torque CHEVROLET COLORADO 2022 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2022, Model line: COLORADO, Model: CHEVROLET COLORADO 2022Pages: 362, PDF Size: 13.62 MB

Page 269 of 362

Chevrolet Colorado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

15274222) - 2022 - CRC - 11/2/21

268 Vehicle Care

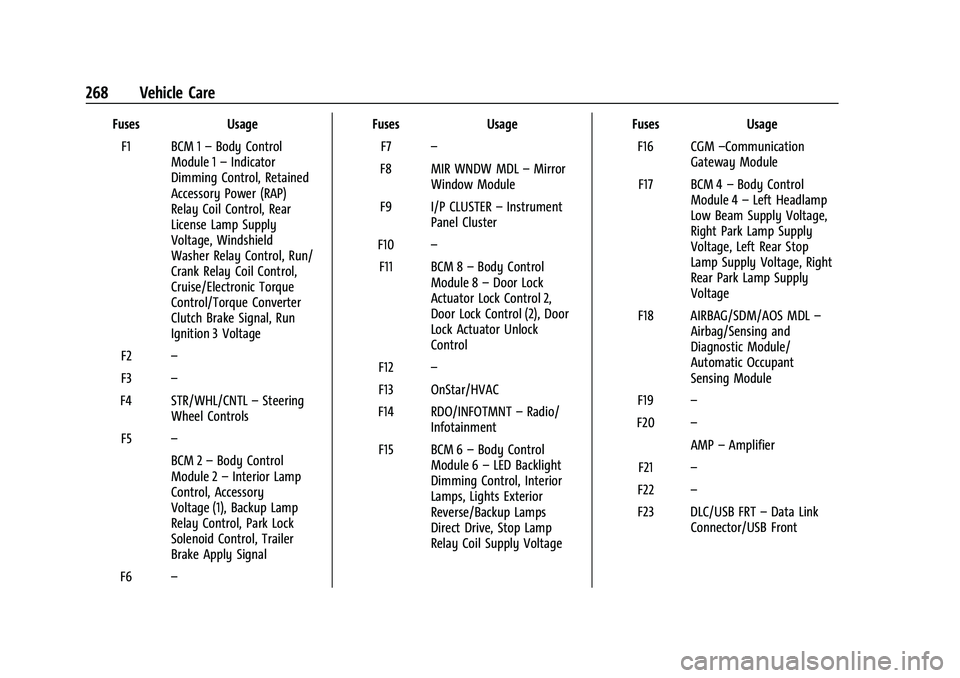

FusesUsage

F1 BCM 1 –Body Control

Module 1 –Indicator

Dimming Control, Retained

Accessory Power (RAP)

Relay Coil Control, Rear

License Lamp Supply

Voltage, Windshield

Washer Relay Control, Run/

Crank Relay Coil Control,

Cruise/Electronic Torque

Control/Torque Converter

Clutch Brake Signal, Run

Ignition 3 Voltage

F2 –

F3 –

F4 STR/WHL/CNTL –Steering

Wheel Controls

F5 –

BCM 2–Body Control

Module 2 –Interior Lamp

Control, Accessory

Voltage (1), Backup Lamp

Relay Control, Park Lock

Solenoid Control, Trailer

Brake Apply Signal

F6 – Fuses

Usage

F7 –

F8 MIR WNDW MDL –Mirror

Window Module

F9 I/P CLUSTER –Instrument

Panel Cluster

F10 –

F11 BCM 8 –Body Control

Module 8 –Door Lock

Actuator Lock Control 2,

Door Lock Control (2), Door

Lock Actuator Unlock

Control

F12 –

F13 OnStar/HVAC

F14 RDO/INFOTMNT –Radio/

Infotainment

F15 BCM 6 –Body Control

Module 6 –LED Backlight

Dimming Control, Interior

Lamps, Lights Exterior

Reverse/Backup Lamps

Direct Drive, Stop Lamp

Relay Coil Supply Voltage Fuses

Usage

F16 CGM –Communication

Gateway Module

F17 BCM 4 –Body Control

Module 4 –Left Headlamp

Low Beam Supply Voltage,

Right Park Lamp Supply

Voltage, Left Rear Stop

Lamp Supply Voltage, Right

Rear Park Lamp Supply

Voltage

F18 AIRBAG/SDM/AOS MDL –

Airbag/Sensing and

Diagnostic Module/

Automatic Occupant

Sensing Module

F19 –

F20 –

AMP–Amplifier

F21 –

F22 –

F23 DLC/USB FRT –Data Link

Connector/USB Front

Page 282 of 362

Chevrolet Colorado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

15274222) - 2022 - CRC - 11/2/21

Vehicle Care 281

Check that all wheel nuts are properly

tightened. See“Wheel Nut Torque”

under Capacities and Specifications

0 328.

