ignition CHEVROLET CORVAIR 1965 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1965, Model line: CORVAIR, Model: CHEVROLET CORVAIR 1965 2.GPages: 56, PDF Size: 22.29 MB

Page 6 of 56

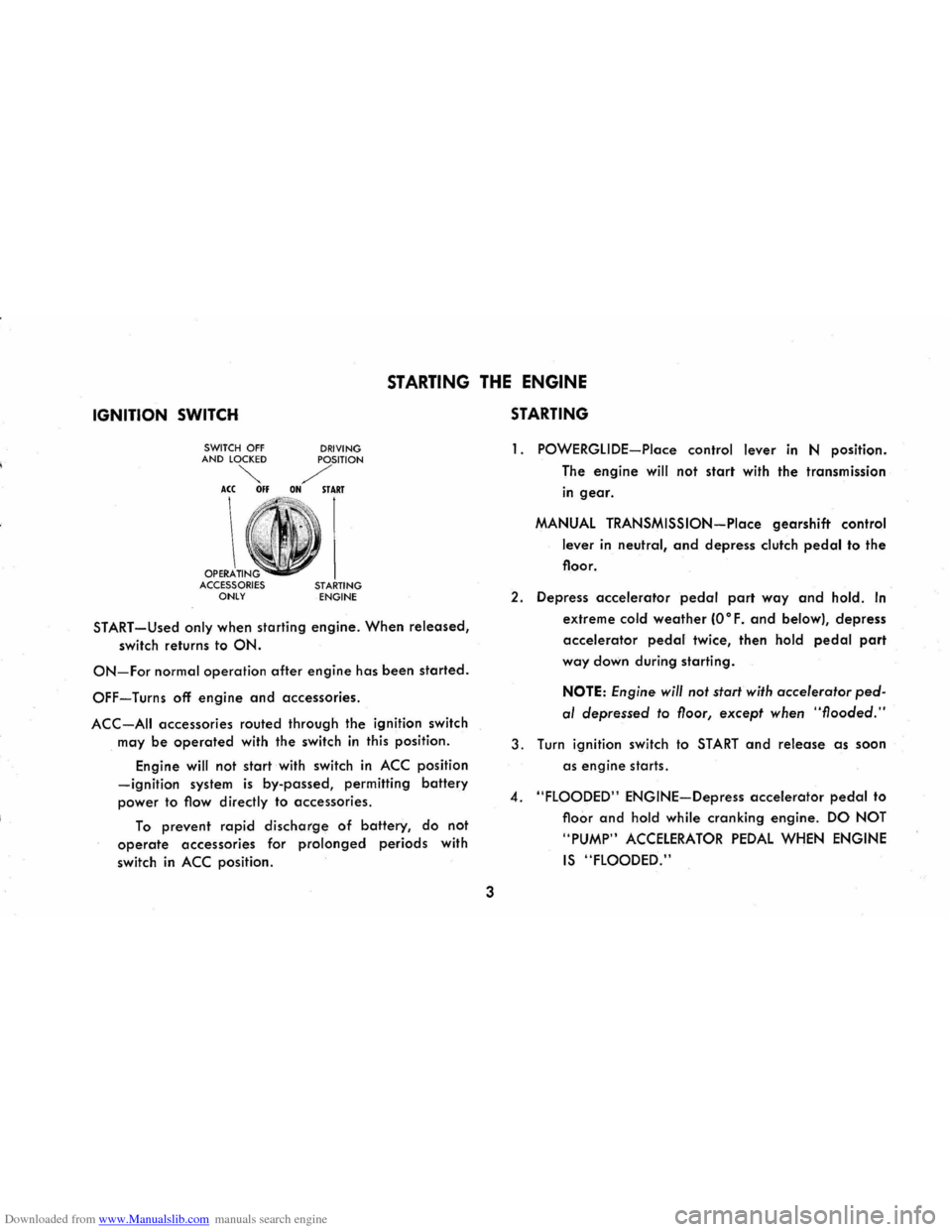

Downloaded from www.Manualslib.com manuals search engine IGNITION SWITCH

STARTING THE ENGINE

STARTING

SWITCH OFF AND LOCKED

~ ACC 011

OPERATI ACCESSORIES ONLY

DRIVING

POSITION

/' ON START

STARTING ENGINE

START -Used only when starting engine. When released,

switch returns to ON.

ON-For normal operation after engine has been started.

OFF-Turns off engine and accessories.

ACC-AII accessories routed through the ignition switch

may

be operated with the switch in this position.

Engine

will not start with switch in ACC position

-ignition system is by-passed, permitting battery

power to flow directly to accessories .

To prevent rapid discharge of battery, do not

operate accessories for prolonged periods with

switch

in ACC position.

3

1. POWERGLIDE-Place control lever in N position.

The

engine will not start with the transmission

in gear.

MANUAL TRANSMISSION-Place gearshift control

lever

in neutral, and depress clutch pedal to the

floor.

2. Depress

accelerator pedal part way and hold. In'

extreme cold weather (O°F. and below), depress

accelerator pedal twice, then hold pedal part

way down during starting.

NOTE:

Engine will not start with accelerator ped

al depressed to floor, except when "flooded."

3. Turn ignition switch to START and release as soon

as engine starts.

4. "FLOODED" ENGINE-Depress accelerator pedal to

floor and hold while cranking engine. DO NOT

"PUMP"

ACCELERATOR PEDAL WHEN ENGINE

IS "FLOODED."

