check oil CHEVROLET CITATION 1980 1.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1980, Model line: CITATION, Model: CHEVROLET CITATION 1980 1.GPages: 95, PDF Size: 21.48 MB

Page 16 of 95

Downloaded from www.Manualslib.com manuals search engine Tir,s

When lowing trailers using a dead-weight hitch, inflate tires to the "Cold Tire

Pressure" for ·'Max . Load" show n on the Tire Placard on the left front door.

The allowable passenger and cargo load for this car,

also sh o wn on· the Tire

Placard, is reduced by the trailer tongue weight whenever the trailer is attached

t o the car.

Maintenance

More frequen.t servic e is requi red when using your car to pull a trailer. See Section

A of the Maint enance Schedule folder for Tran saxle Fluid and Engine Oil chang e

requirement~ for traitering.

Now and then. check that all trailer hitch bolts an d nuts are tight. Also see

"the Maintenance Schedule rol_def, and the Index in this manual , for important facts

o n

belts, coo ling system care and brake adjustment.

Break-In Schedule

See the new car break~in instru ctions in this manual. Also,. we recommend you

drive your new car for

500 mil es (800 kilometer s) before trailer tOwing. At the

" end

of this 500 mile (800 kilome te r) break-in period, avoid speeds over 50 mph (80 km/h) and full throttl e start s during the first 500 miles (800 kilometers) of

trailer towing.

If a new engine or transaxle is ins talled in you r car, observe the

same

care.

CAUTIONS:

Brakes -To help avoid personal injury due to poor braking action:

• Trailer brakes of adequate size are required on trailer s over 450 kilograms

(1,000 pounds) loaded weight.

• If you use trailer brakes with this car, follow the installation and balan ce

instructi ons

of the trailer brake maker.

• Do nol lap into the car's brake system if the trailer brake system uses more than 0.3 cubic centimeter (0.02 cubic inch) of nuid from the ca r's master

cylinder. In this case, the car's brake fluid capacity will not be enough to

operate

both the car and trailer brakes under all kind s, of use.

• All brak e fluid parts must be able to stand 20 685 kPa (3,000 psi). The brake

fluid tap must be made al th e upper rear master cylinder port. Copper tubing is subject to fatigue failure and must no t be used.

• Before going down a sleep or long grade , reduce speed and shift the tran saxle

into a lower gear to control your car's speed.

Try not to hold the brake pedal

down too long or too often. This could cause the brake s to get hot and not

work

as well.

Hitches -To help avoid personal injury due to sway caused by such things as

c rosswind

s, big trucks passing or road roughn ess, or due to sepa ration of the

trailer :

• Keep the trailer tongue load at 10% of the loaded trailer weight for

dead-w eight hitches. Tongue loads can be adjusted by proper distribution of the load in the trailer. This can be checked by weighing separately the loaded

trailer and then the tongue,

• When you remove a frailer hitch, be sure to seal any mountin g h'oles in the

body . This will help prevent entry of exhaust fumes, dirt or water. (See

"Engine Exhaust Gas Caution (Carbon Monoxide) " at the beginning of "Starting and Operating," Section 2 of this manual.)

1-12

Page 33 of 95

Downloaded from www.Manualslib.com manuals search engine '" 0;

