jack CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 451 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 451

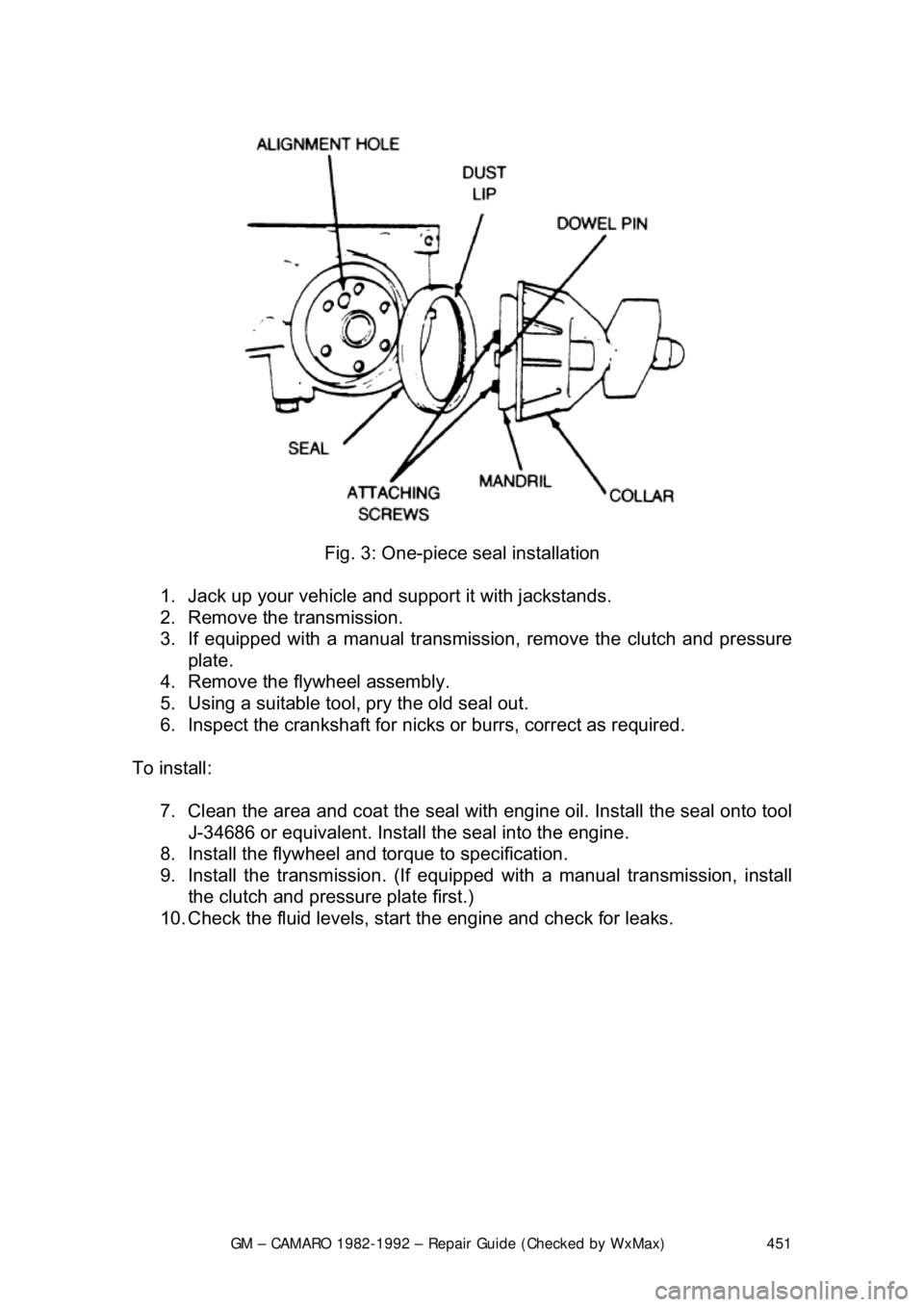

Fig. 3: One-piece seal installation

1. Jack up your vehicle and support it with jackstands.

2. Remove the transmission.

3. If equipped with a manual transmission, remove the clutch and pressure

plate.

