charging CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 141 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 141

4. To isolate the short, probe a test point

at either end of the isolated circuit

(the light should be on or the mete r should indicate continuity).

5. Leave the test light probe engaged and sequentiall y open connectors or

switches, remove parts, etc. until t he light goes out or continuity is

broken.

6. When the light goes out, the shor t is between the last two circuit

components which were opened.

VOLTAGE

This test determines voltage available fr om the battery and should be the first

step in any electrical troubleshooting pr ocedure after visual inspection. Many

electrical problems, especially on co mputer controlled systems, can be caused

by a low state of charge in the battery. Excessive corrosion at the battery cable

terminals can cause poor contact that will prevent proper charging and f\

ull

battery current flow.

1. Set the voltmeter selector switch to the 20V position.

2. Connect the multimeter negative lead to the battery's negative (-) post or

terminal and the positive lead to t he battery's positive (+) post or

terminal.

3. Turn the ignition switch ON to provide a load.

4. A well charged battery should register over 12 volts. If the meter reads

below 11.5 volts, the battery power may be insufficient to operate the

electrical system properly.

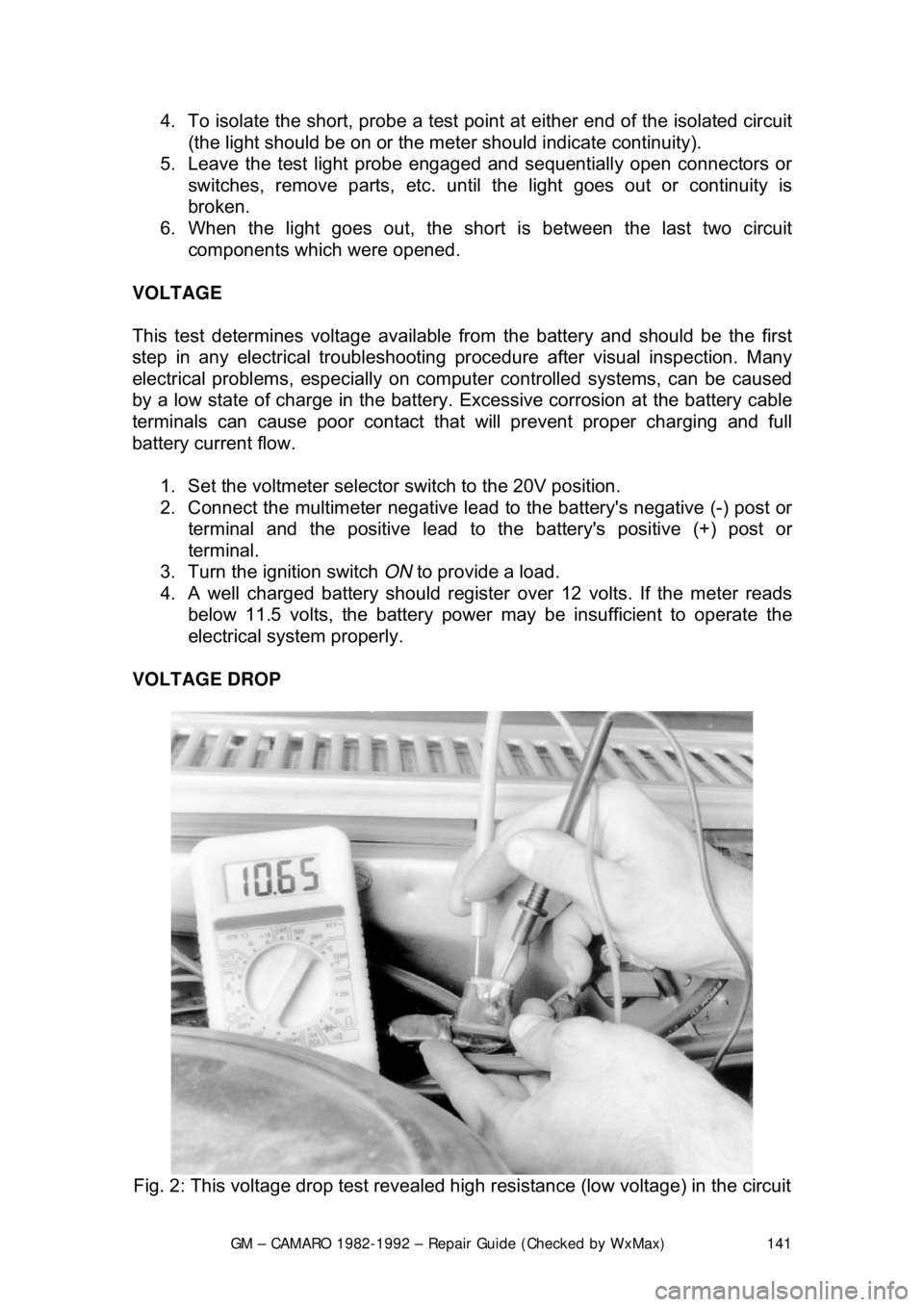

VOLTAGE DROP

Fig. 2: This voltage drop test revealed high resistance (low voltage) in the circuit

Page 160 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 160

damage, and legal considerations (such as t

he fact that it is a federal crime to

vent refrigerant into the atmosphere), dictate that the A/C components on your

vehicle should be serviced only by a Motor Vehicle Air Conditioning (MVAC)

trained, and EPA certified aut omotive technician.

If your vehicle's A/C system uses R-12 re frigerant and is in need of recharging,

the A/C system can be c onverted over to R-134a refrigerant (less

environmentally harmful and expensive). Refer to General Information &

Maintenance for additional information on R- 12 to R-134a conversions, and for

additional considerations dealing with your vehicle's A/C system.