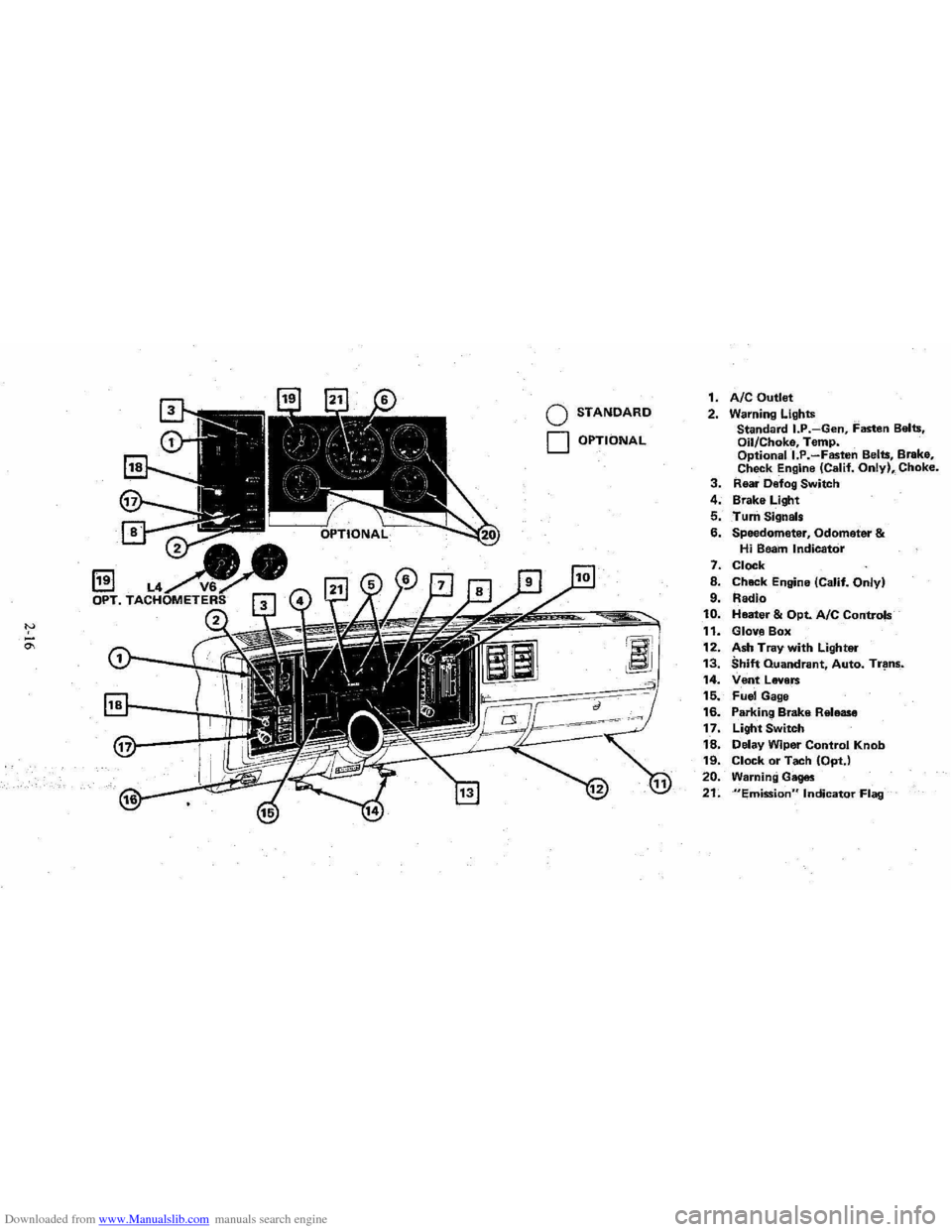

o STANDARD

o OPTIONAL

1. AIC Outlet 2. Warning Lights

Standard I.P.-Gen, Fasten Belts.

Oil/Choke, Temp.

Optionall.P.-Fasten Belts, Brake,

Check Engine (Calif. Only), Choke. 3. Rear Defog Switch

4. Brake Light

5. Turn Signals

6. Speedometer, Odometer & Hi Beam Indicator

7. Clock

8. Chack Engine (Calif. Only)

9. Radio 10. Heater & Opt. Ale Controls

11. Glove Box

12. Ash Tray with Lighter 13. Shift Quandrant, Auto. Tr~ns_.

14. Vent Levers 15. Fuel Gage

16. Parking Brake Release

17. Light Switch

18. Delay Wiper Control Knob 19. Clock or Tach (OptJ

20. Warning Gages

21. "Emission" Indicator Flag

Page 34 of 95

Downloaded from www.Manualslib.com manuals search engine Oil/Choke Indicator Light

This light will c0!TIe on to provide a "bulb check", w hen the igni tion is turned on, but sh Qu19 go out after the _ engine is started. If tight fails to

come on wit h ignitio~ turned on, it could indicate a burned out bulb , a

defective electric choke hea ter circuit (on L4 and V6 engines), or a blown

instrument lamp fuse. Have system repaired if light does not come on d min g ch eck .

Occa sionally. this light may flicker momentarily while the engine is running. Should this occur, CHECK EN GINE OIL LEVEL as outlined in Section 5,

"Checking Oil Level." If the light comes on continuously, pull over toa safe place and STOP THE ENGINE until the source of trouble can be loca ted and corrected.

The source of tro uble could be any of the following:

• Loss of engine oil press ure (cbec k eng ine oil level).

• Blown choke heater fuse.

• Loss. of electric choke heate r voltage.

Continuing to run the engine with an illuminated oil pressure light can cause

serious engine damage or unusu ally high exhaust system temperature which can

r esult in serio us damage to the

vehicle. Pull over to a safe place and STOP THE

VEHICLE IMMEDIATELY AND SHUT OFF ENGINE. If the light flashe s

momentarily , ch

eck engine oil leve l as outlined in Sectio n 5 of thi s manu al

Choke Warning Indicator Light

On some vehicles equipped with the optiona l oil pressure gage, an amber choke

warning indicator light replaces the red oil pressure indicator light in the

instrument cluste

r. If this light comes on, indicating loss of electric choke heater

volta

ge, have your authoriz ed Dea ler .locate and correct th e tro uble as soon as

p ossib l

e.

Generator Indicator Light The red ligh t GEN will go on when the ignition key is in the "run" _posit ion, but

before the engi ne

is started. After the engine s tarts, the light should 'go out and

r e m ain out .

If th e light remains on when en gine is running , have your Authorized

D eale r loca te and correct the troubl e as soo n as possibl

e.

Engine Temperature .Indicator Light This indicator light is provided in th e instrument cluster to quickly warn of an

overh eated en gi ne. With the igniti on switch in the START position, the red

TEMP indicator (hot light) will light to let you know that it is operati ng prope rly.

When the engi ne is started ;-th e re d light will go out imm ediate ly. It wilUight up

a t n o other time unleSS for some reason the engine reaches a dangerously high ope ra tin g temperature . 1f the light comes on during extreme driving condition s,

such as an exte nded idle, see "E ngine Cooling

System" on page 3-3. Glance at

th e instrument cluster frequently as you drive to see if this

ligh t is on.

