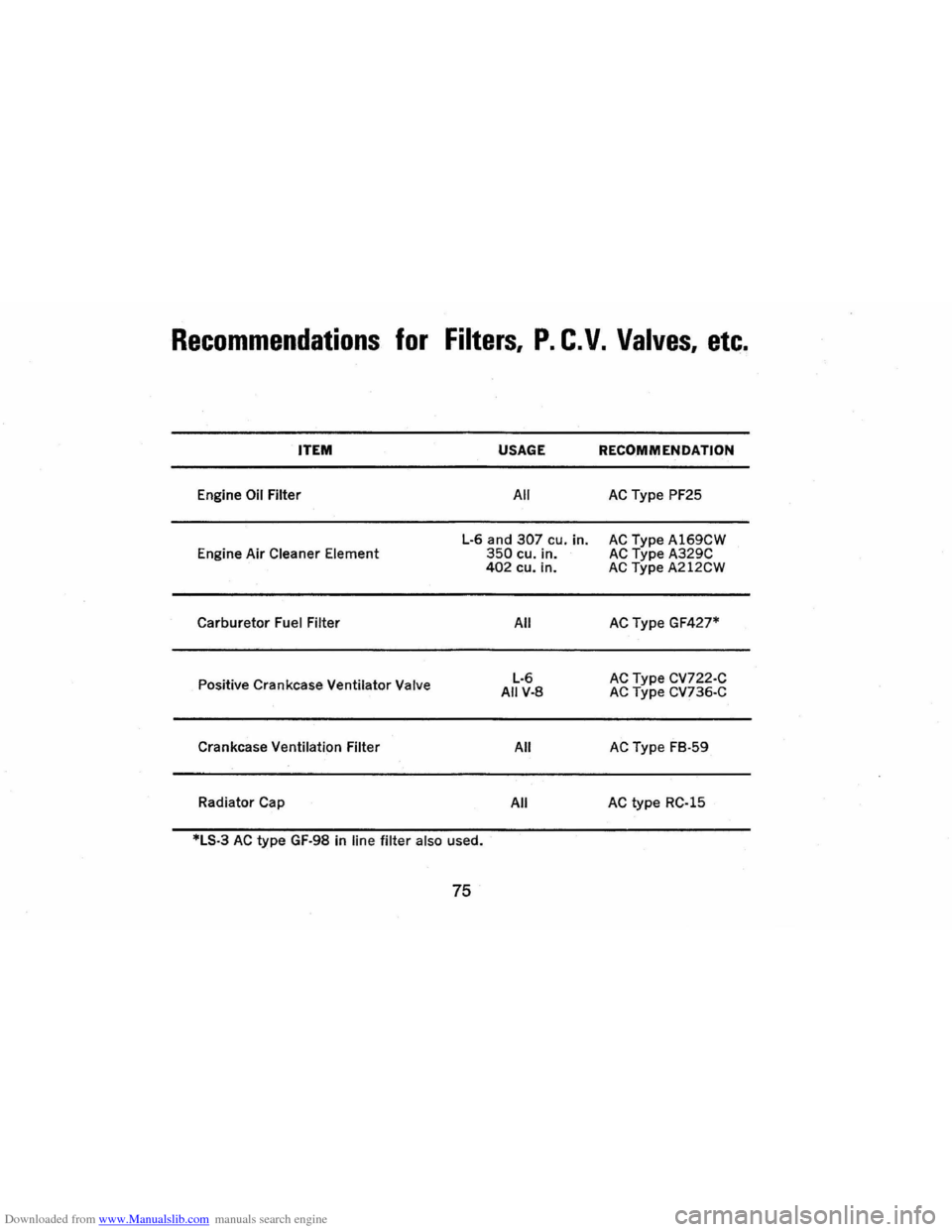

Downloaded from www.Manualslib.com manuals search engine Recommendations for Filters, P. C. V. Valves, etc.

ITEM

Engine Oil Filter

Engine Air

Cleaner Element

Carburetor Fuel Filter

Positive Crankcase Ventilator

Valve

Crankcase Ventilation Filter

Radiator Cap

USAGE

All

L·G and 307 cu. in. 350 cu. in. 402 cu. in.

All

L·G AIIV·8

All

All

*LS·3

AC type GF·98 in line filter also used.

