brakes CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 74 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 74

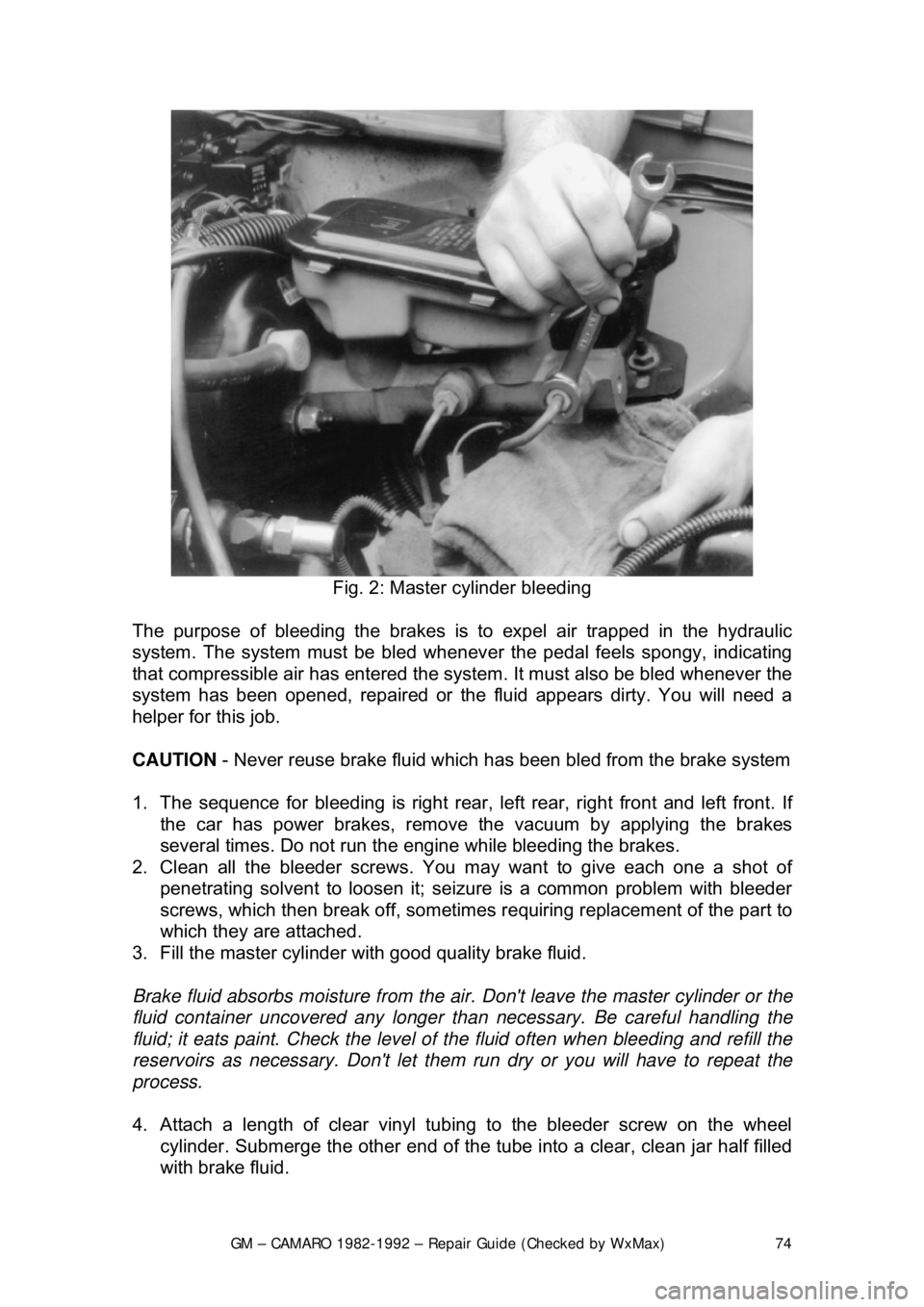

Fig. 2: Master cylinder bleeding

The purpose of bleeding the brakes is to expel air trapped in the hydraulic

system. The system must be bled whenever the pedal feels spongy, indicating

that compressible air has ent ered the system. It must also be bled whenever the

system has been opened, repaired or the fluid appears dirty. You will need a

helper for this job.