Page 11 of 56

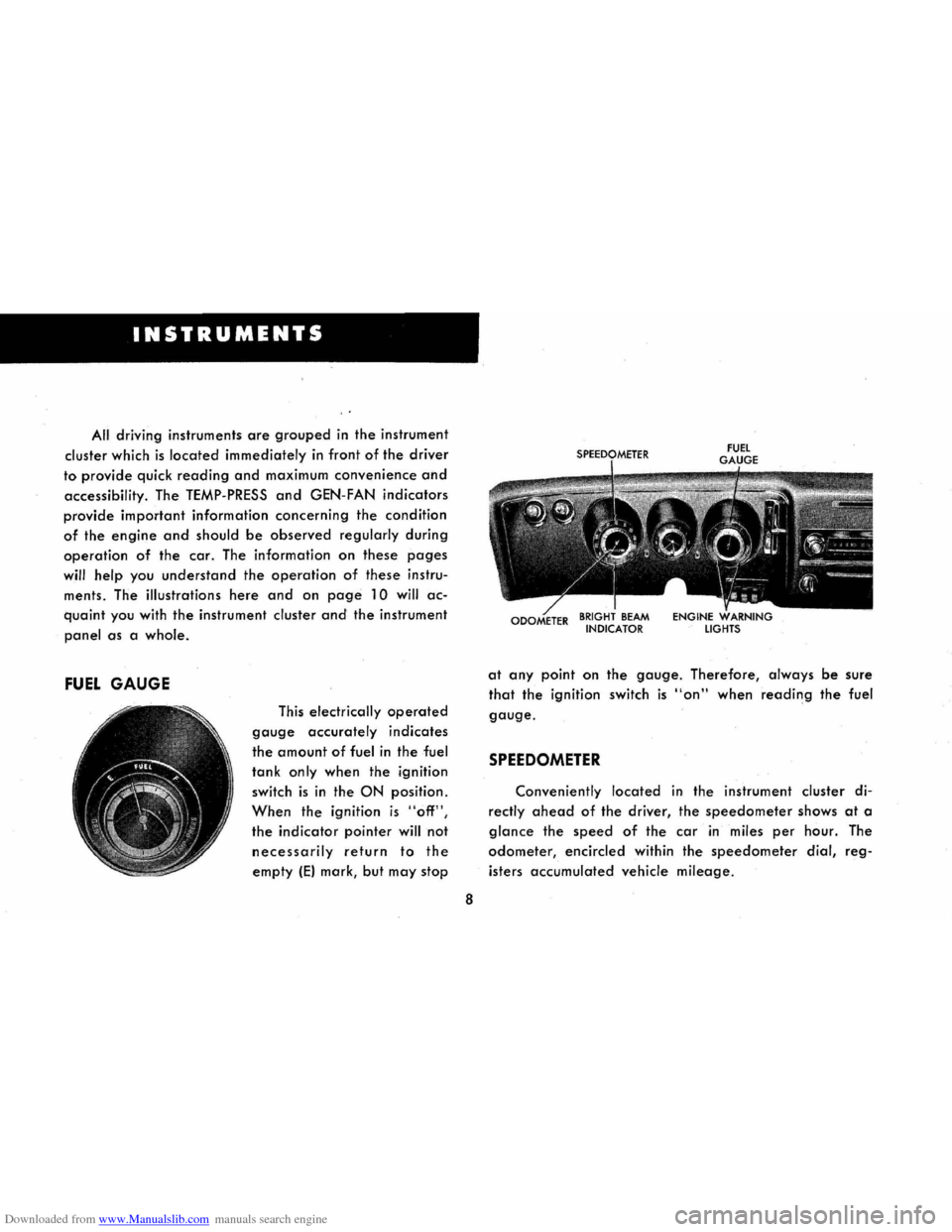

Downloaded from www.Manualslib.com manuals search engine INSTRUMENTS

All driving instruments are grouped in the instrument

cluster

which is located immediately in front of the driver

to provide quick reading and maximum convenience and

accessibility. The TEMP-PRESS and GEN-FAN indicators

provide important information concerning the condition

of the engine and should be observed regularly during

operation of the car. The information on these pages

will help you understand the operation of these instru

ments. The illustrations here

and on page 10 will ac

quaint you with the instrument cluster and the instrument

panel as a whole.

FUEL GAUGE

This electrically operated

gauge accurately indicates

the amount of fuel in the fuel

tank only when the ignition

switch is in the ON position.

When the ignition is "off",

the indicator pointer will not

necessarily return to the

empty IE) mark, but may stop

8

at any point on the gauge. Therefore, always be sure

that the ignition switch is "on" when reading the fuel

gauge.

SPEEDOMETER

Conveniently located in the instrument cluster di

rectly ahead of the driver, the speedometer shows at a

glance the speed of the car in miles per hour. The

odometer, encircled within the speedometer dial, reg

isters accumulated vehicle mileage.

Page 12 of 56

Downloaded from www.Manualslib.com manuals search engine TEMP-PRESS AND GEN-FAN INDICATORS

These indicators provide a check on the operating

condition of the engine and the generator. Both indi

cators should light with the ignition switch ON before

starting the engine and should go out after the engine

is started. The lights should remain out while engine is

operating, except the GEN-FAN indicator may flicker

when

engine is idling.

CAUTION: If either of these indicators light

while car is

being driven, immediately follow the

procedure outlined under "EMERGENCY OPER

ATING INSTRUCTIONS," so car may be driven

to

the nearest service facility.

EMERGENCY OPERATING INSTRUCTIONS

(To be followed if either

TEMP-PRESS or GEN-FAN indi

cators light while car is being

driven.)

