lock CHEVROLET COBALT 2007 1.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2007, Model line: COBALT, Model: CHEVROLET COBALT 2007 1.GPages: 450, PDF Size: 2.48 MB

Page 291 of 450

A. Engine Air Cleaner/Filter. SeeEngine

Air Cleaner/Filter on page 300.

B. Engine Oil Fill Cap. See “When to Add

Engine Oil” underEngine Oil on page 293.

C. Engine Oil Dipstick (Out of View).

See “Checking Engine Oil” under

Engine Oil on page 293.

D. Brake Master Cylinder Reservoir. See “Brake

Fluid” underBrakes on page 318andHydraulic

Clutch on page 302.

E. Engine Compartment Fuse Block. SeeEngine

Compartment Fuse Block on page 386.F. Remote Positive (+) Terminal. SeeJump

Starting on page 322.

G. Remote Negative (−) Terminal. SeeJump

Starting on page 322.

H. Engine Coolant Surge Tank. SeeCooling

System on page 311.

I. Windshield Washer Fluid Reservoir.

See “Adding Washer Fluid” underWindshield

Washer Fluid on page 317.

291

Page 293 of 450

A. Windshield Washer Fluid Reservoir. See

“Adding Washer Fluid” underWindshield

Washer Fluid on page 317.

B. Engine Oil Dipstick. See “Checking Engine Oil”

underEngine Oil on page 293.

C. Engine Oil Fill Cap. See “When to Add Engine

Oil” underEngine Oil on page 293.

D. Intercooler System Pressure Cap. SeeEngine

Coolant on page 302.

E. Brake Master Cylinder Reservoir. See “Brake

Fluid” underBrakes on page 318andHydraulic

Clutch on page 302.

F. Engine Compartment Fuse Block. SeeEngine

Compartment Fuse Block on page 386.

G. Remote Positive (+) Terminal. SeeJump

Starting on page 322.

H. Remote Negative (−) Terminal. SeeJump

Starting on page 322.

I. Engine Coolant Surge Tank. SeeCooling

System on page 311.

J. Engine Air Cleaner/Filter. SeeEngine

Air Cleaner/Filter on page 300.Engine Oil

Checking Engine Oil

It is a good idea to check the engine oil every time

you get fuel. In order to get an accurate reading,

the oil must be warm and the vehicle must be

on level ground.

The engine oil dipstick handle is a yellow loop.

SeeEngine Compartment Overview on page 290

for the location of the engine oil dipstick.

1. Turn off the engine and give the oil several

minutes to drain back into the oil pan. If you

do not do this, the oil dipstick might not

show the actual level.

2. Pull out the dipstick and clean it with a paper

towel or cloth, then push it back in all the

way. Remove it again, keeping the tip down,

and check the level.

293

Page 299 of 450

After changing the engine oil, the system must be

reset as follows:

1. Turn the ignition to RUN, with the engine off.

2. Press the information and reset buttons

on the DIC at the same time to enter the

personalization menu. SeeDIC Vehicle

Personalization on page 186.

3. Press the information button to scroll through

the available personalization menu modes

until the DIC display shows OIL-LIFE RESET.

4. Press and hold the reset button until the DIC

display shows ACKNOWLEDGED. This will

tell you the system has been reset.

5. Turn the key to LOCK.

If the CHANGE OIL SOON message comes back

on when you start your vehicle, the engine oil

life system has not reset. Repeat the reset

procedure.What to Do with Used Oil

Used engine oil contains certain elements that may

be unhealthy for your skin and could even cause

cancer. Do not let used oil stay on your skin for

very long. Clean your skin and nails with soap and

water, or a good hand cleaner. Wash or properly

dispose of clothing or rags containing used engine

oil. See the manufacturer’s warnings about the use

and disposal of oil products.

Used oil can be a threat to the environment. If you

change your own oil, be sure to drain all the oil from

the �lter before disposal. Never dispose of oil by

putting it in the trash, pouring it on the ground, into

sewers, or into streams or bodies of water. Instead,

recycle it by taking it to a place that collects used

oil. If you have a problem properly disposing of

your used oil, ask your dealer, a service station,

or a local recycling center for help.

299

Page 308 of 450

{CAUTION:

You can be burned if you spill coolant

on hot engine parts. Coolant contains

ethylene glycol, and it will burn if the

engine parts are hot enough. Do not spill

coolant on a hot engine.

1. You can remove the �ll neck pressure cap

when the intercooler system, including the

upper intercooler hose, is no longer hot.

