maintenance schedule CHEVROLET CITATION 1980 1.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1980, Model line: CITATION, Model: CHEVROLET CITATION 1980 1.GPages: 95, PDF Size: 21.48 MB

Page 63 of 95

Downloaded from www.Manualslib.com manuals search engine CATALYTIC CONVERTER

. The catalytic converter is an emission control device added to the

exhaust system to reduce exhaust gas pollutants. The converter

contains a ceramic material coated with noble metal catalysts. To prevent

contamination of the cata lysts,

unle~ded gasoline must be used. Unleaded gasoline

also reduc es combustion chamber deposits and exhaust system corrosion.

The catalytic converter requires the use of unleaded gasoline. Use

of leaded gasoline will cause the converter to lose its effectiveness for emission control. On some engines, the catalyst must be changed at cer tain inter vals in orde r for

the emissio n control system to continue to operat e properly. The change intervals

are speci fied in Section C of the Maintenance Schedule folder.

On cars that require this catalyst change, the word "EMISSION" will

appear on an indicator in the speedometer face at the specified change

in terval

s. This is a reminder that the cata lyst must be changed. (If the indicator does not appear, your car does not need this catalyst change).

Your Chevrolet deale r will perform the lirst cataly st cha nge at no charge, whether yO'u are the first owner or a subsequent owner. As part of this service, the indicator

should be reset to appear

at the next specified chang e interval. To help prevent

damage:

1. Keep your engine properly maintained. Engine malfunctions involving th e electrical, carburetion or ignition systems may result in unusually high

conve rter and exhaust system temperatures .

Do not keep driving your vehicle if you detect engine misfire. noticeable loss of

perform,8nce. or other unusual operating conditions. Instead, have it serviced promptly. A properly ···maintained engine will he lp avoid

malfunction s that could damage the converter.

It will also help provide good

emissio.n cq!).,trol and gasoline economy. See the Maintenance Schedule folder

for inform ation on inspecting a

nd maintaining the engi ne. exhaust system.

and other compone nts.

2 .

Do not drive through, idle, or park your vehicle over combustibl e materials,

s u ch as grass

or leaves. They could 'touch the hot exhaust system and ignite.

3. Do n o t push or tow this vehicle 10 stan it. This cou ld damage (he converter.

Disregarding this information could damage the catalytic converter, the vehicle,

or nearby property.

C-4 (COMPUTER CONTROLLED CATALYTIC CONVERTER)

SYSTEM If your new car was purchased in California, it has a special emission control

system, called

the C-4 (Computer Co ntrolled Catalytic Converter) System. The C4 System monitors the exhaust stream with an oxygen sensor. Based 4

on senso r signals, the electr onic control module adjusts the carburetor

air~fuel ratio as needed. It is very important to use only unleaded gasoline

in cars with

the C-4 System. Leaded gasoline will damage the oxygen

sensor. which may affect emission

control, fuel economy and drivability.

Some cars equipped with the C-4 System need an oxygen sensOr change

at the intervals specified in Section C of the Maintenance Schedule folder.

On these cars, an oxyge n sensor maintenance reminder is included in the

instrument paneL The word "EMISSIONS" is designed to appear in a

window in the speedometer face at the intervals outlined in the Maintenance

Schedule folder. The "EMISSIONS " indicator is a reminder that the oxygen

sensor must be repl aced with a new sensor.

Such replacement is necessary

in order to maintain the correct operation of the emiss ion control system.

The indicator must be reset as part of this service.

5-2

Page 66 of 95

Downloaded from www.Manualslib.com manuals search engine NOTICE: You cannot read the correct fluid level if you have just driven the car for a long time at high speed, in city traffic in hot weather, or if the car has been pulling a trailer. Wait. until the fluid has cooled down (about 30 minutes).

Remove the dipstick located on the driver's side forward of the cowl. Carefully

touch the wet end of the dipstick to find out if the fluid is cool, warm or hot. Wipe

it clean and push it back in until the cap seats. Pull

out the dipstick and read the

fluid level.

• If it felt cool or warm (about room temperature), the level should be

between the dimples above the "Full" mark.

• If it was too hot to hold. the level should be at or in the hatched area.

Add just enough DEXRON-®n fluid to fill the transaxle. It takes only 0.5 liter

(one pint)to raise the level from "Add" to "Full" with a hot transaxle.

Do not overfill the transaxle. Overfilling can cause foaming and loss of fluid, which

could result in transaxle damage.

