oil pan CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 317 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 317

1. Place the shifter lever in the

P position. Remove the negative battery

cable.

2. Turn the key to RUN.

3. Remove the left side instrument panel sound insulator and kick panels.

4. Remove the floor console.

5. Remove the cable nut and clip. Remove the cable from the bracket, move the button to the UP position and unsnap the cable end from the

lever lock pin.

6. Lower the steering column. Remove the cable clips.

To install: 7. Place the shifter lever into the P position and the ignition key to the RUN

position.

8. After installing the cable ends, push the cable connector nose toward th\

e connector as far as possible and push down the lock button.

9. Complete the installation by reversing the removal procedure.

EXTENSION HOUSING SEAL (IN VEHICLE)

REMOVAL & INSTALLATION

This seal controls transmission oil leakage around the driveshaft. Continued

failure of this seal usually indicates a worn output shaft bushing. If so, there will

be signs of the same wear on the driveshaft where it contacts the seal and

bushing. The seal is available and is fairly simple to install, with the proper tool.

1. Raise and safely support rear of t he vehicle to minimize transmission oil

loss when the driveshaft is removed.

2. Unbolt the driveshaft fr om the differential and center support bearing, if

equipped. Wrap tape around the bearing cu ps to keep them in place on

the universal joint and slide the sh aft out of the transmission.

3. Use a small pry tool to carefully pr y out the old seal. Be careful not to

insert the tool too far into the hous ing or the bushing will be damaged.

4. Use an oil seal installation tool to evenly drive the new seal into the

housing. Make sure the tool only cont acts the outer metal portion of the

seal.

5. Install the driveshaft. Torque the uni versal bearing cup retainer bolts to

15 ft. lbs. (20 Nm). Recheck fluid level.

TRANSMISSION

REMOVAL & INSTALLATION 1. Disconnect the negative batte ry cable at the battery.

2. Remove the air cleaner assembly.

3. Disconnect the throttle valve (TV) control cable at the carburetor.

Page 323 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 323

Replacement kits include new bearing

cups and conventional snaprings to

replace the original nylon rings. These replacement rings must go inboard of the

yoke in contrast to outboard mounting of the Dana and Cleveland designs.

Previous service to the Saginaw U-joints can be recognized by the presence of

snaprings inboard of the yoke.

Bad U-joints, requiring replacement, will produce a clunking sound when the car

is put into gear. This is due to worn needle bearings or a scored trunnion end

possibly caused by improper lubricati on during assembly. Camaro U-joints

require no periodic maintenance and theref ore have no lubrication fittings.

