fuse box CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 561 of 2438

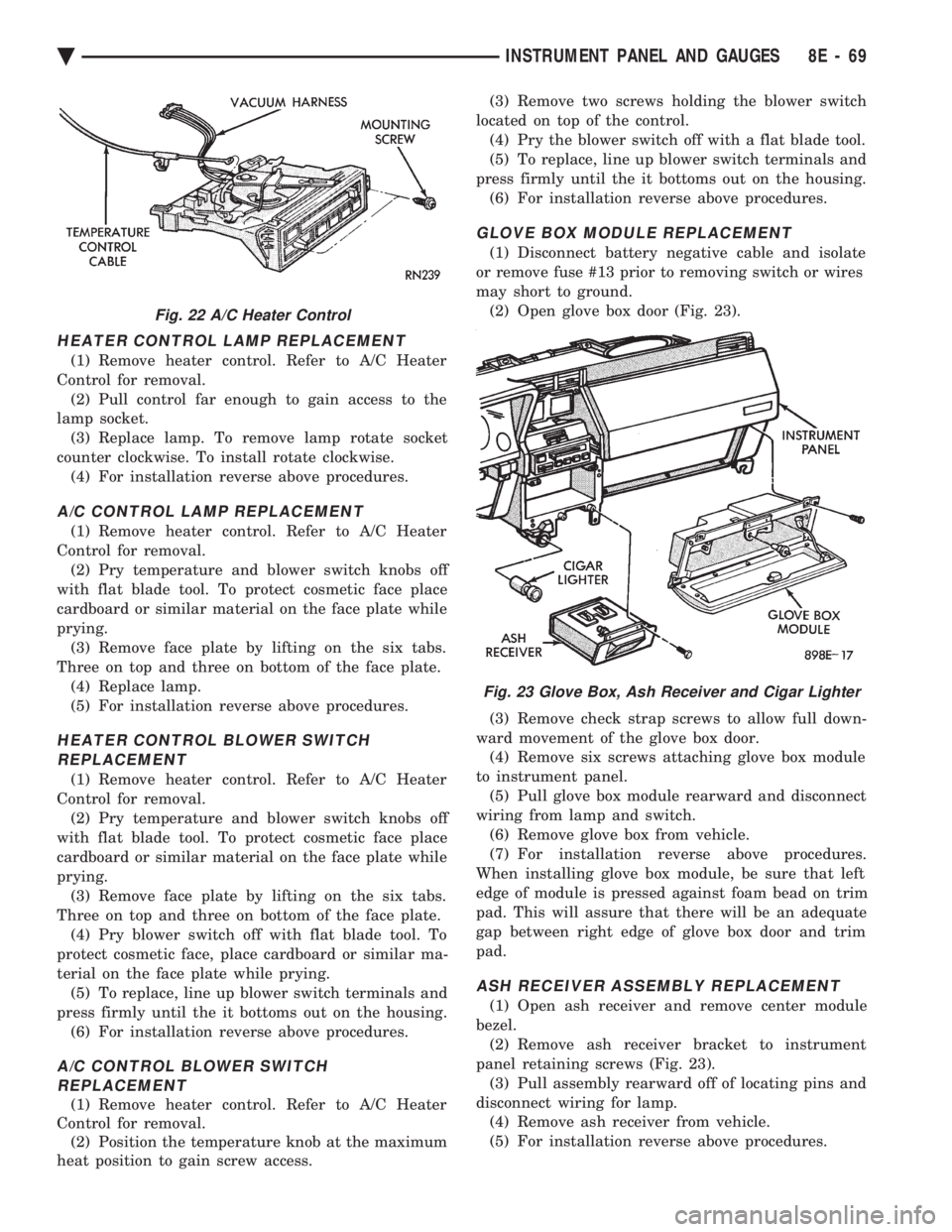

HEATER CONTROL LAMP REPLACEMENT

(1) Remove heater control. Refer to A/C Heater

Control for removal. (2) Pull control far enough to gain access to the

lamp socket. (3) Replace lamp. To remove lamp rotate socket

counter clockwise. To install rotate clockwise. (4) For installation reverse above procedures.

A/C CONTROL LAMP REPLACEMENT

(1) Remove heater control. Refer to A/C Heater

Control for removal. (2) Pry temperature and blower switch knobs off

with flat blade tool. To protect cosmetic face place

cardboard or similar material on the face plate while

prying. (3) Remove face plate by lifting on the six tabs.

Three on top and three on bottom of the face plate. (4) Replace lamp.

(5) For installation reverse above procedures.

HEATER CONTROL BLOWER SWITCHREPLACEMENT

(1) Remove heater control. Refer to A/C Heater

Control for removal. (2) Pry temperature and blower switch knobs off

with flat blade tool. To protect cosmetic face place

cardboard or similar material on the face plate while

prying. (3) Remove face plate by lifting on the six tabs.

Three on top and three on bottom of the face plate. (4) Pry blower switch off with flat blade tool. To

protect cosmetic face, place cardboard or similar ma-

terial on the face plate while prying. (5) To replace, line up blower switch terminals and

press firmly until the it bottoms out on the housing. (6) For installation reverse above procedures.

A/C CONTROL BLOWER SWITCHREPLACEMENT

(1) Remove heater control. Refer to A/C Heater

Control for removal. (2) Position the temperature knob at the maximum

heat position to gain screw access. (3) Remove two screws holding the blower switch

located on top of the control. (4) Pry the blower switch off with a flat blade tool.

(5) To replace, line up blower switch terminals and

press firmly until the it bottoms out on the housing. (6) For installation reverse above procedures.

