diagram CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 36 of 2438

BLEEDING BENDIX ANTILOCK 4 BRAKE SYSTEM......5-3

BASE BRAKE SYSTEM BLEEDING PROCEDURE.........5-3

MASTER CYLINDER FLUID LEVEL................5-3

TESTING FOR FLUID CONTAMINATION.............5-4 WIRING DIAGRAMS AA-BODY

..................8W-1

INDEX...............................8W-1

WIRING DIAGRAMS AJ BODY ..................8W-8

ALPHABETICAL INDEX.....................8W-8

Page 137 of 2438

(2) Check all connectors for correct assembly. Check

all connectors for incorrectly installed termi-

nals. (3) Check pin #21 for minimum of 9.5 volts.

(4) Check pin #20 for minimum of 9.5 volts (with

ignition key on). (5) Check voltage at pins #5 and #16. The measure-

ment should exceed 0 volts. (6) Check pin #19 for continuity.

(7) The engine speed should exceed 680 rpm during

idle. All doors and trunk must be closed for the

system to function.

DIAGNOSTICS PROCEDURES

(1) Use the D.R.B. II tester and the 1991 air suspen-

sion diagnostic service cartridge to begin the trouble-

shooting process. (2) Use the D.R.B. mating connector under the dash

(drivers side) to plug-in the D.R.B. II test connector

(Fig. 10). (3) The tester will conduct a complete check of the

suspension system status. (4) The tester will list the steps to follow to access

and diagnose the failure. (5) A Volt/Ohm meter can be used for some diagnos-

tic testing.

HEIGHT SENSOR CHECK

If a sensor signal/signals are missing. Follow the

repair procedure listed below. (1) Check ground circuit continuity. (Remember

front and rear grounds are on different circuits. (2) For front ground circuit continuity check circuit

S 33. (3) For rear ground circuit continuity check circuit

X20. (4) Refer to control module pin out chart and wiring

diagram (see Group 8F in wiring diagram manual) for

individual circuit details. (5) If open circuits are not found replace the compo-

nent. Complete circuit testing and connector assem-

blies before replacing a strut or right rear shock. (6) To measure resistance values, see Height Sensor

Logic Chart and Initial Diagnostic Check in System

Operation.

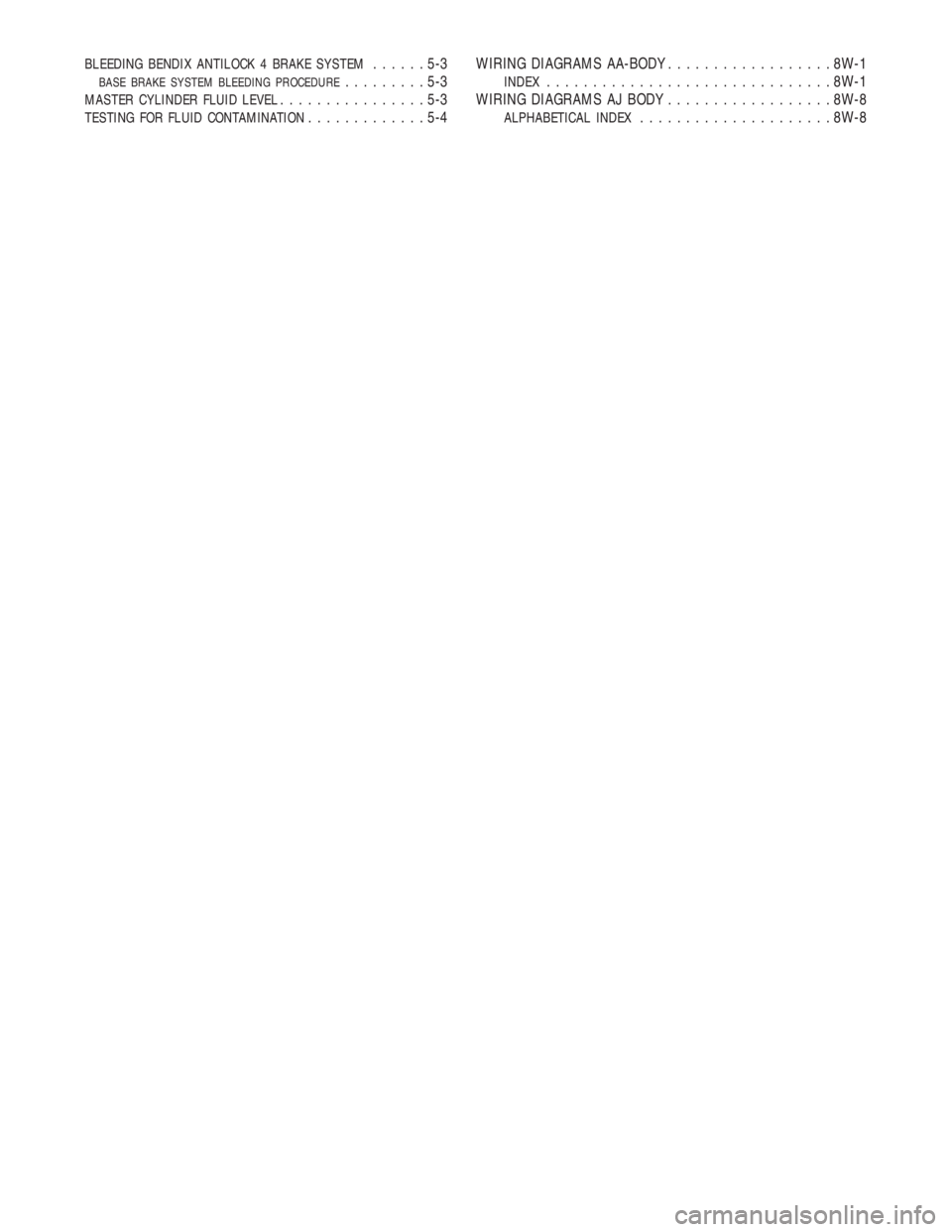

HEIGHT SENSOR LOGIC CHART

Ä SUSPENSION AND DRIVESHAFTS 2 - 79

Page 162 of 2438

ing inserted in jaws but do not apply heavy pressure

to handle as this will lock tubing in place.Place gauge (Form A) on edge over end of brake

tubing. Push tubing through jaws until end of tubing

contacts the recessed notch in gauge matching the

tubing size. Squeeze handles of flaring tool and lock

tubing in place. Place 3/16 inch plug of gauge (A)

down in end of tubing. Swing compression disc over

gauge and center tapered flaring screw in recess of

disc. Screw in until plug gauge has seated on jaws of

flaring tool. This action has started to invert the ex- tended end of the tubing. Remove gauge and continue

to screw down until tool is firmly seated in tubing.