CAUTION - Never reuse brake fluid which has been bled from the brake system

1. The sequence for bleeding is right rear , left rear, right front and left front. If

the car has power brakes, remove the vacuum by applying the brakes

several times. Do not run the engine while bleeding the brakes.

2. Clean all the bleeder screws. You ma y want to give each one a shot of

penetrating solvent to loosen it; seiz ure is a common problem with bleeder

screws, which then break off, sometimes requiring replacement of the part to

which they are attached.

3. Fill the master cylinder with good quality brake fluid.

Brake fluid absorbs moisture from the air. Don't leave the master cylinder or the

fluid container uncovered any longer t han necessary. Be careful handling the

fluid; it eats paint. Check the level of the fluid often when bleeding and refill the

reservoirs as necessary. Don't let them run dry or you will have to repeat the

process.

4. Attach a length of clear vinyl t ubing to the bleeder screw on the wheel

cylinder. Submerge the other end of the tube into a clear, clean jar half filled

with brake fluid.

Page 75 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 75

5. Have your assistant sl

owly depress the brake pedal. As this is done, open

the bleeder screw 3/4 of a turn and allow the flui d to run through the tube.

Then close the bleeder screw before the pedal reaches the end of its travel.

Have your assistant slo wly release the pedal. Rep eat this process until no

air bubbles appear in the expelled fluid.

6. Repeat the procedure on the other three br akes, checking the level of fluid in

the master cylinder reservoir often.

7. Upon completion, check the brak e pedal for sponginess and the brake

warning light for unbalanced pressure . If necessary, repeat the entire

bleeding procedure.

FRONT DISC BRAKES

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

BRAKE PADS

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

INSPECTION

The pad thickness should be inspected ever y time that the tires are removed for

rotation. The outer pad can be checked by looking in each end, which is the

point at which the highest rate of wear occurs. The inner pad can be checked by

looking down through the inspection hole in the top of the caliper. If the

thickness of the pad is worn to within 0.030 in. (0.8mm) of the rivet at either end

of the pad, all the pads should be replaced.

Always replace all pads on both front wheel s at the same time. Failure to do so

will result in uneven braking action and premature wear.

REMOVAL & INSTALLATION

Page 80 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 80

4. Remove the mounting bo

lts, if equipped with single piston caliper or the

circlip and pin, if equipped with dual piston ca liper. Inspect the bolts for

corrosion and replace as necessary.

5. Remove the caliper fr om the steering knuckle an d suspend it from the body

of the car with a length of wire. Do not allow the caliper to hang by its hose.

6. Remove the pad retaining springs and remove the pads from the caliper.

7. Remove the plastic sleeves and the rubber bushings from the mounting bolt

holes.

8. Obtain a pad replacem ent kit. Lubricate and install the new sleeves and

bushings with a light coat of silicone grease.

9. Install the retainer spring on the i nboard pad, if equipped with single piston

caliper.

A new spring should be included in the pad replacement kit.

10. Install the new inboard pad into the caliper with the wear sensor at the

leading end of the shoe duri ng forward wheel rotation.

11. Install the outboard pad into the caliper.

12. Use a large pair of slip joint plie rs to bend the outer pad ears down over the

caliper, if equipped with t he single piston caliper.

13. Install the calip er onto the steering knuckle. Tighten the mounting bolts to

21-35 ft. lbs. (28-47 Nm), if equipped. In stall the wheel and lower the car. Fill

the master cylinder to its proper le vel with a good quality brake fluid.

14. Pump the brake pedal slowly a nd firmly 3 times with the engine running

before attempting to move the vehicle; bleed the brakes as required.

BRAKE CALIPER

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

REMOVAL & INSTALATION

Page 82 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 82

Avoid inhaling any dust from

any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

1. Remove

2/3 of the brake fluid from the mast er cylinder. Raise the vehicle and

remove the wheel.

2. Place a C-clamp across the caliper, positioned on the brake pads. Tighten it

until the piston is forced into its bore.

3. Remove the C-clamp. Remove the bolt holding the brake hose to the caliper.

4. Remove the Allen head caliper mounting bolts. Inspect them for corrosion

and replace them if necessary. Remove the caliper.

To install:

5. Position the caliper with the brake pad installed and install Allen head caliper

mounting bolts. Mounting bo lt torque is 21-35 ft. lbs. (28-47 Nm.) for the

caliper.

