gas type CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 587 of 2438

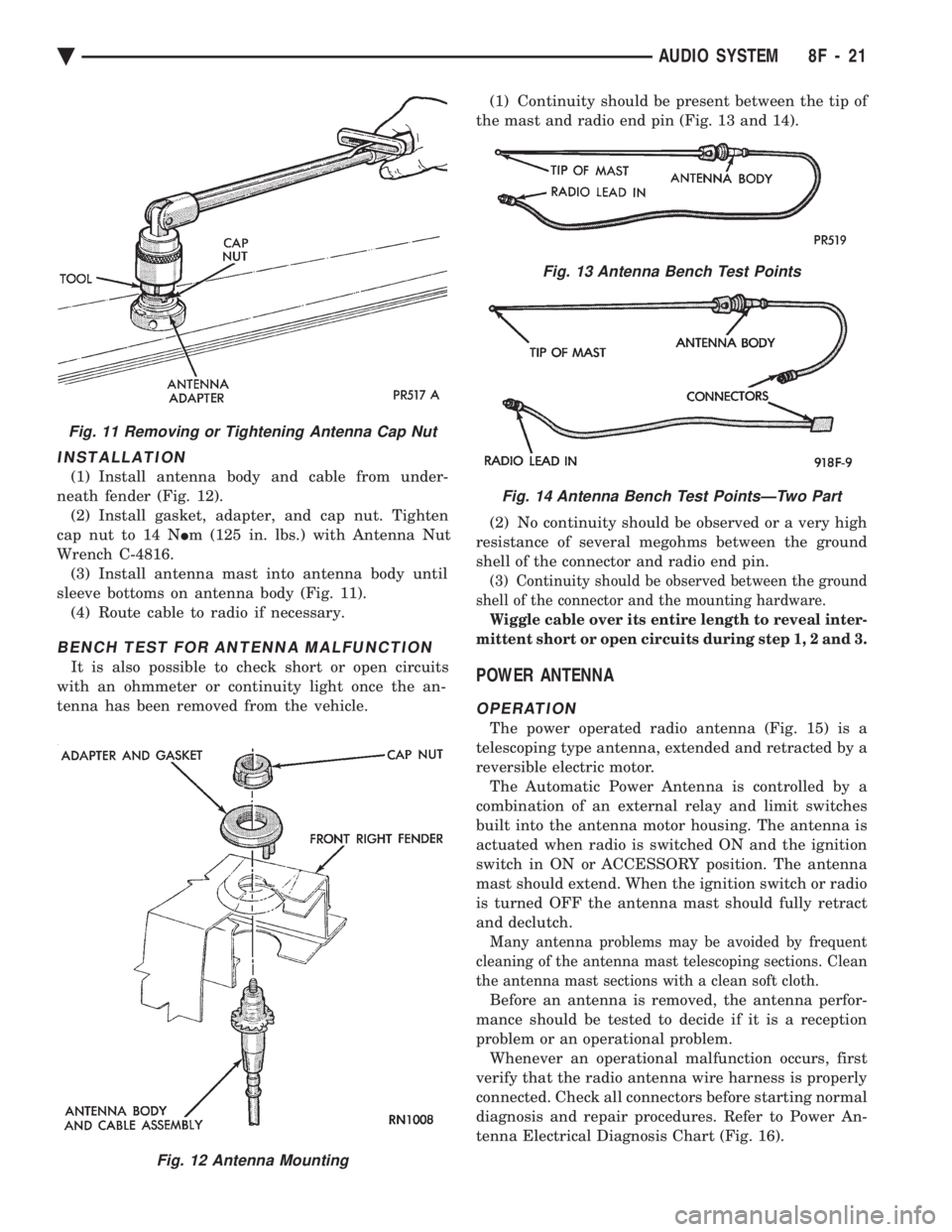

INSTALLATION

(1) Install antenna body and cable from under-

neath fender (Fig. 12). (2) Install gasket, adapter, and cap nut. Tighten

cap nut to 14 N Im (125 in. lbs.) with Antenna Nut

Wrench C-4816. (3) Install antenna mast into antenna body until

sleeve bottoms on antenna body (Fig. 11). (4) Route cable to radio if necessary.

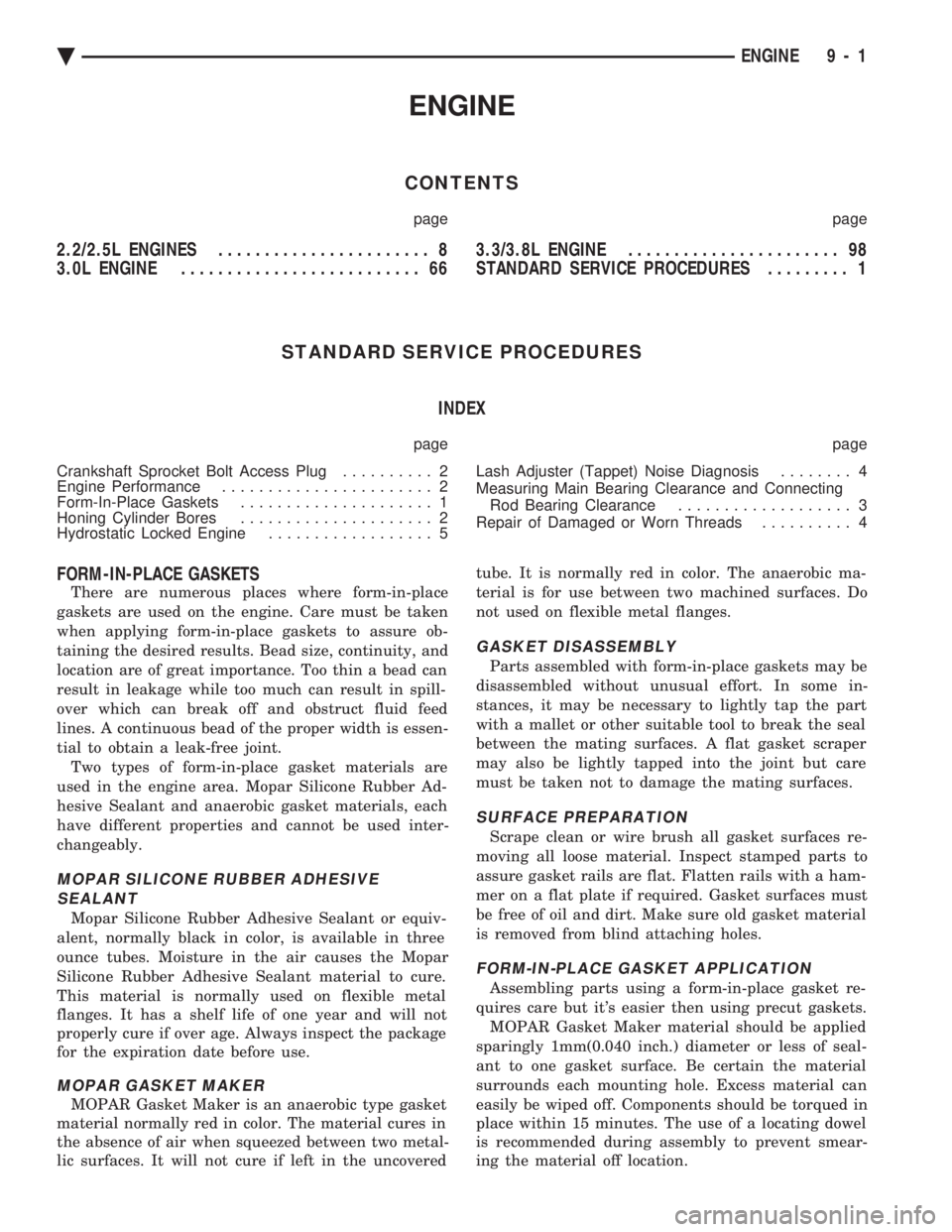

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the an-

tenna has been removed from the vehicle. (1) Continuity should be present between the tip of

the mast and radio end pin (Fig. 13 and 14).