CONTROL CABLES

REMOVAL & INSTALLATION

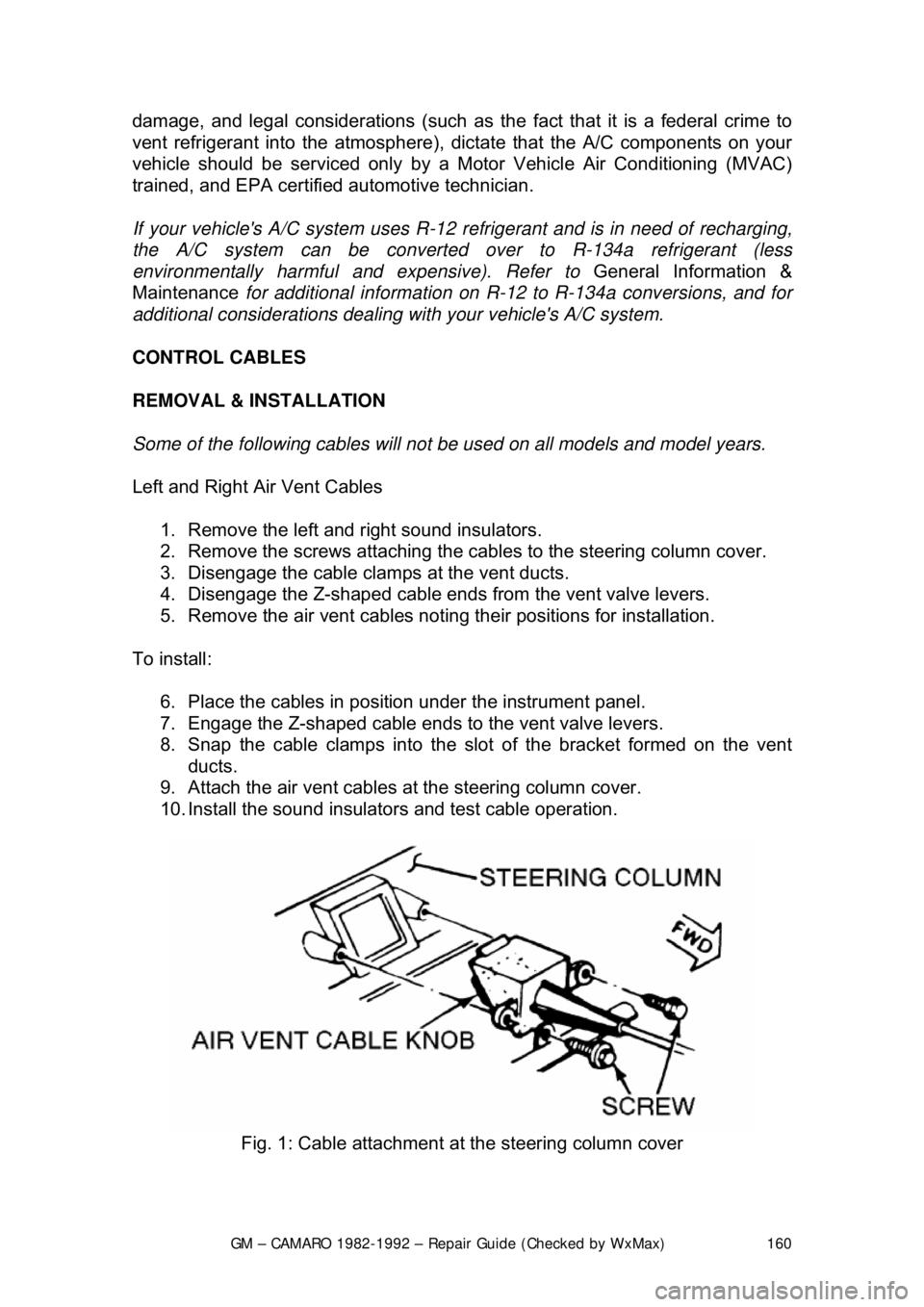

Some of the following cables will not be used on all models and model years.

Left and Right Air Vent Cables 1. Remove the left and right sound insulators.

2. Remove the screws attaching the cabl es to the steering column cover.

3. Disengage the cable clamps at the vent ducts.

4. Disengage the Z-shaped c able ends from the vent valve levers.

5. Remove the air vent cables notin g their positions for installation.

To install: 6. Place the cables in posi tion under the instrument panel.

7. Engage the Z-shaped cable ends to the vent valve levers.

8. Snap the cable clamps into the slot of the bracket formed on the vent

ducts.

9. Attach the air vent cables at the steering column cover.

10. Install the sound insulators and test cable operation.

Fig. 1: Cable attachment at the steering column cover

Page 223 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 223

FUSIBLE LINKS

In addition to circuit breakers and fuses,

the wiring harness incorporates fusible

links to protect the wiring. Links are used rather than a fuse, in wiring circuits

that are not normally fused, such as th e ignition circuit. The fusible links are

color coded red in the charging and load circuits to match the color coding of

the circuits they protect. Each link is four gauges smaller than the cable it

protects, and is marked on the insulation with the gauge size because the