6. Install the bolt holding the brake hos e to the caliper and tighten to 18-30 ft.

lbs. (24-40 Nm.).

7. Fill the master cylinder with brake fluid.

8. Install the wheels and lower the vehicle.

CAUTION - Before moving the vehicle, pump the brakes several times to seat

the brake pad against the rotor

OVERHAUL

Some vehicles may be equipped dual piston calipers. The procedure to

overhaul the caliper is e ssentially the same with t he exception of multiple

pistons, O-rings and dust boots.

1. Remove the caliper from the ve hicle and place on a clean workbench.

CAUTION - NEVER place your finger s in front of the pistons in an attempt to

catch or protect the pistons when applying compressed air. This could result in

personal injury!

Depending upon the vehicle, there are two different ways to remove the piston

from the caliper. Refer to the brake pad replacement procedure to make sure

you have the correct procedure for your vehicle.

2. The first method is as follows: a. Stuff a shop towel or a block of wood into the caliper to catch the piston.

b. Remove the caliper piston using co mpressed air applied into the caliper

inlet hole. Inspect the piston for scor ing, nicks, corrosion and/or worn or

damaged chrome plating. The piston mu st be replaced if any of these

conditions are found.

Page 92 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 92

1. Check the rotor surface for wear, sco

ring, grooves or rust pitting. Rotor

damage can be corrected by refacing, cons ult your local garage or machine

shop. If the damage exceeds the minimu m thickness, which is stamped on

the rotor, replace the rotor.

2. Check the rotor parallelism at four or more points around the circumference,

it must not vary more than 0.0005 in . (0.013mm). Make all measurements at

the same distance in from the edge of the ro tor. Refinish the rotor if it fails to

meet specification.

3. Measure the disc runout with a dial indicator. If runout exceeds 0.004 in.

(0.10mm), and the wheel bearings are okay (runout is measured with the

disc on the car), the rotor must be refaced or replaced.