(2) No continuity should be observed or a very high

resistance of several megohms between the ground

shell of the connector and radio end pin.

(3) Continuity should be observed between the ground

shell of the connector and the mounting hardware.

Wiggle cable over its entire length to reveal inter-

mittent short or open circuits during step 1, 2 and 3.

POWER ANTENNA

OPERATION

The power operated radio antenna (Fig. 15) is a

telescoping type antenna, extended and retracted by a

reversible electric motor. The Automatic Power Antenna is controlled by a

combination of an external relay and limit switches

built into the antenna motor housing. The antenna is

actuated when radio is switched ON and the ignition

switch in ON or ACCESSORY position. The antenna

mast should extend. When the ignition switch or radio

is turned OFF the antenna mast should fully retract

and declutch.

Many antenna problems may be avoided by frequent

cleaning of the antenna mast telescoping sections. Clean

the antenna mast sections with a clean soft cloth.

Before an antenna is removed, the antenna perfor-

mance should be tested to decide if it is a reception

problem or an operational problem. Whenever an operational malfunction occurs, first

verify that the radio antenna wire harness is properly

connected. Check all connectors before starting normal

diagnosis and repair procedures. Refer to Power An-

tenna Electrical Diagnosis Chart (Fig. 16).

Fig. 12 Antenna Mounting

Fig. 11 Removing or Tightening Antenna Cap Nut

Fig. 13 Antenna Bench Test Points

Fig. 14 Antenna Bench Test PointsÐTwo Part

Ä AUDIO SYSTEM 8F - 21

Page 1567 of 2438

ENGINE

CONTENTS

page page

2.2/2.5L ENGINES ....................... 8

3.0L ENGINE .......................... 66 3.3/3.8L ENGINE

....................... 98

STANDARD SERVICE PROCEDURES ......... 1

STANDARD SERVICE PROCEDURES INDEX

page page

Crankshaft Sprocket Bolt Access Plug .......... 2

Engine Performance ....................... 2

Form-In-Place Gaskets ..................... 1

Honing Cylinder Bores ..................... 2

Hydrostatic Locked Engine .................. 5 Lash Adjuster (Tappet) Noise Diagnosis

........ 4

Measuring Main Bearing Clearance and Connecting Rod Bearing Clearance ................... 3

Repair of Damaged or Worn Threads .......... 4

FORM-IN-PLACE GASKETS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure ob-

taining the desired results. Bead size, continuity, and

location are of great importance. Too thin a bead can

result in leakage while too much can result in spill-

over which can break off and obstruct fluid feed

lines. A continuous bead of the proper width is essen-

tial to obtain a leak-free joint. Two types of form-in-place gasket materials are

used in the engine area. Mopar Silicone Rubber Ad-

hesive Sealant and anaerobic gasket materials, each

have different properties and cannot be used inter-

changeably.

MOPAR SILICONE RUBBER ADHESIVE SEALANT

Mopar Silicone Rubber Adhesive Sealant or equiv-

alent, normally black in color, is available in three

ounce tubes. Moisture in the air causes the Mopar

Silicone Rubber Adhesive Sealant material to cure.

This material is normally used on flexible metal

flanges. It has a shelf life of one year and will not

properly cure if over age. Always inspect the package

for the expiration date before use.

MOPAR GASKET MAKER

MOPAR Gasket Maker is an anaerobic type gasket

material normally red in color. The material cures in

the absence of air when squeezed between two metal-

lic surfaces. It will not cure if left in the uncovered tube. It is normally red in color. The anaerobic ma-

terial is for use between two machined surfaces. Do

not used on flexible metal flanges.

GASKET DISASSEMBLY

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some in-

stances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

SURFACE PREPARATION

Scrape clean or wire brush all gasket surfaces re-

moving all loose material. Inspect stamped parts to

assure gasket rails are flat. Flatten rails with a ham-

mer on a flat plate if required. Gasket surfaces must

be free of oil and dirt. Make sure old gasket material

is removed from blind attaching holes.

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket re-

quires care but it's easier then using precut gaskets. MOPAR Gasket Maker material should be applied

sparingly 1mm(0.040 inch.) diameter or less of seal-

ant to one gasket surface. Be certain the material

surrounds each mounting hole. Excess material can

easily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing the material off location.

Ä ENGINE 9 - 1

Page 1575 of 2438

Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. Engine components which are required for safe op-

eration using fuel containing methanol alcohol are

identified by a standard green color and/or display

the statement methanol compatible imprinted on the

component. To ensure continued safe operation, these

components must be serviced only with genuine MO-

PAR replacement parts. Methanol compatible parts for the 2.5L FFV (Flex-

ible Fuel Vehicle) engine include, but are not limited

to; the valve stem oil seals, all piston rings, the oil

fill cap, the fuel injectors, fuel rail, fuel pressure reg-

ulator, hoses and the vacuum control harness hose. BLOCK: All four cylinder cast iron blocks have

cast-in recesses in the bottom of each cylinder bore to

provide connecting rod clearance; especially needed

for 2.5L engines. The bores are also siamese to min-

imize engine length. A coolant passage is drilled

cross-ways through the siamese section to enhance

between the bore cooling on some engine types. A

partial open deck is used for cooling and weight re-

duction with oil filter, water pump, and distributor

mounting bosses molded into the front (radiator side)

of the block. Nominal wall thickness is 4.5 mm. Five

main bearing bulkheads and a block skirt extending

3 mm below the crankshaft center line add to the

blocks high rigidity with light weight. CRANKSHAFT: A nodular cast iron crankshaft is

used in TBI engines. A forged steel crankshaft is

used in the Turbo III engine. All engines have 5 main bearings, with number 3 flanged to control

thrust. The 60 mm diameter main and 50 mm diam-

eter crank pin journals (all) have undercut radiuses

fillets that are deep rolled for added strength. To op-

timize bearing loading 4 counterweights are used.

