hood release CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1064 of 2438

Wiring Diagram

Name Sheet Number

Relay Bank ............................. .106

Blower Slide Control ...........................51

Bulkhead Disconnect (50 Way) ................181, 182

Bulkhead Disconnect (50-Way) (2.5L Engine) .......183, 184

Bulkhead Disconnect (50-Way) (3.0L Engine) .......185, 186

Bulkhead Disconnect (50-Way) (3.3L & 3.8L Engine) ......................... .187, 188

Camshaft Position Sensor .......................28

Crankshaft Position Sensor .......................28

Cellular Phone System ........................ .126

Antenna ............................... .126

Center Phone ............................ .126

External Speaker .......................... .126

Microphone ............................. .126

Transmitter/Receiver Unit .................... .126

Visor Phone ............................. .126

Charging System (2.5L Engine) ...................5,6

Battery ...................................5

Generator .................................6

Power Distribution Center .......................6

Charging System (3.0L Engine) ...................7,8

Battery ...................................7

Generator .................................8

Power Distribution Center .......................8

Charging System (3.3L & 3.8L Engine) .............9,10

Battery ...................................9

Generator ................................10

Power Distribution Center ......................10

Cigar Lighter .......................... .111, 112

Circuit Breakers Concealed Headlamps .......................2,68

Power Door Locks ........................2,139

Power Seats ............................2,149

Power Windows .........................3,158

Compressor Motor ........................ .40, 42

Concealed Headlamp Controls .....................68

Circuit Breaker .............................68

Headlamp Door Motor ........................68

Headlamp Door Relays ........................68

Headlamp Relay ............................68

Relay Bank ...............................68

Courtesy Lamp System .................87, 88, 89, 90

Left Front Door Courtesy Lamp ..................87

Left Front Door Jamb Switch ....................87

Left Illuminated Visor Vanity Mirror ................89

Left Illuminated Visor Vanity Mirror Switch ...........89

Left Lamp and Switch ........................89

Left Rear Door Courtesy Lamp ...................87

Left Rear Door Jamb Switch ....................87

Left Rear Quarter Reading Lamp ..................90

Right Front Door Courtesy Lamp .................88

Right Front Door Jamb Switch ...................88

Right Illuminated Visor Vanity Mirror ...............89

Right Illuminated Visor Vanity Mirror Switch ..........89

Right Lamp and Switch .......................89

Right Rear Door Courtesy Lamp ..................88

Right Rear Door Jamb Switch ...................88Wiring Diagram

Name Sheet Number

Right Rear Quarter Reading Lamp .................90

Trunk Lamp ...............................90

Data Link Connectors ..........14, 23, 100, 103, 106, 110,

130, 134, 136

Deck Lid Release and Deck Lid Pull-Down System . . . .159, 160

Deck Lid Pull-Down Unit ..................... .160

Deck Lid Release Solenoid .................159, 160

Deck Lid Release Solenoid/Pull-Down Key Cylinder Switch ............................... .160

Mercury Switch .......................... .159

Underhood Light .......................... .159

Dimmer Switch-Optical Horn ....................1,66

Distributor .............................. .17, 19

Door Ajar System w/Electronic Cluster ...............92

Left Front Door Ajar Switch .....................92

Left Rear Door Ajar Switch .....................92

Right Front Door Ajar Switch ....................92

Right Rear Door Ajar Switch ....................92

Door Ajar System w/Mechanical Cluster and Visual Mess Ctr ...............................93

Left Front Door Ajar Switch .....................93

Left Rear Door Ajar Switch .....................93

Right Front Door Ajar Switch ....................93

Right Rear Door Ajar Switch ....................93

Door Ajar System w/Mechanical Cluster w/o Visual Mess Ctr ...............................94