{Warning

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

cause wheel nuts to become loose

over time. The wheel could come off

and cause a crash. When changing a

wheel, remove any rust or dirt from

places where the wheel attaches to

the vehicle. In an emergency, a cloth

or paper towel can be used; however,

use a scraper or wire brush later to

remove all rust or dirt.

Lightly coat the inner diameter of the

wheel hub opening with wheel bearing

grease after a wheel change or tire

rotation to prevent corrosion or rust

buildup.

{Warning

Do not apply grease to the wheel

mounting surface, wheel conical

seats, or the wheel nuts or bolts.

Grease applied to these areas could

cause a wheel to become loose or

come off, resulting in a crash.

When It Is Time for New Tires

Factors, such as maintenance, temperatures,

driving speeds, vehicle loading, and road

conditions affect the wear rate of the tires.

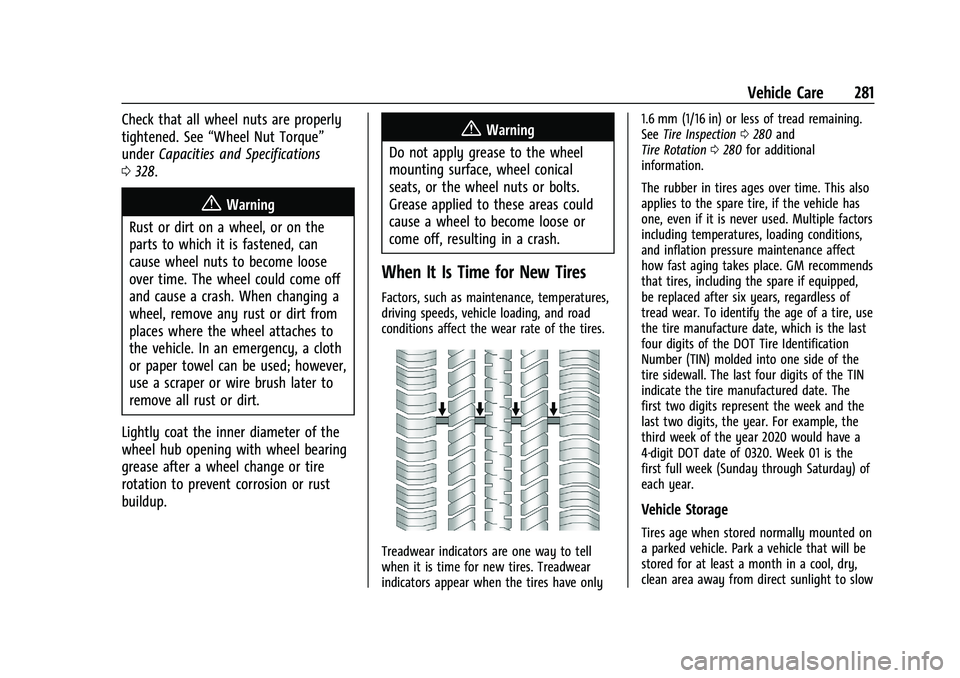

Treadwear indicators are one way to tell

when it is time for new tires. Treadwear

indicators appear when the tires have only 1.6 mm (1/16 in) or less of tread remaining.

See

Tire Inspection 0280 and

Tire Rotation 0280 for additional

information.

The rubber in tires ages over time. This also

applies to the spare tire, if the vehicle has

one, even if it is never used. Multiple factors

including temperatures, loading conditions,

and inflation pressure maintenance affect

how fast aging takes place. GM recommends

that tires, including the spare if equipped,

be replaced after six years, regardless of

tread wear. To identify the age of a tire, use

the tire manufacture date, which is the last

four digits of the DOT Tire Identification

Number (TIN) molded into one side of the

tire sidewall. The last four digits of the TIN

indicate the tire manufactured date. The

first two digits represent the week and the

last two digits, the year. For example, the

third week of the year 2020 would have a

4-digit DOT date of 0320. Week 01 is the

first full week (Sunday through Saturday) of

each year.