insulation makes it appear heavier than it really is. The engine compartment

wiring harness has several fusible links. The same size wire with a special

Hypalon insulation must be used w hen replacing a fusible link.

For more details, see the information on fusible links at the beginning of this

section.

The links are located in the following areas:

1. A molded splice at the starter solenoid Bat terminal, a 14 gauge red wire.

2. A 16 gauge red fusible link at the j unction block to protect the unfused

wiring of 12 gauge or larger wire. This link stops at the bulkhead

connector.

3. The alternator warning light and fiel d circuitry is protected by a 20 gauge

red wire fusible link used in the batte ry feed-to-voltage regulator number

3 terminal. The link is installed as a molded splice in the circuit at the

junction block.

4. The ammeter circuit is protected by two 20 gauge fusible links installed

as molded splices in the circuit at t he junction block and battery to starter

circuit.

REPLACEMENT 1. Determine the circuit that is damaged.

2. Disconnect the negative battery terminal.

3. Cut the damaged fuse link from the harness and discard it.

4. Identify and procure the proper fuse link and butt connectors.

5. Strip the wire about

1/2 in. (13mm) on each end.

6. Connect the fusible link and crimp the butt connectors making sure that the wires are secure.

7. Solder each connection with resin core solder, and wrap the connections

with plastic electrical tape.