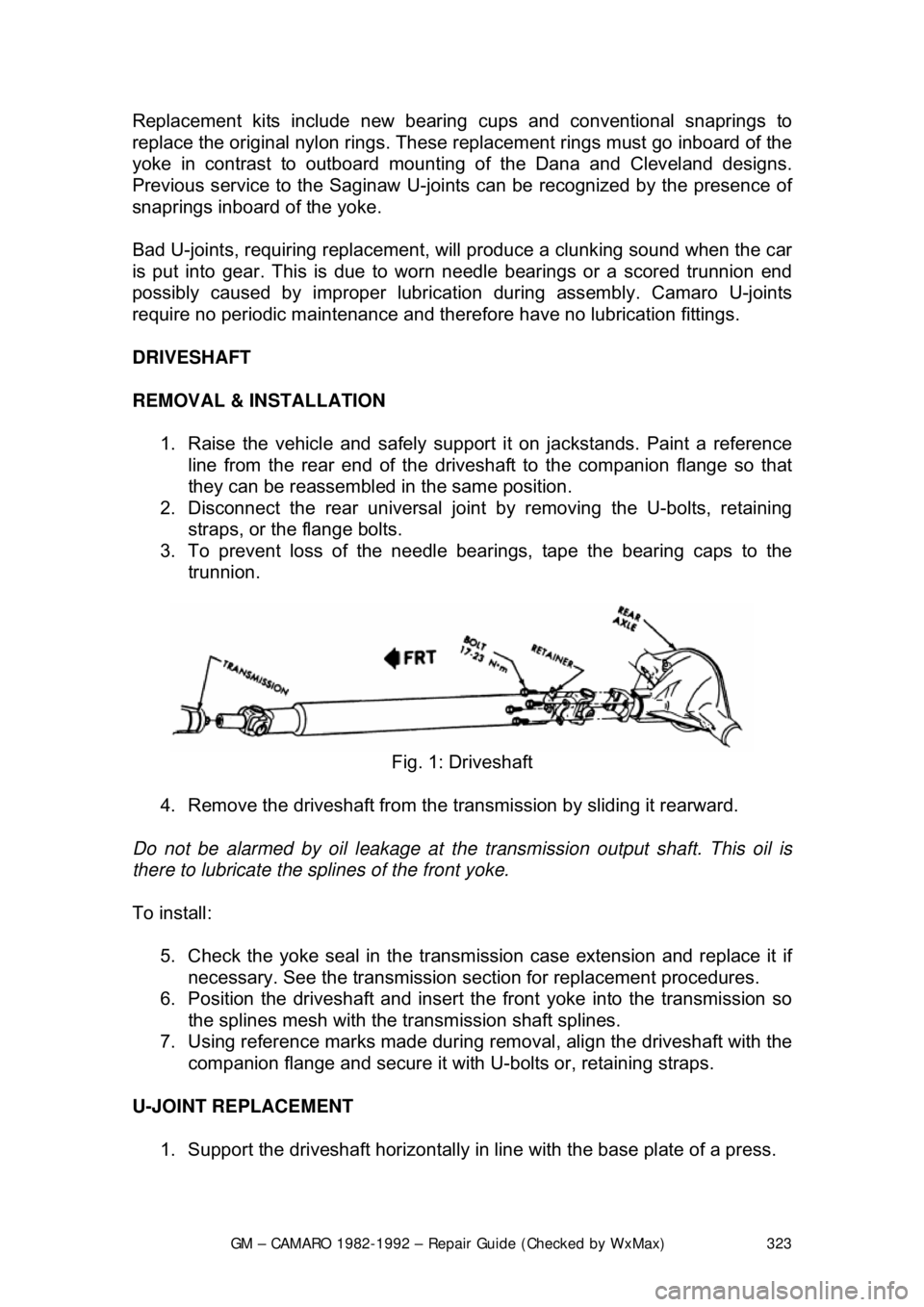

DRIVESHAFT

REMOVAL & INSTALLATION 1. Raise the vehicle and safely su pport it on jackstands. Paint a reference

line from the rear end of the drives haft to the companion flange so that

they can be reassembled in the same position.

2. Disconnect the rear universal join t by removing the U-bolts, retaining

straps, or the flange bolts.

3. To prevent loss of the needle bear ings, tape the bearing caps to the

trunnion.

Fig. 1: Driveshaft

4. Remove the driveshaft from the tr ansmission by sliding it rearward.

Do not be alarmed by oil l eakage at the transmission output shaft. This oil is

there to lubricate the sp lines of the front yoke.

To install: 5. Check the yoke seal in the transmi ssion case extension and replace it if

necessary. See the transmission sect ion for replacement procedures.

6. Position the driveshaft and insert t he front yoke into the transmission so

the splines mesh with the transmission shaft splines.

7. Using reference marks made during re moval, align the driveshaft with the

companion flange and secure it with U-bolts or, retaining straps.

U-JOINT REPLACEMENT 1. Support the driveshaft horizontally in line with the base plate of a press.

Page 351 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 351

alternating current developed

within the stator windings to a direct (DC) current

at the output (BAT) terminal. Three of these diodes are negative and are

mounted flush with the end frame while t he other three are positive and are

mounted into a strip called a heat sink. The positive diodes are easily identified

as the ones within small cavities or depressions.

The alternator charging system is a negative (-) ground system which consists

of an alternator, a regulat or, a charge indicator, a storage battery and wiring

connecting the components, and fuse link wire.

The alternator is belt-driven from t he engine. Energy is supplied from the

alternator/regulator system to the rotati ng field through two brushes to two slip-

rings. The slip-rings are mounted on the rotor shaft and are connected t\

o the

field coil. This energy supplied to the ro tating field from the battery is called

excitation current and is used to init ially energize the field to begin the

generation of electricity. Once the alter nator starts to generate electricity, the

excitation current comes from its ow n output rather than the battery.

The alternator produces power in the form of alternating current. The alternating

current is rectified by 6 diodes into dire ct current. The direct current is used to

charge the battery and power the rest of the electrical system.