Remove tubing from flaring tool and inspect seat. Refer

to routing diagrams (Figs. 18 to 21) for proper routing

and clip location. Replace any damaged tube routing

clips.

ISO TUBING FLARES

CAUTION: All ISO style tubing flares (Fig. 13 & 16 ) are

of metric dimensions. When performing any service

procedures on vehicles using ISO style tubing flares,

metric size tubing of 4.75 mm MUST be used with

metric ISO tube flaring equipment.

To create a (metric) ISO style tubing flare, Use

Snap-On Flaring Tool TFM-428, or equivalent. See

(Fig. 17) and proceed with the steps listed below. Be

sure to place the tubing nut on the tube before

flaring the tubing. (1) Carefully prepare the end of the tubing to be

flared. Be sure the end of the tubing to be flared is

square and all burrs on the inside of the tubing are

removed (Fig. 15). This preparation is essential to

obtain the correct form of a (metric) ISO tubing

flare. (2) Open the jaws of the Flaring Tool. Align the

mating size jaws of the flaring tool around the size of

the tubing to be flared. Close the jaws of the Flaring

Tool around the tubing to keep it from sliding out of the

flaring tool, but do not lock the tubing in place. See

(Fig. 17)

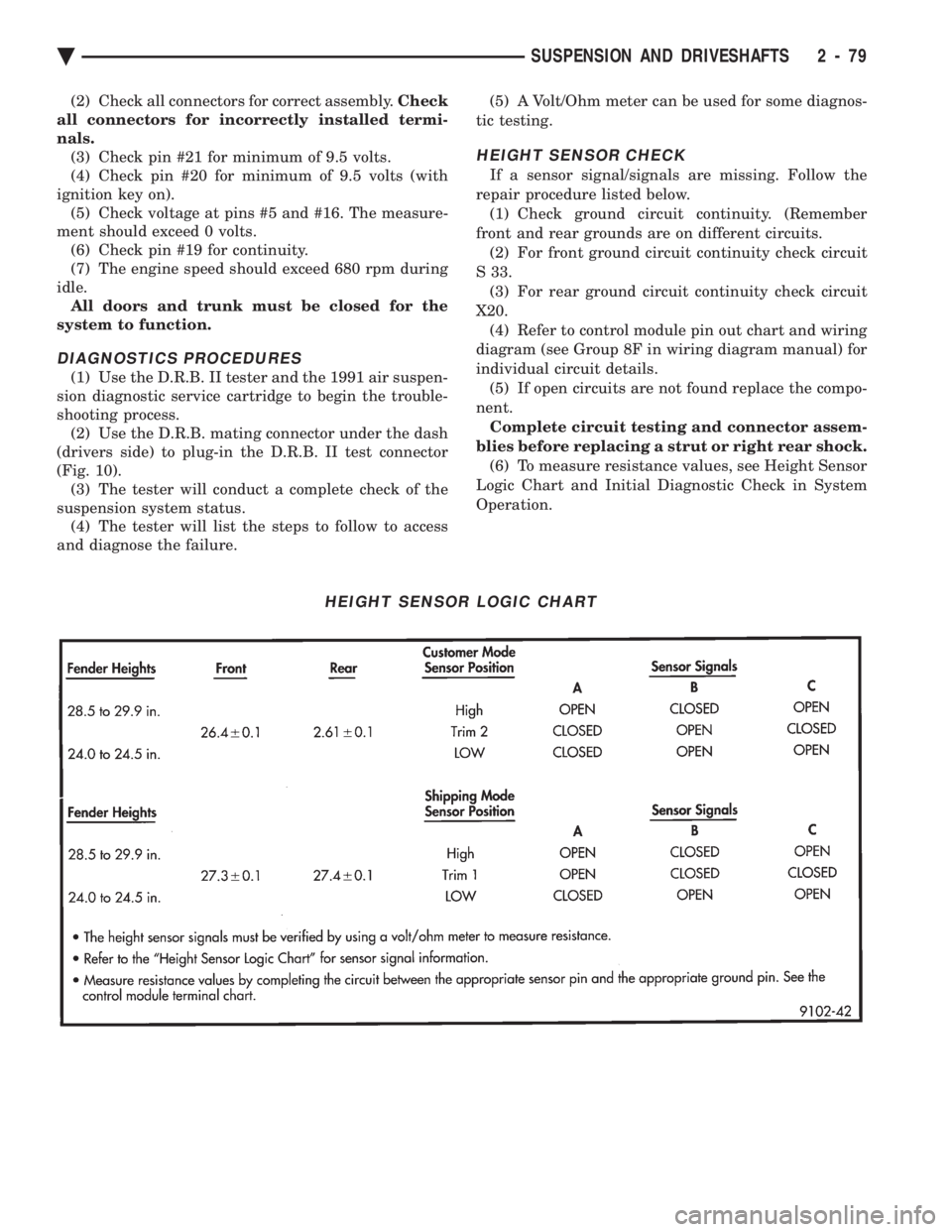

Fig. 14 Cutting and Flaring of Brake Line Tubing

Fig. 15 Brake Tube Preparation For Flaring

Fig. 16 Double Flare And ISO-Flare Tubing Connec- tions

5 - 12 BRAKES Ä

Page 228 of 2438

pared by the (CAB) and used to detect brake system

faults that would require Anti -Lock Braking to be

disabled.The Boost Pressure Transducer is mounted on the

bottom of the hydraulic assembly, (Fig. 1) and moni-

tors booster servo pressure. The Primary Pressure

Transducer is mounted on the left side of the hydrau-

lic assembly and monitors primary master cylinder

pressure.