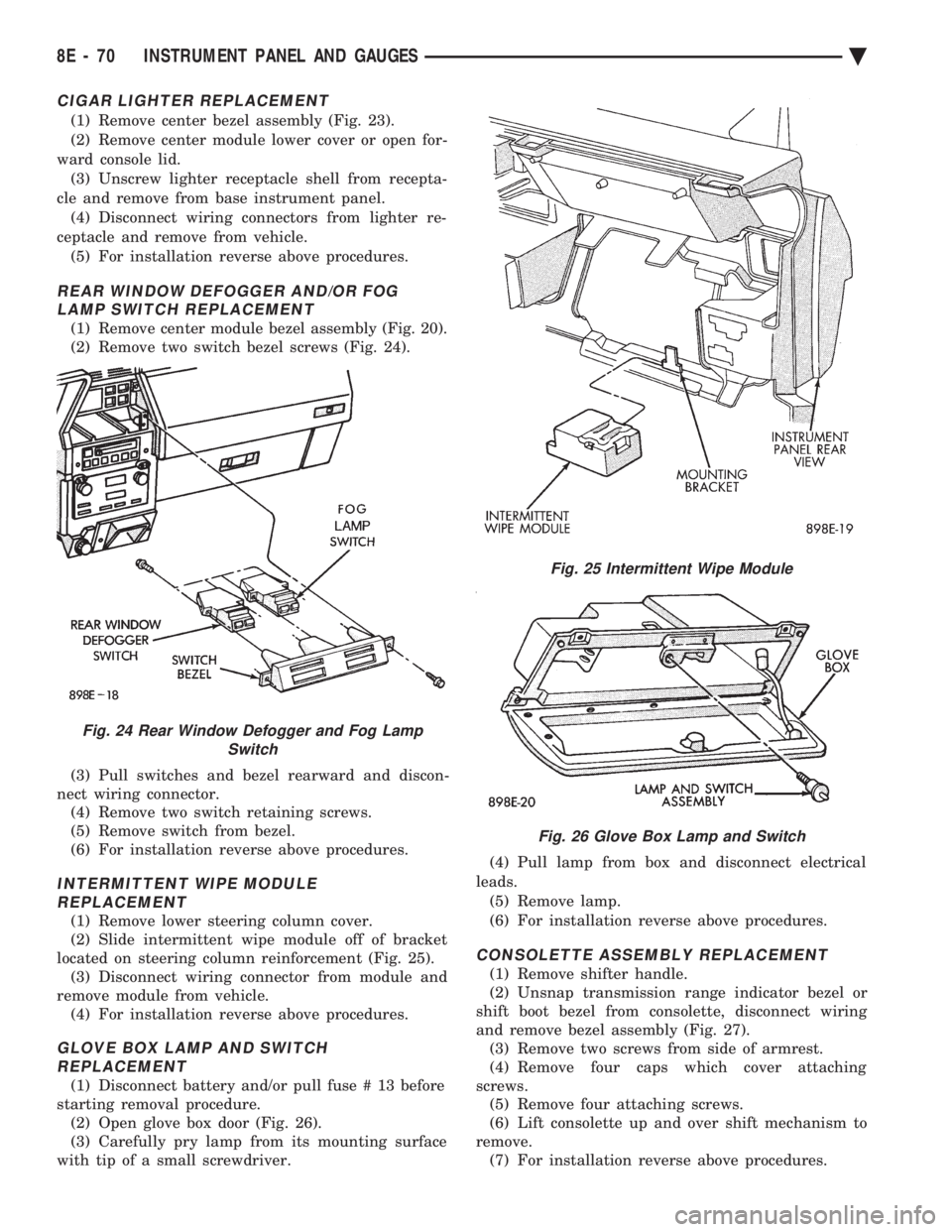

GLOVE BOX MODULE REPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #13 prior to removing switch or wires

may short to ground. (2) Open glove box door (Fig. 23).

(3) Remove check strap screws to allow full down-

ward movement of the glove box door. (4) Remove six screws attaching glove box module

to instrument panel. (5) Pull glove box module rearward and disconnect

wiring from lamp and switch. (6) Remove glove box from vehicle.

(7) For installation reverse above procedures.

When installing glove box module, be sure that left

edge of module is pressed against foam bead on trim

pad. This will assure that there will be an adequate

gap between right edge of glove box door and trim

pad.

ASH RECEIVER ASSEMBLY REPLACEMENT

(1) Open ash receiver and remove center module

bezel. (2) Remove ash receiver bracket to instrument

panel retaining screws (Fig. 23). (3) Pull assembly rearward off of locating pins and

disconnect wiring for lamp. (4) Remove ash receiver from vehicle.

(5) For installation reverse above procedures.

Fig. 22 A/C Heater Control

Fig. 23 Glove Box, Ash Receiver and Cigar Lighter

Ä INSTRUMENT PANEL AND GAUGES 8E - 69

Page 562 of 2438

CIGAR LIGHTER REPLACEMENT

(1) Remove center bezel assembly (Fig. 23).

(2) Remove center module lower cover or open for-

ward console lid. (3) Unscrew lighter receptacle shell from recepta-

cle and remove from base instrument panel. (4) Disconnect wiring connectors from lighter re-

ceptacle and remove from vehicle. (5) For installation reverse above procedures.

REAR WINDOW DEFOGGER AND/OR FOG LAMP SWITCH REPLACEMENT

(1) Remove center module bezel assembly (Fig. 20).

(2) Remove two switch bezel screws (Fig. 24).

(3) Pull switches and bezel rearward and discon-

nect wiring connector. (4) Remove two switch retaining screws.

(5) Remove switch from bezel.

(6) For installation reverse above procedures.

INTERMITTENT WIPE MODULE REPLACEMENT

(1) Remove lower steering column cover.

(2) Slide intermittent wipe module off of bracket

located on steering column reinforcement (Fig. 25). (3) Disconnect wiring connector from module and

remove module from vehicle. (4) For installation reverse above procedures.

GLOVE BOX LAMP AND SWITCHREPLACEMENT

(1) Disconnect battery and/or pull fuse # 13 before

starting removal procedure. (2) Open glove box door (Fig. 26).

(3) Carefully pry lamp from its mounting surface

with tip of a small screwdriver. (4) Pull lamp from box and disconnect electrical

leads. (5) Remove lamp.

(6) For installation reverse above procedures.

CONSOLETTE ASSEMBLY REPLACEMENT

(1) Remove shifter handle.

(2) Unsnap transmission range indicator bezel or

shift boot bezel from consolette, disconnect wiring

and remove bezel assembly (Fig. 27). (3) Remove two screws from side of armrest.

(4) Remove four caps which cover attaching

screws. (5) Remove four attaching screws.

(6) Lift consolette up and over shift mechanism to

remove. (7) For installation reverse above procedures.

Fig. 24 Rear Window Defogger and Fog Lamp Switch

Fig. 25 Intermittent Wipe Module

Fig. 26 Glove Box Lamp and Switch

8E - 70 INSTRUMENT PANEL AND GAUGES Ä

Page 595 of 2438

² If no short to ground at connector, check speaker

resistance at amplifier connector for an reading of

three to five ohms.

² If resistance is OK, refer to Radio Diagnosis. If ra-

dio checks OK, replace amplifier.

² If resistance is less than three ohms check

speaker. Check across the speaker connector if less

than three ohms replace speaker. If resistance is OK

repair wires

CONDITION: MECHANICAL NOISE DISTORTION

² Check trim for loose parts and speaker attach-

ments for buzzes

² Remove speaker still connected and listen for dis-

tortion. Distortion replace speaker.

CONDITION: ONE SPEAKER NON-OPERATIVE

² Remove output signal connector from amplifier

and check for three to five ohms resistance to the

non-operative speaker. Refer to Fig. 34 for the appro-

priate pin numbers.

² If resistance is less than three ohms, test speaker

for resistance.

² If OK repair wire. If not replace speaker.

CONDITION: ALL SPEAKERS NON-OPERATIVE

²Check radio for being ON, are the display lights

on

² Radio not ON, refer to Radio Diagnosis

² Check Amplifier Connectors and wires for proper

connection

² Check pin 9 and pin 27 for battery voltage

² If voltage OK replace amplifier ²

If pin 27 has battery voltage and pin 9 has 0 volt-

age. Refer to Power Antenna Diagnosis and test volt-

age at antenna relay.

² If pin 9 has battery voltage and pin 27 has 0 volt-

age. Check pin 27 for short to ground.

² If shorted to ground repair wire

² If no short to ground check fuse cavity number 16

for blown fuse.