Left Front Door Ajar Switch .....................94

Left Rear Door Ajar Switch .....................94

Right Front Door Ajar Switch ....................94

Right Rear Door Ajar Switch ....................94

Door Electrical Ground Systems ...................165

Door Jamb Courtesy Lamp Switches ..............87, 88

Door Lock System ....................... .139, 140

Circuit Breaker ........................... .139

Connector and Door Lock Switch Function .......139, 140

Door Lock Relay .......................... .140

Door Unlock Relay ......................... .140

Left Front Door Lock Motor ................... .139

Left Front Door Lock Switch ...................139

Left Rear Door Lock Motor ................... .139

Relay Bank ............................. .139

Right Front Door Lock Motor ...................140

Right Front Door Lock Switch ..................140

Right Rear Door Lock Motor ...................140

Exhaust Gas Recirculation Solenoid ............14, 21, 26

Electronically Tuned Stereo Radio ..............119, 120

Left Door Speaker ......................... .120

Left Rear Speaker ......................... .120

Right Door Speaker ........................ .120

Right Rear Speaker ........................ .120

Electronically Tuned Stereo Radio with RS Amplifier ....................... .121, 122, 123

Left Door Speaker ......................... .123

Left Front Speaker ......................... .123

Left Rear Speaker ......................... .123

Right Door Speaker ........................ .123

Right Front Speaker ........................ .123

Right Rear Speaker ........................ .123

8W - 314 WIRING DIAGRAMS AC-AY BODY Ä

Page 1069 of 2438

Wiring Diagram

Name Sheet Number

Left Side Marker Lamp ...................... .163

Right Back-Up Lamp ....................... .164

Right Center High Mounted Stop Lamps ............164

Right Inboard Tail, Stop & Turn Signal Lamp .........164

Right License Lamp ........................ .164

Right Outboard Tail, Stop & Turn Signal Lamp ........164

Right Side Marker Lamp ..................... .164

Recliner Position Sense Resistor ..................154

Relay Bank ............................... .171

Relay Module ............................. .171

Relays ABS System Relay ..........................47

A/C Compressor Clutch .................54, 56, 113

Air Suspension .............................42

Automatic Shut Down .................. .15, 23, 29

Automatic Load Leveling .......................40

Back-Up Lamp .............................33

Door Lock/Unlock ......................... .140

Engine Starter .......................... .12, 13

Fan Control ............................. .114

Fuel Pump ...............................36

Horn ...................................63

Headlamp ................................68

Headlamp Door ............................68

Park Lamp .............................. .125

Power Antenna/Name Brand Speaker Relay ..........118

Pump and Motor Relay .......................46

Radiator Fan Control Relay A/C ................54, 56

Radiator Fan Relay ATC ..................... .114

Radiator Fan Relay-Heater ......................52

Safety Shut Down ...........................35

Yellow Lamp Relay ..........................49

Remote Keyless Entry ..................... .141, 142

Program Module .......................... .141

Remote Keyless Entry Module ...............141, 142

Right Body to Instrument Panel Wiring ...........192, 193

Right Front Wheel Sensor .......................50

Right Rear Wheel Sensor ........................50

RS Amplifier ........................... .122, 123

Safety Shut Down Relay ........................35

Seat Belt Warning System .......................67

Seat Belt Switch .............................67

Seat Track Position Sense Resistor .................154

Security Alarm Module Connector (Elec Cluster) ........202

Security Alarm Module Connector (Mech Cluster) ........203

Security Alarm System (Electronic Cluster) ........135, 136,

137, 138

Deck Lid Key Cylinder ...................... .135

Data Link Connector ....................... .136

Left Door Key Cylinder ...................... .135