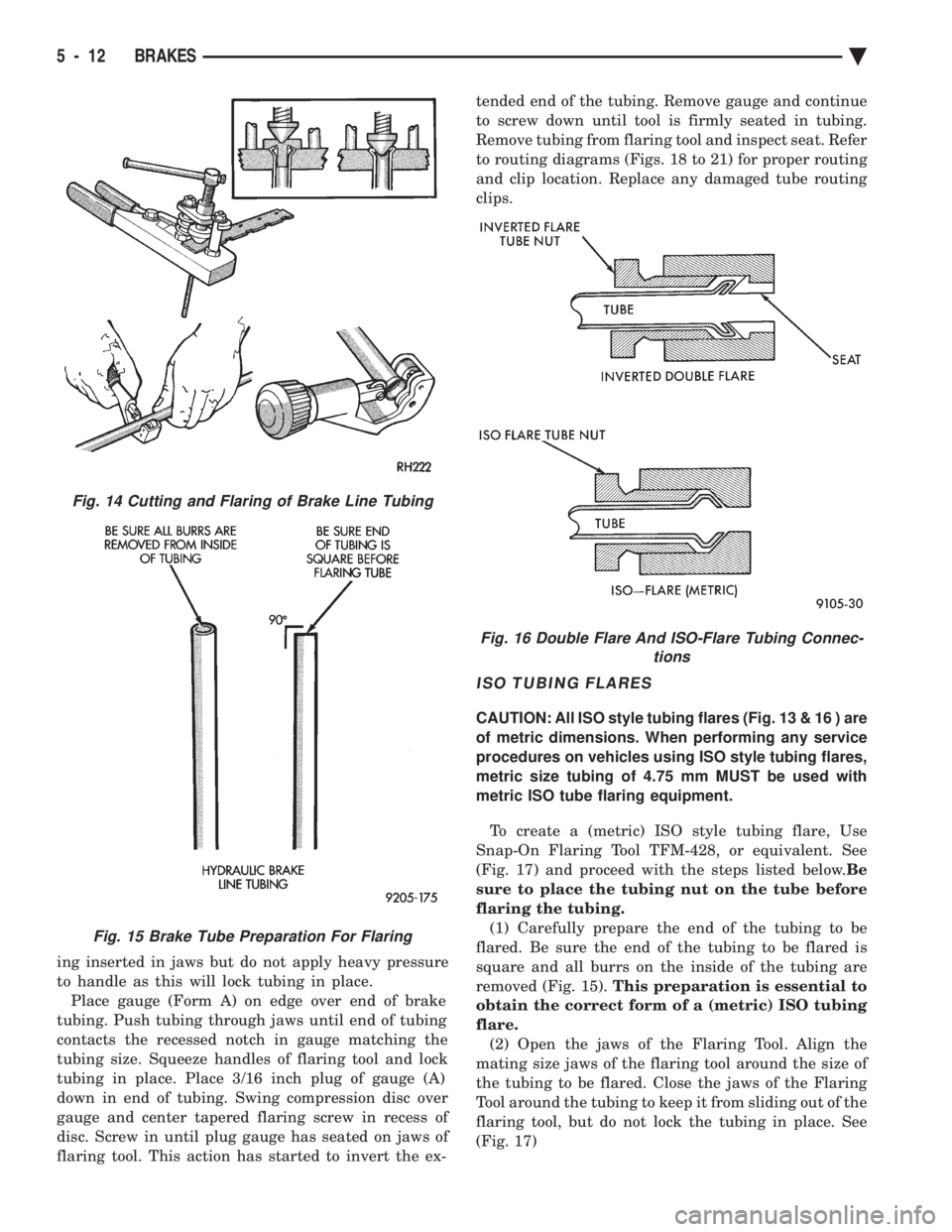

DIFFERENTIAL PRESSURE SWITCH

A non-latching Differential Pressure Switch is used

to detect a pressure difference greater than 2,068

kPa (300 psi.) between the primary and secondary

master cylinder hydraulic circuits. If detected, the

Differential Pressure Switch grounds the output of

the primary pressure transducer (circuit B-218). This

results in a 0.0 volt signal from the Primary Pres-

sure Transducer that is sensed by the (CAB) as a dif-

ferential pressure fault. The (CAB) will then light

the Red Brake Warning Lamp and the Amber Anti-

Lock Warning Lamp and disable the Anti-Lock brak-

ing function. See Fig. 1 for location of the differential

pressure switch.

PROPORTIONING VALVES

The ABS system uses screw-in Proportioning

Valves in place of the conventional Height Sensing Proportioning Valve. Each rear brake circuit has its

own screw-in Proportioning Valve that is attached to

the rear brake outlet ports of the hydraulic assembly

(Fig. 1). These valves limit brake pressure to the

rear brakes after a certain brake pressure is reached.

This improves front to rear wheel brake balance dur-

ing normal braking.

FILTERS-SERVICEABILITY

There is a screen filter in each of the two master

cylinder fill ports. There is also a low pressure filter

for the pump/motor. The filter is integral to the

Pump/Motor low pressure hose.

FLUID LEVEL SWITCH

A Low Fluid Switch is located in the hydraulic as-

sembly fluid reservoir, (Fig. 1). The switch consists of

a float and magnetic reed switch that closes when

low fluid is detected. The Low Fluid Switch is used

as an input, to the Red Brake Warning Lamp, the

(CAB), and the EVIC (if so equipped). When a low

fluid condition exists the switch will close, grounding

the low fluid circuit and illuminating the Red Brake

Warning Lamp. The (CAB) will disable the Anti-

Lock Function and light the Amber Anti-Lock Warn-

ing Lamp if vehicle is in motion above 3 mph. If

vehicle is not in motion, the Amber Anti-Lock Warn-

ing Lamp will NOT be lit.