Turn the pressure cap slowly counterclockwise

about one-quarter of a turn. If you hear a

hiss, wait for that to stop. This will allow any

remaining pressure to be vented.

2. Then keep turning the pressure cap slowly,

and remove it.3. Add the proper DEX-COOL

®coolant mixture

to the �ll neck, until there is coolant visible in

the horizontal tube section of the �ll neck.

4. With the �ll neck pressure cap off, start the

engine and let it run for at least 30 seconds.

Watch out for the engine cooling fan. Turn the

engine off. By this time, the coolant level inside

the �ll neck may be lower. If the level drops so

that coolant is no longer visible in the horizontal

tube section of the �ll neck, add more of the

DEX-COOL

®coolant mixture to the �ll neck

until the level is again visible in the horizontal

tube section.

5. Replace the intercooler system pressure cap.

Be sure the pressure cap is hand-tight and

fully seated.

If the coolant is not at the proper level when

the system cools down again, see your dealer.

308

Page 315 of 450

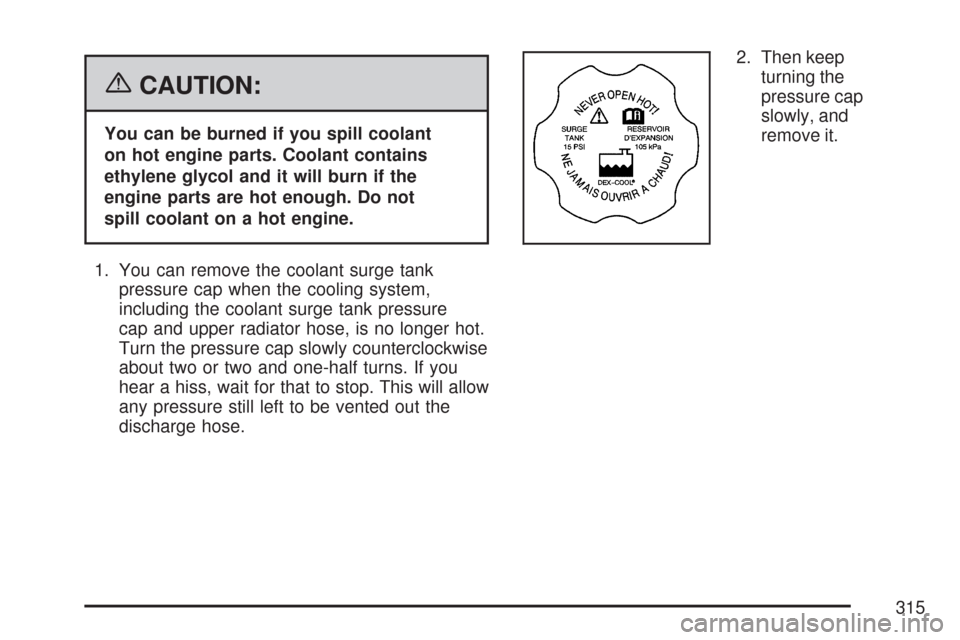

{CAUTION:

You can be burned if you spill coolant

on hot engine parts. Coolant contains

ethylene glycol and it will burn if the

engine parts are hot enough. Do not

spill coolant on a hot engine.

1. You can remove the coolant surge tank

pressure cap when the cooling system,

including the coolant surge tank pressure

cap and upper radiator hose, is no longer hot.

Turn the pressure cap slowly counterclockwise

about two or two and one-half turns. If you

hear a hiss, wait for that to stop. This will allow

any pressure still left to be vented out the

discharge hose.2. Then keep

turning the

pressure cap

slowly, and

remove it.