Brake System Warning Light

The regular braking system is a dual system designed so that one part will provide

some braking action if there is a loss of hydraulic pressure in the other part of

the system. The system has a "Brake" warning light loca ted in the instrum ent

pane\.

• To serve as a reminder , the "Bra ke" lig ht is designed to come on while the

park ing brake is se t and the ignition key

is on.

• The light is also designed to come on briefly during engine starting so you

can chec k that the bulb is okay.

• Have the system repaired if the light does not come on during engine starting

o r when the parking brake

is set. 2-17

Page 36 of 95

Downloaded from www.Manualslib.com manuals search engine Engine Temperature Gage

This gage indicat~cCX?lant temperature which will vary with air temperature and

operating condition~, The ignition must be on for accurate readings. Hard driving

or prolonged idling In very hot weather will cause the pointer to move beyond the center of the band; Should pointer move to the Red Zone, see "Engine Cooling

System" on page 3-3.

Oil Pressure Gage

The oil pressure gage indicates the pn;ssure at which oil is being delivered 10 the various parts of the engine requiring lubrication. Pressures registered by the gage

I11.!lY vary according to outside air temperatures or weight of oil being used. Oil

pressure of a cold engine ~ing operated at a given speed will be somewhat higher

than when the engine is at normal operating temperature at the same speed .

. Prolonged high speed operation on a hot day at the given speed will result in somewhat lower oil pressure readings. Readings of 30 to 40 psi (205 to 275 kPa)

mny

be considered normal during moderate road speeds of 35 to 40 mph (55 to

60 km/h) \\lith the engine at proper operating temperature. Gage readings which

are

consistently high or Im\l under these conditions may indicate lubrication system

When the engine is operating, the voltmeter indicates the electrical system voltage.

During minimum electrical load, the pointer will read to the right of the center.

As the electrical load is increased,

or in stop-and-go driving, the pointer will rotate

to the left. A meter reading continuously in

the left or right red zone indicates

an electrical system

failure .. Cause of the failure should be determined and corrected~

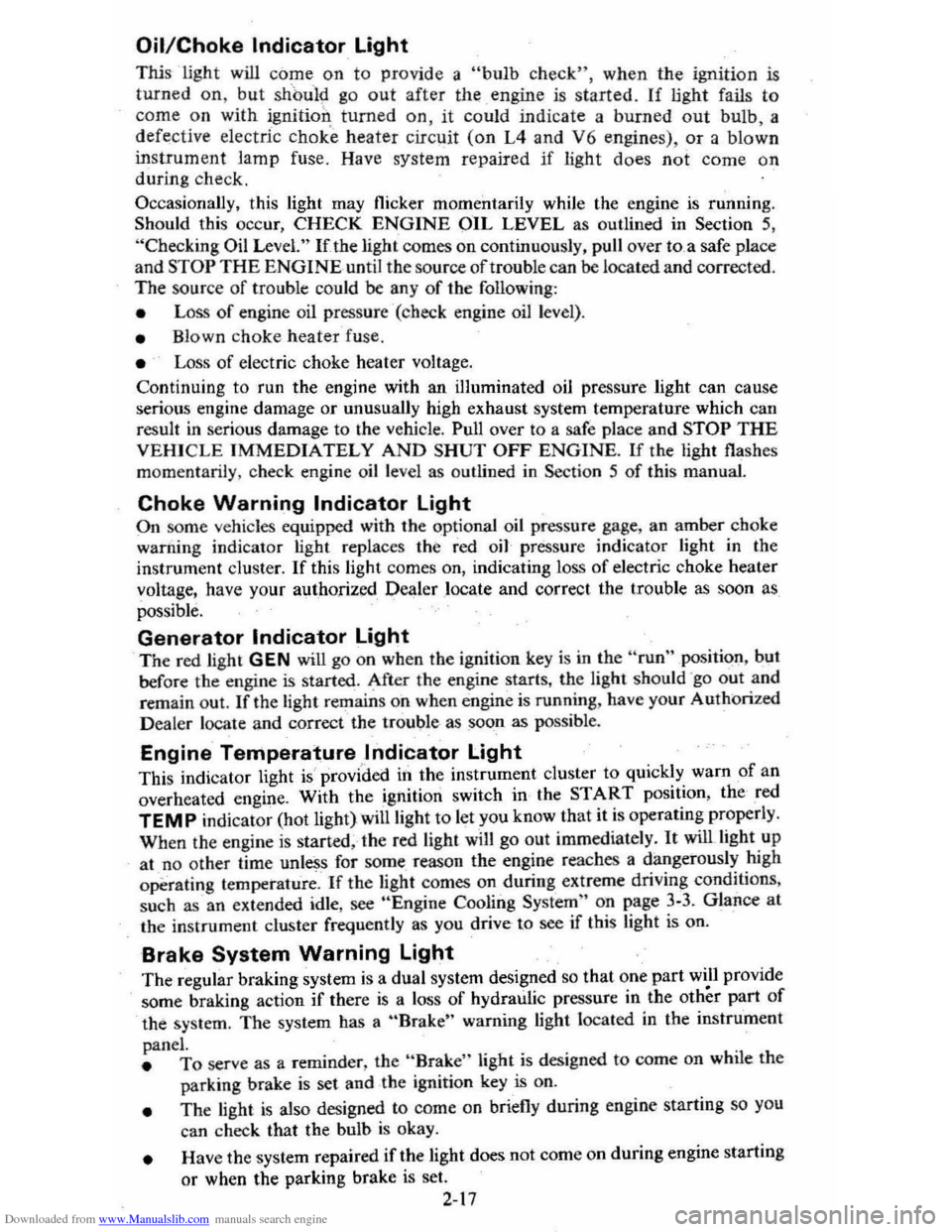

Light Switch

The three position light switch controls the headlights, taillights, parking lights,