DUAL FUNCTION PRESSURE SWITCH WIRING DIAGRAM

5 - 78 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 235 of 2438

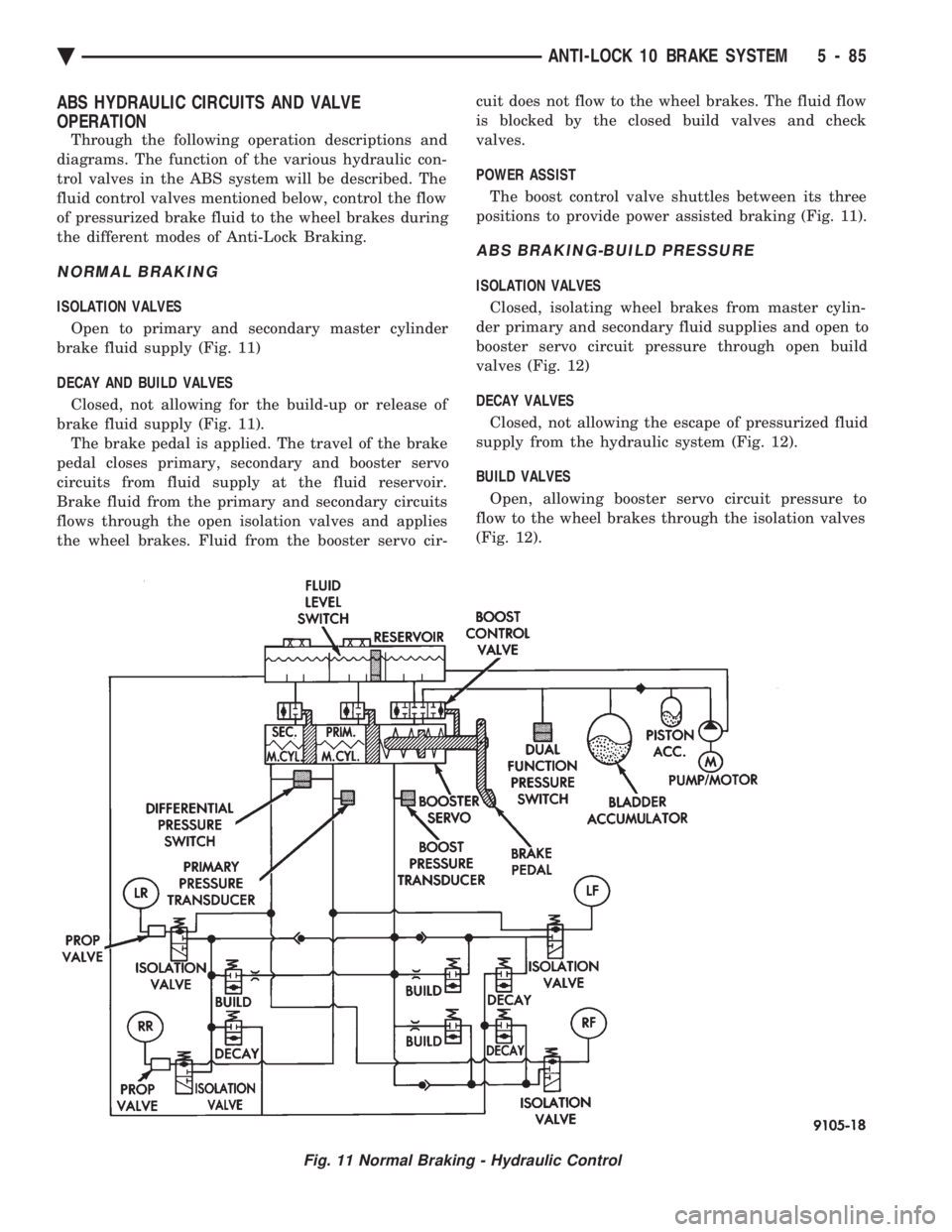

ABS HYDRAULIC CIRCUITS AND VALVE

OPERATION

Through the following operation descriptions and

diagrams. The function of the various hydraulic con-

trol valves in the ABS system will be described. The

fluid control valves mentioned below, control the flow

of pressurized brake fluid to the wheel brakes during

the different modes of Anti-Lock Braking.

NORMAL BRAKING

ISOLATION VALVES

Open to primary and secondary master cylinder

brake fluid supply (Fig. 11)

DECAY AND BUILD VALVES

Closed, not allowing for the build-up or release of

brake fluid supply (Fig. 11). The brake pedal is applied. The travel of the brake

pedal closes primary, secondary and booster servo

circuits from fluid supply at the fluid reservoir.

Brake fluid from the primary and secondary circuits

flows through the open isolation valves and applies

the wheel brakes. Fluid from the booster servo cir- cuit does not flow to the wheel brakes. The fluid flow

is blocked by the closed build valves and check

valves.

POWER ASSIST

The boost control valve shuttles between its three

positions to provide power assisted braking (Fig. 11).

ABS BRAKING-BUILD PRESSURE

ISOLATION VALVES

Closed, isolating wheel brakes from master cylin-

der primary and secondary fluid supplies and open to

booster servo circuit pressure through open build

valves (Fig. 12)

DECAY VALVES

Closed, not allowing the escape of pressurized fluid

supply from the hydraulic system (Fig. 12).

BUILD VALVES

Open, allowing booster servo circuit pressure to

flow to the wheel brakes through the isolation valves

(Fig. 12).

Fig. 11 Normal Braking - Hydraulic Control

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 85

Page 271 of 2438

Lamp Relay opens the Anti-Lock Warning Lamp Re-

lay switch. This breaks the ground path to the Am-

ber Anti-Lock Warning Lamp and the light is turned

off. The (CAB) by itself, also has the ability to turn on

the Amber Anti-Lock Warning Lamp. The (CAB) can

turn on the Amber Anti-Lock Warning Lamp by pro-

viding a ground at pin 15.

ANTI-LOCK WARNING LAMP ON

System Relay and Anti-Lock Warning Lamp

Relay De-Energized. When the Amber Anti-Lock Warning Lamp is on,

there is no electrical current flow from the (CAB) at

pin 57. The System Relay coil is NOT energized. No

electrical current flows to pin 47 and 41 (modulator

valve power), or to the Anti-Lock Warning Lamp Re-

lay coil. Thus, the Amber Anti-Lock Warning Lamp

is not energized. The Amber Anti-Lock Warning Lamp is grounded through the Anti-Lock Warning

Lamp Relay contacts. The Amber Anti-Lock Warning

Lamp is turned on.

HYDRAULIC CIRCUITS AND VALVE OPERATION

Through the following operation descriptions and

diagrams. The function of the various hydraulic con-

trol valves in the ABS system will be described. The

fluid control valves mentioned below, control the flow

of pressurized brake fluid to the wheel brakes during

the different modes of Anti-Lock braking. For explanation purposes we will assume all speed

sensors are sending the same wheel speed informa-

tion, requiring the same hydraulic fluid modulation

at the same rate.

NORMAL BRAKING

ISOLATION VALVES

Open to primary and secondary master cylinder

fluid supply (Fig. 1)

BUILD/DECAY VALVES Closed (Fig. 1)

The brake pedal is applied. The travel of the brake

pedal closes primary and secondary circuits from the

master cylinder fluid supply. Brake fluid from the

primary and secondary circuits flows through the

open isolation valves, through the build/decay valves

to the wheel brakes.

ABS BRAKING-BUILD PRESSURE

ISOLATION VALVES

Closed, isolating wheel brakes from master cylin-

der primary and secondary fluid supply. Through

open build valves (Fig. 2).

BUILD/DECAY VALVES Open (Fig. 2)