Hydrodynamic seals (installed in diecast aluminum

retainers) provide end sealing, where the crankshaft

exits the block. Anaerobic gasket material is used for

retainer-to-block sealing. No vibration damper is

used. A sintered iron (TBI engine and steel billet

Turbo III engines) timing belt sprocket is mounted

on the crankshaft nose. This sprocket provides mo-

tive power; via timing belt to the camshaft and inter-

mediate shaft sprockets (also sintered iron (TBI

engine and steel billet Turbo III engines) providing

timed valve, distributor, and oil pump actuation. PISTONS: Some Chrysler pistons have cast-in

steel struts at the pin bosses for autothermic control.

All 2.2L and 2.5L piston tops have cuts to provide

valve clearance. Some pistons are dished to provide

various compression ratios. Standard 2.2L and 2.5L

engines are designed for 9.5:1 and 8.9:1 compression

ratios respectively. The 2.5L piston is dished and is a

lightweight design to enhance engine smoothness.

The 2.2L turbo III uses dished pistons providing a

8.3:1 compression ratio. All standard 2.2/2.5L and

2.5L FFV engines use pressed-in piston pins to at-

tach forged steel connecting rods, 2.2L turbo III en-

gine uses a full floating piston pin and connecting

rod assembly. PISTONS RINGS: The 2.2/2.5L engines share

common piston rings throughout, including molybde-

num filled top ring for reliable compression sealing

and a tapered faced intermediate ring for additional

cylinder pressure control. The 2.5L FFV engine fea-

ture all chrome rings for enhanced long term dura-

bility under multi-fueled conditions. CYLINDER HEAD: The cylinder head is cast alu-

minum with in-line valves. The 2.2/2.5L and 2.5L

FFV valves are arranged with alternating exhaust

and intake. The intake and exhaust ports are located

in the rearward, facing side of the head. The Turbo

III valves are arranged in two inline banks, with the

ports of the bank of two intake valves per cylinder

facing toward the radiator side of engine and ports of

the bank of two exhaust valve per cylinder facing to-

ward the dash panel. The intake ports feed fast-burn

design combustion chambers (2.2/2.5L and 2.5L FFV

only) with the spark plug located close to the center

line of the combustion chamber for optimum effi-

ciency. An integral oil gallery within the cylinder

head supplies oil to the hydraulic lash adjusters,

camshaft, and valve mechanisms. CAMSHAFT: The nodular iron camshaft has five

bearing journals (2.2/2.5L and 2.5L FFV). The Turbo

III employs dual camshafts that have nine bearing

journals. Flanges at the rear journal control cam-

Fig. 1 Engine Identification

Ä 2.2/2.5L ENGINE 9 - 9

Page 1576 of 2438

shaft end play. A sintered iron (TBI engine and steel

billet Turbo III engines) timing belt sprocket is

mounted on the cam nose, and a hydrodynamic oil

seal is used for oil control at the front of the cam-

shaft. ACCESSORY SHAFT: The iron accessory shaft

has two bearing journals and is housed in the for-

ward facing side of the block. A hydrodynamic seal,

installed in an aluminum housing attached to the

block, provides retention, shaft thrust, and oil con-

trol. The accessory shaft is driven by the timing belt

through a sintered iron (TBI engine and steel billet

Turbo III engines) sprocket mounted on the nose of

the accessory shaft. The accessory shaft in turn

drives the oil pump and distributor on 2.2/2.5L and

2.5L FFV and the oil pump only on Turbo III. VALVES: The valves are actuated by roller cam

followers which pivot on stationary hydraulic lash

adjusters. The valve train with 40.6 mm (1.60 inch)

diameter intake valves and 35.4 mm (1.39 inch) di-

ameter exhaust valves employ viton rubber valve

stem seals except 2.5L FFv . the 2.5L FFV valve

stem seals are made of special rubber compound

which resist the deteriorating effects of methanol

fuel by-products that enter the oil during combus-

tion. Valve springs, spring retainers, and locks are

conventional. For Turbo III engines the valves are

actuated by roller tipped rocker arms with hydraulic

lash adjusters which pivot on a shaft. The valve train

with 33.88 mm (1.33 in.) diameter intake valves are

arranged in line opposite of the 29.26 mm (1.15 in.)

diameter exhaust valves employ locking valve stem

seals. Valve springs, spring retainers, and locks are

not interchangeable with other engines. BALANCE SHAFTS: 2.2 Turbo III and 2.5L en-

gines are equipped with two counter rotating balance

shafts installed in a carrier attached to the lower

crankcase. The shafts are interconnect through

gears. These gears are driven by a short chain from

the crankshaft, to rotate at two times crankshaft

speed. This counterbalances certain engine recipro-

cating forces. INTAKE MANIFOLDS:

All intake manifolds are

aluminum castings, attached to the cylinder head

with eight bolts. N.A. engines use a four branch de-

sign. This long branch fan design enhances low and

midspeed torque. It also features an integrally cast

water crossover passage to warm incoming fuel/air

mixture, plus an EGR mounting boss and PCV inlet. The Turbo III engine intake manifold is a log type

with tuned runners. The manifold is machined to ac-

cept fuel injectors near the ports of each cylinder. EXHAUST MANIFOLDS: The exhaust manifolds

are made of nodular cast iron for strength and high

temperatures. All naturally aspirated (N.A.) and tur-

bocharged engines exit exhaust gasses through a ma-

chined, articulated joint connection to the exhaust

pipe. 2.2/2.5L and 2.5L FFV manifolds intermesh

with the intake manifold at the cylinder head. N.A. engines use a four branch design with cylin-