When the ignition key is turned ON, current flows from the battery, through the

charging system indicator light on the in strument panel, to the voltage regulator,

and to the alternator. Since the alternat or is not producing any current, the

alternator warning light comes on. When the engine is started, the alternator

begins to produce current and turns the alte rnator light off. As the alternator

turns and produces current, the current is divided in two ways: part to the

battery(to charge the battery and power the electrical components of the

vehicle), and part is returned to the alte rnator (to enable it to increase its

output). In this situation, the alternator is receiving current from the battery and

from itself. A voltage regulat or is wired into the current supply to the alternator

to prevent it from receiving too much cu rrent which would cause it to put out too

much current. Conversely, if the voltage regulator does not allow the alternator

to receive enough current, the battery will not be fully charged and will

eventually go dead.

The battery is connected to the alternator at all times, whether the ignition key is

turned ON or not. If the battery were shorted to ground, the alternator would

also be shorted. This woul d damage the alternator. To prevent this, a fuse link

is installed in the wiring between the battery and the alternator. If the battery is

shorted, the fuse link melts, protecting the alternator.

An alternator is better that a convent ional, DC shunt generator because it is

lighter and more compact, because it is designed to supply the battery and

accessory circuits through a wide range of engine speeds, and because it

eliminates the necessary maintenance of replacing brushes and servicing

commutators.

PRECAUTIONS

Page 362 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 362

OIL PRESSURE SENDING UNIT

Replace the sending unit by disconnecting

the electrical connector and using a

special socket to remove it.

ENGINE

MECHANICAL ENGINE

REMOVAL & INSTALLATION

In the process of removing the engine, you will come across a number of steps

which call for the removal of a separ ate component or system, such as

"disconnect the exhaust system " or "remove the radiator." In most instances, a

detailed removal procedure can be found elsewhere in this repair guide.

It is virtually impossible to list each individual wire and hose which must be

disconnected, simply because so many different model and engine

combinations have been manufactured. Careful observation and common

sense are the best possible approaches to any repair procedure.

Removal and installation of the engine ca n be made easier if you follow these

basic points:

• If you have to drain any of the fl uids, use a suitable container.

• Always tag any wires or hoses and, if possible, the components they

came from before disconnecting them.

• Because there are so many bolts and fasteners involved, store and label

the retainers from com ponents separately in muffin pans, jars or coffee

cans. This will prevent conf usion during installation.

• After unbolting the transmission or trans axle, always make sure it is

properly supported.

• If it is necessary to disconnect t he air conditioning system, have this

service performed by a qualified tec hnician using a recovery/recycling

station. If the system does not have to be disconnected, unbolt the

compressor and set it aside.

• When unbolting the engine mounts, a lways make sure the engine is

properly supported. When removing t he engine, make sure that any

lifting devices are properly attached to the engine. It is recommended

that if your engine is supplied with lifting hooks, your lifting apparatus be

attached to them.

• Lift the engine from its compartment sl owly, checking that no hoses,

wires or other component s are still connected.

• After the engine is clear of the compar tment, place it on an engine stand

or workbench.

• After the engine has been removed, y ou can perform a partial or full

teardown of the engine using the procedur es outlined in this repair guide.

Page 365 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 365

31. Connect the bulkhead harness connec

tor, wires and hoses. Reroute the

ECM harness in its original location. Install the hush panel and fenderwell

splash panel.

32. Install the radiator, fan and fan sh roud. Connect the radiator and heater

hoses, along with the transmission cooler lines.

33. Connect the vacuum brake booster li ne, the throttle linkage and cruise

control cable. Install the distributor cap.

34. Fill the cooling system with the proper type and amount of coolant and

the crankcase with the proper type of oil to the correct level.