² If fuse blows again replace amplifier

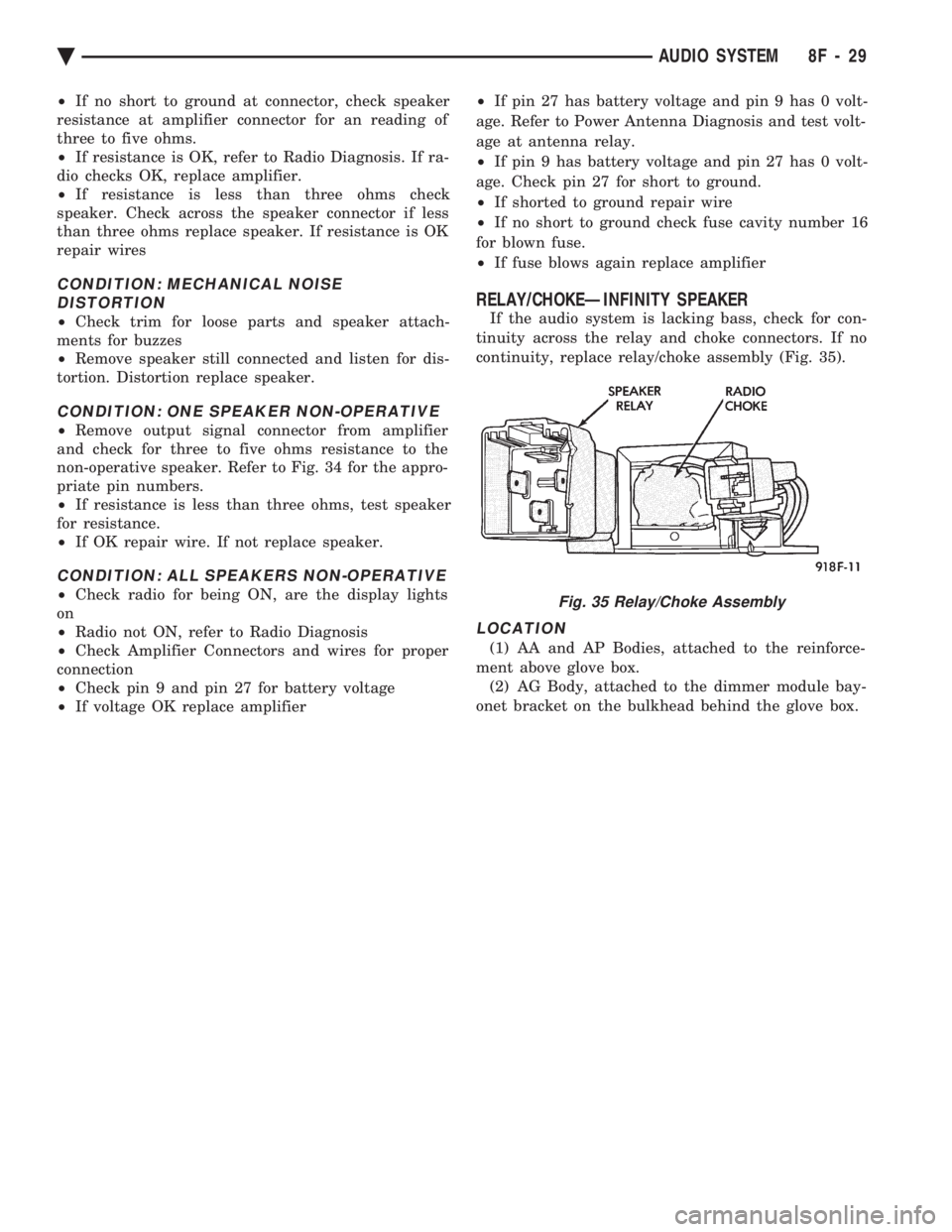

RELAY/CHOKEÐINFINITY SPEAKER

If the audio system is lacking bass, check for con-

tinuity across the relay and choke connectors. If no

continuity, replace relay/choke assembly (Fig. 35).

LOCATION

(1) AA and AP Bodies, attached to the reinforce-

ment above glove box. (2) AG Body, attached to the dimmer module bay-

onet bracket on the bulkhead behind the glove box.

Fig. 35 Relay/Choke Assembly

Ä AUDIO SYSTEM 8F - 29

Page 597 of 2438

HORNS

CONTENTS

page page

GENERAL INFORMATION .................. 1

HORN SWITCH REPLACEMENT ............ 3 TESTING HORN SYSTEM

................. 1

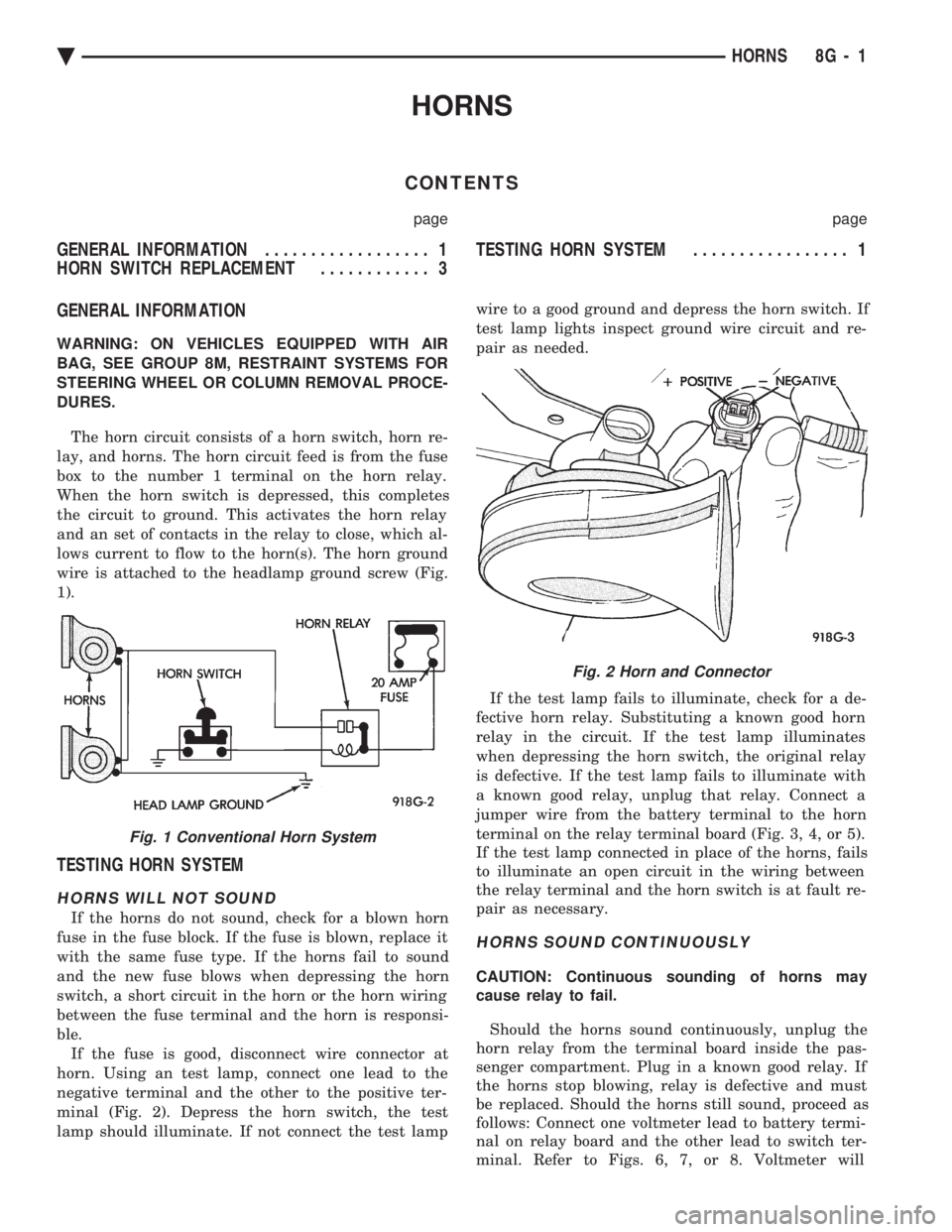

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The horn circuit consists of a horn switch, horn re-

lay, and horns. The horn circuit feed is from the fuse

box to the number 1 terminal on the horn relay.

When the horn switch is depressed, this completes

the circuit to ground. This activates the horn relay

and an set of contacts in the relay to close, which al-

lows current to flow to the horn(s). The horn ground

wire is attached to the headlamp ground screw (Fig.