Automatic Transaxle Drain Intervals

Change the transmission fluid and change the filter (or clean the screen) as

outlined in Section

A of the Maintenance Schedule folder.

ELECTRIC FAN

CAUTION: Keep hands, tools, and clothing away from the angine cooling fan to help prevent personal injury. This fan is electric and can come on whether or not the engine is running. The fan can start automatically in response to a heat sensor when the ignition is in the "Run" position.

ENGINE COOLING SYSTEM

The coolant recovery system is standard. The coolant in the radiator expands with

heat, and the overflow collects in the recovery tank. When the system cools down,

the coolant

is drawn back into the radiator.

The cooling system was filled at the factory with a quality coolant that meets

GM Specification 1899-M. The cooling system is designed to use coolant (a mixture

of water and ethylene glycol antifreeze) rather than plain water. The coolant

solution should be used year round. It has many advantages, such as:

• provides freezing protection down to _37°C, (-34°P)

•

provides boiling protection up to 128QC, (262°P)

•

protects against rust and corrosion in the cooling system,

• maintains the proper engine temperature for efficient operation and emission

control, and

• allows proper operation of the coolant temperature light (or gage).

See Section A of the Maintenance Schedule folder to find out when the coolant

must

be replaced.

COOLING SYSTEM CARE

Check the cooling system at regular intervals, such as during fuel stops. You

usually do not need to remove the radiator cap to check the coolant level. Lift

the engine hood and look at the "see through" coolant recovery tank. When the

engine

is cold, the coolant level -should be at or slightly above the "Full Cold"

mark on the tank. When the engine has fully warmed up, the level should be at ')r slightly below the "Full Hot" mark on the tank. If the coolant level is low,

5-5

Page 67 of 95

Downloaded from www.Manualslib.com manuals search engine remOve tlie cap on the coolant ~ecove~y tank : Add to the tank enough of a 50 150 . mixture of w ater and a g ood quality eth)dene glycol antifreez e to bring the level

up to the .

proper mark. Put the cap bac k on the tank .

Certain

conditi ons; "Such as air trapped in the syste m, may affe ct the coolant level

in

the radiator. You sho uld ch ec k the co olant ·Ievel ·in the radiator while you

change the engine oil and the e ng ine is col d. Follow steps I , 8, 9 and 10 und er

"Coola nt Rep lacement" for the correct way to rt!move the radiator cap .an d add

. coolant.

If you have to add coola nt more than f our tim es a yea r (ei ther to th e recov ery

tank

or to the radiat or). see your dealer. for a. c oo lin g system chec k.

NOTICE: If the proper quality antifreeze is used, there is no .nee~ to add extra inhibltOf"s or additives which claim to improve the svstem .. They may be harmful to the proper operation. I)f the system.

Cooling System Service

The cooling syste m should be serviced at the intervals specifi ed inSection A of

the Maintenan ce Sch edule fold er as follows:

I. W ash the radiatqr cap .and filler neck with clean water. See step J of "Coolant

Replacement" to remove rapiator cap. .

2. C hec k the coolant level in the radiator and have it tes ted for freeze proteCtion . Add·· ethylene gly col antifreeze, if needed, to· m aintain freeze protecti on at -37'C(-34'F),

3~ Have ·the coOlin-g sys tem and radiat or cap tested fo r a press ure capacity of

105 kPa (15 psi) . If a repl acement cap is needed"Hse an AC ca'p,or an

equivalent · cap, designed fOl: coolant recovery system ·s and spe cified for your model;

4. Tighten all radiator hose clamps and heater hose clamps and inspect an hose s.

R

eplace the hose s if they are swollen, "checked" or otherwise worn .

NOTICE: Take care when tightenjng·the hose clemps at tMI radiator. Overtightening COUld. bend or collapse .the radiator fittings.

5. Clean the front. of the radiator core and air condit ioning condenser to re m ove

dirt and oth er·objects. Al so clean the auxiliary engine oil andlor transmission -fluid ' cooler if the vehicle has them.

Coolant, Replacement

At the interval s specified in Section A of the Maintenance Schedule folder, flu sh

a

nd refill the cool ing system as follows :

1. Remove the·radiat or·cap when the engin e is ·cool :

•

Turn . t he cap s lowly to the len until ·it reaches a " stop. " Do not press down while turning the cap.

• 'Wait until any rem aining press ure (indicated by a hissing sound) is

reliev ed. then press down on the cap an d continue turning it t(j the left.

