9. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

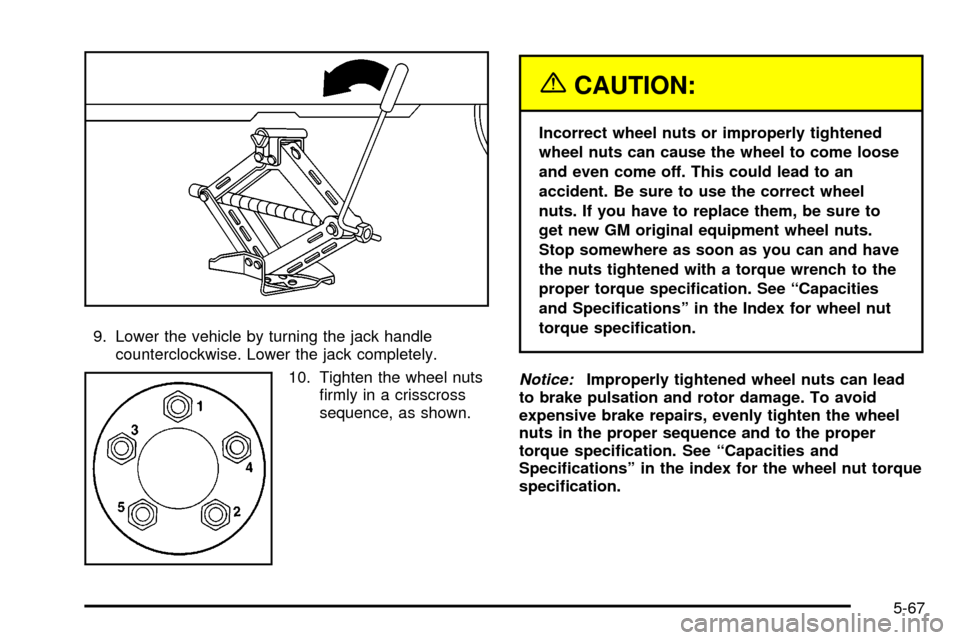

10. Tighten the wheel nuts

®rmly in a crisscross

sequence, as shown.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci®cation. See ªCapacities

and Speci®cationsº in the Index for wheel nut

torque speci®cation.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci®cation. See ªCapacities and

Speci®cationsº in the index for the wheel nut torque

speci®cation.

5-67

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses for proper hook-up, binding, leaks, cracks,

cha®ng, etc. Inspect disc brake pads for wear and rotors

for surface condition. Also inspect drum brake linings

for wear and cracks. Inspect other brake parts, including

drums, wheel cylinders, calipers, parking brake, etc.

Check parking brake adjustment. You may need to have

your brakes inspected more often if your driving

habits or conditions result in frequent braking.

Caliper/Knuckle

MaintenanceInspection

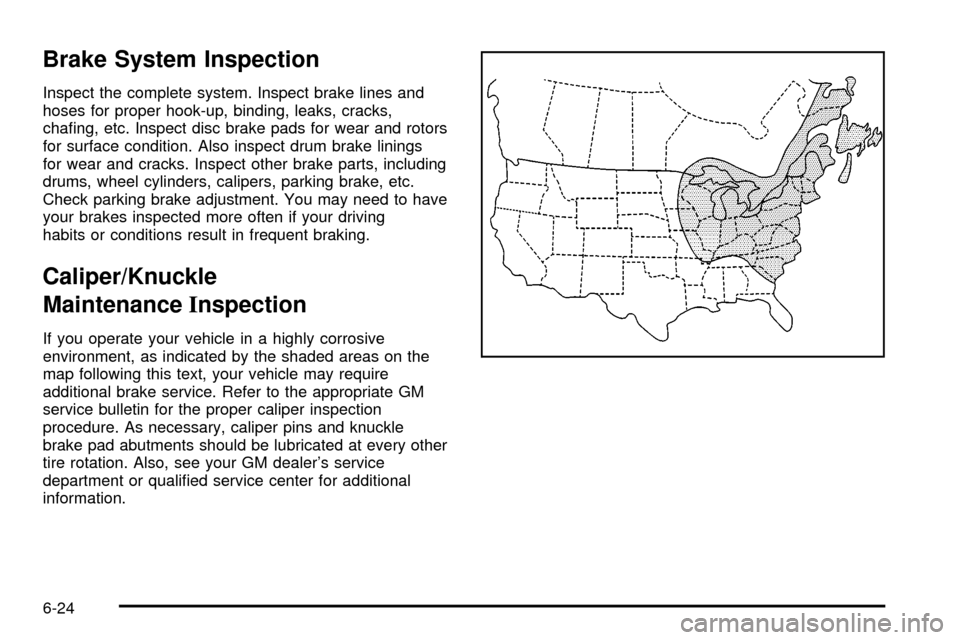

If you operate your vehicle in a highly corrosive

environment, as indicated by the shaded areas on the

map following this text, your vehicle may require

additional brake service. Refer to the appropriate GM

service bulletin for the proper caliper inspection

procedure. As necessary, caliper pins and knuckle

brake pad abutments should be lubricated at every other

tire rotation. Also, see your GM dealer's service

department or quali®ed service center for additional

information.

6-24