8. Reinstall the wir e in the harness.

9. Connect the negative battery terminal and test the system for proper

operation.

CIRCUIT BREAKERS

Various circuit breakers are located under the instrument panel. In order to gain

access to these components, it may be ne cessary to first remove the under

dash padding. Most of the circuit breakers are located in the convenience

center or the fuse panel.

Page 344 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 344

ENGINE & ENGINE OVERHAUL

ENGINE ELECTRICAL

ENGINE ELECTRICAL

The engine electrical system can be brok en down into three inter-related, but

distinct systems:

1. The starting system.

2. The charging system.

3. The ignition system.

BATTERY AND STARTING SYSTEM

The battery is the first link in the chai n of mechanisms which work together to

provide cranking of the autom obile engine. In most modern cars, the battery is a

lead-acid electrochemical device consis ting of six two-volt (2V) subsections

connected in series so the unit is c apable of producing approximately 12V of

electrical pressure. Each subsection, or ce ll, consists of a series of positive and

negative plates held a short distance apart in a solution of sulfuric acid and

water. The two types of plates are of di ssimilar metals. This causes a chemical

reaction to be set up, and it is this reacti on which produces current flow from the

battery when its positive and negative te rminals are connected to an electrical

appliance such as a lamp or motor.

The continued transfer of electrons would ev entually convert the sulfuric acid in

the electrolyte to water and make t he two plates identical in chemical

composition. As electrical energy is removed from the battery, its voltage output

tends to drop. Thus, measuring batte ry voltage and battery electrolyte

composition are two ways of checking the ability of the unit to supply power.

During the starting of the eng ine, electrical energy is removed from the battery.

However, if the charging circuit is in good condition and the operating conditions

are normal, the power removed from the battery will be replaced by the

generator (or alternator) which will forc e electrons back through the battery,

reversing the normal flow, and restoring the ba ttery to its original chemical state.

The battery and starting motor are linked by very heavy electrical cable\

s

designed to minimize resistance to the flow of current. Generally, the major

power supply cable that leaves the batte ry goes directly to the starter, while

other electrical system needs are supplied by a smaller cable. During the starter

operation, power flows from the battery to the starter and is grounded through

the car's frame and the batte ry's negative ground strap.

The starting motor is a specially designed, direct current electric motor capable

of producing a very great am ount of power for its size. One thing that allows the

motor to produce a great deal of power is its tremendous rotating speed. It

drives the engine through a ti ny pinion gear (attached to the starter's armature),

which drives the very large flywheel ring gear at a greatly reduced speed.

Another factor allowing it to produce so much power is that only intermittent

Page 345 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 345

operation is required of it. Thus, little a

llowance for air circulation is required,

and the windings can be built into a very small space.

The starter solenoid is a magnetic dev ice which employs the small current

supplied by the starting switch circuit of the ignition switch. This magnetic action

moves a plunger which mechanically engages the starter and electrically closes

the heavy switch which connects it to t he battery. The starting switch circuit

consists of the starting switch cont ained within the ignition switch, a

transmission neutral safety switch or clutch pedal switch, and the wiring

necessary to connect these with the starter solenoid or relay.

A pinion, which is a small gear, is m ounted to a one-way drive clutch. This

clutch is splined to the starter armature shaft. When the ignition switch is moved

to the start position, the solenoid plunger slides the pinion toward the flywheel

ring gear via a collar and spring. If t he teeth on the pinion and flywheel match

properly, the pinion will engage the flywheel immediately. If the gear teeth butt

one another, the spring will be compressed and will force the gears to mesh as

soon as the starter turns far enough to a llow them to do so. As the solenoid

plunger reaches the end of it s travel, it closes the contacts that connect the

battery and starter and then the engine is cranked.

As soon as the engine star ts, the flywheel ring gear begins turning fast enough

to drive the pinion at an ex tremely high rate of speed. At this point, the one-way

clutch begins allowing the pi nion to spin faster than the starter shaft so that the

starter will not operate at excessive speed. When the i gnition switch is released

from the starter position, the solenoid is de-energized, and a spring contained

within the solenoid assembly pulls the gear out of mesh and interrupts the

current flow to the starter.