315

Page 324 of 450

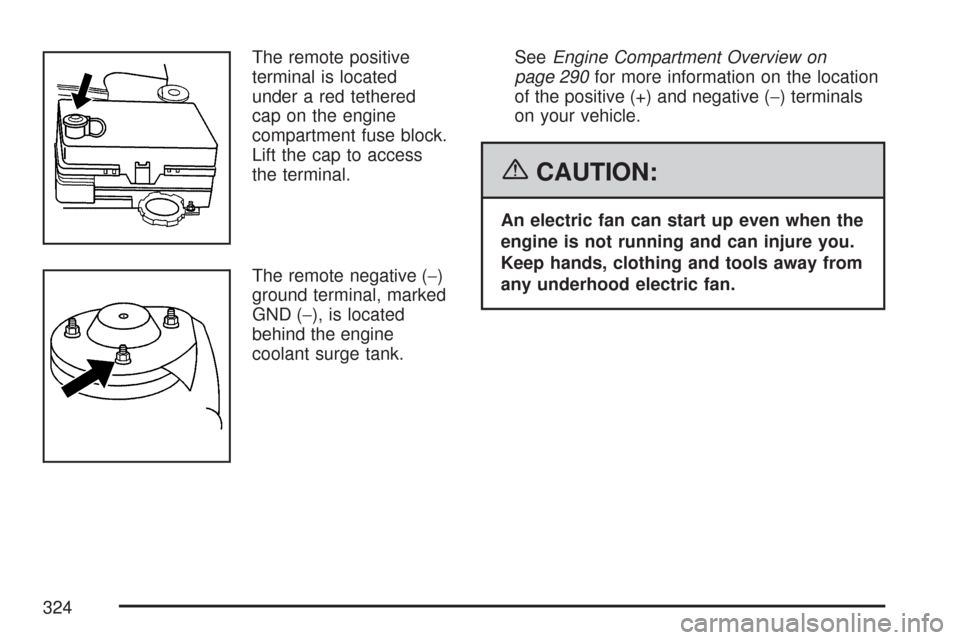

The remote positive

terminal is located

under a red tethered

cap on the engine

compartment fuse block.

Lift the cap to access

the terminal.

The remote negative (−)

ground terminal, marked

GND (−), is located

behind the engine

coolant surge tank.SeeEngine Compartment Overview on

page 290for more information on the location

of the positive (+) and negative (−) terminals

on your vehicle.

{CAUTION:

An electric fan can start up even when the

engine is not running and can injure you.

Keep hands, clothing and tools away from

any underhood electric fan.

324

Page 330 of 450

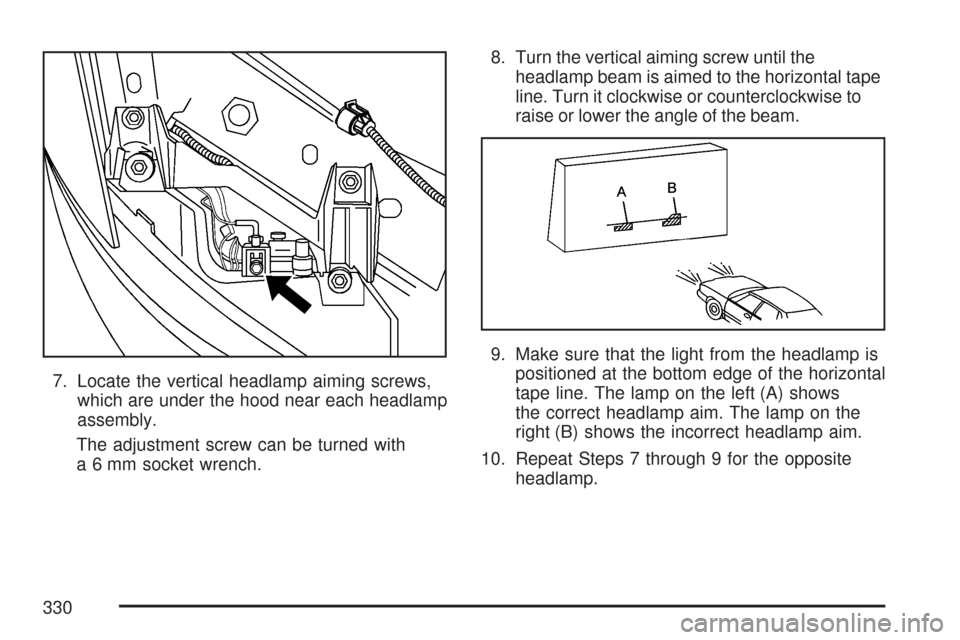

7. Locate the vertical headlamp aiming screws,

which are under the hood near each headlamp

assembly.

The adjustment screw can be turned with

a 6 mm socket wrench.8. Turn the vertical aiming screw until the

headlamp beam is aimed to the horizontal tape

line. Turn it clockwise or counterclockwise to

raise or lower the angle of the beam.

9. Make sure that the light from the headlamp is

positioned at the bottom edge of the horizontal

tape line. The lamp on the left (A) shows

the correct headlamp aim. The lamp on the

right (B) shows the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite

headlamp.