1).

TESTING HORN SYSTEM

HORNS WILL NOT SOUND

If the horns do not sound, check for a blown horn

fuse in the fuse block. If the fuse is blown, replace it

with the same fuse type. If the horns fail to sound

and the new fuse blows when depressing the horn

switch, a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble. If the fuse is good, disconnect wire connector at

horn. Using an test lamp, connect one lead to the

negative terminal and the other to the positive ter-

minal (Fig. 2). Depress the horn switch, the test

lamp should illuminate. If not connect the test lamp wire to a good ground and depress the horn switch. If

test lamp lights inspect ground wire circuit and re-

pair as needed.

If the test lamp fails to illuminate, check for a de-

fective horn relay. Substituting a known good horn

relay in the circuit. If the test lamp illuminates

when depressing the horn switch, the original relay

is defective. If the test lamp fails to illuminate with

a known good relay, unplug that relay. Connect a

jumper wire from the battery terminal to the horn

terminal on the relay terminal board (Fig. 3, 4, or 5).

If the test lamp connected in place of the horns, fails

to illuminate an open circuit in the wiring between

the relay terminal and the horn switch is at fault re-

pair as necessary.

HORNS SOUND CONTINUOUSLY

CAUTION: Continuous sounding of horns may

cause relay to fail.

Should the horns sound continuously, unplug the

horn relay from the terminal board inside the pas-

senger compartment. Plug in a known good relay. If

the horns stop blowing, relay is defective and must

be replaced. Should the horns still sound, proceed as

follows: Connect one voltmeter lead to battery termi-

nal on relay board and the other lead to switch ter-

minal. Refer to Figs. 6, 7, or 8. Voltmeter will

Fig. 1 Conventional Horn System

Fig. 2 Horn and Connector

Ä HORNS 8G - 1

Page 700 of 2438

(1) Be sure that the module has a battery feed

from the 20 Amp breaker in cavity 1 of the black

connector. Also affected would be the optical horn

and the stop lamps. (2) Be sure that the module has an ignition feed

from 5 Amp fuse in cavity 8 of the black connector.

Also affected would be the body computer, instru-

ment cluster and message center. (3) Be sure that the module has a ground from the

right side cowl behind the body computer to the cav-

ity 5 of the black connector. (4) Be sure that you are supplying a good ground

to the programming wire. (5) If the above circuits are good, replace the Re-

ceiver Module. CONDITION: Doors can be locked or unlocked with

the Keyless Entry transmitter. But the doors will not

lock. The Vehicle Theft Alarm system will not arm,

when using only the power door LOCK switch in the

driver's door. (1) Be sure you have not left key in the ignition

column lock cylinder. (2) If step 1 is OK, check the Key in Lock switch

circuit in the steering column for a short to ground. (3) In this problem the body computer controls the

LOCK function. Be sure that it is providing a battery

voltage output to the door lock relay. The door lock

relay controls the door lock motors. CONDITION: Doors will lock but Vehicle Theft

System will not arm when using the transmitter. (1) The Keyless Entry Receiver Module controls

the door lock signal to the door lock relay. The door

lock relay controls the door lock motors. Check for

battery voltage at cavity 10 of the Theft Alarm mod-

ule from the Receiver module. (2) If voltage is OK, replace Receiver module.

CONDITION: All doors except driver's door will

lock with the transmitter. (1) Test the driver's door output of the Receiver

Module for a ground. (2) If there is no ground at the pin, replace the Re-

ceiver module. (3) If there is a ground at the output, replace the

door lock motor. CONDITION: Only driver's door will lock with the

transmitter.

² Repair ground circuit to unlock relay

² Replace unlock relay

CONDITION: Doors do not lock with the transmit-

ter, but still get horn CHIRP that indicates that they

did lock. Replace Receiver module. CONDITION: Doors will lock with the transmitter

but there is no horn CHIRP. (1) Press horn button, listen horn sound.

(2) If the horn sounded, change horn relay. (3) Still no CHIRP, check continuity between the

horn relay and the receiver output pin. Repair as

necessary. (4) Still no horn CHIRP, replace the receiver mod-

ule. (5) If using a DRB II, refer to Body Diagnostic Pro-

cedures.

REMOTE KEYLESS MODULE REPLACEMENT

(1) Remove lower right instrument panel silencer.

(2) Remove glove box assembly.

(3) Remove three screws attaching the mounting

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connector. (5) Remove two screws attaching the Remote Key-

less entry Module to bracket. (6) Remove two screws attaching the security mod-

ule to bracket. (7) To installation reverse above procedures.

LAMP OUTAGE MODULE REPLACEMENT

(1) Remove lower right instrument panel silencer.

(2) Remove glove box and ash receiver module.

(3) Remove three screws attaching the mounting

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connectors. (5) Remove two screws attaching the Lamp Outage

Module to bracket. (6) Remove two screws attaching the security mod-

ule to bracket. (7) To installation reverse above procedures.

DOOR LOCK INHIBIT

The power door lock inhibit system prevents the

doors from being locked using the power door locks

when either of two conditions occur: (1) The key is in the ignition switch and any of the

doors are open. The ignition switch does not have to

be ON. (2) The key is in the ignition switch and the head-

lamp are on.

AC, AG, AJ AND AY BODIES

With the ignition switch in the ON or OFF position

and the driver's door open the Body Controller will

ignore the command to lock the power door locks.

Once the key is removed, or the driver's door is

closed, the Body Controller will allow the power door

locks to lock. Refer to Body Diagnostic Procedure

Manual for further testing procedures.