1.

Set heater FAN and HEAT

controls to full "ON" positions.

(If

equipped with air conditioning, turn air condi

tioning COOL switch to OFF.)

9

NOTE: After setting the heater controls, leave

them in that position until cause of trouble is

corrected ..

2. Stop the car as soon as driving conditions permit.

Turn ignition key to

OFF to stop engine but turn

key

back to ON so heater blower will continue

to cool engine.

3. Check for broken fan belt or belt off pulleys or

engine low oil level. If only GEN-FAN indicator

is lighted, belt is not broken or off pulleys and en

gine oil level is satisfactory, car can be driven at

slow speeds; however, generator must be checked

and serviced as soon as possible.

4. If trouble is found to be a broken fan belt or belt

off pulleys, wait approximately five minutes, start

engine and drive car at no more than 25 miles per

hour until TEMP-PRESS indicator comes on, then

repeat Step 2.

NOTE: The GEN-FAN indicator will stay on until

fan

belt is installed .

5. Repeat Step 4 as necessary until facility is reached

where fan belt can be installed.

Page 21 of 56

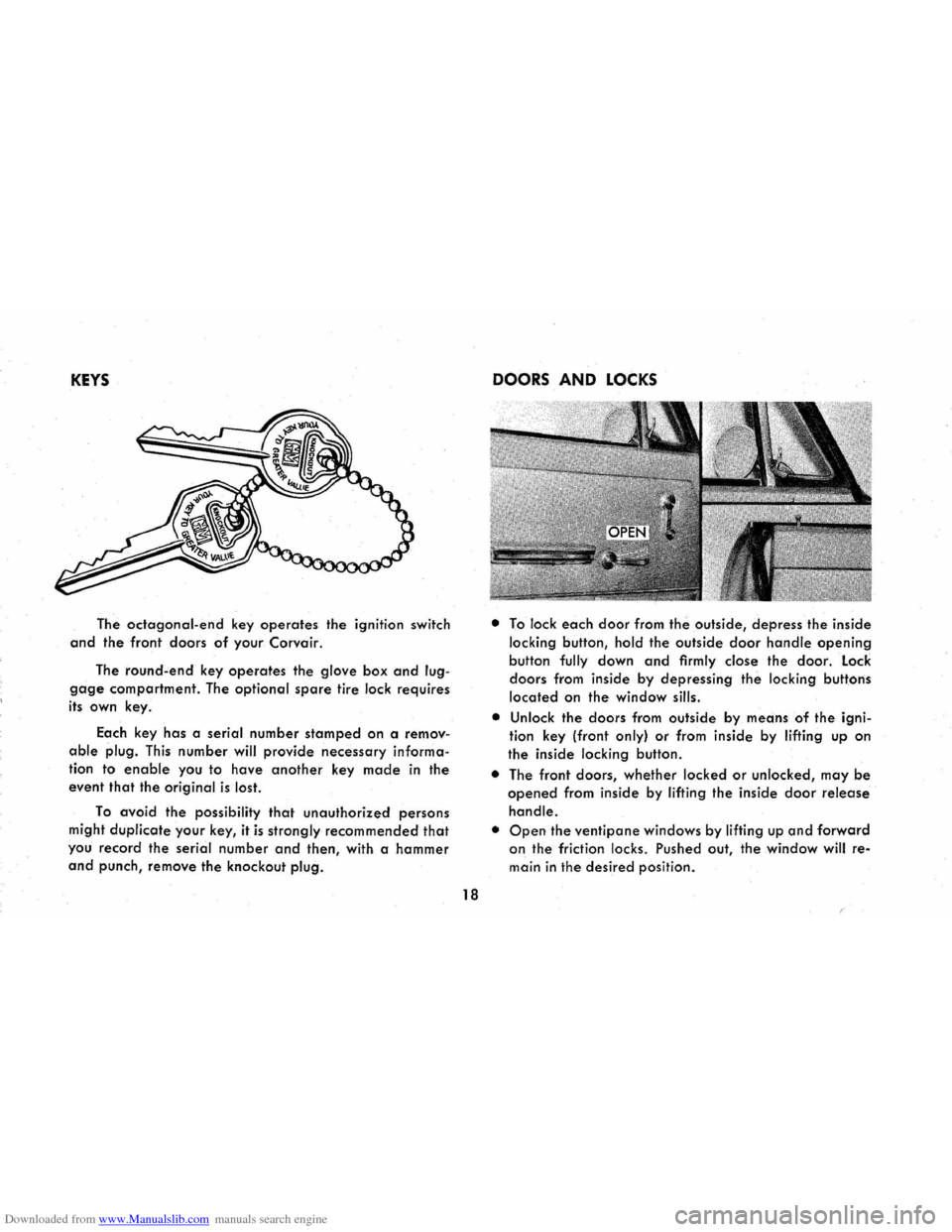

Downloaded from www.Manualslib.com manuals search engine KEYS

The octagonal-end key operates the ignition switch

and the front doors of your Corvair.

The round-end key operates the glove box and lug

gage compartment. The optional spare tire lock requires

its

own key.

Each key has a

serial number stamped on a remov

able plug. This number will provide necessary informa

tion to enable you to have another key made in the

event

that the original is lost.

To avoid the possibility that unauthorized persons

might duplicate your key, it is strongly recommended that

you record the serial number and then, with a hammer

and punch, remove the knockout plug.

18

DOORS AND LOCKS

• To lock each door from the outside, depress the inside

locking button, hold the outside door handle opening

button fully down and firmly close the door. lock

doors from inside by depressing the locking buttons

located on the window sills.