CAUTION:· To help ~lVoid the danger of being ,burned, do not remove the radiator cap while the angine and radiator are still hot s.c.lding flutd and steam can be bk)wn out under pressure if the·cap is taken off.too soon.

2. Whe n the cap is re m oved, run the eng ine until the upper radiator hose is hot.

(This shows that the thermostat is open and the coola nt is flow ing through

the . system.)

5·6

•

Page 70 of 95

Downloaded from www.Manualslib.com manuals search engine CAUTION: If the air cleaner is removed during repair or maintenance, be sure to . put It back on correctly. If the air cleaner is not correctly installed, there could be II fire In the engine compartment (if there should happen to be a backfire), or other engine malfunction.

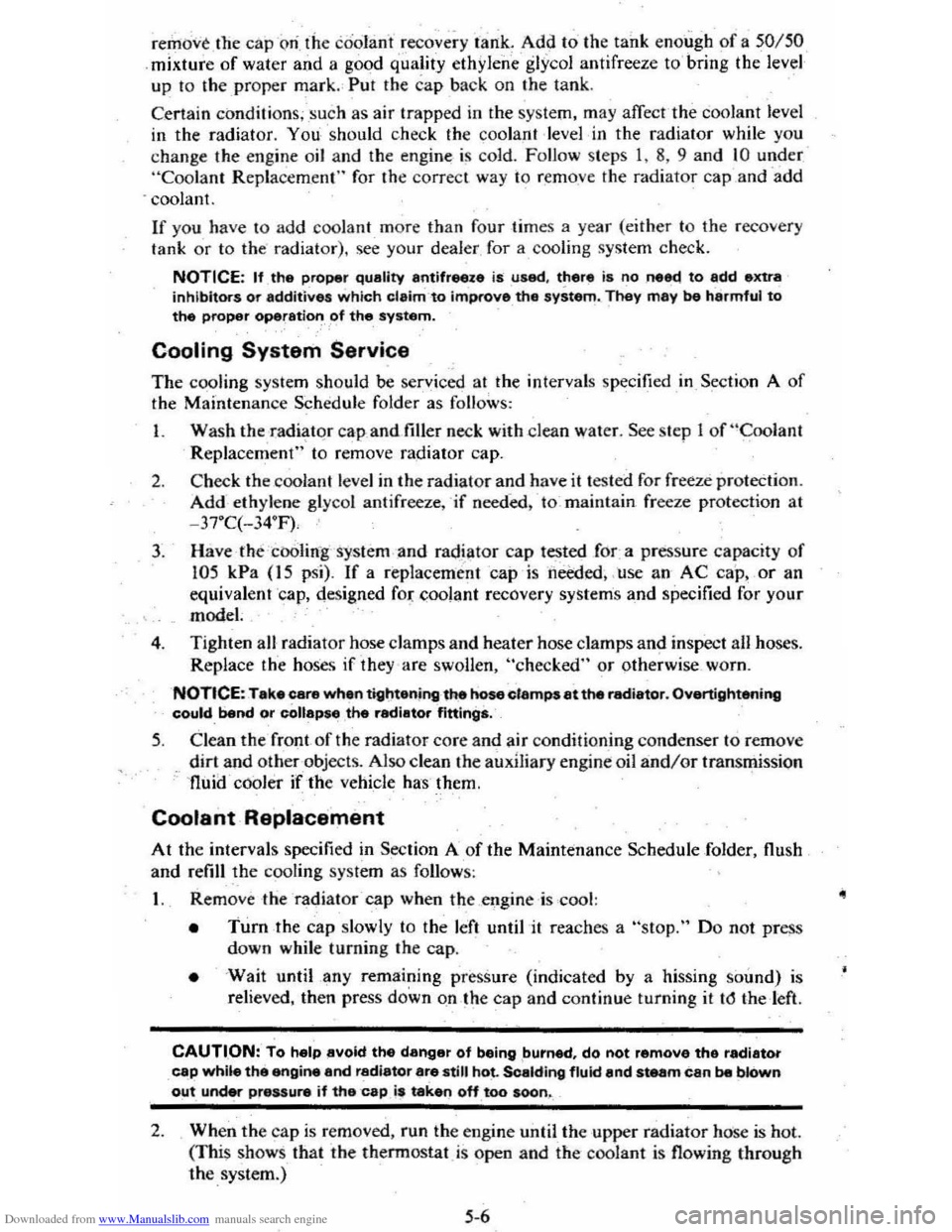

Power Steering System

Check the 'fluid level in the power steering pump at each engine oil change. Add GM :Power Steering Fluid, (Part Number GM 1050017) as needed:

, • Ifnuid is warmed up (abo ut 66°C or lSO"F --hot to the to uch), the fluid level

should be between the "Hot" and "Cold" marks on the filler cap indicat or.