sidemarker lights, instrument lights and dome lights as shown. The headlamp

circuit is protected by a circuit breaker in

the light switch. An overload on the

breaker will cause the lamps to "flicker" on and off. If this condition develops,

have your headlamp wiring checked immediately.

The headlight beam changer is located. in the

Turn Signal Lever; for operation

see Section 2 under heading "Tum Signal and Headlight Beam Lever."

TUIN KNOt TO VAr:t'INSTRUMENT lIGHTS_'UtLy COUNTERClOCKWISE RlR DOME

0"

MAltlCfIt LIGHTS , INSTRUMENT LIGHTS

Headlamp "ON" Warning Buzzer

The optional headlamp reminder buzzer provides an audible warning that the

main light switch is in one

of the "on" positions, either parking lights or

headlights.

The reminder buzzer

is actuated only when the ignition switch is turned to "OFF," "LOCK" or "ACCESSORY" position.

2-19

Page 51 of 95

Downloaded from www.Manualslib.com manuals search engine • pull over-to a 'safe p'late and stop (he car:-=Set the parking brake and shift to "P"(Park) (with a manual transaxle. shift to Neutral first, then set the parking

brake).

• DON'T TURN OFF THE ENGINE AND DON'T INCREASE THE ENGINE SPEED~ Let the engin e run at normal idle speed for two or three

minutes.

If the

''TEMP'' light still doesn't go off (or the gage needle doesn't start to drop) , NOW TURN OFF THE ENGINE and proceed as follows.

CAUTION: Keep henda, tools end clothing awey from'the engine COOling fen to help prevent personal Injury. This fen ia electric end can come on whether or not the eR8ine is runnirl'jJ. The fan Cen etert eutomatically in reapon .. to a heet ~, wrth the ignitkNl in ~Run."

• Lift the engine hood. Look at the coolant level.in the "see through " coolant

recovery tank. The coolant level should be at or above the "Fun Hot" mark

o n the tank.

If it looks like the coolant is boiling, wait until it stops before

proceeding You should :not need to remove the radiator cap to check the

coolant level and it can be dangerous if the coolant is still hot. See the

following Caution.

CAUTION: To help avoid the dange, of being burned:

• cia not remove the coolent recov.ry tank cap while the coolant is boiling.. and

• cia not remove the .rad~:_c.p white the engine end radiator are atill hot.

Scelding fluid and ateam can be blow, Qut under presau,.. If either cap ia taken off too soon.

• If the coolant level is low:

• look for leak s at the radiator hoses and connectio ns, heater hoses and

connections. radiator, and water pump.

See that the water pump belts

are not

brok~ or otT the pulleys and that the fan runs when the engine is running and theUTEMP" light ison (or the gage needle is in the

warning zone).

• add coolant to the recovery tank.

If the level in the recovery tank is at the correct level and the "TEMP" light (gage) still comes on, air may be-trappedin the, cooling system . This may prevent coolant

from returning to the radiator.

In this case. you may have to add coolant directly

to th e radiator.

See "Coolant Replacement" in "Service and Maintenance," Section 5 of this manual. Follow steps I and 10 for the correct way to remove

the radiator cap and add coolant to the radiator.

After the "TEMP" light is out (or the gage needle is out of the warning zone).

resume driving

at a reduced speed. Return to normal driving after about ten

minutes if the light does not come back on (or the gage needle does not go back

into the warning

~one).

J.4

Page 53 of 95

Downloaded from www.Manualslib.com manuals search engine JACKING

CAUTION

To help avoid personal injury:

• Follow all jackin g and stowag e instructions.

• Use jack only fo r liftin g this venicle du -rin g wheel c h a ng e.

• Nev er ge t ben eath th e vehiCle, start or run en g in e while vehicle is supported b y jac k.

• Always securely res tow spare tire (o r flat tire ) an d all jackin g equipment.

Wheel Nut Torque

CAUTION: As soon as possible after Installing 8 wheel-and at the intervals shown on the chart-in the Maintenance Schedule foldet-han 8 m.chanic tighten whe&l nuta with II torque wrench to the specifications shown in "SpeCifications ," Section 7 of this manual. Wheel nuts should be tightened alternately and evenly to the correct torque. Never us. oil or grease on studs or nuts. Improperly tightened wheel nuts could eventually allow the wheel to come off while the vehicle is moving, possibty causing loss of control.IAlso see the Caution in "Service and Maintenance," Seetion 5 of this manual regarding the danger of mixing metric and customary fasteners.)