ders one and four joined and cylinder two and three

joined to exit at the outlet. The Turbo III engine exhaust manifold also carries

the turbocharger. This manifold has a modified log

type collector with exhaust gasses directed to and

through the turbocharger to exit the conical (articu-

lated joint) outlet machined into the turbocharger ex-

haust elbow. ENGINE LUBRICATION: Refer to Group 0 Lu-

brication and Maintenance for recommended oil to be

used in various engine application. System is full

flow filtration, pressure feed type. The oil pump is

mounted within the crankcase and driven by the ac-

cessory shaft. Pressurized oil is then routed through

the main oil gallery, running the length of the cylin-

der block, supplying main and rod bearings with fur-

ther routing (for 2.2L turbo III and 2.5L engines) to

the lower balance shaft assemblies. Pistons are lubri-

cated from directed holes in the connecting rod as-

semblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

9 - 10 2.2/2.5L ENGINE Ä

Page 1624 of 2438

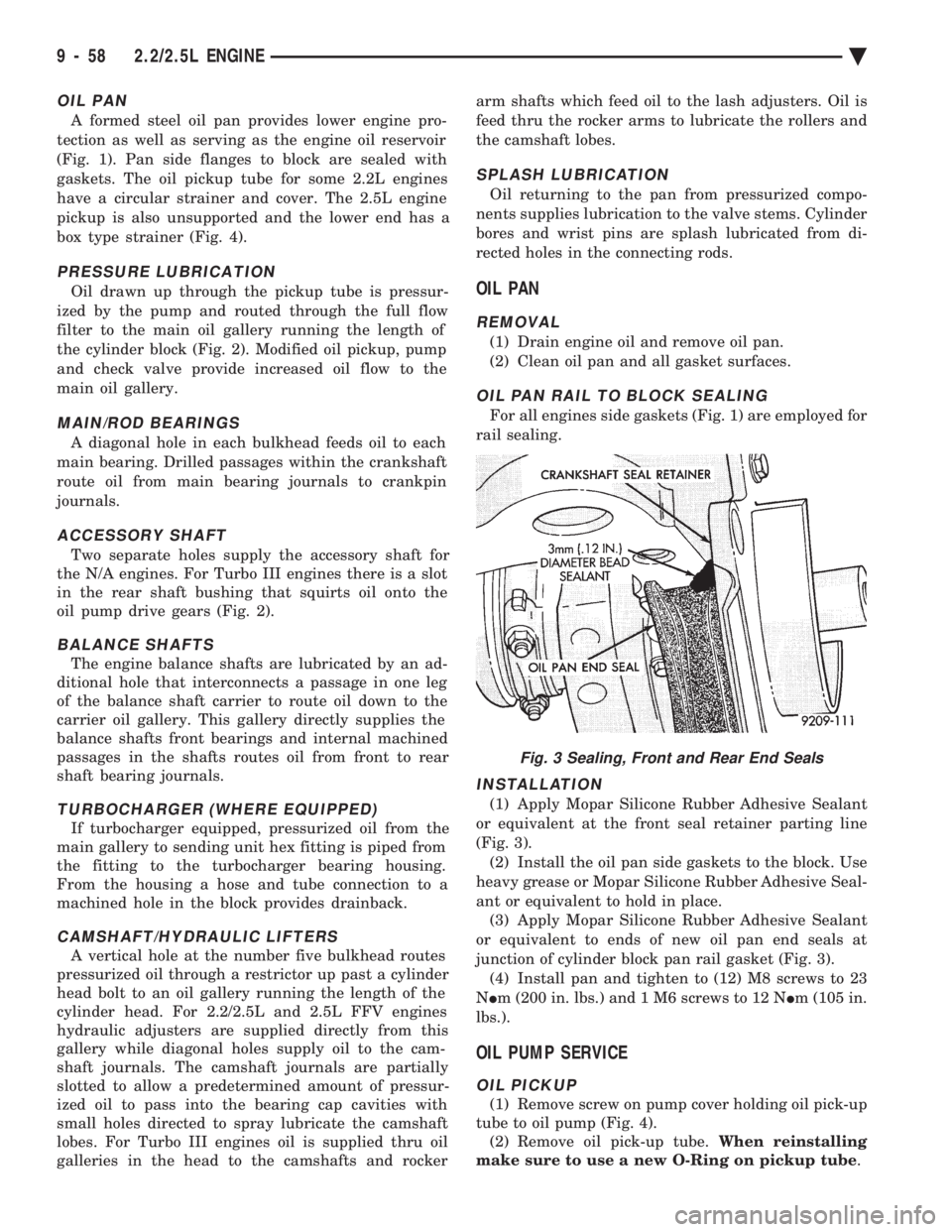

OIL PAN

A formed steel oil pan provides lower engine pro-

tection as well as serving as the engine oil reservoir

(Fig. 1). Pan side flanges to block are sealed with

gaskets. The oil pickup tube for some 2.2L engines

have a circular strainer and cover. The 2.5L engine

pickup is also unsupported and the lower end has a

box type strainer (Fig. 4).

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full flow

filter to the main oil gallery running the length of

the cylinder block (Fig. 2). Modified oil pickup, pump

and check valve provide increased oil flow to the

main oil gallery.

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to crankpin

journals.

ACCESSORY SHAFT

Two separate holes supply the accessory shaft for

the N/A engines. For Turbo III engines there is a slot

in the rear shaft bushing that squirts oil onto the

oil pump drive gears (Fig. 2).

BALANCE SHAFTS

The engine balance shafts are lubricated by an ad-

ditional hole that interconnects a passage in one leg

of the balance shaft carrier to route oil down to the

carrier oil gallery. This gallery directly supplies the

balance shafts front bearings and internal machined

passages in the shafts routes oil from front to rear

shaft bearing journals.

TURBOCHARGER (WHERE EQUIPPED)

If turbocharger equipped, pressurized oil from the

main gallery to sending unit hex fitting is piped from

the fitting to the turbocharger bearing housing.

From the housing a hose and tube connection to a

machined hole in the block provides drainback.

CAMSHAFT/HYDRAULIC LIFTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up past a cylinder

head bolt to an oil gallery running the length of the

cylinder head. For 2.2/2.5L and 2.5L FFV engines

hydraulic adjusters are supplied directly from this

gallery while diagonal holes supply oil to the cam-

shaft journals. The camshaft journals are partially

slotted to allow a predetermined amount of pressur-

ized oil to pass into the bearing cap cavities with

small holes directed to spray lubricate the camshaft

lobes. For Turbo III engines oil is supplied thru oil

galleries in the head to the camshafts and rocker arm shafts which feed oil to the lash adjusters. Oil is

feed thru the rocker arms to lubricate the rollers and

the camshaft lobes.

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylinder

bores and wrist pins are splash lubricated from di-

rected holes in the connecting rods.

OIL PAN

REMOVAL

(1) Drain engine oil and remove oil pan.

(2) Clean oil pan and all gasket surfaces.

OIL PAN RAIL TO BLOCK SEALING

For all engines side gaskets (Fig. 1) are employed for

rail sealing.

INSTALLATION

(1) Apply Mopar Silicone Rubber Adhesive Sealant

or equivalent at the front seal retainer parting line

(Fig. 3). (2) Install the oil pan side gaskets to the block. Use

heavy grease or Mopar Silicone Rubber Adhesive Seal-

ant or equivalent to hold in place. (3) Apply Mopar Silicone Rubber Adhesive Sealant

or equivalent to ends of new oil pan end seals at

junction of cylinder block pan rail gasket (Fig. 3). (4) Install pan and tighten to (12) M8 screws to 23

N Im (200 in. lbs.) and 1 M6 screws to 12 N Im (105 in.

lbs.).

OIL PUMP SERVICE

OIL PICKUP

(1) Remove screw on pump cover holding oil pick-up

tube to oil pump (Fig. 4). (2) Remove oil pick-up tube. When reinstalling

make sure to use a new O-Ring on pickup tube .