Some starters employ a separate relay, mounted away from the starter, to

switch the motor and solenoid current on and off. The relay thus replaces the

solenoid electrical switch, but does not eliminate the need for a solenoid

mounted on the starter used to mechanica lly engage the starter drive gears.

The relay is used to reduce the amount of current the starting switch must carry.

THE CHARGING SYSTEM

The automobile charging system provides electrical power for operation of the

vehicle's ignition and star ting systems and all the electrical accessories. The

battery serves as an electrical surge or storage tank, storing (in chemical form)

the energy originally pr oduced by the engine driven gen erator. The system also

provides a means of regulating alternat or output to protect the battery from

being overcharged and to avoid excess ive voltage to the accessories.

The storage battery is a chemical device in corporating parallel lead plates in a

tank containing a sulfuric acid-water solution. Adjacent plates are slightly

dissimilar, and the chemical reaction of the two dissimilar plates produces

electrical energy when the battery is connected to a load such as the starter

motor. The chemical reaction is reversible, so that when the generator i\

s

producing a voltage (electrical pressure ) greater than that produced by the

Page 351 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 351

alternating current developed

within the stator windings to a direct (DC) current

at the output (BAT) terminal. Three of these diodes are negative and are

mounted flush with the end frame while t he other three are positive and are

mounted into a strip called a heat sink. The positive diodes are easily identified

as the ones within small cavities or depressions.

The alternator charging system is a negative (-) ground system which consists

of an alternator, a regulat or, a charge indicator, a storage battery and wiring

connecting the components, and fuse link wire.

The alternator is belt-driven from t he engine. Energy is supplied from the

alternator/regulator system to the rotati ng field through two brushes to two slip-

rings. The slip-rings are mounted on the rotor shaft and are connected t\

o the

field coil. This energy supplied to the ro tating field from the battery is called

excitation current and is used to init ially energize the field to begin the

generation of electricity. Once the alter nator starts to generate electricity, the

excitation current comes from its ow n output rather than the battery.

The alternator produces power in the form of alternating current. The alternating

current is rectified by 6 diodes into dire ct current. The direct current is used to

charge the battery and power the rest of the electrical system.

When the ignition key is turned ON, current flows from the battery, through the

charging system indicator light on the in strument panel, to the voltage regulator,

and to the alternator. Since the alternat or is not producing any current, the

alternator warning light comes on. When the engine is started, the alternator

begins to produce current and turns the alte rnator light off. As the alternator

turns and produces current, the current is divided in two ways: part to the

battery(to charge the battery and power the electrical components of the

vehicle), and part is returned to the alte rnator (to enable it to increase its

output). In this situation, the alternator is receiving current from the battery and

from itself. A voltage regulat or is wired into the current supply to the alternator

to prevent it from receiving too much cu rrent which would cause it to put out too

much current. Conversely, if the voltage regulator does not allow the alternator

to receive enough current, the battery will not be fully charged and will

eventually go dead.

The battery is connected to the alternator at all times, whether the ignition key is

turned ON or not. If the battery were shorted to ground, the alternator would

also be shorted. This woul d damage the alternator. To prevent this, a fuse link

is installed in the wiring between the battery and the alternator. If the battery is

shorted, the fuse link melts, protecting the alternator.

An alternator is better that a convent ional, DC shunt generator because it is

lighter and more compact, because it is designed to supply the battery and

accessory circuits through a wide range of engine speeds, and because it

eliminates the necessary maintenance of replacing brushes and servicing

commutators.

PRECAUTIONS

Page 352 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 352

To prevent serious damage to the alte

rnator and the rest of the charging

system, the following precauti ons must be observed:

• Never reverse the battery connections.

• Booster batteries for starting must be connected properly: positive-to-

positive and negative-to-ground.

• Disconnect the battery cables before using a fast charger; the charger

has a tendency to force current through the diodes in the opposite

direction for which they were designed. This burns out the diodes.