Stowage of Tire and Jack

CAUTION:·AlwaYs MOurely restow the spare tire assembty (or flat tire). all jacking equipment. and the cover, using the means provided. When driving the car with the compact spare installed and the reer seat folded down, stow the wheel cover flat on the rear floor behind the-right front seat. When the rear seat is up (or If It does not fold), stow the wheel cover in the trunk area. This will help keep such things from being thrown about and injuring peopla In the car in an accident.

Compact Spare

The compa ct sp are is des ig ned to save space in yo ur trunk, and its lighler weig ht

m ak es

it easi er to in stall if a flat tire occurs. The light~r weig ht als o helps improve fuel eco no my.

If you have a flat tire, follow the jack ing in struction s in this manual while keeping

t h ese point s in min d:

• Chec k inflati on press ure as soo n as practical after in sta llin g the s pa re ( use of a pocke t type: high pressure inflatio n gage is adv ised) and adjust to 415

k Pa (60 psi). The tire pressur e sh o uld be checked at least monthl y and kept at 415 kPa (60 ps i) while the tire is s tored.

• Co ntinuou s use at spe eds over 50 mph (80 km/h) is not re c omme nded .

NOTICE: Because this tire is amaUer than the standar d tire, vehicle ground clearance is reduced, Avoid driving over obstacles, and do not take your car U,rough an automatic car wash whila the spare is installed. The car may get caught possibly resulting in property damage.

• A trea d life of up to 3,000 mil es (4 800 kilomet ers) ca n b e expe cted, depe nding

on roa d condi tions and you r

driv ing habits . T o co nserve tire t read life. return the spar e to the sto rage area as soo n as the sta nd ard tir e ca n be repa ir ed -or

r

epl ac ed .

• Beca use the co mpac t spare was spec ifica lly designe d for your car, it s hould

no t be used on any other vehicle.

3-6

Page 64 of 95

Downloaded from www.Manualslib.com manuals search engine On all C-4 cars, a "CHECK ENGINE" light on the instrument panel is

designed to come on during engine starting , to let you know the bulb is working. (The light will stay on a short time after the engine starts.) If the light comes on while driving, service to the emission control system

may be required. See your Chevrolet dealer' as soon as possible for an inspection of the system. Continued driving without having the C-4 System serviced _ could eventually

cause damage

to the emission control system . It could also affect fuel

e conomy and drivabili -ty.

ENGINE OIL AND FILTER RECOMMENDATIONS • Engine oils' are labeled on 'the containers with various API (American

Petroleum Institute) designations 6f quality. Use engine oils that are labeled

5E or SE/CC. Do not use oils labeled only SA, 5B, 5C, SD, CA, CB, CC or CD; _or oils with the combination label SE and CD (SE/CD). Higher

quality oils labeled SF will be introduced soon (late 1979, or 1980). These SF oils are preferred and should be used when available.

• The oil and filter change intervals for your engine are based on the use of SE-quality or SF-quality oils and ,high- quality filters such as AC oil filters. Using oils other than SE-quality or SF-quality oils, or oil change intervals

longer than recommended. could reduce -engine life and might affect your

warranty.

• Your engine was filled with a high·quality engine oil when it was built. You do ,not have to change this oil before the suggested change period.

•

If your normal driving does nQt include one or more of the four "severe service" conditions listed below. change the oil every 7,500 miles (12 000 ' kilometers) or 12 months, whichever comes first. Change the oillilter at the

first oil change. then every second oil change, if mileage (7,500 miles or 12

000. kilom~ters) determines .w ,hen you change the oil. If _time (12 months)

determines when you change the oil, change the filter with every oil change.

• Change the oil and oil filter every 3,000 miles (4 800 kilometers) , or three

months if you often drive under one or more of these 'severe service·,~.

conditions: • Driving in dusty areas

• Towing ,3 trailer

• Frequent idling or idling for long periods

• Driving 4 miles (6 kilometers) br'less in freezing weather,o~other short trips in cold weather, where the engine does not thoTough ,ly warm up.

• Change the oil and oil filter as soon as -possible after driving in a dust

storm.