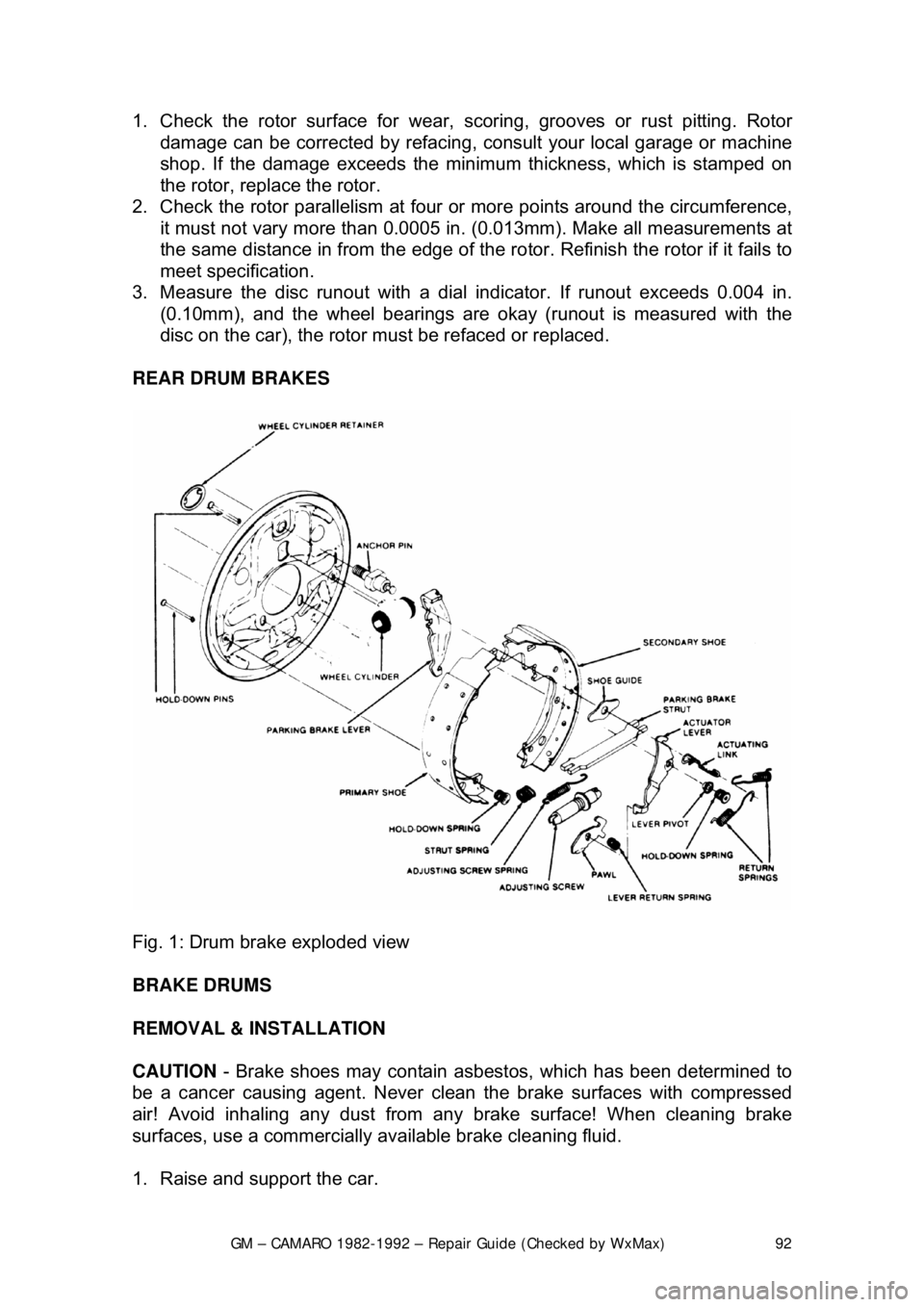

REAR DRUM BRAKES

Fig. 1: Drum brake exploded view

BRAKE DRUMS

REMOVAL & INSTALLATION

CAUTION - Brake shoes may contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

1. Raise and support the car.

Page 93 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 93

2. Remove the wheel or wheels.

3. Pull the brake drum off. It may be nec

essary to gently tap the rear edges of

the drum to start it off the studs.

4. If extreme resistance to removal is encountered, it will be necessary to

retract the adjusting screw. Knock out the access hole in the backing plate

and turn the adjuster to retract th e linings away from the drum.

5. Install a replacement hole co ver before reinstalling drum.

6. Install the drums in the same position on the hub as removed.

DRUM INSPECTION

1. Check the drums for any cracks, scores, grooves, or an out-of-round

condition. Replace if cracked. Slight scores can be removed with fine emery

cloth while extensive scoring requires turning the drum on a lathe.

2. Never have a drum turned mo re than 0.060 in. (1.524mm).

BRAKE SHOES

ADJUSTMENT

Rotate the star wheel adjuster until a sl ight drag is felt between the shoes and

drum, then back off 12 clicks on the adjusting wheel. Put the car in reverse and,

while backing up, apply the brakes seve ral times. This will allow the self-

adjusters to complete the adjustment.