• Never use a fast charger as a booster for starting the vehicle.

• Never disconnect the voltage regulator while the engine is running.

• Avoid long soldering times when replacing diodes or transistors.

Prolonged heat is damaging to AC alternators.

• Do not use test lamps of more t han 12 volts (V) for checking diode

continuity.

• Do not short across or ground any of the terminals on the AC alternator.

• The polarity of the battery, alter nator, and regulator must be matched

and considered before making any elec trical connections within the

system.

• Never operate the alternator on an open circuit. make sure that all

connections within the circ uit are clean and tight.

• Disconnect the battery terminals when performing any service on the

electrical system. This wil l eliminate the possibility of accidental reversal

of polarity.

• Disconnect the battery ground cable if arc welding is to be done on any

part of the car.

CHARGING SYSTEM TROUBLESHOOTING

There are many possible ways in whic h the charging system can malfunction.

Often the source of a problem is diffi cult to diagnose, requiring special

equipment and a good deal of experience. However, when the charging system

fails completely and causes the dash boar d warning light to come on or the

battery to become dead the following items may be checked:

1. The battery is known to be good and fully charged.

2. The alternator belt is in good condition and adjusted to the proper

tension.

3. All connections in t he system are clean and tight.

REMOVAL & INSTALLATION

Page 810 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 810

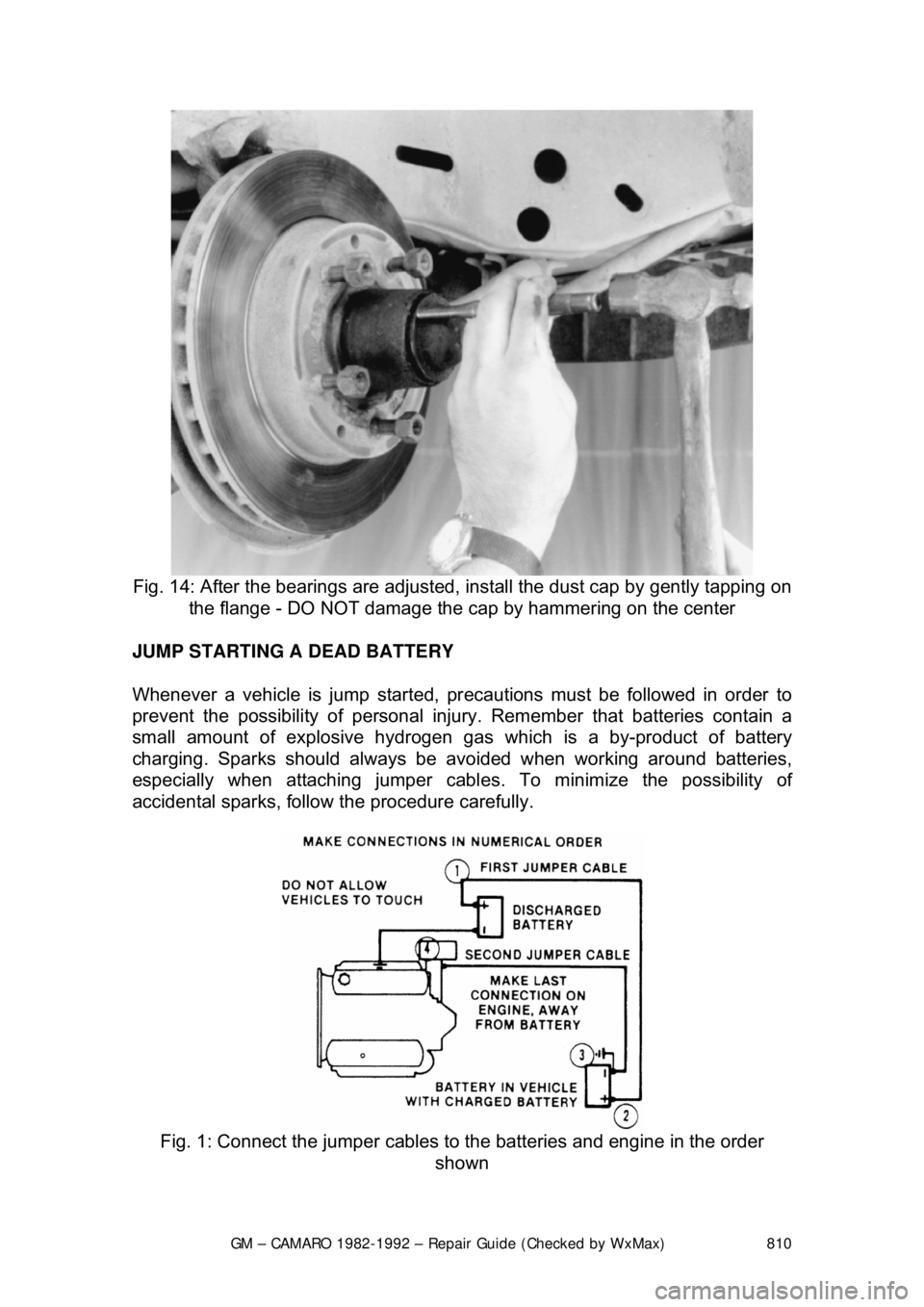

Fig. 14: After the bearings are adjusted, install the dust cap by gently tapping on

the flange - DO NOT damage the c ap by hammering on the center

JUMP STARTING A DEAD BATTERY

Whenever a vehicle is jump started, pr ecautions must be followed in order to

prevent the possibility of personal inju ry. Remember that batteries contain a

small amount of explosive hydrogen gas which is a by-product of battery

charging. Sparks should always be av oided when working around batteries,

especially when attaching jumper cabl es. To minimize the possibility of

accidental sparks, follow the procedure carefully.