4. Remove the flywheel assembly.

5. Using a suitable tool, pry the old seal out.

6. Inspect the crankshaft for nicks or burrs, correct as required.

To install: 7. Clean the area and coat the seal with eng ine oil. Install the seal onto tool

J-34686 or equivalent. Install the seal into the engine.

8. Install the flywheel and torque to specification.

9. Install the transmission. (If equipped with a manual transmission, install

the clutch and pressure plate first.)

10. Check the fluid levels, star t the engine and check for leaks.

Page 490 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 490

To replace cast-in type valve guides, t

hey must be drilled out, then reamed to

accept replacement guides. This must be done on a fixture which will allow

centering and leveling off of the original valve seat or guide, otherwise a serious

guide-to-seat misalignment may occur maki ng it impossible to properly machine

the seat.

Replaceable-type guides are pressed into the cylinder head. A hammer and a

stepped drift or punch may be used to inst all and remove the guides. Before

removing the guides, measure the protrusi on on the spring side of the head and

record it for installation. Use the stepped drift to hammer out the old guide from

the combustion chamber side of the head. When installing, determine whether

or not the guide also seal s a water jacket in the head, and if it does, use the

recommended sealing agent. If there is no water jacket, grease the valve guide

and its bore. Use the stepped drift, and hamme r the new guide into the cylinder

head from the spring side of the cylinder head. A stack of washers the same

thickness as the measured protrusion may help the installation process.

VALVE SEATS

Before any valve seat machining can be performed, the guides must be within

factory recommended specifications.

If any machining or replacements were made to the valve guides, the seats

must be machined.

If the seats are in good condition, the va lves can be lapped to the seats, and the

cylinder head assembled. See the valves in formation for instructions on lapping.

If the valve seats are worn, cracked or damaged, they must be serviced by a

machine shop. The valve seat must be per fectly centered to the valve guide,

which requires very accurate machining.

CYLINDER HEAD SURFACE

If the cylinder head is war ped, it must be machined flat. If the warpage is

extremely severe, the head may need to be replaced. In some instances, it may

be possible to straighten a warped head enough to allow machining. In either

case, contact a professional machine shop for service.

CRACKS AND PHYSICAL DAMAGE

Certain cracks can be repaired in both ca st iron and aluminum heads. For cast

iron, a tapered threaded insert is inst alled along the length of the crack.

Aluminum can also use the tapered inse rts, however welding is the preferred

method. Some physical damage can be repaired through brazing or welding.

Contact a machine shop to get expert advice for your particular dilemma.

ASSEMBLY

Page 639 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 639

In the HEI system, as in other electr

onic ignition systems, the breaker points

have been replaced wit h an electronic switch - a tr ansistor - which is located

within the ignition module. This switching transistor pe rforms the same function

the points did in a conventi onal ignition system; it simply turns the coil's primary

current on and off at the correct time. Essentially, electronic and conventional

ignition systems operate on t he same principle.

The module which houses the switching transistor is controlled (turned on and

off) by a magnetically gener ated impulse induced in the pickup coil. When the

teeth of the rotating timer align with t he teeth of the pole piece, the induced

voltage in the pickup coil signals the elec tronic module to open the coil primary

circuit. The primary current then decreases, and a high voltage is induced in the

ignition coil secondary windings, which is then directed through the rotor and

high voltage leads (spark plug wires) to fire the spark plugs.

In essence, the pickup coil module system simply replaces the conventional

breaker points and condenser. The condenser found within the distributor is for

radio suppression purposes only and has nothing to do with the ignition

process. The ignition module automatically controls the dwell period, increasing

it with increasing en gine speed. Since dwell is co ntrolled in this manner, it

cannot be adjusted. The module itse lf is non-adjustable/non-repairable and

must be replaced if found defective.

SYSTEM PRECAUTIONS

Before proceeding with troubleshooting, ta ke note of the following precautions:

TIMING LIGHT USE

Care should be exercised when connec ting a timing light or other pick-up

equipment. Do not force anything between the boots and wiring, or through the

silicone jacket. Connections should be made in parallel using an adapter.

Inductive pickup timing lights are the bes t kind to use with the ignition systems

covered by this information.