8P - 6 POWER LOCKS Ä

Page 702 of 2438

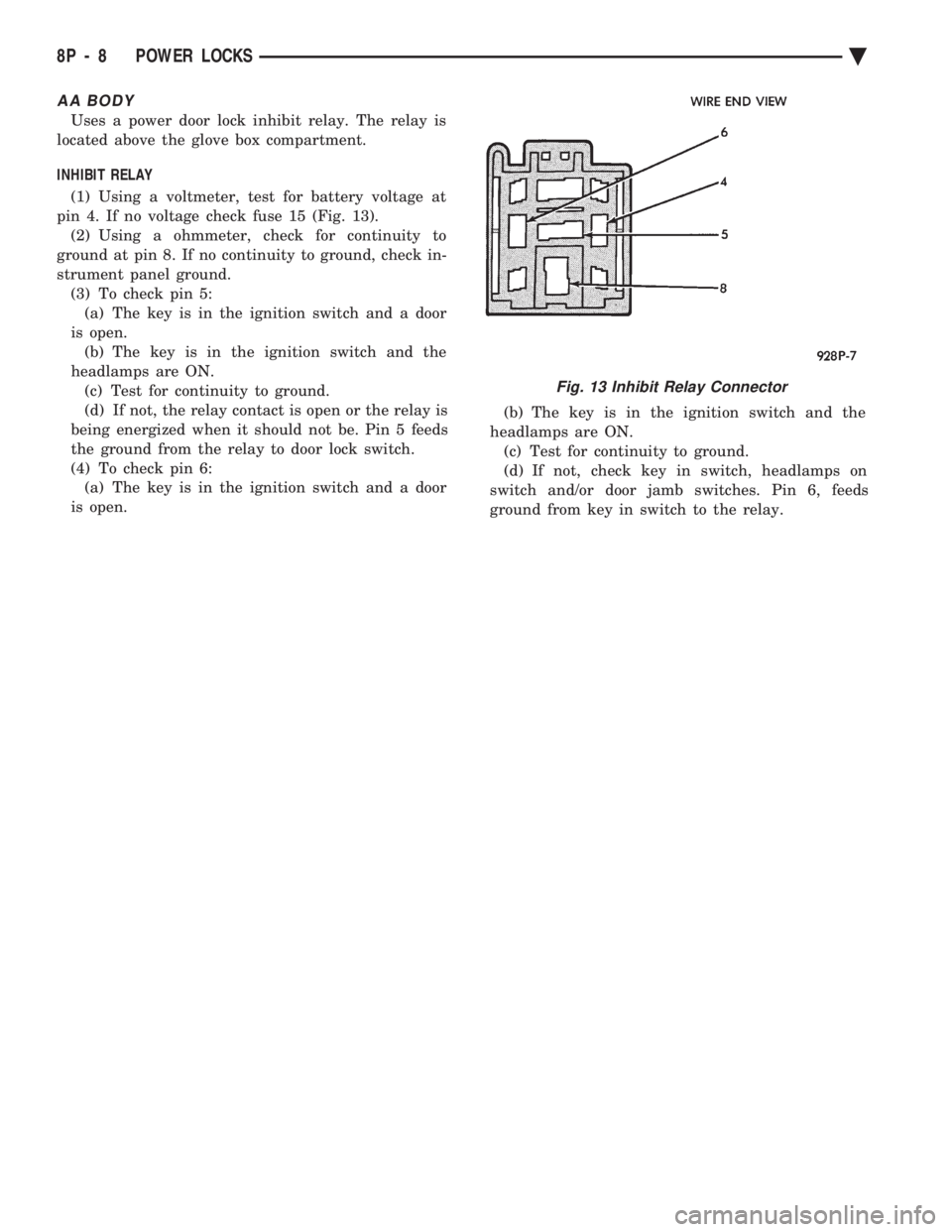

AA BODY

Uses a power door lock inhibit relay. The relay is

located above the glove box compartment.

INHIBIT RELAY

(1) Using a voltmeter, test for battery voltage at

pin 4. If no voltage check fuse 15 (Fig. 13). (2) Using a ohmmeter, check for continuity to

ground at pin 8. If no continuity to ground, check in-

strument panel ground. (3) To check pin 5:(a) The key is in the ignition switch and a door

is open. (b) The key is in the ignition switch and the

headlamps are ON. (c) Test for continuity to ground.

(d) If not, the relay contact is open or the relay is

being energized when it should not be. Pin 5 feeds

the ground from the relay to door lock switch.

(4) To check pin 6: (a) The key is in the ignition switch and a door

is open. (b) The key is in the ignition switch and the

headlamps are ON. (c) Test for continuity to ground.

(d) If not, check key in switch, headlamps on

switch and/or door jamb switches. Pin 6, feeds

ground from key in switch to the relay.

Fig. 13 Inhibit Relay Connector

8P - 8 POWER LOCKS Ä

Page 707 of 2438

POWER SEATS

CONTENTS

page page

ADJUSTER ............................. 3

CIRCUIT BREAKER TEST .................. 1

ENTHUSIAST SEAT ....................... 4

GENERAL INFORMATION .................. 1

HARNESS VOLTAGE TEST ................. 1

HORIZONTAL AND VERTICAL TRANSMISSIONS ....................... 3

MEMORY CONTROL MODULE REPLACEMENT ....................... 19

MOTOR ................................ 3

MOTOR TESTS .......................... 1

POWER MEMORY SEAT, RECLINER AND MIRRORS ............................. 5 POWER MEMORY SEAT, RECLINER AND

MIRRORS DIAGNOSIS ................... 9

POWER RECLINER MECHANISM ........... 18

POWER RECLINER MOTOR AND CABLE ..... 17

RECLINER SWITCH REPLACEMENT ......... 19

RECLINER SWITCH TEST ................. 19

SEAT ASSEMBLY ........................ 3

SWITCH REPLACEMENT REMOVAL .......... 5

SWITCH TEST ........................... 5

SWITCH TEST ........................... 3

TEST PROCEDURES ...................... 6

TEST PROCEDURES ...................... 1

GENERAL INFORMATION

Power seats can be adjusted in six different direc-

tions up, down, forward, back, tilt forward, or tilt

rearward. A three armature permanent magnet reversible mo-

tor is coupled through cables to worm gear box assem-

blies located in the seat tracks, providing the various

seat movements. The electrical circuit is protected by a 30 amp circuit

breaker located on the fuse block.

TEST PROCEDURES

Before any testing is attempted the battery should be

carefully charged and all connections and terminals

cleaned and tightened to insure proper continuity and

grounds. With dome lamp on, apply switch in direction of

failure. If dome lamp dims the seat motor is trying to

work indicating mechanical jamming. If dome lamp

does not dim, then proceed with the following electrical

tests.

CIRCUIT BREAKER TEST

Find correct circuit breaker on fuse block. Pull out

slightly but be sure that circuit breaker terminals still

contact terminals in fuse block. Connect ground wire of

voltmeter to a good ground. With probe of voltmeter

positive wire, check both terminals of circuit breaker

for battery voltage. If only one terminal checks at

battery voltage, circuit breaker is defective and must

be replaced. If neither terminal shows battery voltage,

check for open or shorted circuit to circuit breaker.

HARNESS VOLTAGE TEST

The following test will determine whether or not

voltage is continuous through the body harness to the

switch. (1) Remove power seat switch from mounting posi-

tion and disconnect switch from wiring harness. (2) Connect one lead of test light to ground terminal,

black wire (BK) of center section, and touch other test

light lead to red wire (RD) terminal. (3) If test light comes on, harness to switch is good.

If test light does not come on, perform circuit breaker

test.

MOTOR TESTS

AA BODY

(1) Remove switch from mounting position and dis-

connect from harness. (2) To check the center motor, connect a jumper wire

between pin 5 and pin 3 (Fig. 1). Connect a second

jumper wire between pin 7 and pin 4 If motor does not

operate, reverse the jumpers, pin 5 to pin 4 and pin 7 to

pin 3. If motor still does not operate check wiring

between switch connector and motor assembly. If wir-

ing checks good replace motor assembly. (3) To check the front motor, connect a jumper wire

between pin 5 and pin 1 (Fig. 1). Connect a second

jumper wire between pin 7 and pin 8. If motor does not

operate, reverse the jumpers, pin 5 to pin 8 and pin 7 to

pin 1. If motor still does not operate check wiring

between switch connector and motor assembly. If wir-

ing checks good replace motor assembly.