• Unlock the doors from outside by means of the igni

tion key (front only) or from inside by lifting up on

the inside

locking button.

• The front doors, whether locked or unlocked, may be

opened from inside by lifting the inside door release

handle.

• Open the venti pane windows by lifting up and forward

on the friction locks. Pushed out, the window will re

main in the desired

position.

Page 27 of 56

Downloaded from www.Manualslib.com manuals search engine CORVAIR GREENBRIER

INSTRUMENTS AND CONTROLS

The Corvair Greenbrier instr~ments and controls are

essentially the same as those of the Covair which are de

scribed in preceding pages of this book. However, due to

body construction, various items differ somewhat in

operation and location. The next few pages cover those

items

peculiar to the Corvair Greenbrier only.

AIR VENTS

Additional outside air may be admitted into the

vehicle through air inlets located on each side of the

passenger compartment. The Air Control Lever must be

in the down position to admit outside air to the inlets.

Place

the lever in the up position to eliminate flow of outside air to inlets.

24

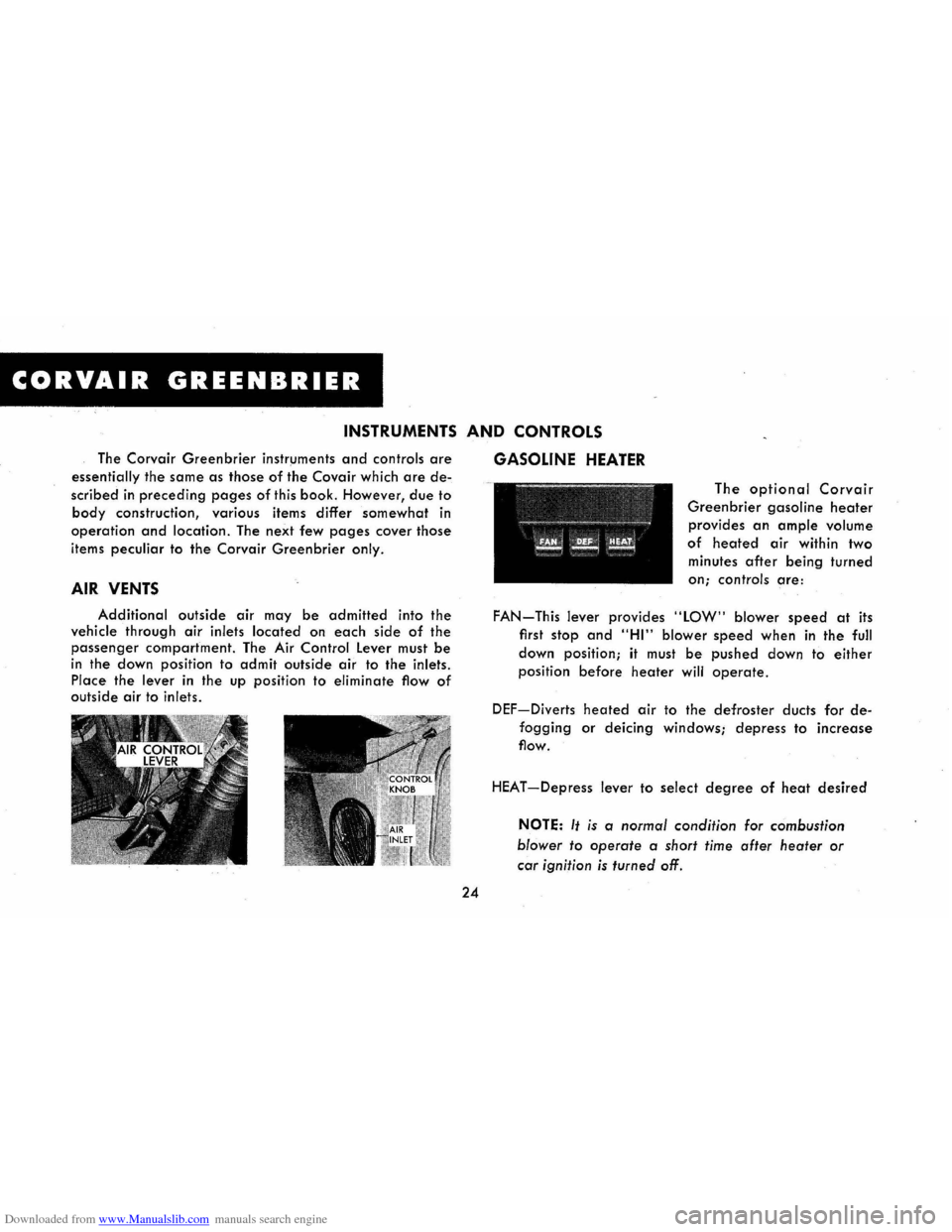

GASOLINE HEATER

The optional Corvair

Greenbrier gasoline heater

provides an ample volume

of heated air within two

minutes

after being turned

on; controls are:

FAN-This lever provides "LOW" blower speed at its

first

stop and "HI" blower speed when in the full

down position; it must be pushed down to either

position before heater will operate.

DEF-Diverts heated air to the defroster ducts for de

fogging or deicing windows; depress to increase

flow.

HEAT -Depress lever to select degree of heat desired

NOTE: It is a normal condition for combustion

blower to operate

a short time after heater or

car ignition

is turned off.