330

Page 332 of 450

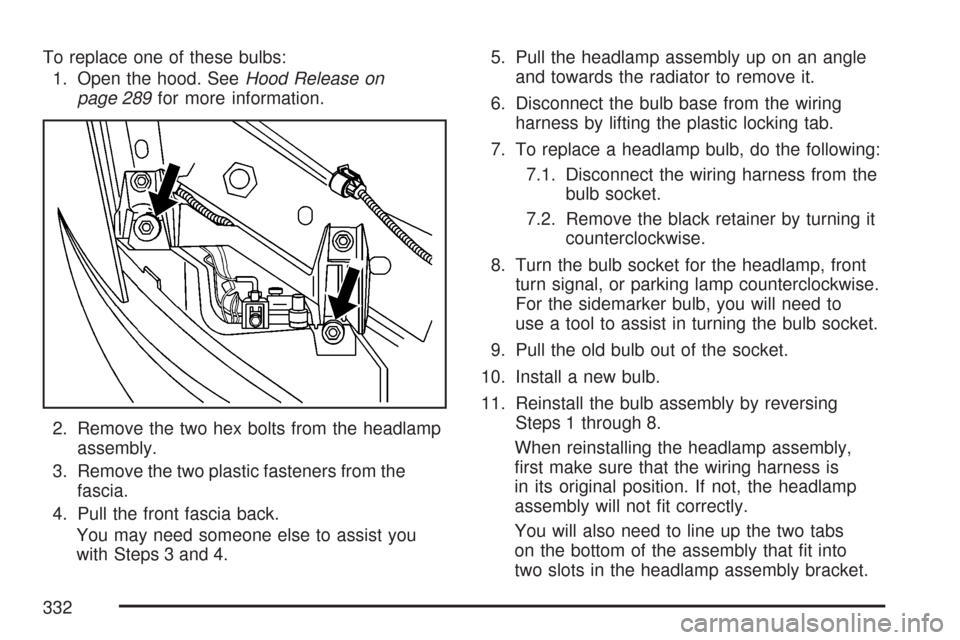

To replace one of these bulbs:

1. Open the hood. SeeHood Release on

page 289for more information.

2. Remove the two hex bolts from the headlamp

assembly.

3. Remove the two plastic fasteners from the

fascia.

4. Pull the front fascia back.

You may need someone else to assist you

with Steps 3 and 4.5. Pull the headlamp assembly up on an angle

and towards the radiator to remove it.

6. Disconnect the bulb base from the wiring

harness by lifting the plastic locking tab.

7. To replace a headlamp bulb, do the following:

7.1. Disconnect the wiring harness from the

bulb socket.

7.2. Remove the black retainer by turning it

counterclockwise.

8. Turn the bulb socket for the headlamp, front

turn signal, or parking lamp counterclockwise.

For the sidemarker bulb, you will need to

use a tool to assist in turning the bulb socket.

9. Pull the old bulb out of the socket.

10. Install a new bulb.

11. Reinstall the bulb assembly by reversing

Steps 1 through 8.

When reinstalling the headlamp assembly,

�rst make sure that the wiring harness is

in its original position. If not, the headlamp

assembly will not �t correctly.

You will also need to line up the two tabs

on the bottom of the assembly that �t into

two slots in the headlamp assembly bracket.