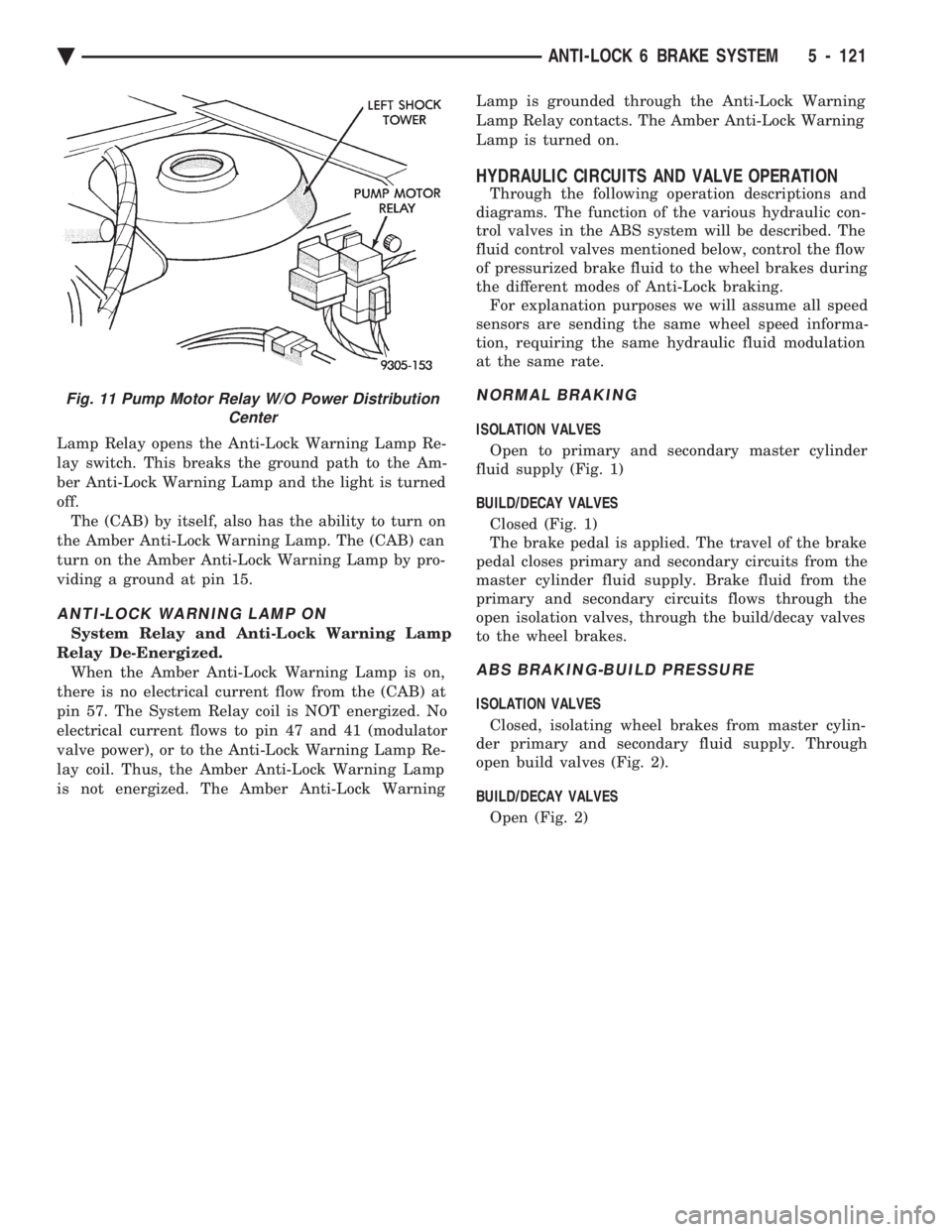

Fig. 11 Pump Motor Relay W/O Power Distribution Center

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 121

Page 306 of 2438

ANTILOCK WARNING LAMP DIODE

The Warning Lamp Relay on the Bendix Antilock

4 Brake System has been replaced with a diode. The

diode is used to control the function of the warning

lamp and is located inside the CAB module wiring

harness. The diode is a replaceable component of the

wiring harness, and will not require replacement of

the entire wiring harness if only the diode is diag-

nosed to have failed. When the system relay is de-energized, the Anti-

lock warning lamp will be lit. This will occur because

a ground path exists for the Antilock warning lamp

through the Antilock warning lamp diode and the

system relay armature. When the system relay is en-

ergized by the CAB, the system relay armature will

no longer provide a ground and the lamp will turn

off. Thus, the lamp will be lit if either the CAB is

disconnected or a system fault causes the Antilock to

be turned off.

PUMP/MOTOR RELAY

Pump/Motor power is supplied by the Pump/Motor

Relay. The Pump/Motor Relay is either mounted on

the left front inner fender shield, or the front of the

left shock tower. The mounting location is dependent

on whether the vehicle is or is not equipped with a

power distribution center. See (Fig. 11 and 12) for

specific mounting locations.

ANTILOCK WARNING LAMP OFF

System Relay Energized

From pin 57, the CAB energizes the Antilock sys-

tem relay coil, thus the electrical current flow in the

coil closes the system relay. Then electrical current

is provided to pins 47 and 41 of the CAB to provide

power to the modulator valves. The CAB turns off the Amber Antilock Warning

Lamp by breaking the ground path through pin 15 of

the CAB.

ANTILOCK WARNING LAMP ON

System Relay De-Energized.

When the Amber Antilock Warning Lamp is on,

there is no electrical current flow from the CAB at

pin 57 and the System Relay coil is NOT energized.

No electrical current flows to pin 47 and 41 (modula-

tor valve power), or to the Antilock Warning Lamp

diode. Thus, the Amber Antilock Warning Lamp is

not energized. The Amber Antilock Warning Lamp is

now grounded through the Antilock Warning Lamp

diode and pin 15 of the CAB turning on the Amber

Antilock Warning Lamp.

HYDRAULIC CIRCUITS AND VALVE OPERATION

Through the following operation descriptions and

diagrams. The function of the various hydraulic con-

trol valves in the ABS system will be described. The

fluid control valves mentioned below, control the flow

of pressurized brake fluid to the wheel brakes during

the different modes of Antilock braking. For explanation purposes we will assume all speed

sensors are sending the same wheel speed informa-

tion, requiring the same hydraulic fluid modulation

at the same rate.

NORMAL BRAKING

BUILD/DECAY VALVES

Closed (Fig. 1)

The brake pedal is applied. The travel of the brake

pedal closes primary and secondary circuits from the

master cylinder fluid supply. Brake fluid from the

master cylinder primary and secondary circuits flows

through the build/decay valves to the wheel brakes.

ABS BRAKING-BUILD PRESSURE

BUILD/DECAY VALVES

Open (Fig. 2)