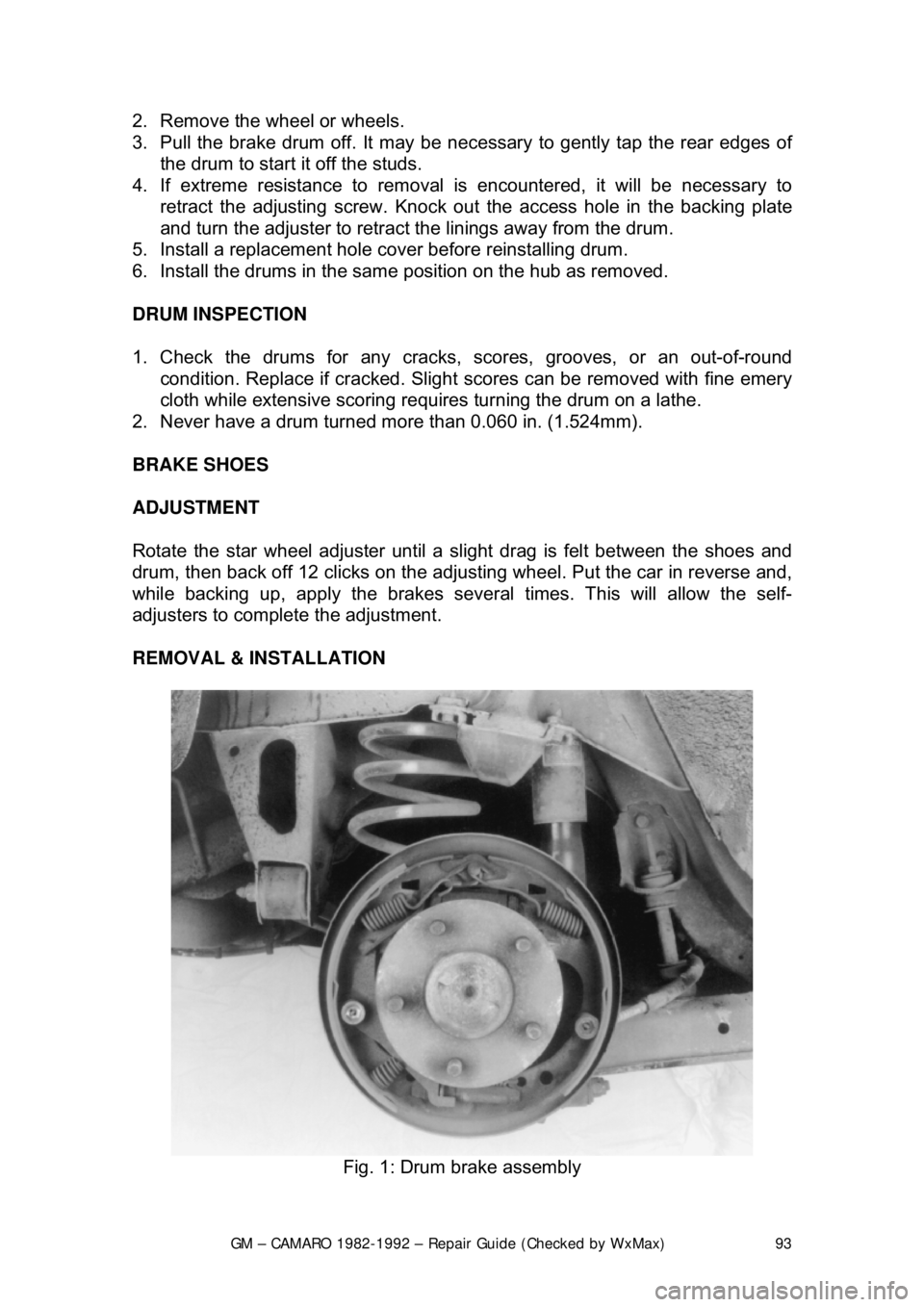

REMOVAL & INSTALLATION

Fig. 1: Drum brake assembly

Page 102 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 102

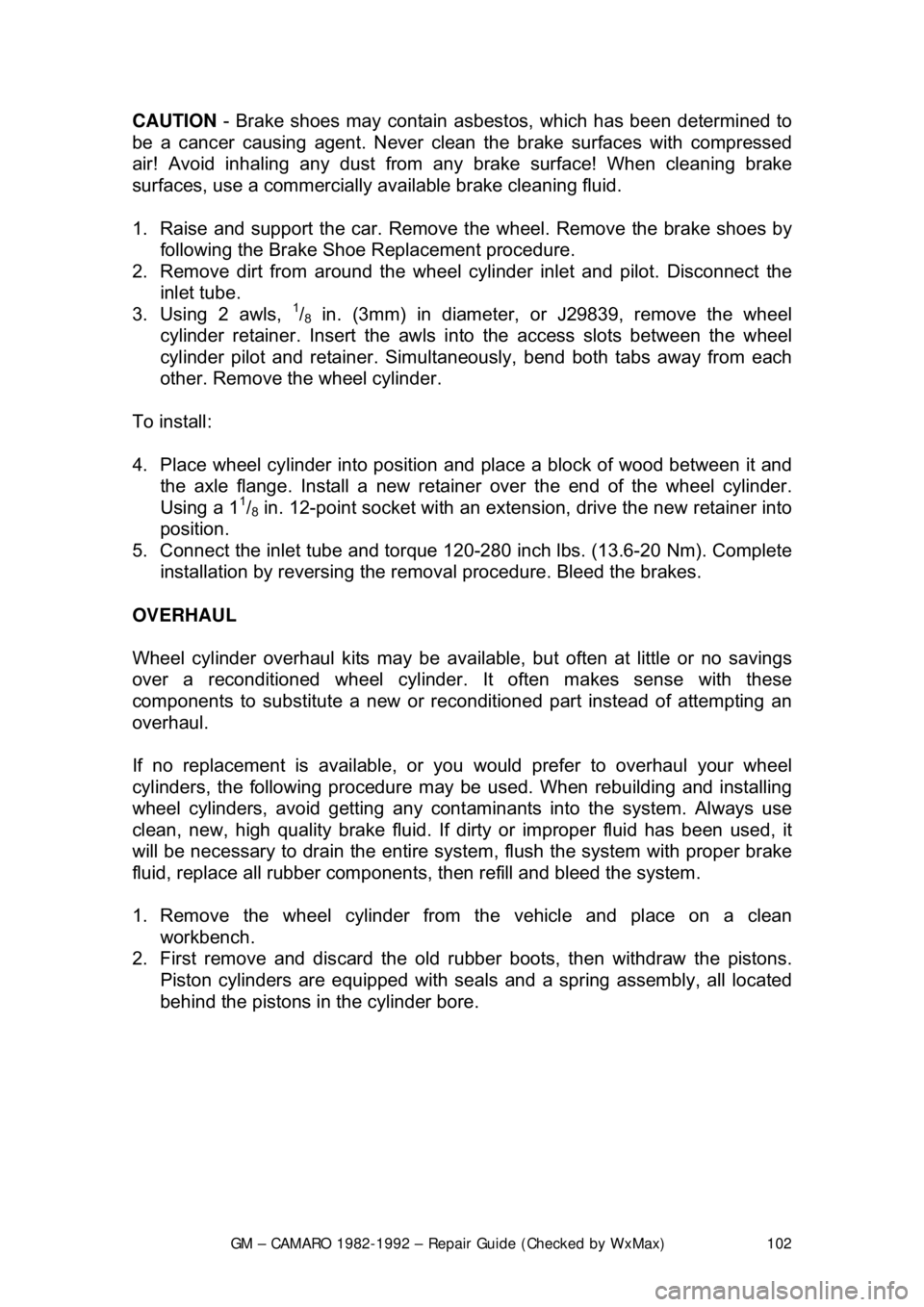

CAUTION

- Brake shoes may contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

1. Raise and support the car. Remove t he wheel. Remove the brake shoes by

following the Brake Shoe R eplacement procedure.

2. Remove dirt from ar ound the wheel cylinder inle t and pilot. Disconnect the

inlet tube.

3. Using 2 awls,

1/8 in. (3mm) in diameter, or J29839, remove the wheel

cylinder retainer. Insert the awls in to the access slots between the wheel

cylinder pilot and retainer. Simultaneous ly, bend both tabs away from each

other. Remove the wheel cylinder.

To install:

4. Place wheel cylinder into position and place a block of wood between it and

the axle flange. Install a new retainer over the end of the wheel cylinder.

Using a 1

1/8 in. 12-point socket with an extensi on, drive the new retainer into

position.

5. Connect the inlet tube and torque 120-280 inch lbs. (13.6-20 Nm). Complete

installation by reversing the remova l procedure. Bleed the brakes.

OVERHAUL

Wheel cylinder overhaul kits may be available, but often at little or no savings

over a reconditioned wheel cylinder. It often makes sense with these

components to substitute a new or re conditioned part instead of attempting an

overhaul.

If no replacement is availabl e, or you would prefer to overhaul your wheel

cylinders, the following procedure may be used. When rebuilding and installing

wheel cylinders, avoid getting any cont aminants into the system. Always use

clean, new, high quality brake fluid. If di rty or improper fluid has been used, it

will be necessary to drain the entire syst em, flush the system with proper brake

fluid, replace all rubber components , then refill and bleed the system.

1. Remove the wheel cylinder from the vehicle and place on a clean

workbench.

2. First remove and discard the old r ubber boots, then withdraw the pistons.

Piston cylinders are equipped with seals and a spring assembly, all located

behind the pistons in the cylinder bore.