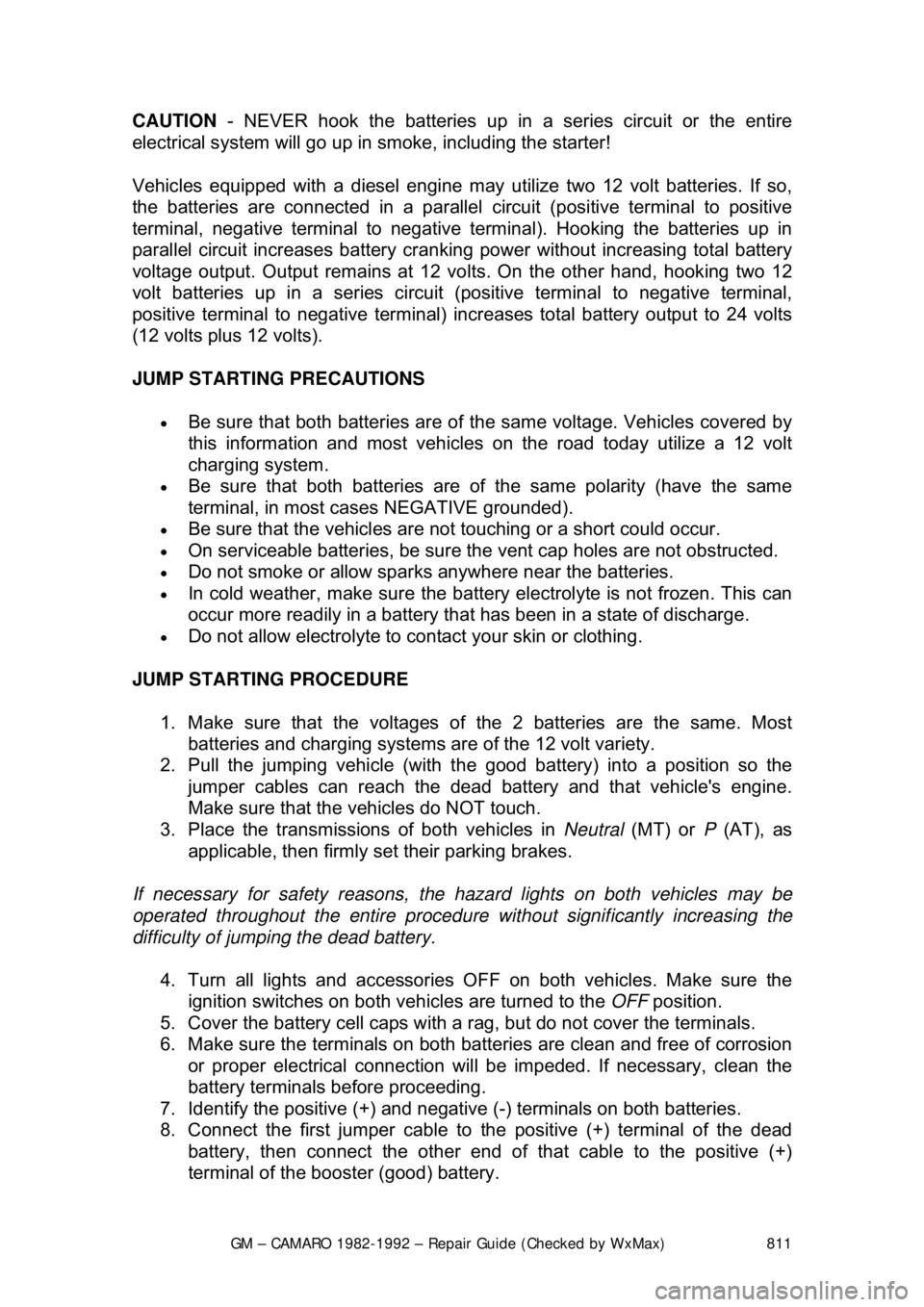

Fig. 1: Connect the jumper cables to the batteries and engine in the order

shown

Page 811 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 811

CAUTION

- NEVER hook the batteries up in a series circuit or the entire

electrical system will go up in smoke, including the starter!

Vehicles equipped with a diesel engine may utilize two 12 volt batteries. If so,

the batteries are connected in a parallel circuit (positive terminal to positive

terminal, negative terminal to negative te rminal). Hooking the batteries up in

parallel circuit increases battery cranki ng power without increasing total battery

voltage output. Output remains at 12 vo lts. On the other hand, hooking two 12

volt batteries up in a series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) incr eases total battery output to 24 volts

(12 volts plus 12 volts).

JUMP STARTING PRECAUTIONS

• Be sure that both batteries are of t he same voltage. Vehicles covered by

this information and most vehicles on the road today utilize a 12 volt

charging system.

• Be sure that both batteries are of the same polarity (have the same

terminal, in most cases NEGATIVE grounded).

• Be sure that the vehicles are not touching or a short could occur.

• On serviceable batteries, be sure the v ent cap holes are not obstructed.

• Do not smoke or allow sparks anywhere near the batteries.

• In cold weather, make sure the battery electrolyte is not frozen. This can

occur more readily in a battery that has been in a state of discharge.

• Do not allow electrolyte to c ontact your skin or clothing.

JUMP STARTING PROCEDURE 1. Make sure that the voltages of the 2 batteries are the same. Most

batteries and charging systems are of the 12 volt variety.

2. Pull the jumping vehicle (with t he good battery) into a position so the

jumper cables can reach the dead battery and that vehicle's engine.

Make sure that the ve hicles do NOT touch.

3. Place the transmissions of both vehicles in Neutral (MT) or P (AT), as

applicable, then firmly set their parking brakes.

If necessary for safety reasons, the hazard lights on both vehicles may be

operated throughout the entir e procedure without significantly increasing the

difficulty of jumping the dead battery.

4. Turn all lights and accessories OFF on both vehicles. Make sure the ignition switches on both vehicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do not cover the terminals.

6. Make sure the terminals on both batte ries are clean and free of corrosion

or proper electrical connection wil l be impeded. If necessary, clean the

battery terminals before proceeding.

7. Identify the positive (+) and negat ive (-) terminals on both batteries.

8. Connect the first jumper cable to the positive (+) terminal of the dead

battery, then connect the other end of that cable to the positive (+)

terminal of the booster (good) battery.