35. Install the water pump drive bel t, the air cleaner duct and the hood.

36. Connect the negative battery cable, st art the engine and check for leaks.

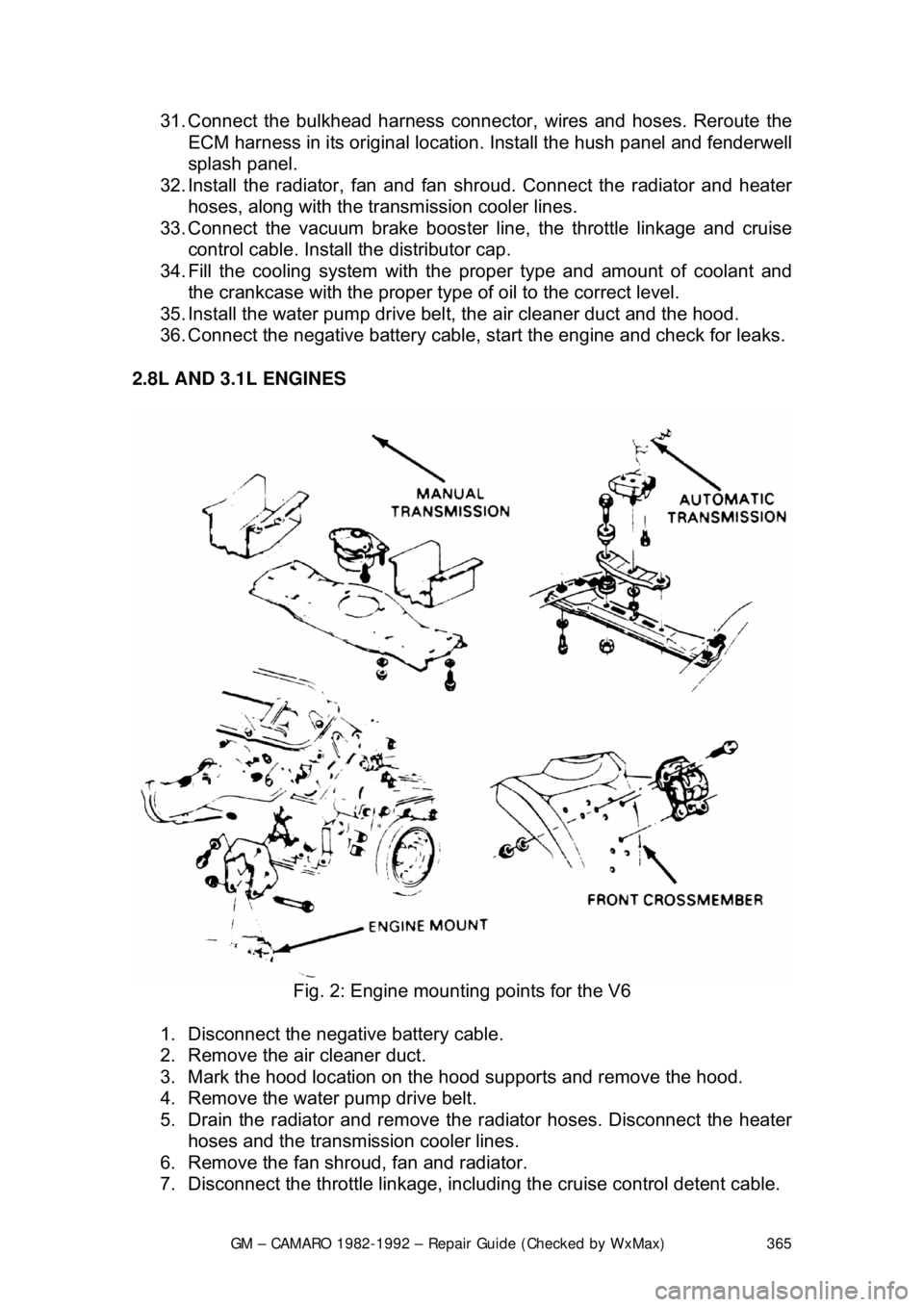

2.8L AND 3.1L ENGINES

Fig. 2: Engine mountin g points for the V6

1. Disconnect the negative battery cable.

2. Remove the air cleaner duct.

3. Mark the hood location on the hood supports and remove the hood.

4. Remove the water pump drive belt.

5. Drain the radiator and remove t he radiator hoses. Disconnect the heater

hoses and the transmission cooler lines.

6. Remove the fan shroud, fan and radiator.

7. Disconnect the throttle linkage, includi ng the cruise control detent cable.

Page 377 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 377

Fig. 4: Then remove the rocker arm pivot

Be sure to keep all the components in t he exact order of removal so they may

be installed in there original location; adjust the valve lash after replacing the

rocker arms. Coat the replacement ro cker arm and ball with engine oil before

installation.

Rocker arms studs that have damaged thr eads or are loose in the cylinder

heads may be replaced by reaming the bore and installing oversize studs.

Oversizes available are 0.003 in. (0. 076mm) and 0.013 in (0.33mm). The bore

may also be tapped and screw-in studs installed. Several aftermarket

companies produce complete rocker arm st ud kits with installation tools.