Page 108 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 108

11. Install the wheel cylinder.

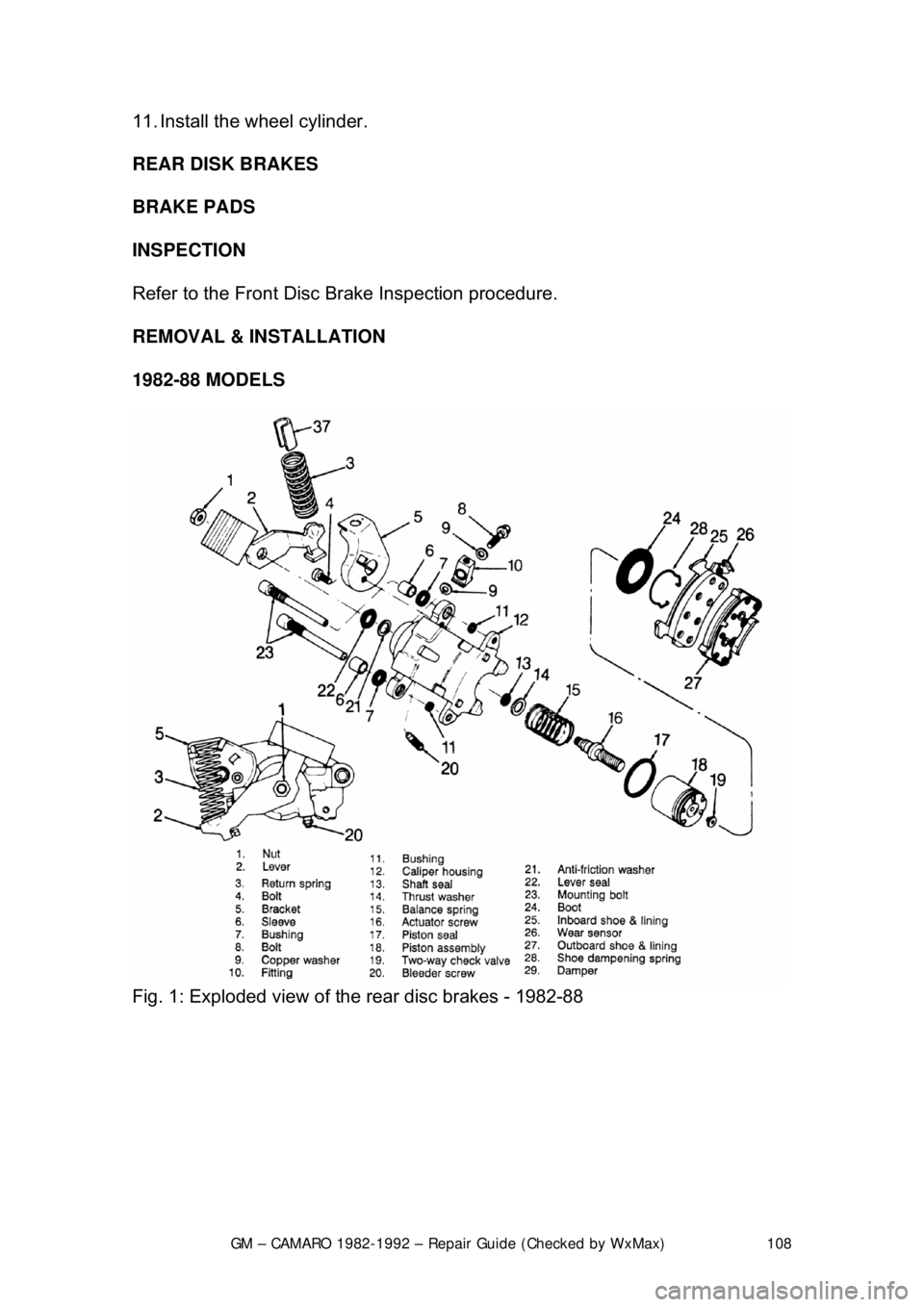

REAR DISK BRAKES

BRAKE PADS

INSPECTION

Refer to the Front Disc Brake Inspection procedure.

REMOVAL & INSTALLATION

1982-88 MODELS

Fig. 1: Exploded view of t he rear disc brakes - 1982-88

Page 110 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 110

4. Position the brake pads

into the caliper. Lubricate and install new bushings,

sleeves and check valve.

5. When installing the inner brake pad, make sure that the D-shaped tab of the

pad engages with the D-shaped notch of the piston, as illustrated.

6. Upon installation of the inner pad, make sure that the wear sensor of the pad

is at the leading edge of the shoe during forward wheel rotation. Slide the

metal edge of the pad under the ends of the dampening spring and snap the

pad into position against the piston.

7. Install the outer pad and caliper. Afte r installing the caliper, apply the brakes,

then bend the ears of the out er pad against the caliper and ensure that there

is no excessive clearance.