SPARK PLUG WIRES

The plug wires used with these systems are of a different construction than

conventional wires. When replacing them, make sure you get the correct wires,

since conventional wires will not carry the voltage. Also, handle the wires

carefully to avoid cracking or splitti ng them, and NEVER pierce the wires.

TACHOMETER USE

Not all tachometers will operate or indi cate correctly when used on an HEI or

C

3I system. While some tachometers ma y give a reading, this does not

necessarily mean the reading is correct. In addition, some tachometers hook up

differently from others. If you cannot fi gure out whether or not your tachometer

will work on your car, check with the tachometer manufacturer.

Page 763 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 763

•

Jackstands for support.

• Oil filter wrench.

• Spout or funnel for pouring fluids.

• Grease gun for chassis lubrication (unl ess your vehicle is not equipped

with any grease fittings)

• Hydrometer for checking the battery (unless equipped with a sealed,

maintenance-free battery).

• A container for draining oil and other fluids.

• Rags for wiping up the inevitable mess.

Fig. 1: All but the most basic procedures will require an assortment of ratchets

and sockets

Fig. 2: In addition to ratchets, a good set of wrenches and hex keys will be

necessary

Page 764 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 764

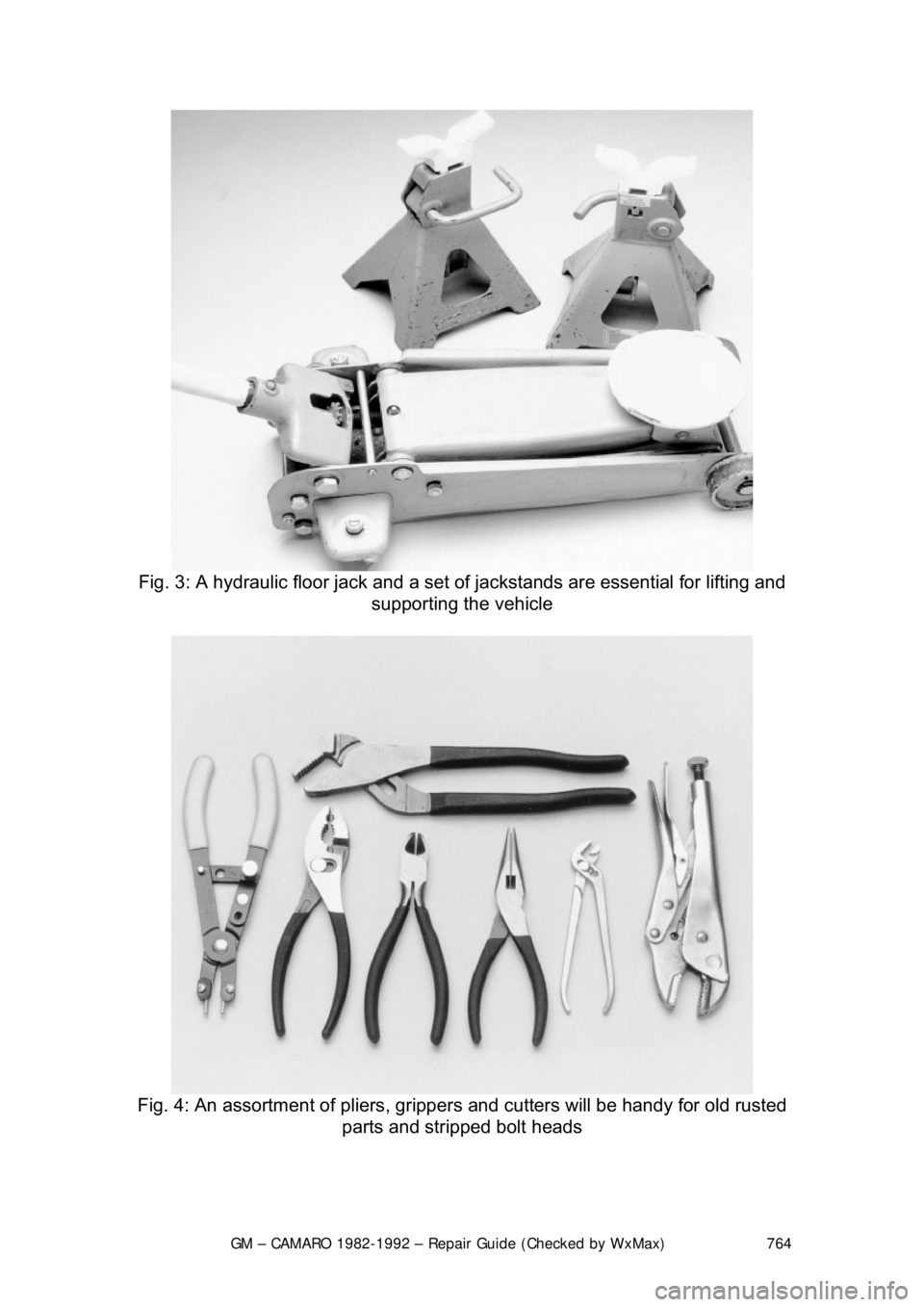

Fig. 3: A hydraulic floor jack and a set of jackstands are essential for lifting and

supporting the vehicle

Fig. 4: An assortment of pliers, gr ippers and cutters will be handy for old rusted