Fig. 3 Sealing, Front and Rear End Seals

9 - 58 2.2/2.5L ENGINE Ä

Page 1627 of 2438

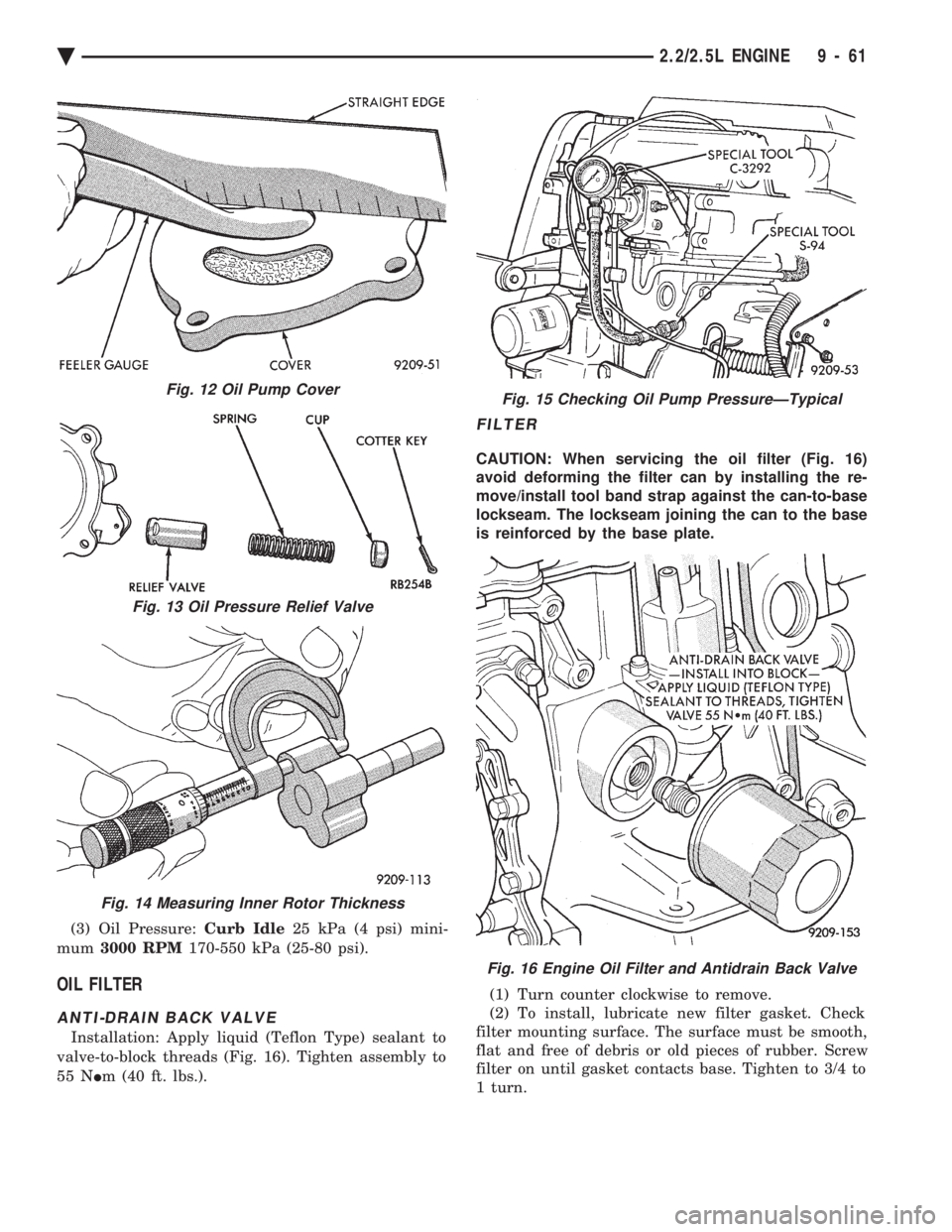

(3) Oil Pressure: Curb Idle25 kPa (4 psi) mini-

mum 3000 RPM 170-550 kPa (25-80 psi).

OIL FILTER

ANTI-DRAIN BACK VALVE

Installation: Apply liquid (Teflon Type) sealant to

valve-to-block threads (Fig. 16). Tighten assembly to

55 N Im (40 ft. lbs.).

FILTER

CAUTION: When servicing the oil filter (Fig. 16)

avoid deforming the filter can by installing the re-

move/install tool band strap against the can-to-base

lockseam. The lockseam joining the can to the base

is reinforced by the base plate.

(1) Turn counter clockwise to remove.

(2) To install, lubricate new filter gasket. Check

filter mounting surface. The surface must be smooth,

flat and free of debris or old pieces of rubber. Screw

filter on until gasket contacts base. Tighten to 3/4 to

1 turn.

Fig. 12 Oil Pump Cover

Fig. 13 Oil Pressure Relief Valve

Fig. 14 Measuring Inner Rotor Thickness

Fig. 15 Checking Oil Pump PressureÐTypical

Fig. 16 Engine Oil Filter and Antidrain Back Valve

Ä 2.2/2.5L ENGINE 9 - 61

Page 1634 of 2438

shaped and provides the same spring tension as

longer springs. Valve spring retainers, locks and

seals are conventional.INTAKE MANIFOLD: The aluminum alloy man-

ifold is a cross type with long runners to improve in-

ertia. The runners, attaching below at the cylinder

head, also attach above and support an air plenum.

The air plenum chamber absorbs air pulsations cre-

ated during the suction phase of each cylinder. EXHAUST MANIFOLDS: Both manifolds are a