Vehicle Storage

Tires age when stored normally mounted on

a parked vehicle. Park a vehicle that will be

stored for at least a month in a cool, dry,

clean area away from direct sunlight to slow

Page 293 of 362

Chevrolet Colorado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

15274222) - 2022 - CRC - 11/2/21

292 Vehicle Care

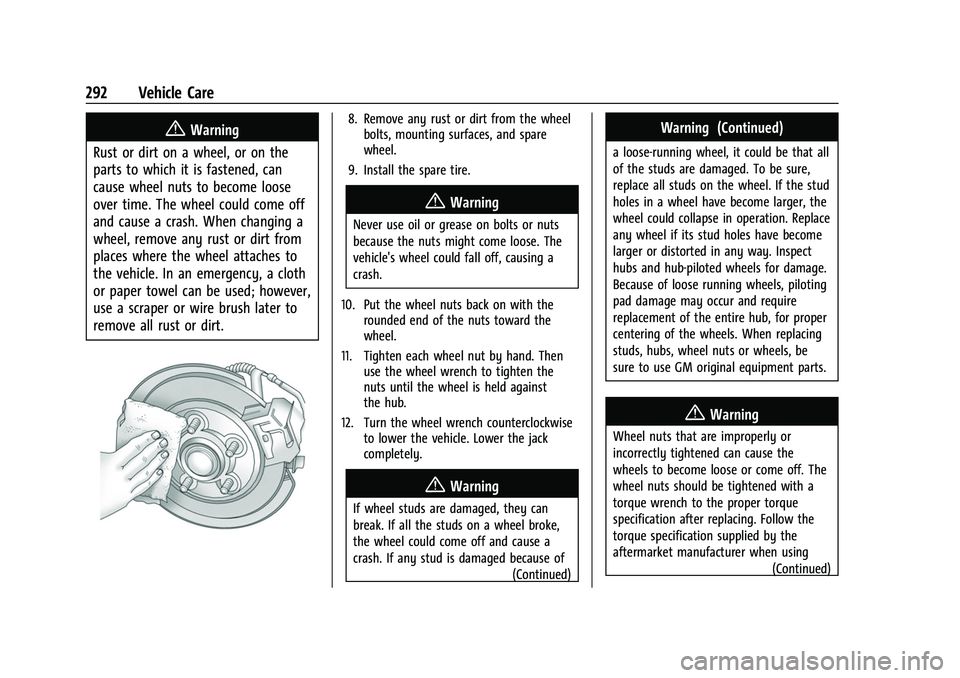

{Warning

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

cause wheel nuts to become loose

over time. The wheel could come off

and cause a crash. When changing a

wheel, remove any rust or dirt from

places where the wheel attaches to

the vehicle. In an emergency, a cloth

or paper towel can be used; however,

use a scraper or wire brush later to

remove all rust or dirt.8. Remove any rust or dirt from the wheel bolts, mounting surfaces, and spare

wheel.

9. Install the spare tire.

{Warning

Never use oil or grease on bolts or nuts

because the nuts might come loose. The

vehicle's wheel could fall off, causing a

crash.

10. Put the wheel nuts back on with the rounded end of the nuts toward the

wheel.

11. Tighten each wheel nut by hand. Then use the wheel wrench to tighten the

nuts until the wheel is held against

the hub.

12. Turn the wheel wrench counterclockwise to lower the vehicle. Lower the jack

completely.

{Warning

If wheel studs are damaged, they can

break. If all the studs on a wheel broke,

the wheel could come off and cause a

crash. If any stud is damaged because of

(Continued)

Warning (Continued)

a loose-running wheel, it could be that all

of the studs are damaged. To be sure,

replace all studs on the wheel. If the stud

holes in a wheel have become larger, the

wheel could collapse in operation. Replace

any wheel if its stud holes have become

larger or distorted in any way. Inspect

hubs and hub‐piloted wheels for damage.

Because of loose running wheels, piloting

pad damage may occur and require

replacement of the entire hub, for proper

centering of the wheels. When replacing

studs, hubs, wheel nuts or wheels, be

sure to use GM original equipment parts.

{Warning

Wheel nuts that are improperly or

incorrectly tightened can cause the

wheels to become loose or come off. The

wheel nuts should be tightened with a

torque wrench to the proper torque

specification after replacing. Follow the

torque specification supplied by the

aftermarket manufacturer when using

(Continued)

Page 294 of 362

Chevrolet Colorado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

15274222) - 2022 - CRC - 11/2/21

Vehicle Care 293

Warning (Continued)

accessory locking wheel nuts. See

Capacities and Specifications0328 for

original equipment wheel nut torque

specifications.