parts and stripped bolt heads

Page 773 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 773

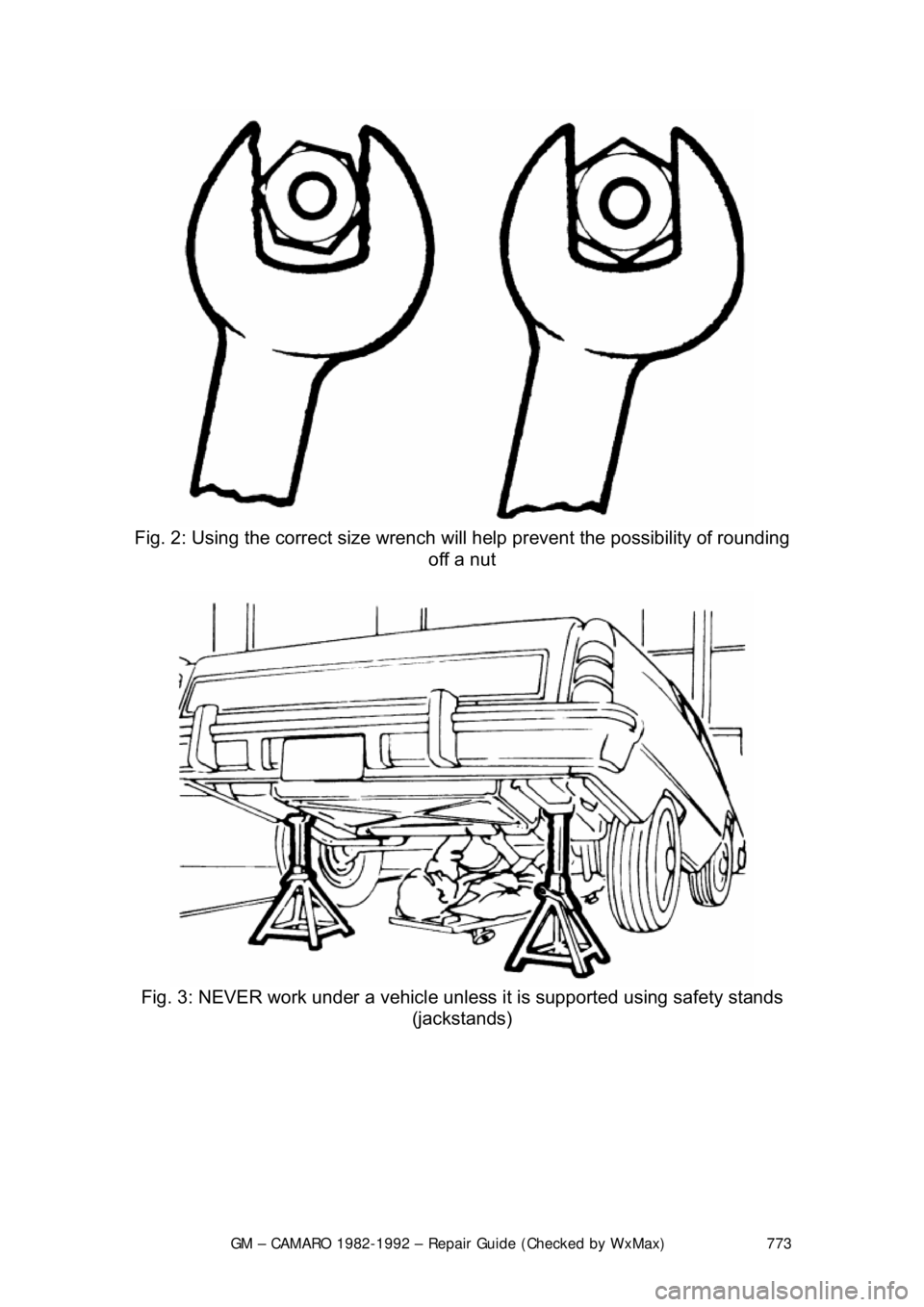

Fig. 2: Using the correct size wrench wil l help prevent the possibility of rounding