75

RECOMMENDATION

AC Type PF25

AC Type AIG9CW AC Type A329C AC Type A212CW

AC Type GF427*

AC Type CV722·C AC Type CV73G·C

AC Type FB·59

AC type RC·15

Page 86 of 88

Downloaded from www.Manualslib.com manuals search engine INDEX

Air Cleaner. . . . . . . . . . . . . . . . . . . . . . . . .. 55

Air Conditioning. . . . . . . . . . . . . . . . . . . .. 29

Air Pollution Control Systems ...... .... 41

Ammeter ............................ 23

Antenna ............... .............. 29

Appearance Care ..................... 47

Automatic Brake Adjusters ............ 31

Axle, Rear. . . . . . . . . . . . . . . . . . . . . . . . . .. 32

Battery .. .................... ........ 64

Bearings, Front Wheel. . . . . . . . . . . . . . . .. 58

Before Driving your Car.. . . . . . . . . . . . .. 3

Brakes

................... ........... 31 Driving Through Deep Water ........ 31

Maintenance. . . . . . . . . . . . . . . . . . . . . .. 58

Master Cylinder Level. . . . . . . . . . . . . .. 58

Parking Brake ...................... 31

Warning Light. . . . . . . . . . . . . . . . . . . .. 21

Break-In Period Cars Pulling Trailers. . . . . . . . . . . . . . . . 9

New

Car . ......................... 2

Bulbs and Fuses .

..................... 76

Bumper Jack

Operation

......... . ................ 40 Stowage ........................... 40

Carbon Monoxide Caution ......... .... 11

Circuit Breakers, Headlamps. . . . . . .. 74, 76

Cleaning ............................. 47

Clock ..

............................. 24

Clutch ..................... .......... 32

Controls ....... .... ....... ........... 31

Cooling System Care. . . . . . . . . . . . . . . . .. 60

Defogger, Rear Window

............... 26

Defroster , Defogger, Windshield ........ 25

Dimmer Switch, Headlamp . . . . . . . . . . . .. 32

Directional Signals. . . . . . . . . . . . . . . . . . .. 16

Door Locks.. . . .. . . .. . . . . . . . . . . .. .. .. 3

Emergency, In Case

Of ................ 38

Brake Warning Light. . . . . . . . . . . . . . .. 21 Generator Indicator Not

Charging. . . . . . . . . . . . . . . . . . . . . . .. 21 Hazard Warning Flasher ........... .. 38

Jacking To Change Wheels ........... 40

Jump Starting With Auxiliary

Battery .......................... 39

Overheated Radiator. . . . . . . . . . . . . . .. 39

Towing ..................... ..... .. 38

Emission Control Systems .............. 41

Engine

Cooling

........................... 60

Exhaust Gas Caution ................ 11 Flooded, Starting Procedure . . . . . . . . .. 13

Overheating. . . . . . . . . . . . . . . . . . . . . . .. 39

Specifications . . . . . . . . . . . . . . . . . . . . . .. 72

Starting . . . . . . . . . . . . . . . . . . . . . . . . . .. 13

Temperature Gauge. . . . . . . . . . . . . . . .. 23

Engine Oil

Capacity. . . . . . . . . . . . . . . . . . . . . . . . . .. 72

Change Interval. . . . . . . . . . . . . . . . . . .. 53 Dip Stick. . . . . . . . . . . . . . . . . . . . . . . . . . 52

Filter .......... .................... 53

Oil Recommendations ............... 52

Viscosity

.............. ........ . .. .. 54

Exhaust

System .................... ... 37 Filters .................... ........... 75

Flashers

Hazard Warning

.................... 38 Turn Signal. ...................... , 16

Fluid Levels

Battery

............... Inside Back Cover

Brake Master Cylinder . . . . . . . . . . . .

.. 58

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . .. 52

Power Steering. . . . . . . . . . . . . . . . . . . .. 59

Radiator. . . . . . . . . . . . . . . . . . . . . . . . . .. 39

Rear Axle. . . . . . . . . . . . . . . . . . . . . . .

.. 32

Transmission. . . . . . . . . . . . . . . . . . . . . .. 56

Foreign Countries, Operation In

...... .. 65

Fuel Gauge. . . . . . . . . . . . . . . . . . . . . . . . .. 20

Full Rated Load (See Tires)

Fumes ..

........ ..... ............ .. .. 37

Fuses ............................... 76

Gasoline Filler Cap

......... 51, Inside Back Cover

Low-Lead .

........................ 42

Recommendations. . . . . . . . . . . . . . . . ..

42

Generator Indicator Light. ............. 21