Page 29 of 56

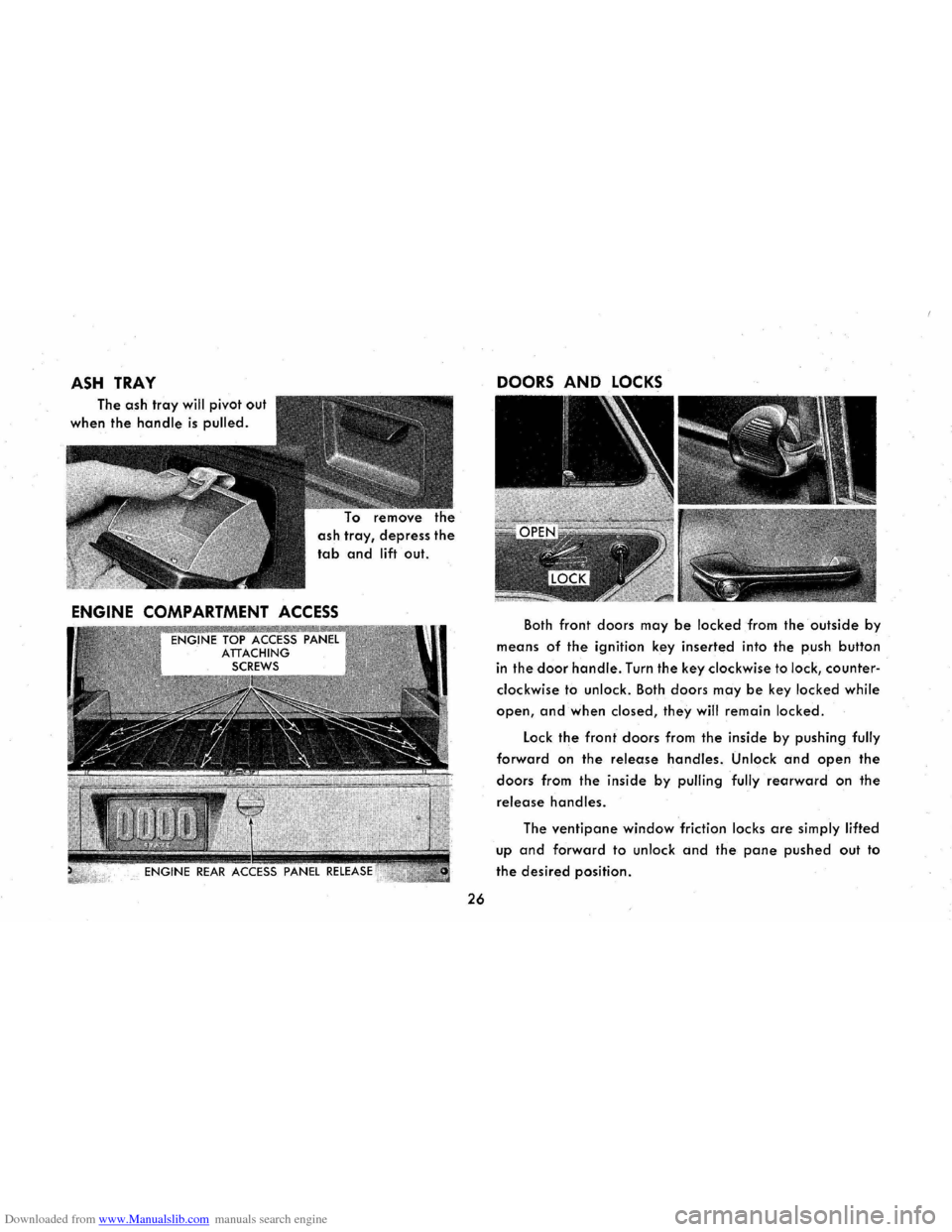

Downloaded from www.Manualslib.com manuals search engine ASH TRAY

The ash tray will pivot out

when the handle is pulled.

ash tray, depress the

tab and lift out.

ENGINE COMPARTMENT ACCESS

26

DOORS AND LOCKS

Both front doors may be locked from the outside by

means of the ignition key inserted into the push button

in the door handle. Turn the key clockwise to lock, counter

clockwise

to unlock. Both doors may be key locked while

open, and when closed, they will remain locked.

lock the front doors from the inside by pushing fully

forward on the release handles. Unlock and open the

doors from the inside by pulling fully rearward on the

release handles.

The ventipane window friction locks are simply lifted

up and forward to unlock and the pane pushed out to

the desired position.