log style made of ductile cast iron. Exhaust gasses,

collected from the front cylinder bank, leave the

front manifold through an end outlet and are fed

through an upper crossover tube to the rear mani-

fold. The collected exhaust from both manifolds are

combined, and exit to the exhaust pipe through an

articulated joint. ENGINE LUBRICATION: System is a full flow

filtration, pressure feed type. The oil pump is

mounted in the chaincase cover. The pump inner ro-

tor is driven by the crankshaft. The engine oil pan

contains a baffle plate to control oil level fluctuation

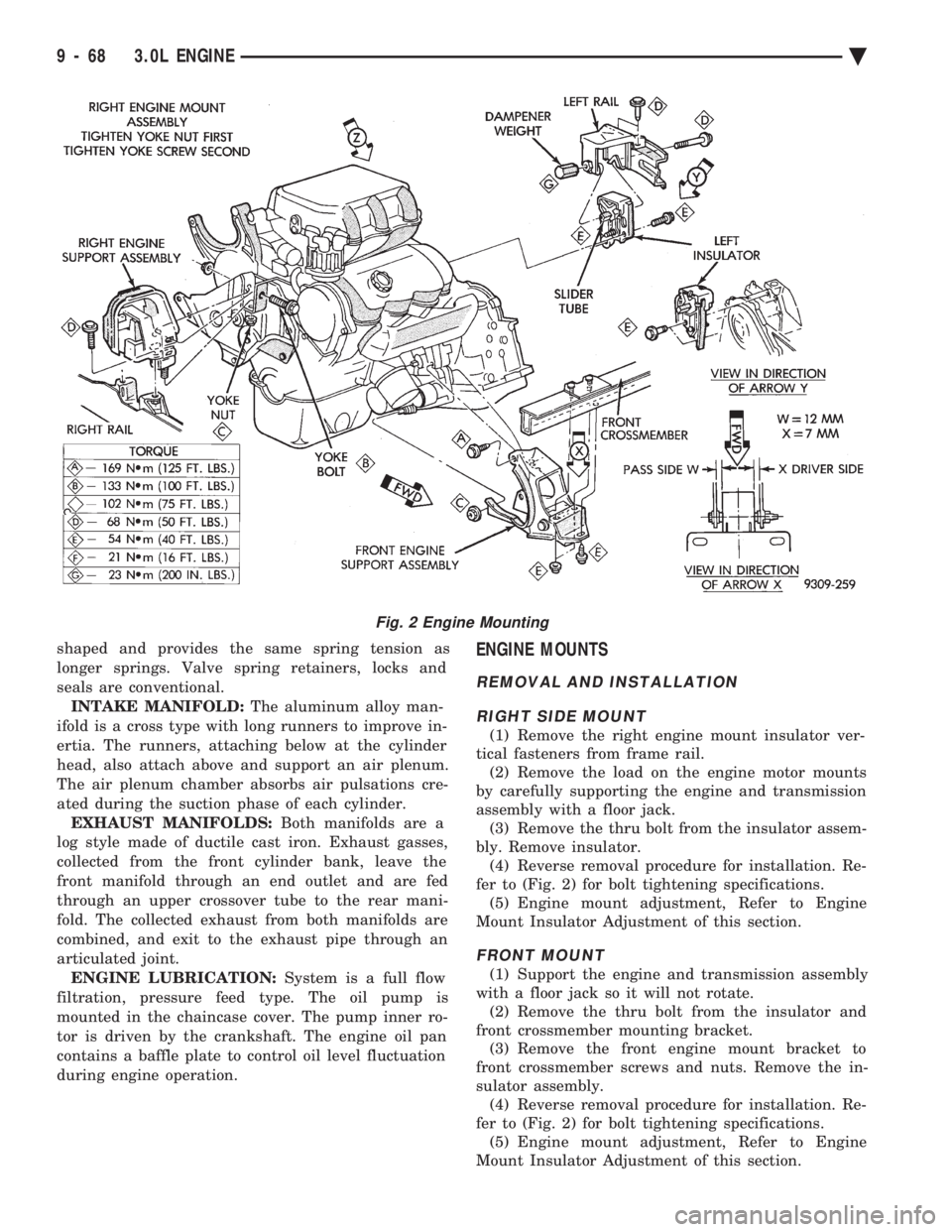

during engine operation.ENGINE MOUNTS

REMOVAL AND INSTALLATION

RIGHT SIDE MOUNT

(1) Remove the right engine mount insulator ver-

tical fasteners from frame rail. (2) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack. (3) Remove the thru bolt from the insulator assem-

bly. Remove insulator. (4) Reverse removal procedure for installation. Re-

fer to (Fig. 2) for bolt tightening specifications. (5) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

FRONT MOUNT

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate. (2) Remove the thru bolt from the insulator and

front crossmember mounting bracket. (3) Remove the front engine mount bracket to

front crossmember screws and nuts. Remove the in-

sulator assembly. (4) Reverse removal procedure for installation. Re-

fer to (Fig. 2) for bolt tightening specifications. (5) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

Fig. 2 Engine Mounting

9 - 68 3.0L ENGINE Ä

Page 1665 of 2438

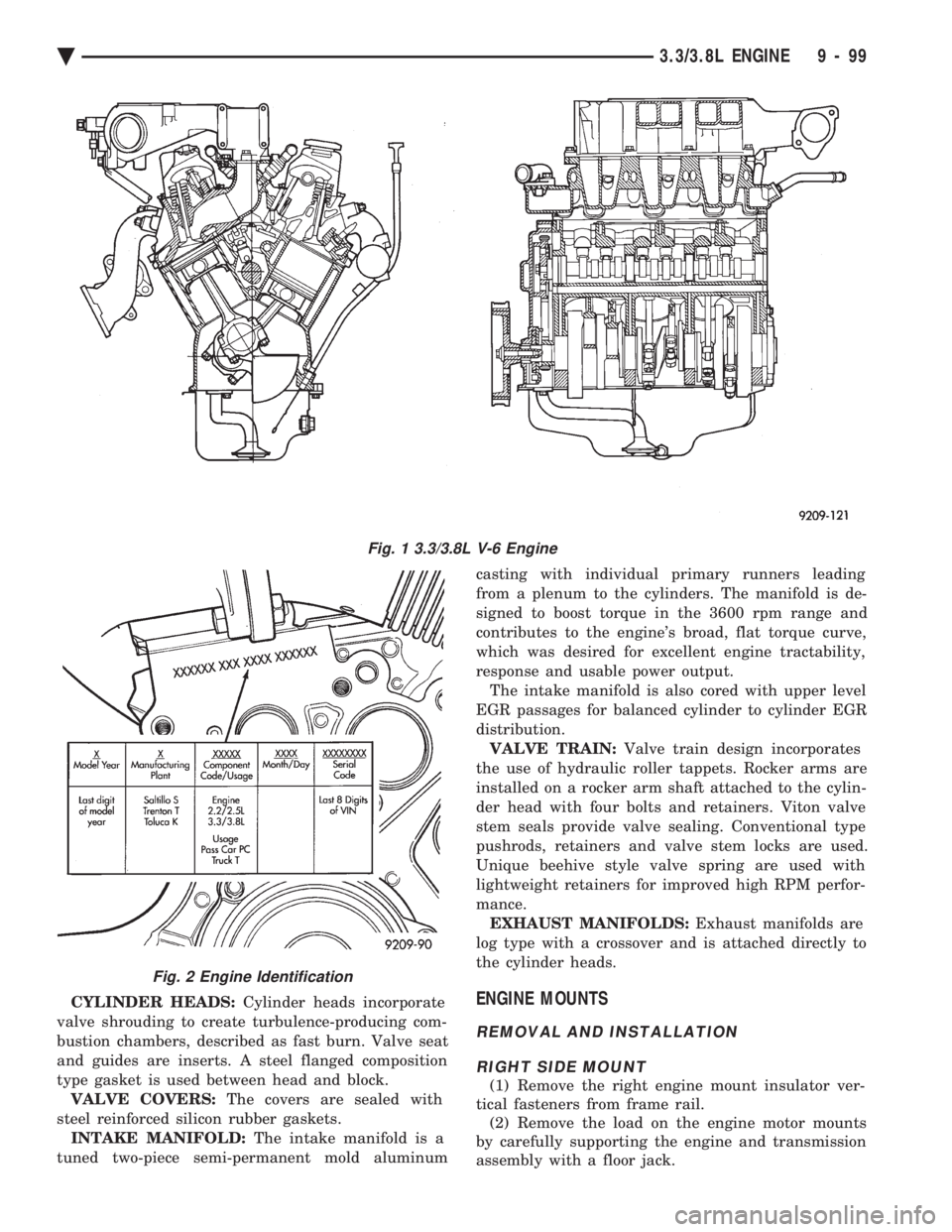

CYLINDER HEADS: Cylinder heads incorporate

valve shrouding to create turbulence-producing com-

bustion chambers, described as fast burn. Valve seat

and guides are inserts. A steel flanged composition

type gasket is used between head and block. VALVE COVERS: The covers are sealed with

steel reinforced silicon rubber gaskets. INTAKE MANIFOLD: The intake manifold is a

tuned two-piece semi-permanent mold aluminum casting with individual primary runners leading

from a plenum to the cylinders. The manifold is de-

signed to boost torque in the 3600 rpm range and

contributes to the engine's broad, flat torque curve,

which was desired for excellent engine tractability,

response and usable power output. The intake manifold is also cored with upper level

EGR passages for balanced cylinder to cylinder EGR

distribution. VALVE TRAIN: Valve train design incorporates

the use of hydraulic roller tappets. Rocker arms are

installed on a rocker arm shaft attached to the cylin-

der head with four bolts and retainers. Viton valve

stem seals provide valve sealing. Conventional type

pushrods, retainers and valve stem locks are used.