• If cool (about 21°C or 70° F), the fluid level should be between the "Add" and "Cold" marks.

This fluid

does not need ' periodic changing.

Freedom Battery

Your new vehicle has a Delco FREEDOM battery. It needs no periodic

maint enance . Its

lOp is permanently sealed (except for two small vent holes) and

has no filler caps. You will never have to add water. .

The hydrometer (test indicat or) in the top of the battery provides information for

testing purposes only.

For full power needs at repla cement time, a Delco battery with ,the same catalog

number as shown on the original banery's label

is recommended.

CAUTION: FoUow the precautions listed in the Jump Starting Cautton {see the "'n Case of Emergency''' section o"f this manual, when working on or near the battery.

Personal injury (particularly to eyes) or property damage may result from battery explosion, battery acid, or electric.1 (short circuit) burns.

Hood latches and Hood Hinge

At the interval shown in the Maintenance Schedule lubricate hood latch assembly

and hood hinge assembly as follows :

1 . Wipe off any accumulation

of dir.t or contamination on latch parts.

2. Apply Lubriplate or equivalent to latch pilaf bolts and latch loc king

plate .

3. Apply light engine oil to all pivot points in release mechanism, as well

as primary

and secondary latch mechanisms.

5-9

Page 73 of 95

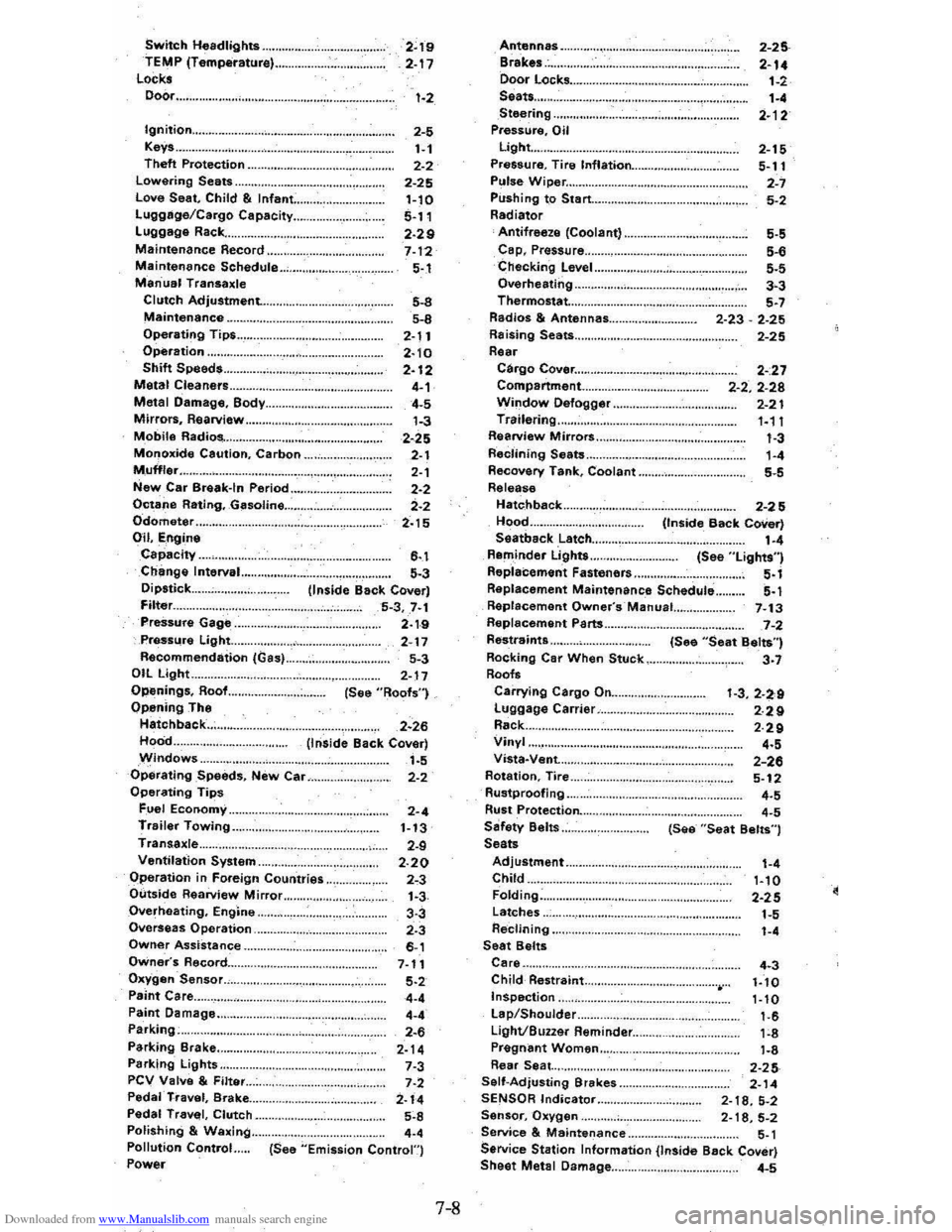

Downloaded from www.Manualslib.com manuals search engine STANDARD EXTRA B C o

TIRE LOAD AND INFLATION PRESSURES

TIRE LOAD RANGE

-(METRIC SIZETIREI -(METRIC SIZETIREI -(ALPHA-NUMERIC SIZE TIREI -(ALPHA-NUMERIC SIZE TIREI -(ALPHA-NUMERIC SIZE TIREI

MAXIMUM COLD INFLATION PRESSURE

240 Ic.Pa 280 kPa 2211 kP. 250 kP, 275 kP,

(35 psi I (41";1 (J2 psil ( 36 psil (40 p.iI

TIRE LOAD RANGE IS MOLDED ON TIRE. (SEE ILLUSTRATION ON PAGES-leFOR LOCATION ON THE TIRE SIOEWALU.