Page 42 of 56

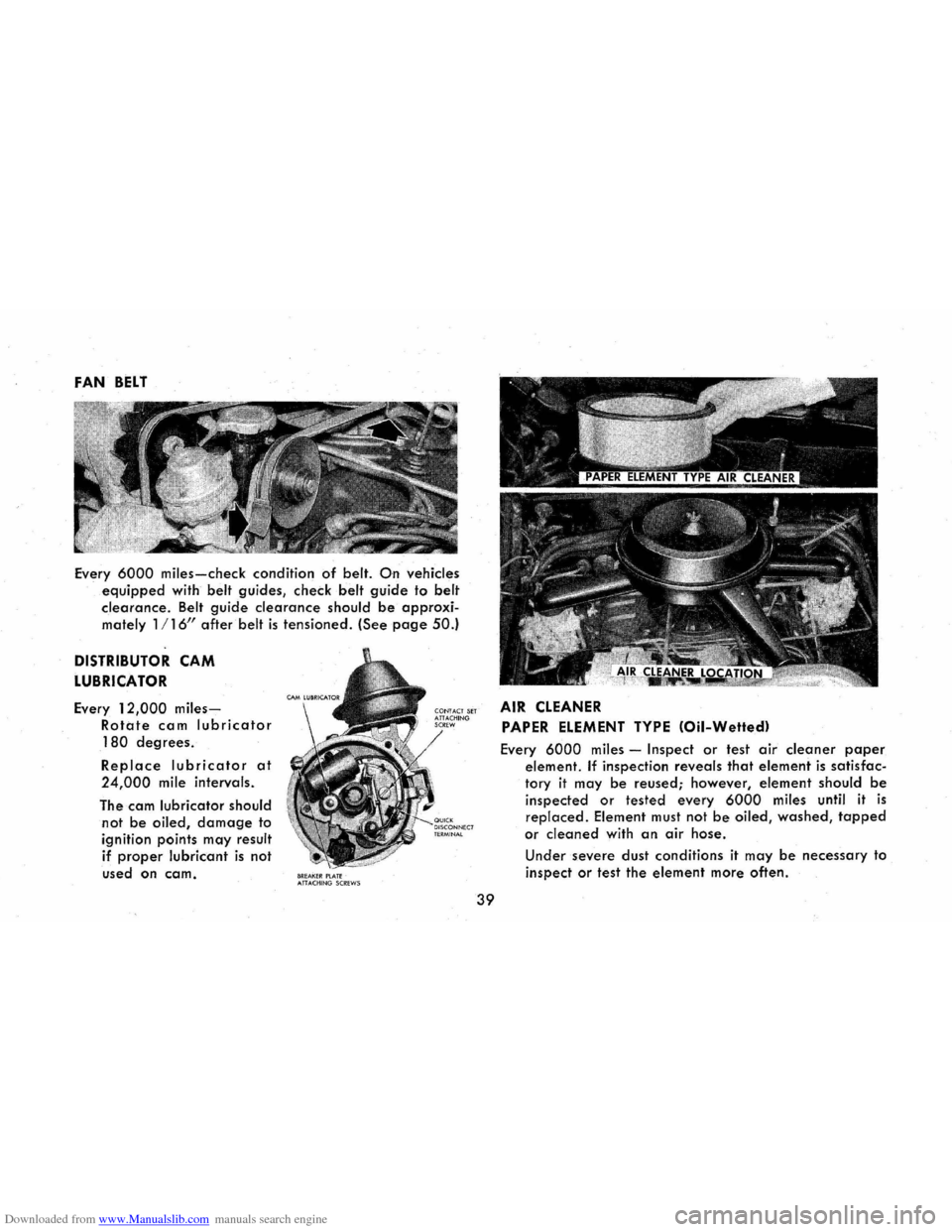

Downloaded from www.Manualslib.com manuals search engine FAN BELT

Every 6000 miles-check condition of belt. On vehicles

. equipped with belt guides, check belt guide to belt

clearance. Belt guide clearance should be approxi

mately 1/ 16/1 after belt is tensioned. (Seepage 50.)

DISTRIBUTOR CAM

LUBRICATOR

Every 12,000 miles-

Rotate cam lubricator

180 degrees.

Replace lubricator at

24,000 mile intervals .

The cam lubricator should

not be oiled, damage to

ignition points

may result

if proper lubricant is not

used on cam.

8R:EAKER PlATE "nACHlNG SCREWS

39

AIR CLEANER

PAPER ELEMENT TYPE (Oil-Wetted)

Every 6000 miles -Inspect or test air cleaner paper

element. If inspection reveals that element is satisfac

tory it may

be reused ; however, element should be

inspected or tested every 6000 miles until it is

replaced. Element must not be oiled, washed, tapped

or cleaned with an air hose.

Under severe dust conditions

it may be necessary to

inspect

or test the element more often.

Page 48 of 56

Downloaded from www.Manualslib.com manuals search engine Idle Speed: 95 hp Turbo-Air 164 w/monuol trans. (In Neutral) .... 450-500 rpm 110 hp Turbo-Air 164 w/manual trans. (In Neutral) .... 600-650 rpm 140 hp Turbo-Air 164 w/manualtrans. (In Neutral) .... 600-650 rpm 180 hp Turbocharged 164 (In Neutral) .................. 850 rpm All Powerglide (In Drive) .............. , .......... 450-500 rpm

Ignition Timing:. 95 hp Turbo-Air 164 (manual transmission) ............ 6° BTDC 110 hp Turbo-Air 164 (manual transmission) ............ 14° BTDC 140 hp Turgo-Air 164 .............................. 18°BTDC

180 hp Turbocharged 164 .......................... 24° BTDC All Powerglide ...........................••....•• . 14° BTDC

Axle Ratios: Engine 95 hp Turbo-Air 164 110 hp Turbo-Air 164

140 hp Turbo-Air 164 180 hp Turbocharged 164

Transmission All 3-and 4-Speed Powerglide

3 -and 4-Speed All

Standard Ratio "

3.27:1

3.27:1

3.55:1 3.55:1

3.55: 1 'Standard Ratio For Corvair Greenbrier and Air Conditioning Equipped Vehicles 3.55:1.

BULB SPECIFICATIONS

Headllamp Unit (Sealed Beam)

Candle Power

Outer-High Beam ......•.........•...... 37% W low Beam ....•.............•..... 55W Inner-High Beam Only ................... 37'!z W

Parking lamp-Directional Signal and Tail-Stap-D irectional Signal lamps ... ...•... 4-32

Back-Up lamps ............................ 32 Instrument lamps ....................••.... 3

Temp. Press., Gen. Fan., and Glove Compartment lamps ..•.............•..... 2 Headlamp High Beam Indicator,' Directional Signal Indicator , and Heater Control Panel lamps •.....•..................•.. 1

Number

4002

4001

1157

1156

GE 1816

1895

1445

45

Dome Lomp ' ................... .. ......... 12 Courtesy lamp .........••.................. 6 license Plate lamp .....•..............•.... 4

Radio Dial lamp ........•.......•.......... 2

BATTERY RATINGS

Corvair-12 volt; 54 plate; 44 amp/hr . Corvoir 95 and Greenbrier-12 volt; 54 plate; 42 amp/hr .