Page 111 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 111

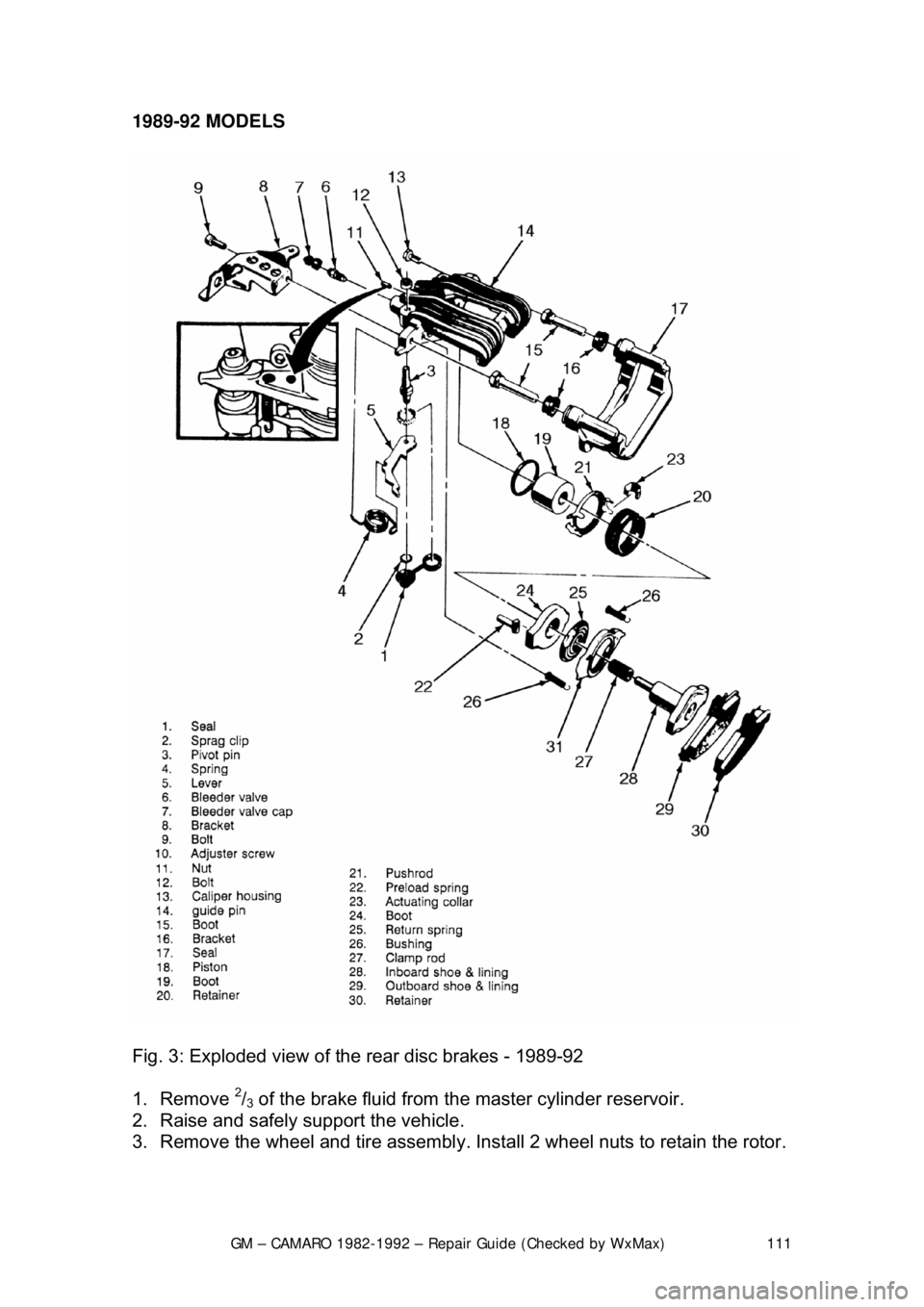

1989-92 MODELS

Fig. 3: Exploded view of t

he rear disc brakes - 1989-92

1. Remove

2/3 of the brake fluid from the master cylinder reservoir.

2. Raise and safely support the vehicle.

3. Remove the wheel and tire assembly. Inst all 2 wheel nuts to retain the rotor.