Fig. 11 Pump Motor Relay Location On AA Body W/O Power Distribution Center

Fig. 12 Pump Motor Relay Location On AJ BodyWith Power Distribution Center

5 - 20 ANTILOCK 4 BRAKE SYSTEM Ä

Page 363 of 2438

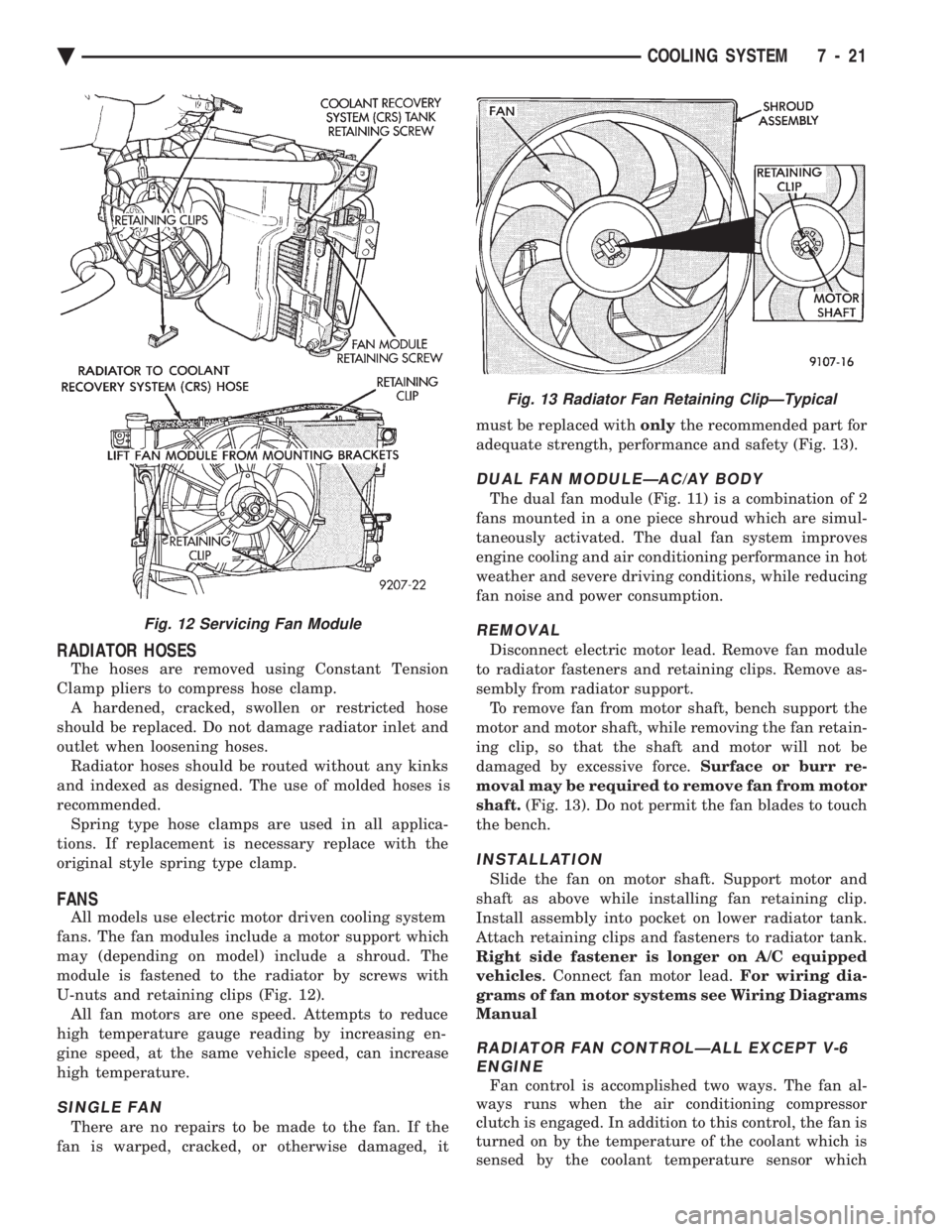

RADIATOR HOSES

The hoses are removed using Constant Tension

Clamp pliers to compress hose clamp. A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses. Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended. Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original style spring type clamp.

FANS

All models use electric motor driven cooling system

fans. The fan modules include a motor support which

may (depending on model) include a shroud. The

module is fastened to the radiator by screws with

U-nuts and retaining clips (Fig. 12). All fan motors are one speed. Attempts to reduce

high temperature gauge reading by increasing en-

gine speed, at the same vehicle speed, can increase

high temperature.

SINGLE FAN

There are no repairs to be made to the fan. If the

fan is warped, cracked, or otherwise damaged, it must be replaced with

onlythe recommended part for

adequate strength, performance and safety (Fig. 13).

DUAL FAN MODULEÐAC/AY BODY

The dual fan module (Fig. 11) is a combination of 2

fans mounted in a one piece shroud which are simul-

taneously activated. The dual fan system improves

engine cooling and air conditioning performance in hot

weather and severe driving conditions, while reducing

fan noise and power consumption.

REMOVAL

Disconnect electric motor lead. Remove fan module

to radiator fasteners and retaining clips. Remove as-

sembly from radiator support. To remove fan from motor shaft, bench support the

motor and motor shaft, while removing the fan retain-

ing clip, so that the shaft and motor will not be

damaged by excessive force. Surface or burr re-

moval may be required to remove fan from motor

shaft. (Fig. 13). Do not permit the fan blades to touch

the bench.

INSTALLATION

Slide the fan on motor shaft. Support motor and

shaft as above while installing fan retaining clip.

Install assembly into pocket on lower radiator tank.

Attach retaining clips and fasteners to radiator tank.

Right side fastener is longer on A/C equipped

vehicles . Connect fan motor lead. For wiring dia-

grams of fan motor systems see Wiring Diagrams

Manual

RADIATOR FAN CONTROLÐALL EXCEPT V-6 ENGINE

Fan control is accomplished two ways. The fan al-

ways runs when the air conditioning compressor

clutch is engaged. In addition to this control, the fan is

turned on by the temperature of the coolant which is

sensed by the coolant temperature sensor which

Fig. 12 Servicing Fan Module

Fig. 13 Radiator Fan Retaining ClipÐTypical

Ä COOLING SYSTEM 7 - 21

Page 364 of 2438

sends the message to the Engine Controller. The En-

gine Controller turns on the fan through the fan re-

lay. See Wiring Diagrams Manual for circuity and

diagnostics provided.Switching through the Engine Controller provides

fan control for the following conditions.

² The fan will not run during cranking until the en-

gine starts no matter what the coolant temperature

is.

² Fan will run when the air conditioning clutch is

engaged and low pressure cutout switch is closed.

² For 4 cylinder application the fan will run at ve-

hicle speeds above about 40 mph only if coolant tem-

perature reaches 110ÉC (230ÉF). It will turn off when

the temperature drops to 104ÉC (220ÉF). At speeds

below 40 mph the fan switches on at 102ÉC (215ÉF)

and off at 93ÉC (200ÉF).

² This is to help prevent steaming. The fan will run

only below 16ÉC (60ÉF) ambient. Between 38ÉC

(100ÉF) to 97ÉC (195ÉF) coolant temperature, at idle

and then only for three minutes.

RADIATOR FAN CONTROLÐAC/AY BODY V-6 ONLY

For this application, fan control is accomplished

based on coolant temperature, and on A/C head pres-

sure. These vehicles receive the variable displace-

ment compressor. The fan will go on when;

² Coolant temperature reaches 102ÉC (215ÉF) and off

at 93.4ÉC (200ÉF) regardless of vehicle speed.

² When the head pressure reaches 1516.9 kPa (220

psi) and turn off when the pressure reaches 1103 kPa

(160 psi).

TEMPERATURE GAUGE INDICATION

At idle the temperature gauge will rise slowly to

about 5/8 gauge travel. The fan will come on and the

gauge will drop to about 1/2 gauge travel, this is nor-

mal.