Unique beehive style valve spring are used with

lightweight retainers for improved high RPM perfor-

mance. EXHAUST MANIFOLDS: Exhaust manifolds are

log type with a crossover and is attached directly to

the cylinder heads.ENGINE MOUNTS

REMOVAL AND INSTALLATION

RIGHT SIDE MOUNT

(1) Remove the right engine mount insulator ver-

tical fasteners from frame rail. (2) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

Fig. 1 3.3/3.8L V-6 Engine

Fig. 2 Engine Identification

Ä 3.3/3.8L ENGINE 9 - 99

Page 1688 of 2438

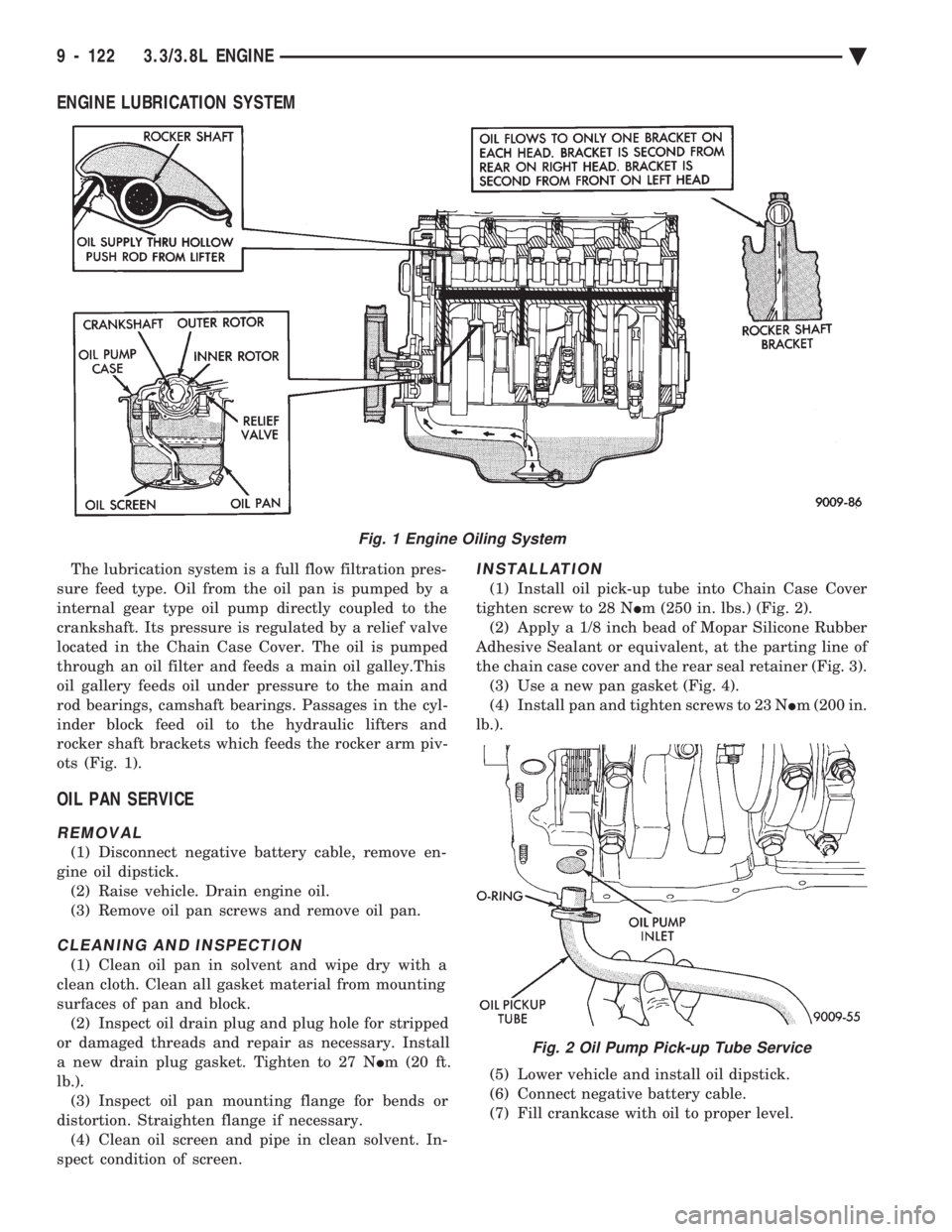

ENGINE LUBRICATION SYSTEM

The lubrication system is a full flow filtration pres-

sure feed type. Oil from the oil pan is pumped by a

internal gear type oil pump directly coupled to the

crankshaft. Its pressure is regulated by a relief valve

located in the Chain Case Cover. The oil is pumped

through an oil filter and feeds a main oil galley.This

oil gallery feeds oil under pressure to the main and

rod bearings, camshaft bearings. Passages in the cyl-

inder block feed oil to the hydraulic lifters and

rocker shaft brackets which feeds the rocker arm piv-

ots (Fig. 1).

OIL PAN SERVICE

REMOVAL

(1) Disconnect negative battery cable, remove en-

gine oil dipstick. (2) Raise vehicle. Drain engine oil.

(3) Remove oil pan screws and remove oil pan.

CLEANING AND INSPECTION

(1) Clean oil pan in solvent and wipe dry with a

clean cloth. Clean all gasket material from mounting

surfaces of pan and block. (2) Inspect oil drain plug and plug hole for stripped

or damaged threads and repair as necessary. Install

a new drain plug gasket. Tighten to 27 N Im (20 ft.

lb.). (3) Inspect oil pan mounting flange for bends or

distortion. Straighten flange if necessary. (4) Clean oil screen and pipe in clean solvent. In-

spect condition of screen.

INSTALLATION

(1) Install oil pick-up tube into Chain Case Cover

tighten screw to 28 N Im (250 in. lbs.) (Fig. 2).

(2) Apply a 1/8 inch bead of Mopar Silicone Rubber

Adhesive Sealant or equivalent, at the parting line of

the chain case cover and the rear seal retainer (Fig. 3). (3) Use a new pan gasket (Fig. 4).

(4) Install pan and tighten screws to 23 N Im (200 in.

lb.).

(5) Lower vehicle and install oil dipstick.

(6) Connect negative battery cable.

(7) Fill crankcase with oil to proper level.