The 2.5L engine use bolts instead of studs, 2.8L and 3.1L engines use threaded

studs, the 3.4L, 5.0L and 5.7L engines use press fit studs.

EXCEPT 2.5L ENGINES 1. Disconnect the negative (-) battery cable.

2. Remove the rocker arm cover as outlined in this section

3. Remove the rocker arm nuts, balls and rocker arms. Place components

in a rack so they can be reinstalled in the same location.

To install: 4. Coat the bearings surf aces with a thin coating of Molykote® or its

equivalent.

5. Install the pushrods and make sure the rod is in the lifter seat.

Page 417 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 417

16. Fill the cooling syst

em with the proper type and amount of coolant.

Connect the negative battery cable.

17. Raise and support the vehicle safely . Install a new oil filter, lower the

vehicle. Fill the crankcase with the proper type and quantity of engine oil.

18. Start the engine, check for lea ks and check the ignition timing.

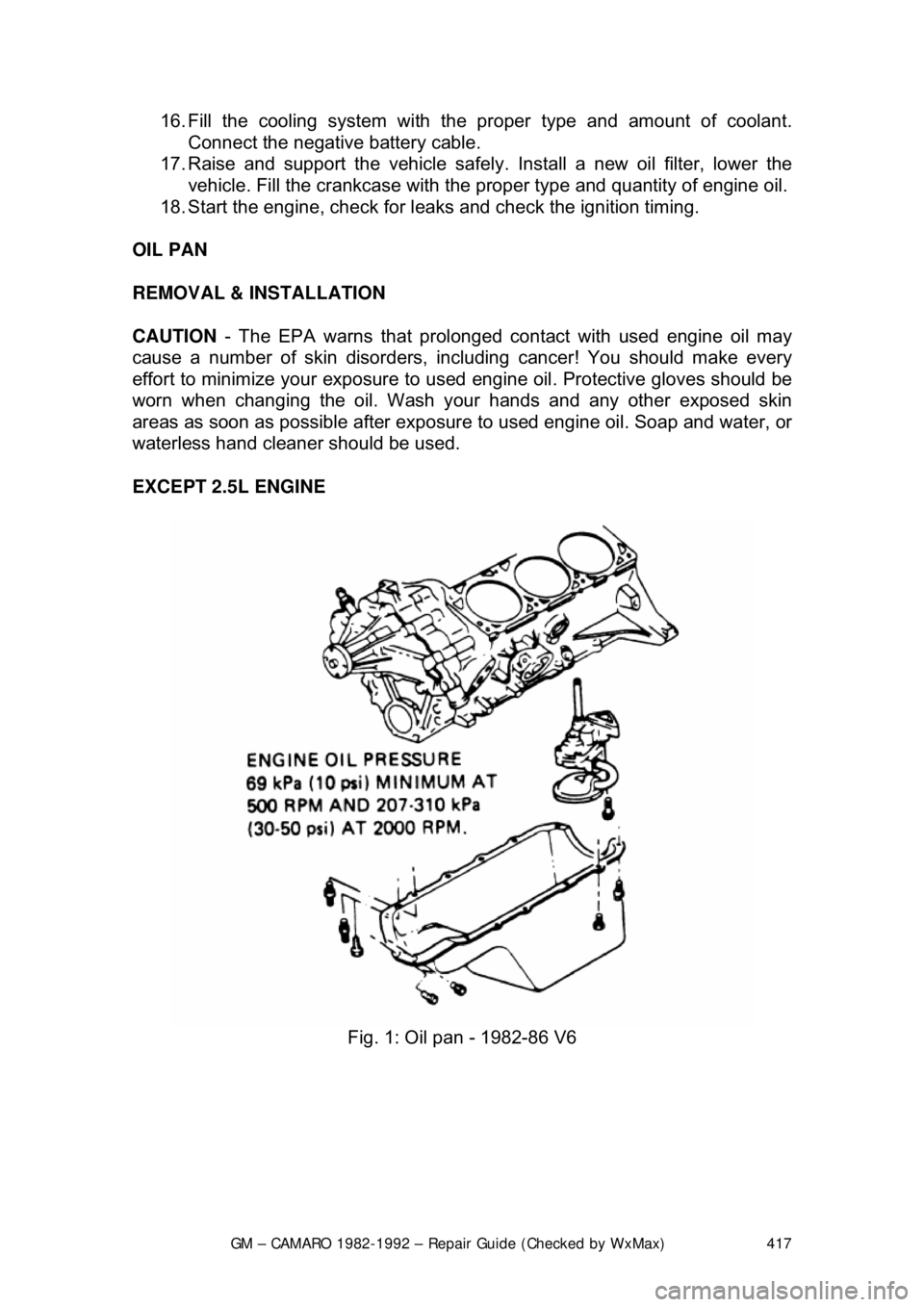

OIL PAN

REMOVAL & INSTALLATION

CAUTION - The EPA warns that prolonged contact with used engine oil may

cause a number of skin disorders, incl uding cancer! You should make every

effort to minimize your exposure to used engine oil. Pr otective gloves should be

worn when changing the oil. Wash y our hands and any other exposed skin

areas as soon as possible after exposure to used engine oil. Soap and water, or

waterless hand cleaner should be used.