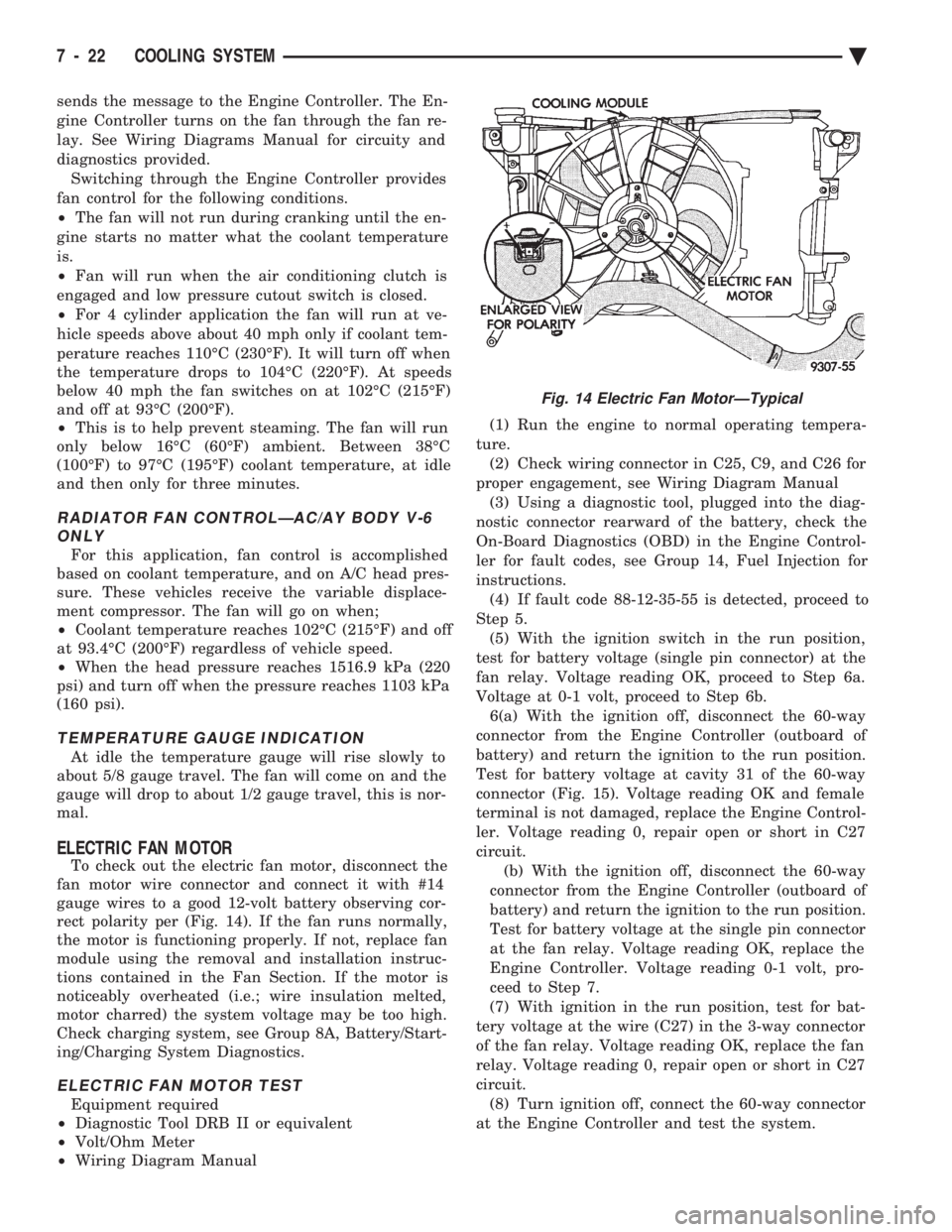

ELECTRIC FAN MOTOR

To check out the electric fan motor, disconnect the

fan motor wire connector and connect it with #14

gauge wires to a good 12-volt battery observing cor-

rect polarity per (Fig. 14). If the fan runs normally,

the motor is functioning properly. If not, replace fan

module using the removal and installation instruc-

tions contained in the Fan Section. If the motor is

noticeably overheated (i.e.; wire insulation melted,

motor charred) the system voltage may be too high.

Check charging system, see Group 8A, Battery/Start-

ing/Charging System Diagnostics.

ELECTRIC FAN MOTOR TEST

Equipment required

² Diagnostic Tool DRB II or equivalent

² Volt/Ohm Meter

² Wiring Diagram Manual (1) Run the engine to normal operating tempera-

ture. (2) Check wiring connector in C25, C9, and C26 for

proper engagement, see Wiring Diagram Manual (3) Using a diagnostic tool, plugged into the diag-

nostic connector rearward of the battery, check the

On-Board Diagnostics (OBD) in the Engine Control-

ler for fault codes, see Group 14, Fuel Injection for

instructions. (4) If fault code 88-12-35-55 is detected, proceed to

Step 5. (5) With the ignition switch in the run position,

test for battery voltage (single pin connector) at the

fan relay. Voltage reading OK, proceed to Step 6a.

Voltage at 0-1 volt, proceed to Step 6b. 6(a) With the ignition off, disconnect the 60-way

connector from the Engine Controller (outboard of

battery) and return the ignition to the run position.

Test for battery voltage at cavity 31 of the 60-way

connector (Fig. 15). Voltage reading OK and female

terminal is not damaged, replace the Engine Control-

ler. Voltage reading 0, repair open or short in C27

circuit. (b) With the ignition off, disconnect the 60-way

connector from the Engine Controller (outboard of

battery) and return the ignition to the run position.

Test for battery voltage at the single pin connector

at the fan relay. Voltage reading OK, replace the

Engine Controller. Voltage reading 0-1 volt, pro-

ceed to Step 7.

(7) With ignition in the run position, test for bat-

tery voltage at the wire (C27) in the 3-way connector

of the fan relay. Voltage reading OK, replace the fan

relay. Voltage reading 0, repair open or short in C27

circuit. (8) Turn ignition off, connect the 60-way connector

at the Engine Controller and test the system.