off a nut

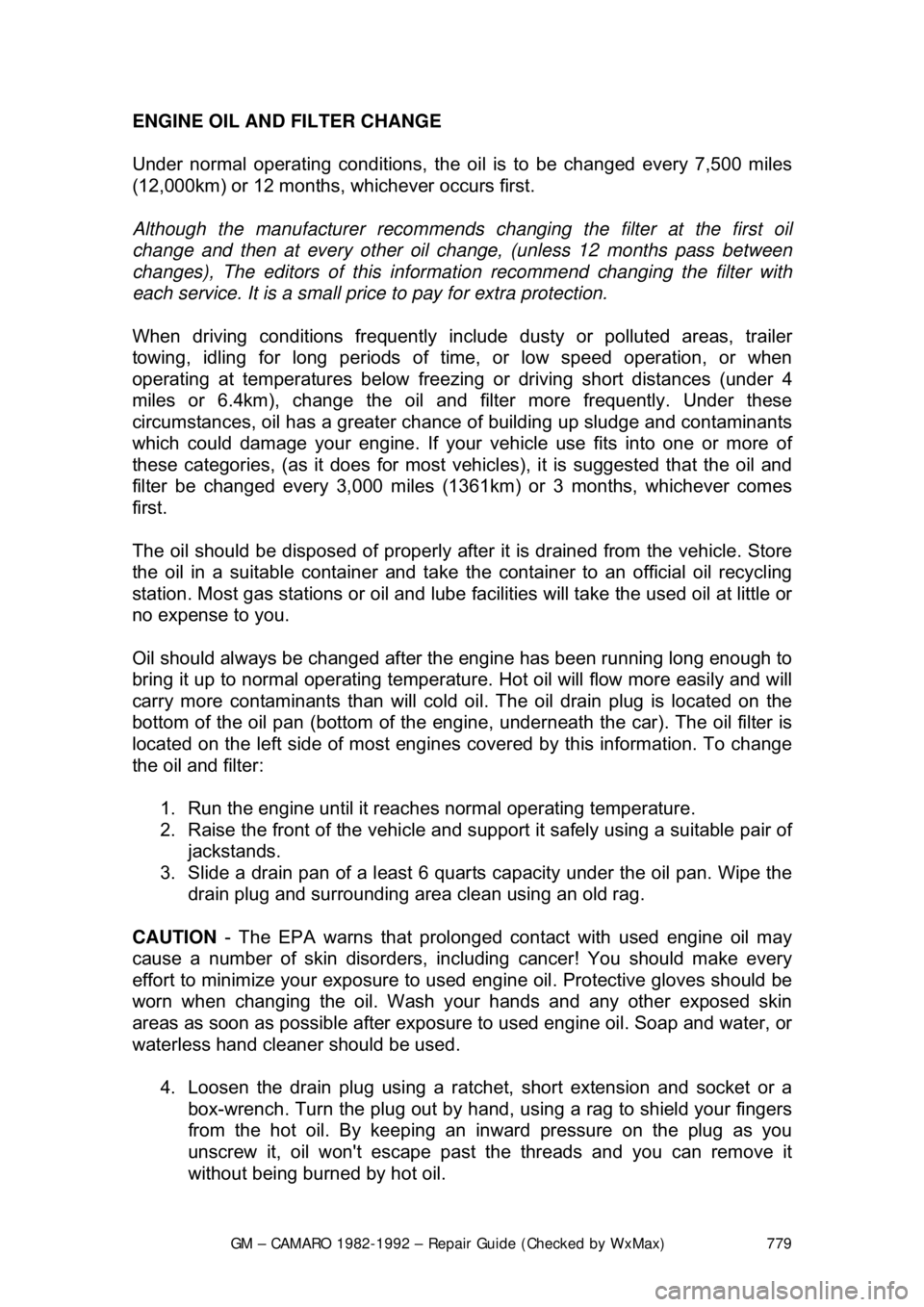

Fig. 3: NEVER work under a vehicle unle ss it is supported using safety stands

(jackstands)

Page 779 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 779

ENGINE OIL AND FILTER CHANGE

Under normal operating conditions, the oi

l is to be changed every 7,500 miles

(12,000km) or 12 months, whichever occurs first.

Although the manufacturer recommends changing the f ilter at the first oil

change and then at every other oil c hange, (unless 12 months pass between

changes), The editors of this informat ion recommend changing the filter with

each service. It is a small price to pay for extra protection.

When driving conditions frequently include dusty or polluted areas, trailer

towing, idling for long periods of ti me, or low speed operation, or when

operating at temperatures below freezing or driving short distances (under 4

miles or 6.4km), change t he oil and filter more frequently. Under these

circumstances, oil has a greater chance of building up sludge and contaminants

which could damage your engine. If your v ehicle use fits into one or more of

these categories, (as it does for most vehicles), it is suggested that the oil and

filter be changed every 3, 000 miles (1361km) or 3 months, whichever comes

first.

The oil should be disposed of properly after it is drained from the vehicle. Store

the oil in a suitable container and take the container to an official oil recycling

station. Most gas stations or oil and lube facilities will take the used oil at little or

no expense to you.

Oil should always be changed after the engine has been running long enough to

bring it up to normal operating temperature. Hot oil will flow more easily and will

carry more contaminants than will cold oi l. The oil drain plug is located on the

bottom of the oil pan (bottom of the engi ne, underneath the car). The oil filter is