FUSES AND CIRCUIT BREAKER

211 631

67

1893

A circuit breaker in the light control switch protects

the head lamp circuit, thus eliminating one fuse. Where

current load is too heavy, the circuit breaker intermittently

opens and closes, protecting the circuit until the cause

is found and eliminated.

Fuses, located in the junction block beneath the

dash are:

1. Healer Blower

Glove Comparlment lamp ........ 3AG/ AGC-1 0 amp

2. Tail and Slop lamps,

Dome lamp ................. .. 3AG / AGC-1 0 amp.

3.

Heater (Total System) Back-up lamp ................. 3AG/ AGC-20 amp.

4. Radio (AM or AM-FM) ........... 3AG/ AGC-2 Y2 amp.

(AM-FM Stereo) .. . .... 3AG/ AGC-71/2 amp.

5. Instrument Panel lamps Radio Panel lamp Heater Conlrol Panel lamp ........ 3AG/ AGC-3 amp. 6. Windshield Wiper Molor ......... 3AG/ AGC-20 amp.

Air Conditioner Fuses ........... 3AG! AGC-15 amp. (Located in 14GA red and 12GA gray wires in area of

ignition switch.)

Page 51 of 56

Downloaded from www.Manualslib.com manuals search engine MINOR TROUBLE SHOOTING PROCEDURES

The chart on the previous page, and the information on the pages

which follow, contains information designed to aid the average

driver to discover, and possibly correct, conditions resulting in minor

mechanical difficulties

in his cor. The chart, designed to point out

possible solutions to severol of the most common automotive mal

functions and point out a logical checking sequence, will lead step

by step to the most

likely causes and corrective procedures. If, after

making the checks and adjustments suggested, the source of the

trouble has not been found and corrected, it is strongly recom.

mended that on Authorized Chevrolet Dealer inspect the vehicle and

make whatever repairs or adjustments are necessary.

FUEL SYSTEM AND ENGINE

If the ignition switch will couse the engine to "turn over" or

"cronk" but the cor will not start, check Steps A through D below.

NOTE: If continual "flooding" of the carburetor is evidenced by a

carburetor wet with fuel or black exhaust smoke, perform the

operation suggested in paragraph D only.

(A) The first and most obvious,

and one of the most frequently overlooked, items to check when

you

have difficulty in starting your

cor is the amount of fuel in the

tonk.

Make it a habit to check the

FUEL GAUGE regularly and most especially at a time when the en

gine will "turn over" but will not

start.

(8) If the fuel tank is not empty, Checking Fuel Flow

48

you may check further to see whether the fuel is reaching the

engine. Disconnect the fuel lines at the carburetor. Place a jar or CliP

under open line and briefly "crank" the engine by means of the

starter. If fuel spurts from the line, you may assume that the FUEL

LINES are dear and the FUEL PUMP is operating properly. If no fuel

leaves the line, either the fuel lines or fuel pump are at fault. See

your Authorized Chevrolet Dealer.

(C) Before reconnecting the fuel lines to the carburetor, remove

the

FUEL FILTER from carburetor inlet and check its condition.

If it appears to be clean, replace it.and reconnect the fuel lines. If

the filter appears to be plugged, clean it as well as possible by

scraping out the foreign material and cleaning in a solvent. Then

r~install the filter and repeat the procedure with the second carbu

r~ior. Replace the filters with new ones as soon as possible .

(0) If the fuel seems to be reaching the carburetors properly, the

problem may

be: an EMPTY CARBURETOR BOWL caused by a

"stuck shut" float valve or a FLOODED CARBURETOR caused by a

"stuck open" condition and evidenced by gasoline flowing down

the outside of the carburetor; or a stuck CHOKE valve. Remove the

air cleaners from the carburetors. Check that the choke valves move

freely and are not stuck. Tap the side of the carburetors sharply

several times with a light tool such as a screwdriver handle or pliers.

Replace the air cleaners and attempt to start the engine in the

normal manner.

(E) If the car will start but stalls when hot or has a rough idle,

you can suspect a faulty IDLE ADJUSTMENT, or extremely dirty

Page 52 of 56

Downloaded from www.Manualslib.com manuals search engine and blocked AIR CLEANER ELEMENTS. Clean and reoil the air

cleaner elements if necessary. Idle adjustment should be performed

by your Chevrolet Dealer.

If the above Fuel System checks and the checks suggested under

the Electrical System following do not correct the malfunction, it is

recommended that you turn to your Authorized Chevrolet Dealer

for further checks , adjustments or repairs.

ELECTRICAL SYSTEM

If, when the ignition key is turned to START, the engine will not

turn

over, you have good reason to suspect electrical trouble.

(F) When there .is no response at all to attempts to start the car,

check the obvious-your AUTOMATIC TRANSMISSION SElECTOR

LEVER must be in neutral position before the engine can be started.

Turning the IGNITION SWITCH rapidly back and forth several

times will sometimes correct a poor internal switch contact.

(G) The

BATTERY may be discharged. If so, lights will be dim and

the horn will have a poor tone if it will blow at all.