Fig. 14 Electric Fan MotorÐTypical

7 - 22 COOLING SYSTEM Ä

Page 381 of 2438

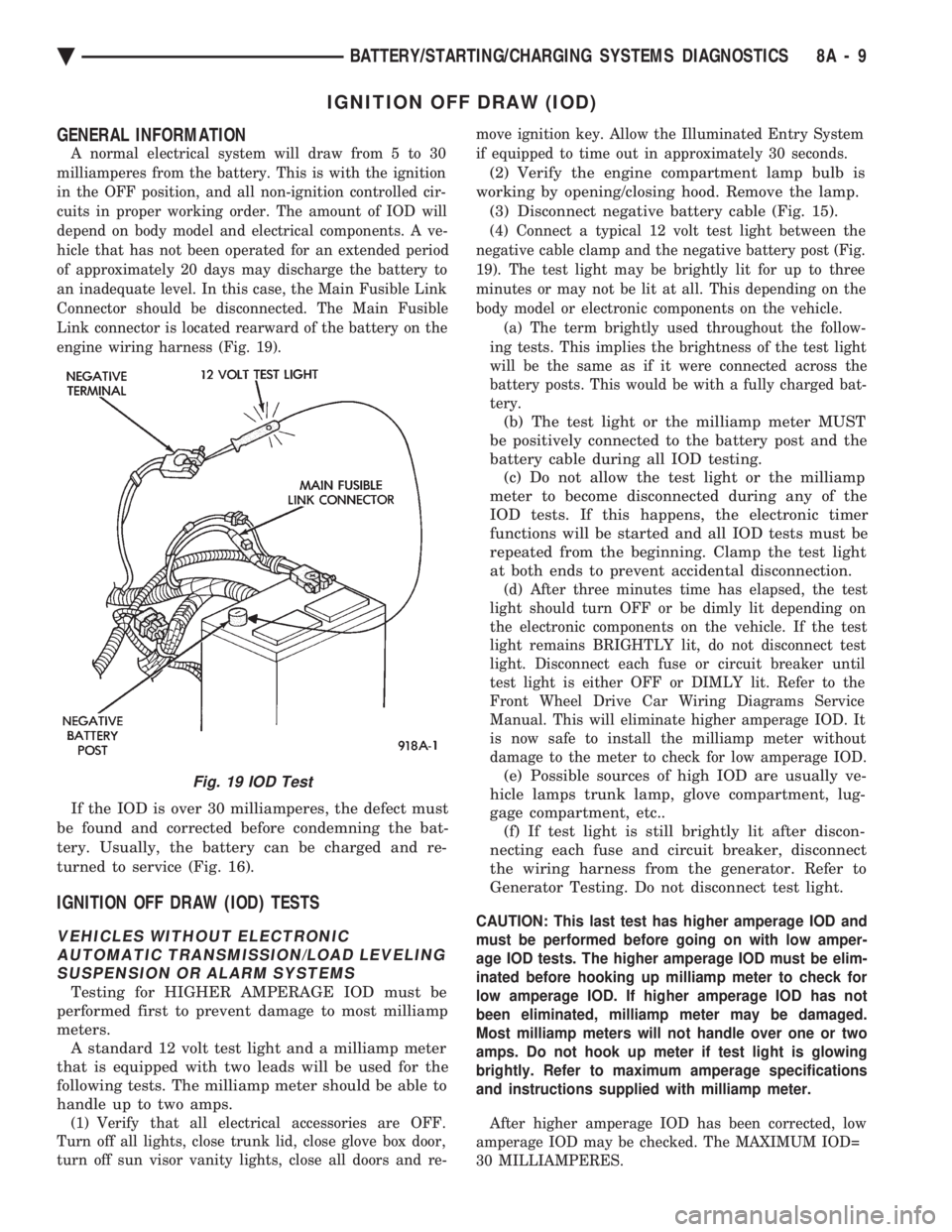

IGNITION OFF DRAW (IOD)

GENERAL INFORMATION

A normal electrical system will draw from 5 to 30

milliamperes from the battery. This is with the ignition

in the OFF position, and all non-ignition controlled cir-

cuits in proper working order. The amount of IOD will

depend on body model and electrical components. A ve-

hicle that has not been operated for an extended period

of approximately 20 days may discharge the battery to

an inadequate level. In this case, the Main Fusible Link

Connector should be disconnected. The Main Fusible

Link connector is located rearward of the battery on the

engine wiring harness (Fig. 19).

If the IOD is over 30 milliamperes, the defect must

be found and corrected before condemning the bat-

tery. Usually, the battery can be charged and re-

turned to service (Fig. 16).

IGNITION OFF DRAW (IOD) TESTS

VEHICLES WITHOUT ELECTRONIC AUTOMATIC TRANSMISSION/LOAD LEVELINGSUSPENSION OR ALARM SYSTEMS

Testing for HIGHER AMPERAGE IOD must be

performed first to prevent damage to most milliamp

meters. A standard 12 volt test light and a milliamp meter

that is equipped with two leads will be used for the

following tests. The milliamp meter should be able to

handle up to two amps.

(1) Verify that all electrical accessories are OFF.

Turn off all lights, close trunk lid, close glove box door,

turn off sun visor vanity lights, close all doors and re- move ignition key. Allow the Illuminated Entry System

if equipped to time out in approximately 30 seconds.

(2) Verify the engine compartment lamp bulb is

working by opening/closing hood. Remove the lamp. (3) Disconnect negative battery cable (Fig. 15).

(4) Connect a typical 12 volt test light between the

negative cable clamp and the negative battery post (Fig.

19). The test light may be brightly lit for up to three

minutes or may not be lit at all. This depending on the

body model or electronic components on the vehicle. (a) The term brightly used throughout the follow-

ing tests. This implies the brightness of the test light

will be the same as if it were connected across the

battery posts. This would be with a fully charged bat-

tery.

(b) The test light or the milliamp meter MUST

be positively connected to the battery post and the

battery cable during all IOD testing. (c) Do not allow the test light or the milliamp

meter to become disconnected during any of the

IOD tests. If this happens, the electronic timer

functions will be started and all IOD tests must be

repeated from the beginning. Clamp the test light

at both ends to prevent accidental disconnection.

(d) After three minutes time has elapsed, the test

light should turn OFF or be dimly lit depending on

the electronic components on the vehicle. If the test

light remains BRIGHTLY lit, do not disconnect test

light. Disconnect each fuse or circuit breaker until

test light is either OFF or DIMLY lit. Refer to the

Front Wheel Drive Car Wiring Diagrams Service

Manual. This will eliminate higher amperage IOD. It

is now safe to install the milliamp meter without

damage to the meter to check for low amperage IOD.

(e) Possible sources of high IOD are usually ve-

hicle lamps trunk lamp, glove compartment, lug-

gage compartment, etc.. (f) If test light is still brightly lit after discon-

necting each fuse and circuit breaker, disconnect

the wiring harness from the generator. Refer to

Generator Testing. Do not disconnect test light.

CAUTION: This last test has higher amperage IOD and

must be performed before going on with low amper-

age IOD tests. The higher amperage IOD must be elim-

inated before hooking up milliamp meter to check for

low amperage IOD. If higher amperage IOD has not

been eliminated, milliamp meter may be damaged.

Most milliamp meters will not handle over one or two

amps. Do not hook up meter if test light is glowing

brightly. Refer to maximum amperage specifications

and instructions supplied with milliamp meter.

After higher amperage IOD has been corrected, low

amperage IOD may be checked. The MAXIMUM IOD=

30 MILLIAMPERES.

Fig. 19 IOD Test

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 9