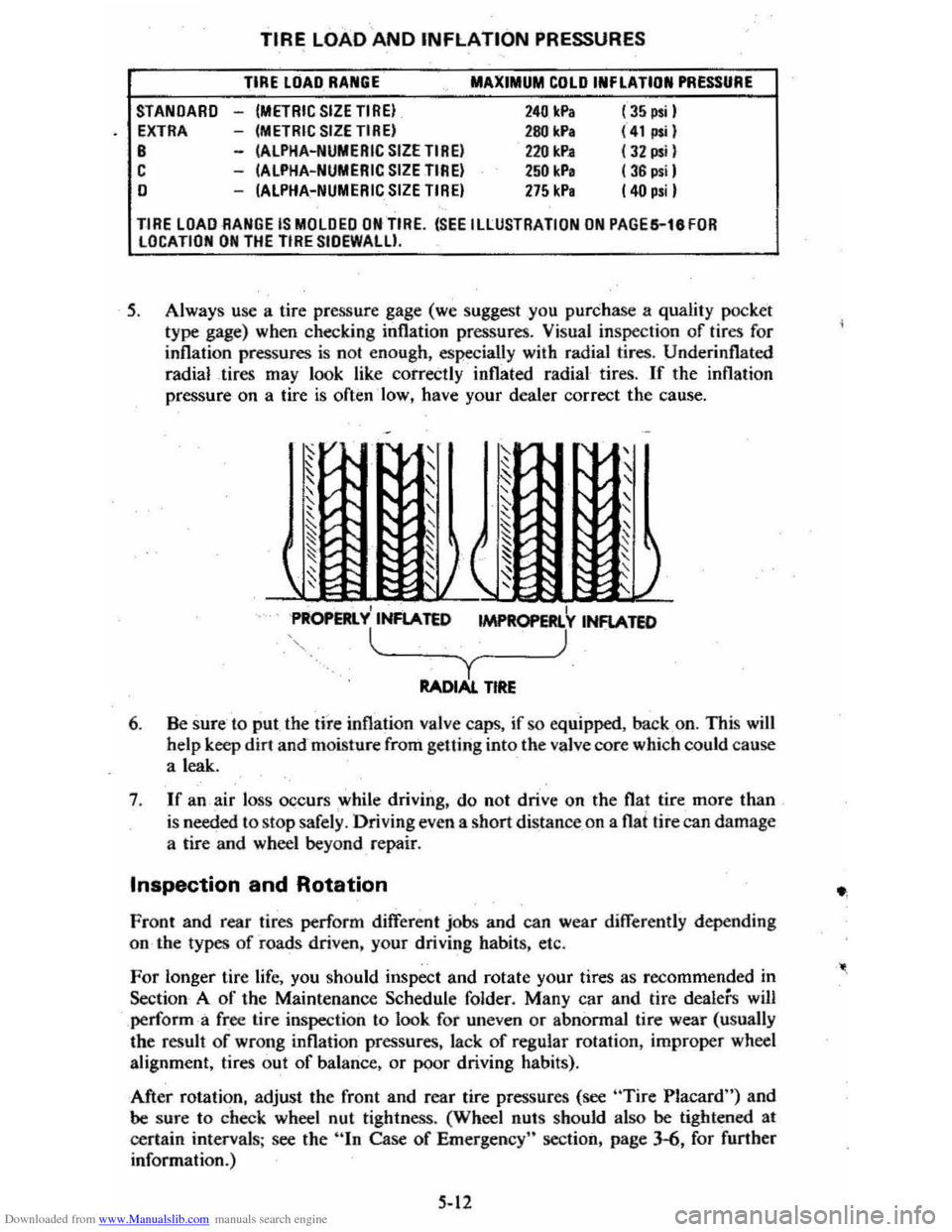

5. Always use a tire pressure gage (we suggest you purchase a quality pocket

type gage) when checking inflation pressures. Visual inspection of tires for

inflation pressures is nol enough, especially with radial tires. Underinflated

radial tires may look like correctly inflated radial tires.

If the inflation

pressure on a tire

is often ·low, have your dealer correct the cause.

, I PROPERlY INFlATED 1MPR0PERl Y INFlATED

l~_~~_~) y RADIAl. TIRE

6. Be sure to put the tire inflation valve caps, if so equipped. back on. This will help keep dirt and-moisture from getting into the valve core which could cause

a leak.

7 .

If an air loss occurs while driving. do not drive on the flat tire more than

is needed to stop safely . Driving even a short distance _on a flat tire can damage

a tire and wheel beyond repair.

Inspection and Rotation

Front and rear tires perform different jobs and can wear differently depending

on the types

of roads driven, your driving habits, etc.

For longer tire life, you should inspect and rotate your tires as recommended in

Section A

of the Maintenance Schedule folder. Many car and tire dealers will perform -a free lire inspection to look for uneven or abnormal tire wear (usually

the result of wrong inflation pressures, lack of regular rotation, improper wheel

alignment, tires out

of balance, or poor driving habits).

After rotation, adjust the front and rear tire pressures (see

"Tire Placard") and be sure to check wheel nut tightness. (Wheel nulS should also be tightened at

certain intervals ; see the

hIn Case of Emergency" section, page 3-6, for further

information.)