(4) To check the rear motor, connect a covered jumper

wire between pin 5 and pin 6 (Fig. 1). Connect a second

Ä POWER SEATS 8R - 1

Page 753 of 2438

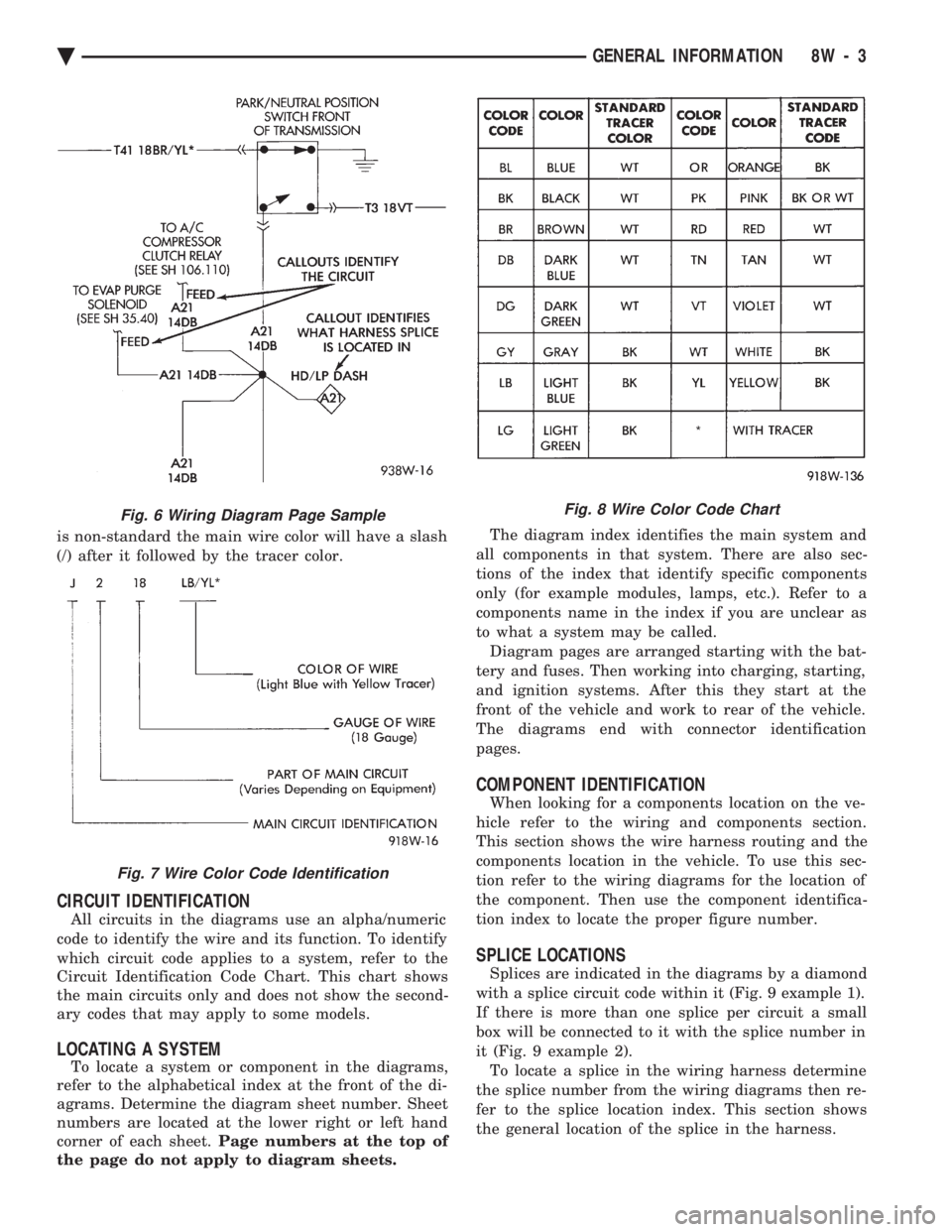

is non-standard the main wire color will have a slash

(/) after it followed by the tracer color.

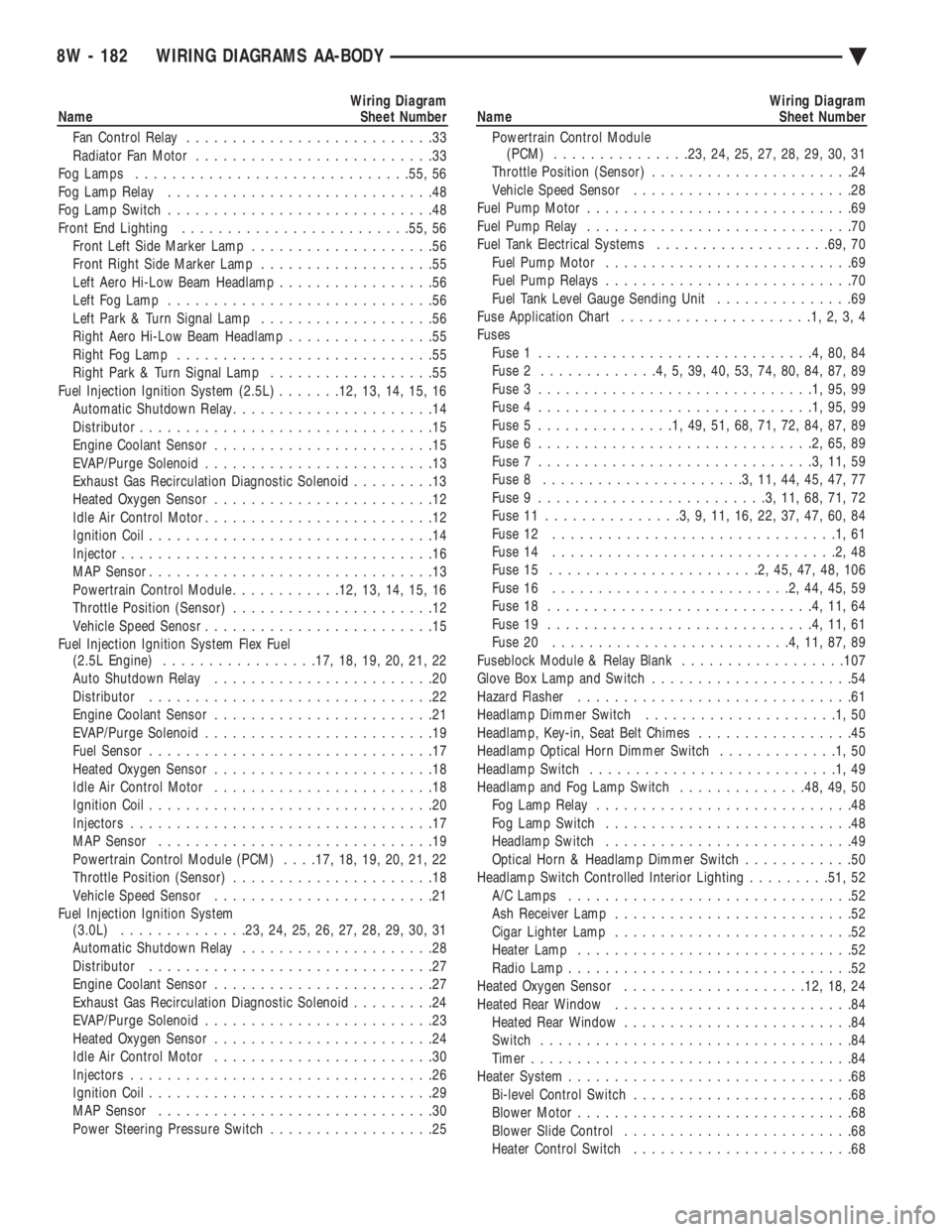

CIRCUIT IDENTIFICATION

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

LOCATING A SYSTEM

To locate a system or component in the diagrams,

refer to the alphabetical index at the front of the di-

agrams. Determine the diagram sheet number. Sheet

numbers are located at the lower right or left hand

corner of each sheet. Page numbers at the top of

the page do not apply to diagram sheets. The diagram index identifies the main system and

all components in that system. There are also sec-

tions of the index that identify specific components

only (for example modules, lamps, etc.). Refer to a

components name in the index if you are unclear as

to what a system may be called. Diagram pages are arranged starting with the bat-

tery and fuses. Then working into charging, starting,

and ignition systems. After this they start at the

front of the vehicle and work to rear of the vehicle.

The diagrams end with connector identification

pages.

COMPONENT IDENTIFICATION

When looking for a components location on the ve-

hicle refer to the wiring and components section.