Fig. 1 Engine Oiling System

Fig. 2 Oil Pump Pick-up Tube Service

9 - 122 3.3/3.8L ENGINE Ä

Page 1709 of 2438

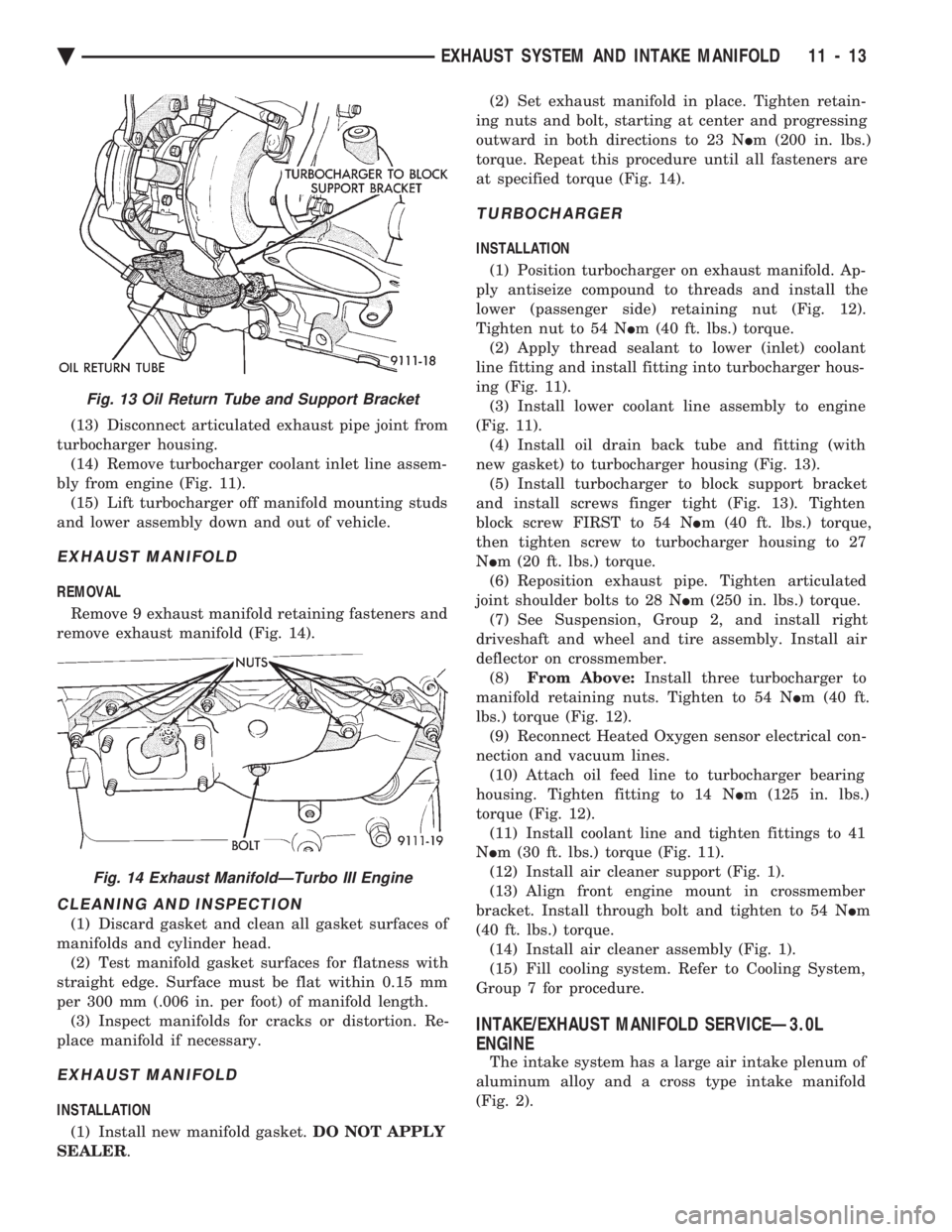

(13) Disconnect articulated exhaust pipe joint from

turbocharger housing. (14) Remove turbocharger coolant inlet line assem-

bly from engine (Fig. 11). (15) Lift turbocharger off manifold mounting studs

and lower assembly down and out of vehicle.

EXHAUST MANIFOLD

REMOVAL

Remove 9 exhaust manifold retaining fasteners and

remove exhaust manifold (Fig. 14).

CLEANING AND INSPECTION

(1) Discard gasket and clean all gasket surfaces of

manifolds and cylinder head. (2) Test manifold gasket surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (.006 in. per foot) of manifold length. (3) Inspect manifolds for cracks or distortion. Re-

place manifold if necessary.

EXHAUST MANIFOLD

INSTALLATION

(1) Install new manifold gasket. DO NOT APPLY

SEALER . (2) Set exhaust manifold in place. Tighten retain-

ing nuts and bolt, starting at center and progressing

outward in both directions to 23 N Im (200 in. lbs.)

torque. Repeat this procedure until all fasteners are

at specified torque (Fig. 14).

TURBOCHARGER

INSTALLATION

(1) Position turbocharger on exhaust manifold. Ap-

ply antiseize compound to threads and install the

lower (passenger side) retaining nut (Fig. 12).

Tighten nut to 54 N Im (40 ft. lbs.) torque.

(2) Apply thread sealant to lower (inlet) coolant

line fitting and install fitting into turbocharger hous-

ing (Fig. 11). (3) Install lower coolant line assembly to engine

(Fig. 11). (4) Install oil drain back tube and fitting (with

new gasket) to turbocharger housing (Fig. 13). (5) Install turbocharger to block support bracket

and install screws finger tight (Fig. 13). Tighten

block screw FIRST to 54 N Im (40 ft. lbs.) torque,

then tighten screw to turbocharger housing to 27

N Im (20 ft. lbs.) torque.

(6) Reposition exhaust pipe. Tighten articulated

joint shoulder bolts to 28 N Im (250 in. lbs.) torque.

(7) See Suspension, Group 2, and install right

driveshaft and wheel and tire assembly. Install air

deflector on crossmember. (8) From Above: Install three turbocharger to

manifold retaining nuts. Tighten to 54 N Im (40 ft.

lbs.) torque (Fig. 12). (9) Reconnect Heated Oxygen sensor electrical con-

nection and vacuum lines. (10) Attach oil feed line to turbocharger bearing

housing. Tighten fitting to 14 N Im (125 in. lbs.)

torque (Fig. 12). (11) Install coolant line and tighten fittings to 41

N Im (30 ft. lbs.) torque (Fig. 11).

(12) Install air cleaner support (Fig. 1).

(13) Align front engine mount in crossmember

bracket. Install through bolt and tighten to 54 N Im

(40 ft. lbs.) torque. (14) Install air cleaner assembly (Fig. 1).

(15) Fill cooling system. Refer to Cooling System,

Group 7 for procedure.

INTAKE/EXHAUST MANIFOLD SERVICEÐ3.0L

ENGINE

The intake system has a large air intake plenum of

aluminum alloy and a cross type intake manifold

(Fig. 2).

Fig. 13 Oil Return Tube and Support Bracket

Fig. 14 Exhaust ManifoldÐTurbo III Engine

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 13