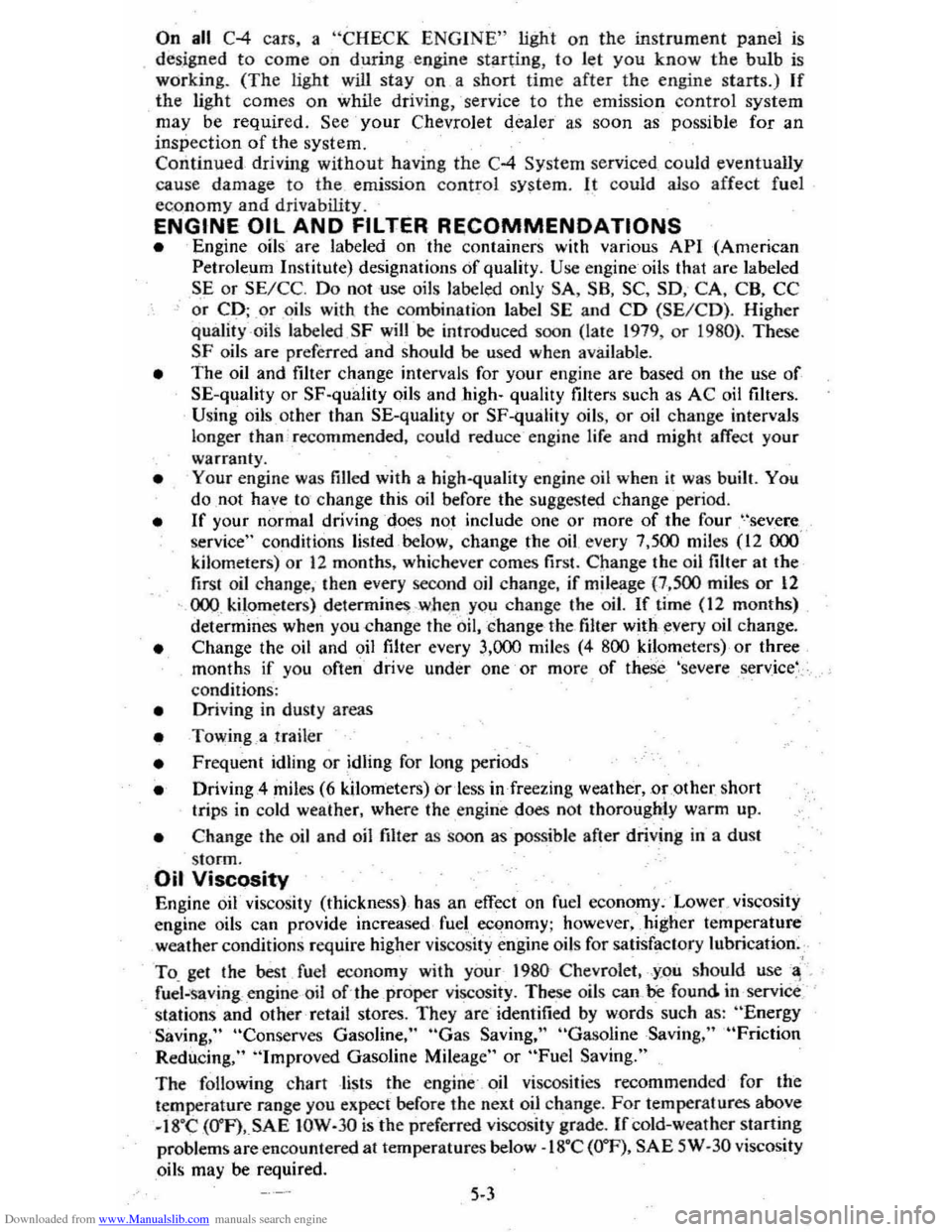

Oil Viscosity

Engine oil viscosity (thickness) has an effect on fuel economy. Lowec viscosity

engine oils can provide increased , fuel " economy; however, higher temperature

weather conditions require higher viscosity engine oils for satisf~ctory lubrication.

To. get the best fuel economy with your-1980 Chevrolet, -iou should use -,, ' .

fuel. 'saviiJ.&:_engine oil ohhe_ proper viscosity. These oils call_ be found. in serviCe

stations and other retail stores. They are-identified by words such as: "Energy Saving," "Conserves Gasoline," "Gas Saving," "Gasoline Saving," '''Friction

Reducing," "Improved Gasoline Mileage" or "Fuel Saving."

The following chart lists the engine ' oil viscosities recommended for the

temperature range you expect before the next oil change. For lemperalures above ,_18°C (O"F),SAE lOW-30 is -the preferred viscosity grade. Ircold-weather starting

problems

are encountered at temperatures below -lSoC (

5-3

Page 65 of 95

Downloaded from www.Manualslib.com manuals search engine USE Tlltst: SAE VISCOSITY GItotoDH

I , , , cl.

*

::0';'~ ,.,..~,: , , , ,

I

lOW , , , ,

,

I I I I , . , " • '" ,~, ." ., , " " " ~ lVitPl .... 1Ul:( lAN<* YOU ElU'EClltfOll( NUT OIl CHANG(

NOTICE: 00 NOT USE SA~ 5W-2 0 OilS fOA CONTINUOUS HIGH-SPEEQ OAIVING. 1,iW-30 OILS MAY III USED .. 4.CYIJNO!!R AND 2.lIll1AE VII EItClMES UP TO 104)

the oil level at regular intervals (such as every 'o ther fuel stop) and keep it above

th e "Add" line. Rem ember, your engine may use more oil when it is new .

• The best time to check the engine oil level is when the oil is warm, such as

during a fuel stop. First, wait about 5 minutes for the oil to drain back to

the oil pan, Then, pull out the dipstick, wipe

it clean, and push it back down

all the way . Now , pull out.th e dipstick and look at the oil-level on the dipstick.

Some

dipSlicks have "Add" and "Full" lines , Others are marked "Add! Qt"

and "Operaling Range." In all cases, keep the oil level above the

"Add" line. Push· the dipstick back down all the way after taking the

reading. _ A ·dd oil , if needed.

• If you check the oil level when the oil is cold, do no t run the engine first. The cold oil wilJ not drain back to the pan fast enough to give a true oil level.

Engine Oil Additives

There are many extra engine oil additives (or helpers) for sale. Your engine should

not need these extra additives if you use SE-quality or SF·quality engine oil and

change

it as suggested. If you think your engine has .an oil-related problem, talk

to your authorized dealer.