This section shows the wire harness routing and the

components location in the vehicle. To use this sec-

tion refer to the wiring diagrams for the location of

the component. Then use the component identifica-

tion index to locate the proper figure number.

SPLICE LOCATIONS

Splices are indicated in the diagrams by a diamond

with a splice circuit code within it (Fig. 9 example 1).

If there is more than one splice per circuit a small

box will be connected to it with the splice number in

it (Fig. 9 example 2). To locate a splice in the wiring harness determine

the splice number from the wiring diagrams then re-

fer to the splice location index. This section shows

the general location of the splice in the harness.

Fig. 6 Wiring Diagram Page Sample

Fig. 7 Wire Color Code Identification

Fig. 8 Wire Color Code Chart

Ä GENERAL INFORMATION 8W - 3

Page 932 of 2438

Wiring Diagram

Name Sheet Number

Fan Control Relay ...........................33

Radiator Fan Motor ..........................33

Fog Lamps ............................. .55, 56

Fog Lamp Relay .............................48

Fog Lamp Switch .............................48

Front End Lighting ........................ .55, 56

Front Left Side Marker Lamp ....................56

Front Right Side Marker Lamp ...................55

Left Aero Hi-Low Beam Headlamp .................56

Left Fog Lamp .............................56

Left Park & Turn Signal Lamp ...................56

Right Aero Hi-Low Beam Headlamp ................55

Right Fog Lamp ............................55

Right Park & Turn Signal Lamp ..................55

Fuel Injection Ignition System (2.5L) .......12, 13, 14, 15, 16

Automatic Shutdown Relay ......................14

Distributor ................................15

Engine Coolant Sensor ........................15

EVAP/Purge Solenoid .........................13

Exhaust Gas Recirculation Diagnostic Solenoid .........13

Heated Oxygen Sensor ........................12

Idle Air Control Motor .........................12

Ignition Coil ...............................14

Injector ..................................16

MAP Sensor ...............................13

Powertrain Control Module ............12, 13, 14, 15, 16

Throttle Position (Sensor) ......................12

Vehicle Speed Senosr .........................15

Fuel Injection Ignition System Flex Fuel (2.5L Engine) ................ .17, 18, 19, 20, 21, 22

Auto Shutdown Relay ........................20

Distributor ...............................22

Engine Coolant Sensor ........................21

EVAP/Purge Solenoid .........................19

Fuel Sensor ...............................17

Heated Oxygen Sensor ........................18

Idle Air Control Motor ........................18

Ignition Coil ...............................20

Injectors .................................17

MAP Sensor ..............................19

Powertrain Control Module (PCM) . . . .17, 18, 19, 20, 21, 22

Throttle Position (Sensor) ......................18

Vehicle Speed Sensor ........................21

Fuel Injection Ignition System (3.0L) ............. .23, 24, 25, 26, 27, 28, 29, 30, 31