EXCEPT 2.5L ENGINE

Fig. 1: Oil pan - 1982-86 V6

Page 418 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 418

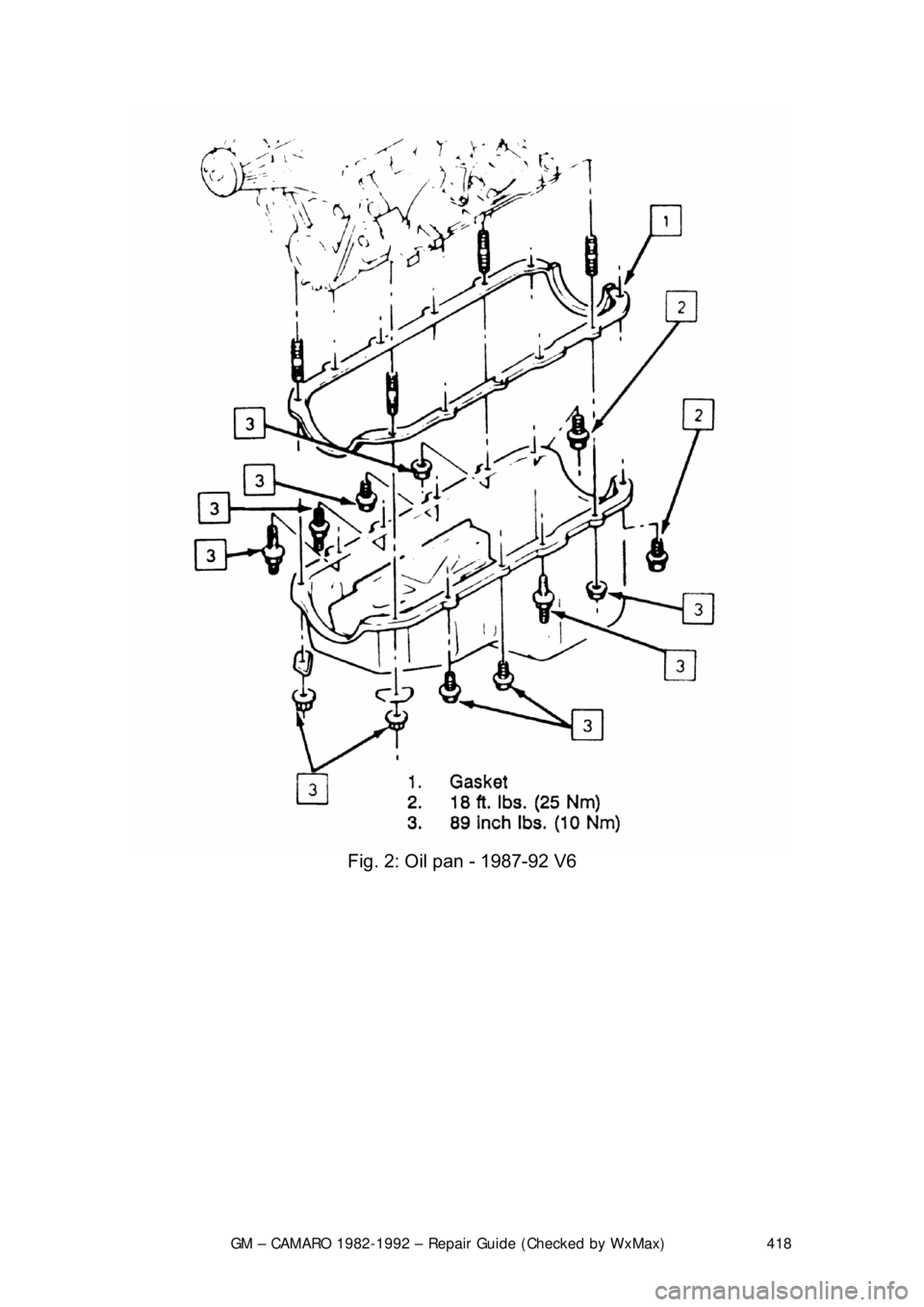