If needed, your dealer can provide you with a tested

and approved oil additive called "GM Engine Oil Supplement."

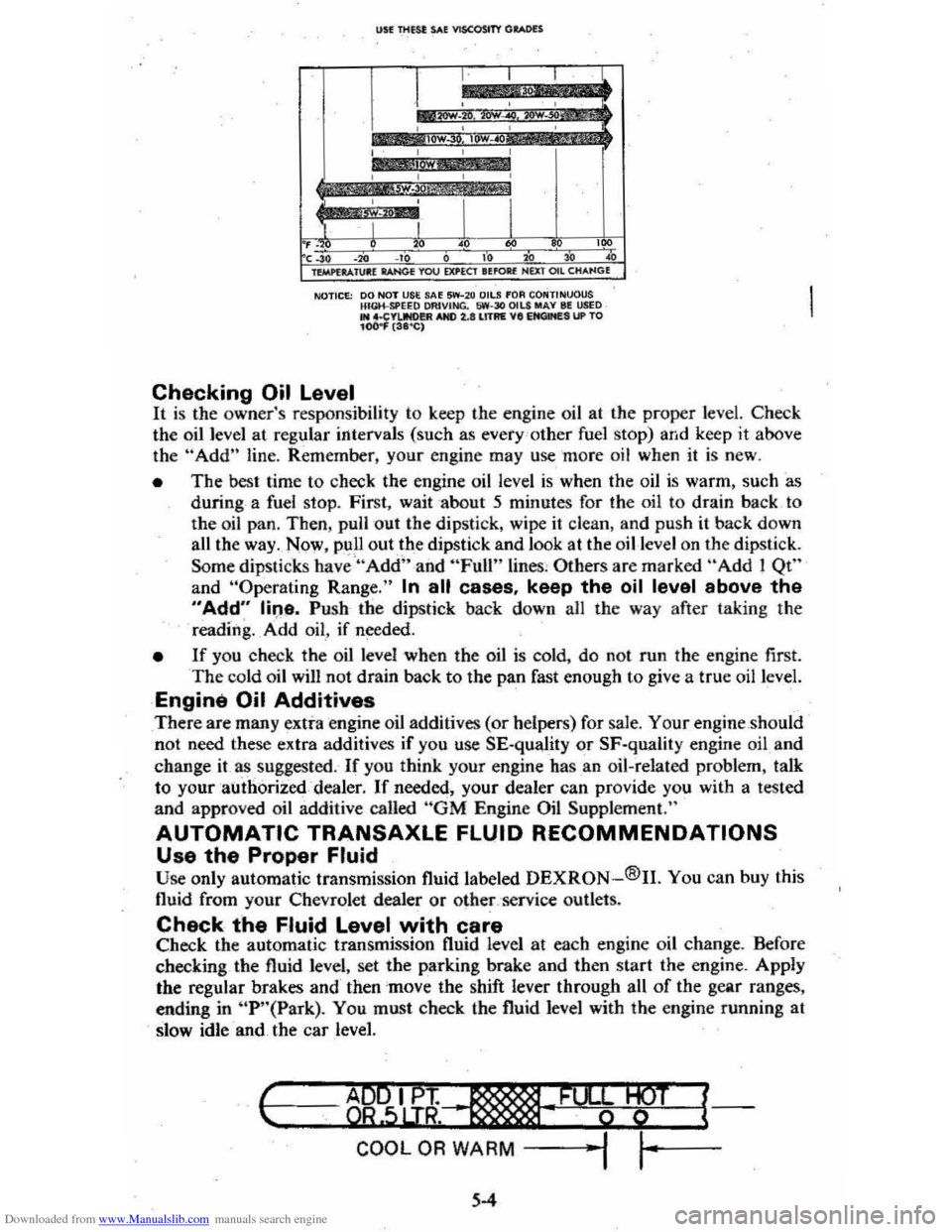

AUTOMATIC TRANSAXLE FLUID RECOMMENDATIONS

Use the Proper Fluid Use only automatic transmission fluid labe led DEXRON-®II. You can buy this

fluid from your Chevrolet dealer or

othe~,'service outlets.

Check the Fluid Level with care Check the automatic transmission fluid level at each engine oil change. Before

checking the fluid level, set the parking brake and then start the engine. AppJy

the regular brakes and then

'mov e the shift lever through all of the gear ranges,

ending in

"P '·(Park). You must check the fluid level with the engine funning at

slow idle and the car level.

I-c ..... --=---=..,~ ..... B9"""5IL.u;~~"-·, __ .........,; ..... _·F_%¥-W+--T -l{

COOL OR WARM -j ""I ,~-

5-4

Page 66 of 95

Downloaded from www.Manualslib.com manuals search engine NOTICE: You cannot read the correct fluid level if you have just driven the car for a long time at high speed, in city traffic in hot weather, or if the car has been pulling a trailer. Wait. until the fluid has cooled down (about 30 minutes).

Remove the dipstick located on the driver's side forward of the cowl. Carefully

touch the wet end of the dipstick to find out if the fluid is cool, warm or hot. Wipe

it clean and push it back in until the cap seats. Pull

out the dipstick and read the

fluid level.