Automatic Shutdown Relay .....................28

Distributor ...............................27

Engine Coolant Sensor ........................27

Exhaust Gas Recirculation Diagnostic Solenoid .........24

EVAP/Purge Solenoid .........................23

Heated Oxygen Sensor ........................24

Idle Air Control Motor ........................30

Injectors .................................26

Ignition Coil ...............................29

MAP Sensor ..............................30

Power Steering Pressure Switch ..................25Wiring Diagram

Name Sheet Number

Powertrain Control Module (PCM) .............. .23, 24, 25, 27, 28, 29, 30, 31

Throttle Position (Sensor) ......................24

Vehicle Speed Sensor ........................28

Fuel Pump Motor .............................69

Fuel Pump Relay .............................70

Fuel Tank Electrical Systems ...................69, 70

Fuel Pump Motor ...........................69

Fuel Pump Relays ...........................70

Fuel Tank Level Gauge Sending Unit ...............69

Fuse Application Chart .....................1,2,3,4

Fuses Fuse 1 ..............................4,80,84

Fuse 2 .............4,5,39,40,53,74,80,84,87,89

Fuse 3 ..............................1,95,99

Fuse 4 ..............................1,95,99

Fuse 5 ...............1,49,51,68,71,72,84,87,89

Fuse 6 ..............................2,65,89

Fuse 7 ..............................3,11,59

Fuse 8 ......................3,11,44,45,47,77

Fuse 9 .........................3,11,68,71,72

Fuse 11 ...............3,9,11,16,22,37,47,60,84

Fuse 12 ...............................1,61

Fuse 14 ...............................2,48

Fuse 15 .......................2,45,47,48,106

Fuse 16 ..........................2,44,45,59

Fuse 18 .............................4,11,64

Fuse 19 .............................4,11,61

Fuse 20 ..........................4,11,87,89

Fuseblock Module & Relay Blank ..................107

Glove Box Lamp and Switch ......................54

Hazard Flasher ..............................61

Headlamp Dimmer Switch .....................1,50

Headlamp, Key-in, Seat Belt Chimes .................45

Headlamp Optical Horn Dimmer Switch .............1,50

Headlamp Switch ...........................1,49

Headlamp and Fog Lamp Switch ..............48, 49, 50

Fog Lamp Relay ............................48

Fog Lamp Switch ...........................48

Headlamp Switch ...........................49

Optical Horn & Headlamp Dimmer Switch ............50

Headlamp Switch Controlled Interior Lighting .........51, 52

A/C Lamps ...............................52

Ash Receiver Lamp ..........................52

Cigar Lighter Lamp ..........................52

Heater Lamp ..............................52

Radio Lamp ...............................52

Heated Oxygen Sensor ................... .12, 18, 24

Heated Rear Window ..........................84

Heated Rear Window .........................84

Switch ..................................84

Timer ...................................84

Heater System ...............................68

Bi-level Control Switch ........................68

Blower Motor ..............................68

Blower Slide Control .........................68

Heater Control Switch ........................68

8W - 182 WIRING DIAGRAMS AA-BODY Ä

Page 1066 of 2438

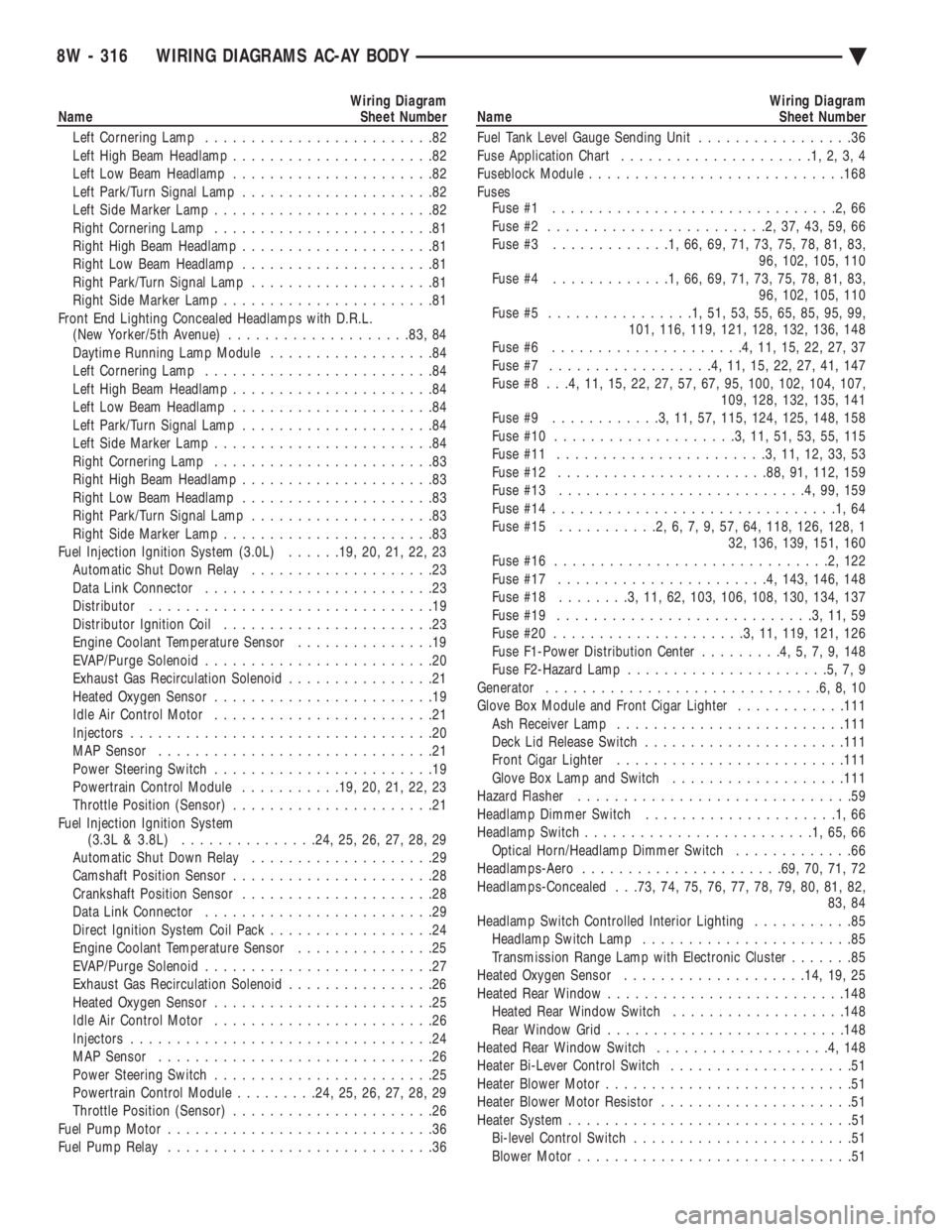

Wiring Diagram

Name Sheet Number

Left Cornering Lamp .........................82

Left High Beam Headlamp ......................82

Left Low Beam Headlamp ......................82

Left Park/Turn Signal Lamp .....................82

Left Side Marker Lamp ........................82

Right Cornering Lamp ........................81

Right High Beam Headlamp .....................81

Right Low Beam Headlamp .....................81

Right Park/Turn Signal Lamp ....................81

Right Side Marker Lamp .......................81

Front End Lighting Concealed Headlamps with D.R.L. (New Yorker/5th Avenue) ................... .83, 84

Daytime Running Lamp Module ..................84

Left Cornering Lamp .........................84

Left High Beam Headlamp ......................84

Left Low Beam Headlamp ......................84

Left Park/Turn Signal Lamp .....................84

Left Side Marker Lamp ........................84

Right Cornering Lamp ........................83

Right High Beam Headlamp .....................83

Right Low Beam Headlamp .....................83

Right Park/Turn Signal Lamp ....................83

Right Side Marker Lamp .......................83

Fuel Injection Ignition System (3.0L) ......19, 20, 21, 22, 23

Automatic Shut Down Relay ....................23

Data Link Connector .........................23

Distributor ...............................19

Distributor Ignition Coil .......................23

Engine Coolant Temperature Sensor ...............19

EVAP/Purge Solenoid .........................20

Exhaust Gas Recirculation Solenoid ................21

Heated Oxygen Sensor ........................19

Idle Air Control Motor ........................21

Injectors .................................20

MAP Sensor ..............................21

Power Steering Switch ........................19

Powertrain Control Module ...........19, 20, 21, 22, 23

Throttle Position (Sensor) ......................21

Fuel Injection Ignition System (3.3L & 3.8L) .............. .24, 25, 26, 27, 28, 29

Automatic Shut Down Relay ....................29

Camshaft Position Sensor ......................28

Crankshaft Position Sensor .....................28

Data Link Connector .........................29

Direct Ignition System Coil Pack ..................24

Engine Coolant Temperature Sensor ...............25

EVAP/Purge Solenoid .........................27

Exhaust Gas Recirculation Solenoid ................26

Heated Oxygen Sensor ........................25

Idle Air Control Motor ........................26

Injectors .................................24

MAP Sensor ..............................26

Power Steering Switch ........................25

Powertrain Control Module .........24, 25, 26, 27, 28, 29

Throttle Position (Sensor) ......................26

Fuel Pump Motor .............................36

Fuel Pump Relay .............................36Wiring Diagram

Name Sheet Number

Fuel Tank Level Gauge Sending Unit .................36

Fuse Application Chart .....................1,2,3,4

Fuseblock Module ........................... .168

Fuses Fuse #1 ...............................2,66

Fuse #2 ........................2,37,43,59,66

Fuse #3 .............1,66,69,71,73,75,78,81,83,

96, 102, 105, 110

Fuse #4 .............1,66,69,71,73,75,78,81,83,

96, 102, 105, 110

Fuse #5 ................1,51,53,55,65,85,95,99,

101, 116, 119, 121, 128, 132, 136, 148

Fuse #6 .....................4,11,15,22,27,37

Fuse #7 ..................4,11,15,22,27,41,147

Fuse #8 . . .4, 11, 15, 22, 27, 57, 67, 95, 100, 102, 104, 107, 109, 128, 132, 135, 141

Fuse #9 ............3,11,57, 115, 124, 125, 148, 158

Fuse #10 ....................3,11,51,53,55,115

Fuse #11 .......................3,11,12,33,53

Fuse #12 ...................... .88, 91, 112, 159

Fuse #13 ...........................4,99,159

Fuse #14 ...............................1,64

Fuse #15 ...........2,6,7,9,57,64, 118, 126, 128, 1

32, 136, 139, 151, 160

Fuse #16 ..............................2,122

Fuse #17 .......................4, 143, 146, 148

Fuse #18 ........3,11,62, 103, 106, 108, 130, 134, 137

Fuse #19 ............................3,11,59

Fuse #20 .....................3,11, 119, 121, 126

Fuse F1-Power Distribution Center .........4,5,7,9,148

Fuse F2-Hazard Lamp ......................5,7,9

Generator ..............................6,8,10

Glove Box Module and Front Cigar Lighter ............111

Ash Receiver Lamp ........................ .111

Deck Lid Release Switch ..................... .111

Front Cigar Lighter ........................ .111

Glove Box Lamp and Switch ...................111

Hazard Flasher ..............................59

Headlamp Dimmer Switch .....................1,66

Headlamp Switch .........................1,65,66

Optical Horn/Headlamp Dimmer Switch .............66

Headlamps-Aero ..................... .69, 70, 71, 72

Headlamps-Concealed . . .73, 74, 75, 76, 77, 78, 79, 80, 81, 82, 83, 84

Headlamp Switch Controlled Interior Lighting ...........85

Headlamp Switch Lamp .......................85

Transmission Range Lamp with Electronic Cluster .......85

Heated Oxygen Sensor ................... .14, 19, 25

Heated Rear Window ......................... .148

Heated Rear Window Switch ...................148

Rear Window Grid ......................... .148

Heated Rear Window Switch ...................4,148

Heater Bi-Lever Control Switch ....................51

Heater Blower Motor ...........................51

Heater Blower Motor Resistor .....................51

Heater System ...............................51

Bi-level Control Switch ........................51

Blower Motor ..............................51

8W - 316 WIRING DIAGRAMS AC-AY BODY Ä