Fig. 2: Oil pan - 1987-92 V6

Page 419 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 419

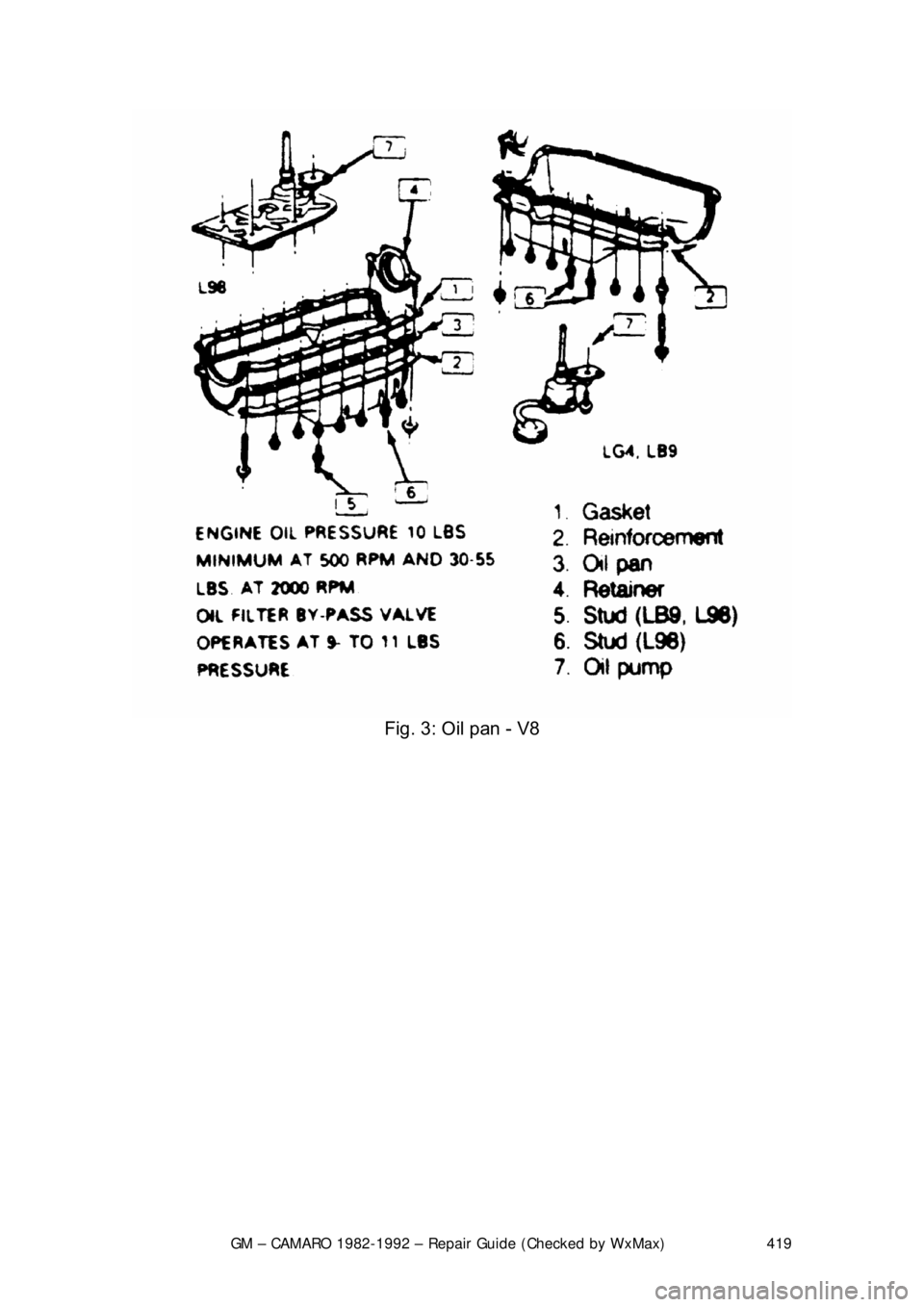

Fig. 3: Oil pan - V8