located on the left side of most engines covered by this information. To change

the oil and filter:

1. Run the engine until it reaches normal operating temperature.

2. Raise the front of the vehicle and s upport it safely using a suitable pair of

jackstands.

3. Slide a drain pan of a least 6 quar ts capacity under the oil pan. Wipe the

drain plug and surrounding area clean using an old rag.

CAUTION - The EPA warns that prolonged contact with used engine oil may

cause a number of skin disorders, incl uding cancer! You should make every

effort to minimize your exposure to used engine oil. Pr otective gloves should be

worn when changing the oil. Wash y our hands and any other exposed skin

areas as soon as possible after exposure to used engine oil. Soap and water, or

waterless hand cleaner should be used.

4. Loosen the drain plug using a ratc het, short extension and socket or a

box-wrench. Turn the plug out by hand, using a rag to shield your fingers

from the hot oil. By keeping an in ward pressure on the plug as you

unscrew it, oil won't escape past the threads and you can remove it

without being burned by hot oil.

Page 782 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 782

10. Refill the engine with the correct amount

of fresh oil. Please refer to the

Capacities chart at the end of this section.

11. Check the oil level on the dipstick. It is normal for the level to be a bit

above the full mark. Start the engine and allow it to idle for a few

minutes.

CAUTION - Do not run the engi ne above idle speed until it has built up oil

pressure, as indicated w hen the oil light goes out

12. Shut off the engine and allow the oil to flow back to the crankcase for a

minute, then recheck the oil level. C heck around the filter and drain plug

for any leaks, and correct as necessary.