5-12

Page 74 of 95

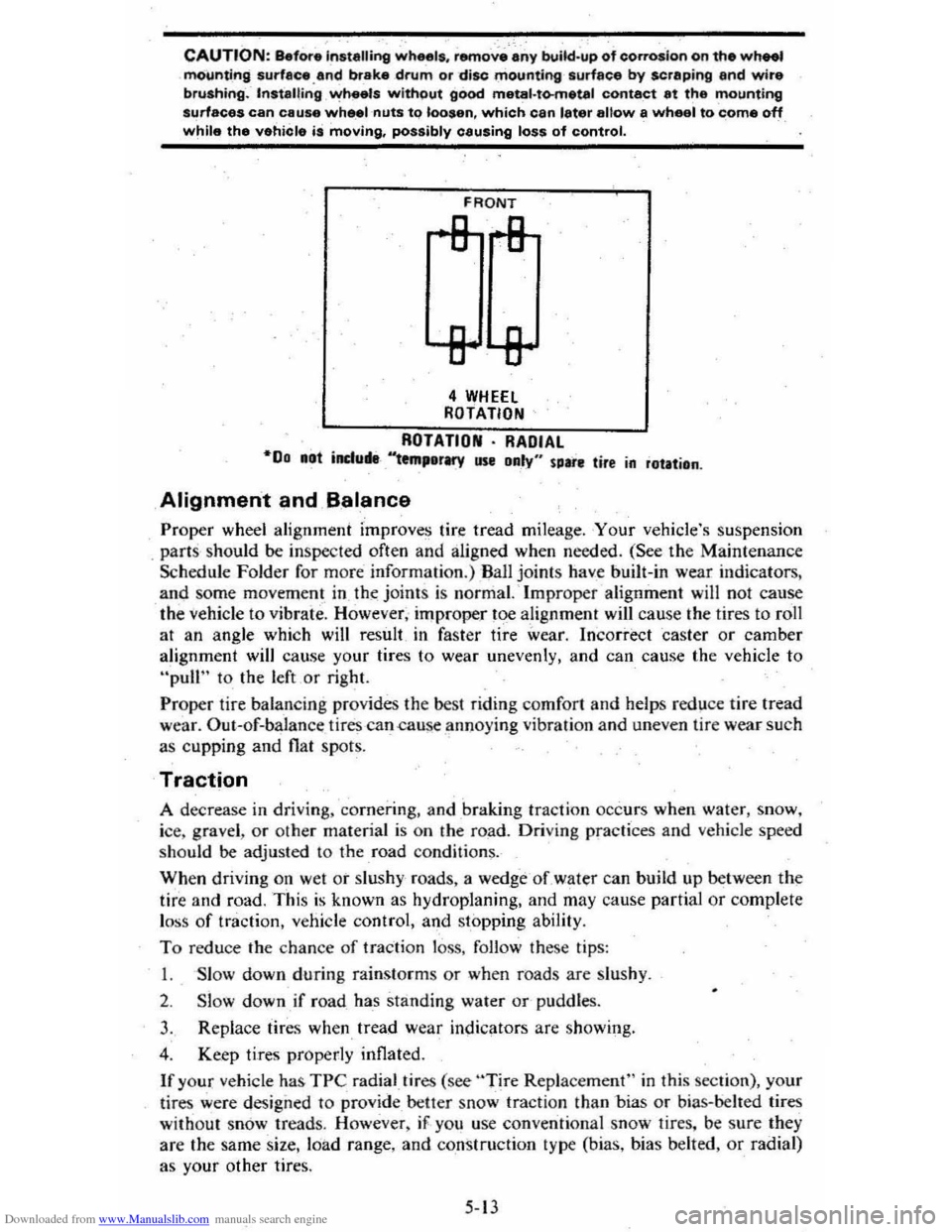

Downloaded from www.Manualslib.com manuals search engine CAUTION: BefOf"e Installing wheels. remo';.'~-~y build.up of corrosion on the wheel mOOnti_ng surfllce.and brake .drum or disc mounting surface by scrllping and wire brushing~-Installing ~h •• ls without good metal·to-metal contact at the mounting surfaces can cause whe.lnuts to loosen. which can later allow a wheel to c;ome off while the vehicle is moving. possibly causing loss of control.

FRONT

4 WHEEl ROTATION

ROTATION· RADIAL "00 .at induM-'''tm,erMY use Daly" sure tire in rotation .

Alignment and B.alance

Proper wheel alignment improves tire tread mileage . Your vehicle's suspension

. parts should be inspected often and aligned when needed. (See the Maintenance

Schedule Folder for m ore information.) Ball joints have built-in wear indicators,

and some movem ent in th~ joint s is normal. ' Improper alignment will not cause

the

vehicle to vibrate. However, improper toe alignment will cause the tires to roll

at an angle which will result in faster tire wear. Incorrect caster or camber

alignment will cause your tires to wear unevenly, and can cause the vehicle to

"pull" to the left or right.

Proper tire balan cing provides the best riding comfort and helps reduce tire tread

wear. Out--of-balan ce tires -can .cause annoying vibration and uneven tire wear such

as cupping and

flat spots.

Traction

A decrease in driving. cornerin g, and braking traction occurs when water, snow,

ice, gravel ,

or other material is on the road. Driving practices and vehicle speed

should be adjusted to the road condition~.

When driving on wet or slushy roads, a wedge -of water can build up between the

tire and road. This is known as hydroplaning, and may cause partial or complete

l oss

of traction, vehicle control, and stopping ability.

To reduce the chance of traction loss, follow these tips:

I. Slow down during rainstorms or when roads are Slu shy .

2. Slow down if road has standing water or-pUddles.

3. Replace tires when tread wear indicators are showing.

4 . Keep tires properly inflated.

If your vehicle has TPC radial.tires (see "Tire Replacement" in this section), your

lir es were design ed to

provide _ better snow tracti on than -bias or bias-belled tires

without snow treads. However , iF . yo u use conventional snow tires. be sure they

are the same size. loa d range, and construction type (bias, bias belted,

or radial)

as your other tire

s.