332

Page 334 of 450

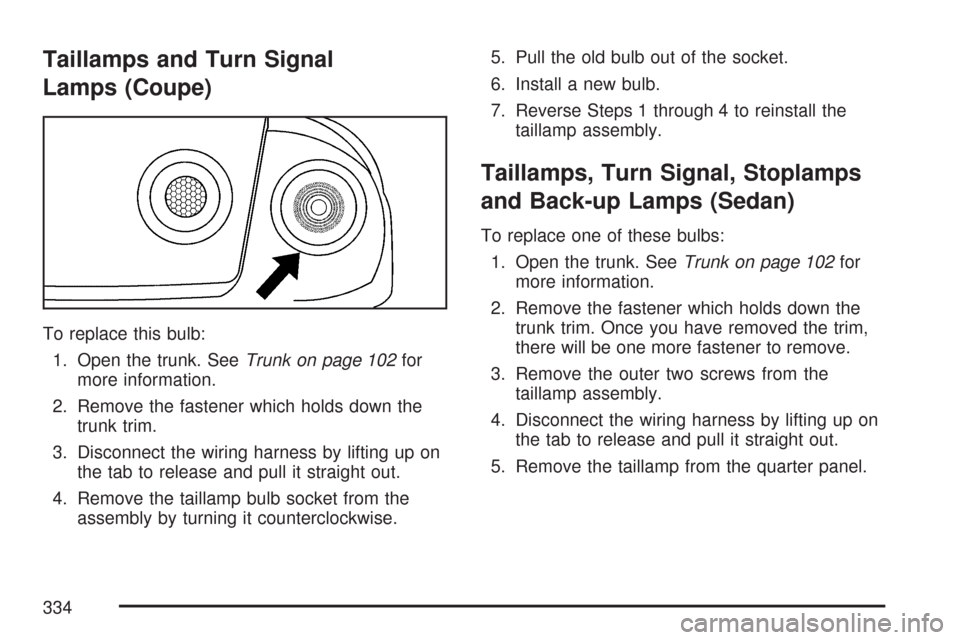

Taillamps and Turn Signal

Lamps (Coupe)

To replace this bulb:

1. Open the trunk. SeeTrunk on page 102for

more information.

2. Remove the fastener which holds down the

trunk trim.

3. Disconnect the wiring harness by lifting up on

the tab to release and pull it straight out.

4. Remove the taillamp bulb socket from the

assembly by turning it counterclockwise.5. Pull the old bulb out of the socket.

6. Install a new bulb.

7. Reverse Steps 1 through 4 to reinstall the

taillamp assembly.

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps (Sedan)

To replace one of these bulbs:

1. Open the trunk. SeeTrunk on page 102for

more information.

2. Remove the fastener which holds down the

trunk trim. Once you have removed the trim,

there will be one more fastener to remove.

3. Remove the outer two screws from the

taillamp assembly.

4. Disconnect the wiring harness by lifting up on

the tab to release and pull it straight out.

5. Remove the taillamp from the quarter panel.

334

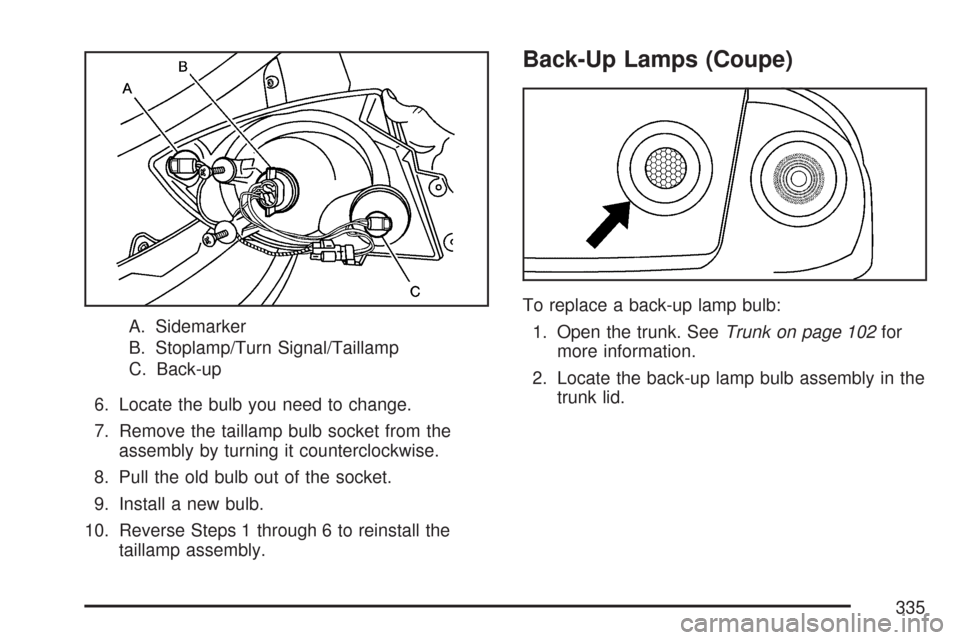

Page 335 of 450

A. Sidemarker

B. Stoplamp/Turn Signal/Taillamp

C. Back-up

6. Locate the bulb you need to change.

7. Remove the taillamp bulb socket from the

assembly by turning it counterclockwise.

8. Pull the old bulb out of the socket.

9. Install a new bulb.

10. Reverse Steps 1 through 6 to reinstall the

taillamp assembly.

Back-Up Lamps (Coupe)

To replace a back-up lamp bulb:

1. Open the trunk. SeeTrunk on page 102for

more information.

2. Locate the back-up lamp bulb assembly in the

trunk lid.

335