• If it felt cool or warm (about room temperature), the level should be

between the dimples above the "Full" mark.

• If it was too hot to hold. the level should be at or in the hatched area.

Add just enough DEXRON-®n fluid to fill the transaxle. It takes only 0.5 liter

(one pint)to raise the level from "Add" to "Full" with a hot transaxle.

Do not overfill the transaxle. Overfilling can cause foaming and loss of fluid, which

could result in transaxle damage.

Automatic Transaxle Drain Intervals

Change the transmission fluid and change the filter (or clean the screen) as

outlined in Section

A of the Maintenance Schedule folder.

ELECTRIC FAN

CAUTION: Keep hands, tools, and clothing away from the angine cooling fan to help prevent personal injury. This fan is electric and can come on whether or not the engine is running. The fan can start automatically in response to a heat sensor when the ignition is in the "Run" position.

ENGINE COOLING SYSTEM

The coolant recovery system is standard. The coolant in the radiator expands with

heat, and the overflow collects in the recovery tank. When the system cools down,

the coolant

is drawn back into the radiator.

The cooling system was filled at the factory with a quality coolant that meets

GM Specification 1899-M. The cooling system is designed to use coolant (a mixture

of water and ethylene glycol antifreeze) rather than plain water. The coolant

solution should be used year round. It has many advantages, such as:

• provides freezing protection down to _37°C, (-34°P)

•

provides boiling protection up to 128QC, (262°P)

•

protects against rust and corrosion in the cooling system,

• maintains the proper engine temperature for efficient operation and emission

control, and

• allows proper operation of the coolant temperature light (or gage).

See Section A of the Maintenance Schedule folder to find out when the coolant

must

be replaced.

COOLING SYSTEM CARE

Check the cooling system at regular intervals, such as during fuel stops. You

usually do not need to remove the radiator cap to check the coolant level. Lift

the engine hood and look at the "see through" coolant recovery tank. When the

engine

is cold, the coolant level -should be at or slightly above the "Full Cold"

mark on the tank. When the engine has fully warmed up, the level should be at ')r slightly below the "Full Hot" mark on the tank. If the coolant level is low,

5-5

Page 67 of 95

Downloaded from www.Manualslib.com manuals search engine remOve tlie cap on the coolant ~ecove~y tank : Add to the tank enough of a 50 150 . mixture of w ater and a g ood quality eth)dene glycol antifreez e to bring the level

up to the .

proper mark. Put the cap bac k on the tank .

Certain

conditi ons; "Such as air trapped in the syste m, may affe ct the coolant level

in

the radiator. You sho uld ch ec k the co olant ·Ievel ·in the radiator while you

change the engine oil and the e ng ine is col d. Follow steps I , 8, 9 and 10 und er

"Coola nt Rep lacement" for the correct way to rt!move the radiator cap .an d add

. coolant.

If you have to add coola nt more than f our tim es a yea r (ei ther to th e recov ery

tank

or to the radiat or). see your dealer. for a. c oo lin g system chec k.

NOTICE: If the proper quality antifreeze is used, there is no .nee~ to add extra inhibltOf"s or additives which claim to improve the svstem .. They may be harmful to the proper operation. I)f the system.

Cooling System Service

The cooling syste m should be serviced at the intervals specifi ed inSection A of

the Maintenan ce Sch edule fold er as follows:

I. W ash the radiatqr cap .and filler neck with clean water. See step J of "Coolant

Replacement" to remove rapiator cap. .

2. C hec k the coolant level in the radiator and have it tes ted for freeze proteCtion . Add·· ethylene gly col antifreeze, if needed, to· m aintain freeze protecti on at -37'C(-34'F),

3~ Have ·the coOlin-g sys tem and radiat or cap tested fo r a press ure capacity of

105 kPa (15 psi) . If a repl acement cap is needed"Hse an AC ca'p,or an

equivalent · cap, designed fOl: coolant recovery system ·s and spe cified for your model;

4. Tighten all radiator hose clamps and heater hose clamps and inspect an hose s.

R

eplace the hose s if they are swollen, "checked" or otherwise worn .

NOTICE: Take care when tightenjng·the hose clemps at tMI radiator. Overtightening COUld. bend or collapse .the radiator fittings.

5. Clean the front. of the radiator core and air condit ioning condenser to re m ove

dirt and oth er·objects. Al so clean the auxiliary engine oil andlor transmission -fluid ' cooler if the vehicle has them.

Coolant, Replacement

At the interval s specified in Section A of the Maintenance Schedule folder, flu sh

a

nd refill the cool ing system as follows :

1. Remove the·radiat or·cap when the engin e is ·cool :

•

Turn . t he cap s lowly to the len until ·it reaches a " stop. " Do not press down while turning the cap.

• 'Wait until any rem aining press ure (indicated by a hissing sound) is

reliev ed. then press down on the cap an d continue turning it t(j the left.

CAUTION:· To help ~lVoid the danger of being ,burned, do not remove the radiator cap while the angine and radiator are still hot s.c.lding flutd and steam can be bk)wn out under pressure if the·cap is taken off.too soon.

2. Whe n the cap is re m oved, run the eng ine until the upper radiator hose is hot.

(This shows that the thermostat is open and the coola nt is flow ing through

the . system.)

5·6

•