Usually a

garage recharge will be necessary to return the battery

to operation. Occasionally, however , a push start and a long drive

will

recharge the battery.

NOTE : If the battery is determined to be dead, and for no apparent

reason , have your Authorized Chevrolet Dealer check the

battery, the GENERATOR and the VOLTAGE REGULATOR .

GENERA TOR trouble should already have been indicated by

the indicator on the instrument panel. Never remove generator

"BAT" lead without first disconnecting battery ground cable.

49

POOR BATTERY CONNECTIONS may be suspected if the car has operated properly a short time before and now not even the horn

will operate. Check both ends of both battery cables. If the con

nections are corroded, a car may sometimes be restored to opera

tion by removing all cable ends, scraping all contacting surfaces clean with a pen knife , and reassembling . If the cables are broken, they must be replaced. The power supply should now be restored unless the battery is dead.

(H) If, however, the lights and horn work properly but the starter will still not turn over, check the STARTER connections. A "click" from the starter solenoid indicates that the wiring to the starter is properly installed . If the wiring seems to be clean and tightly installed, the trouble is probably in the starter itself and should be referred to your Authorized Chevrolet Dealer.

When the engine will "turn over" but will not start, the following

items may be checked along with Fuel System Checks listed

previously .

(I) With a clean dry cloth wipe the ceramic portions of the spark plugs dry. In particularly damp or rainy wellthe'r dampness may be the cause of not starting, especi-: . ally when the engine is cold.

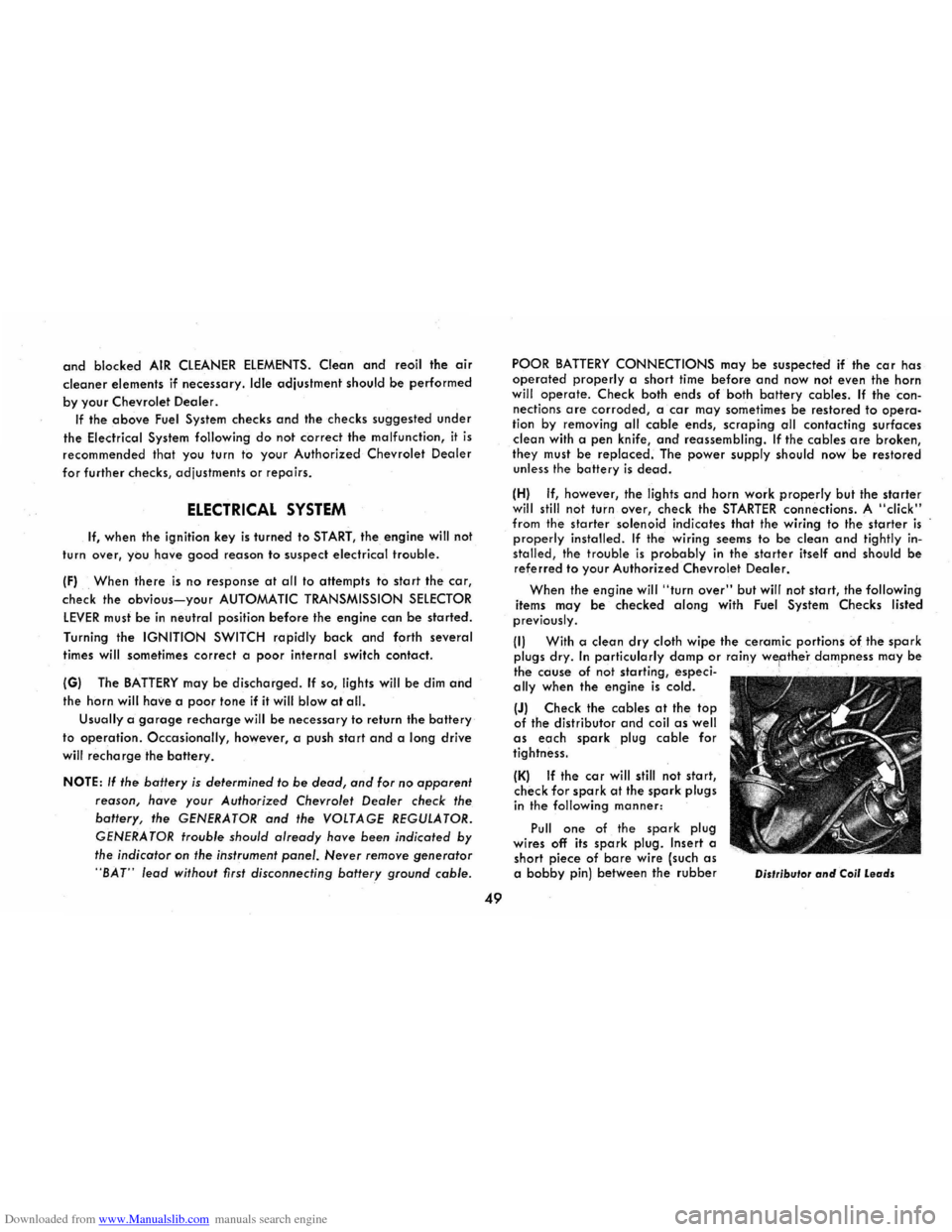

(J) Check the cables at the top of the distributor and coil as well as each spark plug cable for tightness.

(K) If the car will still not start, check for spark at the spark plugs in the following manner:

Pull

one of the spark plug

wires off its spark plug. Insert a

short piece of bare wire (such as a bobby pin) between the rubber Oislribulor and Coil Leads