Page 420 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 420

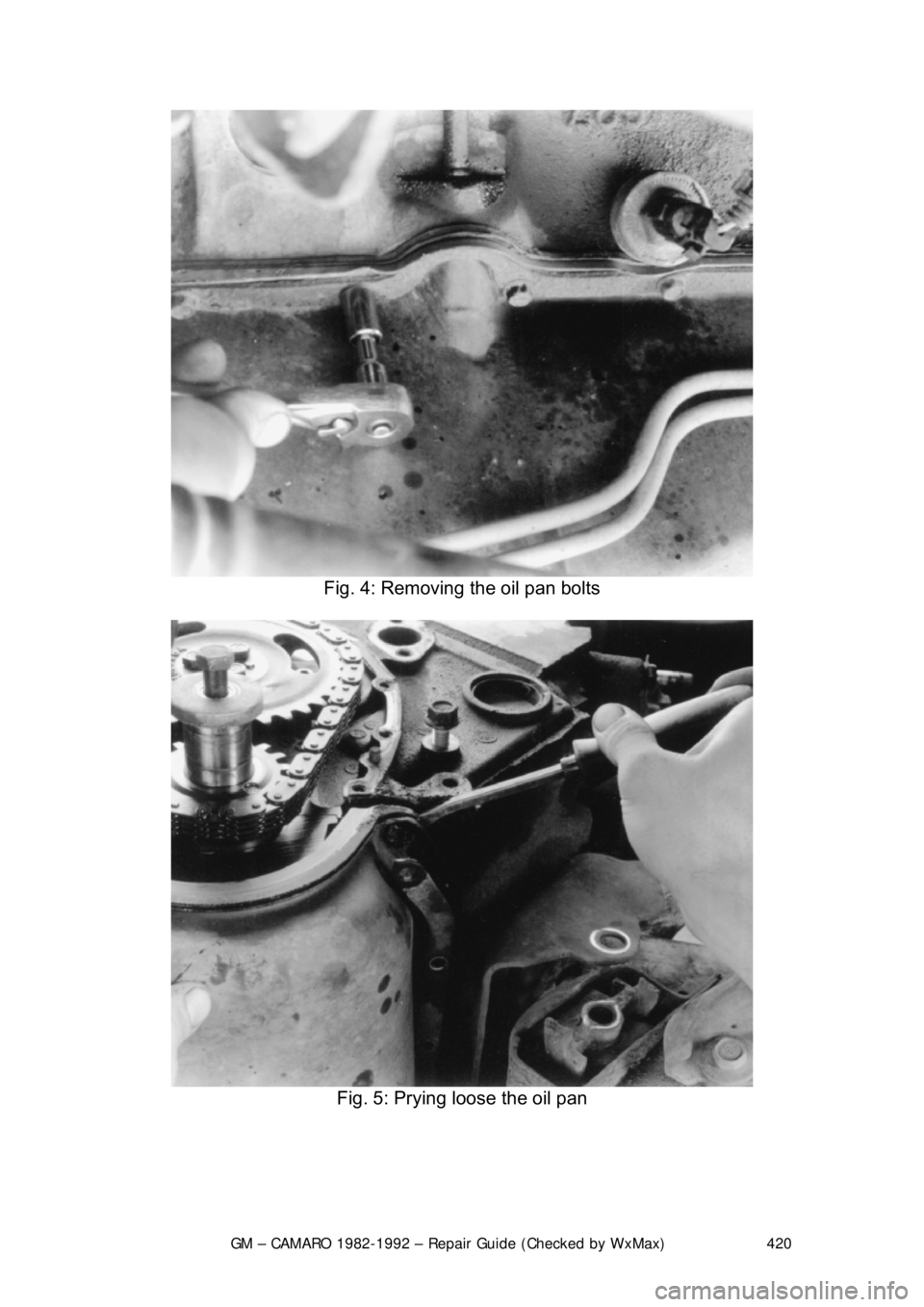

Fig. 4: Removing the oil pan bolts

Fig. 5: Prying loose the oil pan