5-13

Page 90 of 95

Downloaded from www.Manualslib.com manuals search engine Switch Headlights .... TEMP (Temperature) .. Locks Door ...

2~19 2-17 1-2

Ignition ............................................. .. 2-5 1-1 2-2

2-25 Keys .. Theft Protection .. Lowering Seats .. Love Seat, Child & Infant: .. Lugglige/Cargo Capacity ... Luggage Rack ... Maintenance Record .. Maintenance Schedule .. Manual Transaxle Clutch Adjustment. .. .

1-10 5-11 2·29 7-12 5-.1

Maintenance ........................................... . 5-8

5-8

2-11

2· 10 2-12 4-1 4-5

1-3

Operating Tips .. Operation .. Shift Speeds. Metal Cleaners .. Metal Damage, Body ... Mirrors, Rearview .. Mobile Radios-. Monoxide Caution, Carbon .. . 2-25 2-1

2-1 2-2

2-2

2-15 Muffler ............................................... . New Car Break-In Period Octane Rating, Gasoline ... Odometer Oil, Engine Capacity .. Change Interval.. Dipstick ... Filter ... PreSsure Gage .. Pressure Light... Recommendation (Gas) .. OIL Light.. Openings, Roof... Opening The Hatchback ... Hood .. Windows ..

6-.1 5-3 (inside Back Cover) 5-3,7·1 2·1-9 2-17

5-3

2-17 (See "Roofs")

2·26 (Inside Back Cover) 1-5 Operating Speeds, New Car... 2-2 Operating Tips Fuel Economy.. 2-4 Trailer Towing.. 1-13 Transaxle... 2-9 Ventilation System.. 2.20 Operation in Foreign Countries.. 2"3 Outside Rearview Mirror.. 1.3 Overheating, Engine.. 3-3 Overseas Operation.. 2.3 Owner Assistance.. 6-1 Owner's Record... 7-11 Oxygen Sensor., 5.2 Paint Care.. 4-4

Paint Damage .. Parking;. Parking Brake .. Parking Lights .. PCV Valve & Filter .. Peda'·TI"avel, Brake ... Pedal Travel, Clutch .. Polishing & Waxing .. Pollution Control Power

4-' 2-. 2-14 7-3 7·2 2-14 5~8

.-. (See "Emission Contron

7-8

Antennas Brakes .. Door Locks .... Seats ... Steering Pressure, Oil Light ... Pressure. Tire Inflation ... Pulse Wiper ...

2-25

2-14

1-2 1-' 2·12

2-15

5-11

2-7

Pushing to Start ................................ .. 5-2 Radiator Antifreeze (Coolant) .. Cap, Prassure .. Checking Level .. Overheating .. Thermostat...

Radios & Antennas ... Raising Seats ... Rear Cargo Cover ...................... .. Compartment .. . Window Defogger .. Trailering .. Rearview Mirrors .. Reclining Seats .. Recovery Tank, Coolant .. Release

Hatc.hback

Hood .. Seatback Latch ... Reminder Lights ....

Replacement Fasteners

5-5 5-. 5-5 3-3 5-7

2-23 -2-25

2-25

2-:27

2-2,2-28 2-21 '·11 1-3 1-' 5-5

2-25 (Inside Back Cover)

1-' (See "Lights") 5-1

5-1 Replacement Maintenance Schedule .. Raplacement Owner's·Manual... 7-13 Replacement Parts ............. ....................... 7-2 Restraints .. Rocking Car When Stuck .. Roofs Carrying Cargo On ... Luggage Carrier .. Rack .. Vinyl .. Vista-Vent. ... Rotation, Tire .. Rustproofing .. Rust Protection ... Sefety Belts .. Seats (See

"Seat Belts") 3-7

1-3,2-2,9 2·29 2·29

'-5 2-26 5-12

'-5 '-5 (See "Seat Belts")

Adjustment.. 1-4 Child... 1-10 Folding.. 2-25 Latches..

1-5 Reclining.... . '-4 Seat Belts Care.. 4.3 Child Restraint ............................................ 1.10 Inspection.. 1-10 Lap/Shoulder.. 1-6 Light/Buzzer Reminder... 1;8 Pregn~nt Women .. Rear Seat. ... Self-Adjusting Brakes .. SENSOR Indicator ..

1-8 2-25 2-14 2-18,5-2 Sensor, Oxygen.... 2-18,5-2 Service & Maintenance.. 5-1 Service Station Information (InSide Back Cover) Sheet Metlll Damage... 4-5