MANUAL TRANSMISSIONS

FLUID RECOMMENDATIONS

• 1982-85 4-speed manual transmissi ons - SAE 80W/90 GL-5 gear

lubricant

• 1986-87 4-speed manual transmission - Dexron®®II automatic

transmission fluid

• 1982-84 5-speed manual transmissions - use SAE 80W/90 GL-5 gear

lubricant (SAE 80W GL-5 in Canada)

• 1985-92 5-speed manual transmissi ons - Dexron®II automatic

transmission fluid

LEVEL CHECK

The oil in the manual tr ansmission should be check ed every 12 months or

15,000 miles.

1. Raise the car and support on jackstands as close to level as possible. \

2. Remove the filler plug from the side of the transmission housing.

3. If lubricant begins to trickle out of the hole, there is enough and you need

not go any further. Otherwise, carefully insert your finger (watch out for

sharp threads) and check to see if the oil is up to the edge of the hol\

e.

4. If not, add oil through the hole until the level is at the edge of the hole.

Most lubricants come in a plasti c squeeze bottle with a nozzle; making

additions simple.

5. Install and tighten the filler plug.

DRAIN AND REFILL

The fluid in the manual transmission do es not require changing. If you do

choose to change the transmission fluid, the fluid can be drained out through

the lower drain plug hole on the side of the transmission. Fill the transmission

with the recommended lubricant to the bottom of the filler plug hole and install

the filler plug.

Page 785 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 785

The automatic transmission fluid and fi

lter should be changed every 15,000

miles (24,000km) if your Camaro is driven in heavy city traffic in hot weather, in

hilly or mountainous terrain, frequent trailer pulling, or uses such as found in

taxi, police car or delivery service. If your Camaro is driven under other than

listed above conditions, change the fl uid and filter every 30,000 miles

(48,300km).

1. Raise and support the car on jackst ands. Place an oil catch pan under

the transmission.

2. Remove the oil pan bolts fr om the front and sides only.

3. Loosen rear oil pan bolts approximately 4 turns.

WARNING - Do not damage the transmission case or oil pan sealing surfaces.

4. Lightly tap the oil pan with a rubber mallet or gently pry it downward to

allow fluid to drain.

5. Remove the remaining oil pan bolt s, then remove the oil pan and pan

gasket.

6. Remove the filter and seal.

7. Clean the transmission case and oi l pan gasket surfaces with suitable

solvent and air dry. Make sure to re move all traces of the old gasket.

To install: 8. Coat the seal with a sm all amount of Transjel®.

9. Install the new s eal onto the filter.

10. Install the new filter into the case.

11. Install the oil pan and new gasket.

On 1991 and later vehicles, inspect t he oil pan screws and washer assemblies.

The screws must not be used if the coni cal washer is reversed. Failure to

replace the screw and washer assembly may result in improper fastening of

system components.

12. Install the oil pan bolts and tighten them to 12 ft. lbs. (16 Nm).

13. Lower the car.

14. Fill the transmission to proper level with Dexron®II fluid.

15. Check cold fluid level reading fo r initial fill. Do not overfill the

transmission.

16. Follow the fluid level che ck procedure described before.

17. Check the oil pan gasket for leaks.

Page 790 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 790

LEVEL CHECK

Fig. 1: Removing filler plug to check rear axle lubricant

The gear lubricant in the drive axle should be checked every 12 months or

15,000 miles (24,000km).

1. Raise the car and support on jackstands as close to level as possible. \

2. Remove the filler plug from the side of the drive axle housing.

3. If lubricant begins to trickle out of the hole, there is enough and you need

not go any further. Otherwise, carefully insert your finger (watch out for

sharp threads) and check to see if the lubricant is up to the edge of the

hole.

4. If not, add oil through the hole until the level is at the edge of the hole.

Most gear lubricants come in a pl astic squeeze bottle with a nozzle;

making additions simple.

5. Install and tighten the filler plug.

DRAIN AND REFILL

The rear axle should have the gear lubricant changed every 7,500 miles

(12,000km). If equipped with a limited slip differential, be sure to add 4 oz.

(118mL) of GM lim ited slip additive part No. 1052358.

1. Raise the car and support on jackst ands. Place a container under the

differential to catch the fluid.

2. Remove the bolts retaining the par king brake cable guides and position

aside.