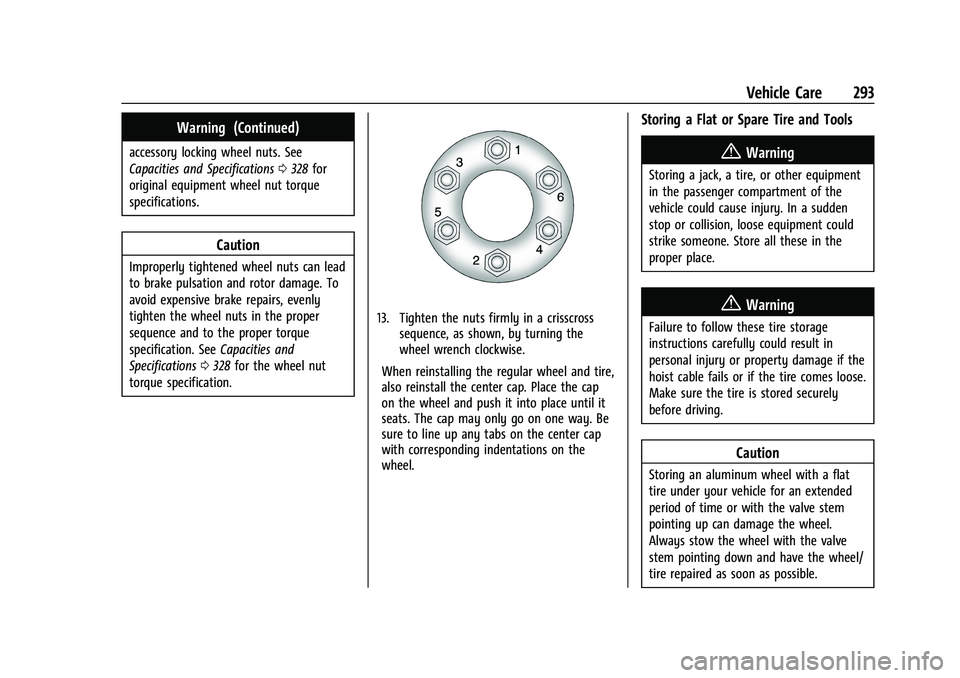

Caution

Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To

avoid expensive brake repairs, evenly

tighten the wheel nuts in the proper

sequence and to the proper torque

specification. See Capacities and

Specifications 0328 for the wheel nut

torque specification.

13. Tighten the nuts firmly in a crisscross sequence, as shown, by turning the

wheel wrench clockwise.

When reinstalling the regular wheel and tire,

also reinstall the center cap. Place the cap

on the wheel and push it into place until it

seats. The cap may only go on one way. Be

sure to line up any tabs on the center cap

with corresponding indentations on the

wheel.

Storing a Flat or Spare Tire and Tools

{Warning

Storing a jack, a tire, or other equipment

in the passenger compartment of the

vehicle could cause injury. In a sudden

stop or collision, loose equipment could

strike someone. Store all these in the

proper place.

{Warning

Failure to follow these tire storage

instructions carefully could result in

personal injury or property damage if the

hoist cable fails or if the tire comes loose.

Make sure the tire is stored securely

before driving.

Caution

Storing an aluminum wheel with a flat

tire under your vehicle for an extended

period of time or with the valve stem

pointing up can damage the wheel.

Always stow the wheel with the valve

stem pointing down and have the wheel/

tire repaired as soon as possible.

Page 330 of 362

Chevrolet Colorado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

15274222) - 2022 - CRC - 11/2/21

Technical Data 329

ApplicationCapacities

Metric English

Transfer Case Fluid 1.9 L 2.0 qt

Wheel Nut Torque 190 Y140 lb ft

All capacities are approximate. When adding, be sure to fill to the approximate level, as recommended in this manual. Recheck fluid level

after filling.

*Engine cooling system capacity values are based on the entire cooling system and its components.

Engine Specifications

Engine VIN CodeSpark Plug Gap

2.5L L4 Engine (LCV) A0.95–1.10mm (0.037–0.043 in)

3.6L V6 Engine (LGZ) N0.80–0.90mm (0.031–0.035 in)

Spark plug gaps are preset by the manufacturer. Re-gapping the spark plug is not recommended and can damage the spark plug.