Relay Bank ............................. .138

Relay Module ............................ .137

Right Door Key Cylinder ..................... .135

Security Alarm Hood Switch ...................136

Security Alarm Module .............135, 136, 137, 138

Security Lamp ........................... .136Wiring Diagram

Name Sheet Number

Security Alarm System (Mech Cluster w/VMC) ......127, 128,

129, 130

Deck Lid Key Cylinder ...................... .127

Data Link Connector ....................... .130

Left Door Key Cylinder ...................... .127

Relay Bank ............................. .130

Relay Module ............................ .129

Right Door Key Cylinder ..................... .127

Security Alarm Hood Switch ...................128

Security Alarm Module .............127, 128, 129, 130

Security Lamp ........................... .128

Security Alarm System (Mech Cluster w/o VMC) . . . .131, 132,

133, 134

Deck Lid Key Cylinder ...................... .131

Data Link Connector ....................... .134

Left Door Key Cylinder ...................... .131

Relay Bank ............................. .134

Relay Module ............................ .133

Right Door Key Cylinder ..................... .131

Security Alarm Hood Switch ...................132

Security Alarm Module .............131, 132, 133, 134

Security Lamp ........................... .132

Sensors Airbag Sensor .............................58

Ambient Sensor .......................... .117

Brake Fluid Level Sensor ......................98

Camshaft Position Sensor ......................28

Coolant Level Sensor .........................98

Crankshaft Position Sensor .....................28

Engine Coolant Temperature Sensors ..........17, 19, 25

Engine Oil Level Sensor .................... .31, 32

Heated Oxygen Sensors ................. .14, 19, 25

Height Sensors ............................44

In Car Senso r............................ .115

Left Front Wheel Sensor .......................50

Left Rear Wheel Sensor .......................50

MAP Sensors ........................ .18, 21, 26

Right Front Wheel Sensor ......................50

Right Rear Wheel Sensor ......................50

Sun Sensor ............................. .115

Throttle Position (Sensors) ................18, 21, 26

Transmission Output Speed Sensor ................34

Turbine Speed Sensor ........................34

Vehicle Speed Sensor .................. .17, 19, 25

Water Sensor ............................ .117

Windshield Washer Low Fluid Level Sensor ...........61

Solenoids Air Exhaust-Automatic Load Leveling Solenoid .........42

Air Suspension Solenoid ................... .41, 44

Deck Lid Release Solenoid ................... .159

EVAP/Purge Solenoids .................. .15, 20, 27

Exhaust Gas Recirculation Solenoids ..........14, 21, 26

Transmission Solenoid .................... .12, 35

Transmission TCC LU Solenoid ..................12

Splices Splice A1 ...........................4,6,8,10

Splice A3 .........................2,37,59,66

Splice A3-1 .....................2,6,8,10,69,71

Ä WIRING DIAGRAMS AC-AY BODY 8W - 319

Page 1071 of 2438

Wiring Diagram

Name Sheet Number

Splice Z1-3 ............... .47, 68, 74, 77, 80, 82, 84

Splice Z1-4 .......... .38, 47, 70, 72, 74, 77, 80, 82, 84

Splice Z1-5 ............................. .155

Splice Z1-6 .....36, 124, 125, 127, 131, 135, 160, 162, 164

Splice Z1-7 .................... .39, 160, 162, 164

Splice Z1-8 ........................... .86, 115

Splice Z1-9 .................. .61, 86, 118, 140, 141

Splice Z1-10 ..............................46

Splice Z1-11 .................. .161, 162, 163, 164

Splice Z1-12 .....52, 54, 56, 63, 69, 71, 73, 75, 78, 81, 83

Splice Z1-13 ............. .90, 124, 125, 147, 162, 164

Splice Z1-14 . . . .91, 127, 131, 135, 143, 149, 152, 158, 165

Splice Z1-15 ........... .67, 88, 91, 112, 127, 131, 135,

149, 152, 155, 158, 165

Splice Z1-16 .....88, 91, 112, 127, 131, 135, 150, 155, 165

Splice Z1-17 ....................... .54, 56, 113

Splice Z1-18 ......................... .162, 164

Splice Z1-19 .............. .70, 72, 73, 74, 75, 77, 78,

80, 81, 82, 83, 84

Splice Z2 .......................... .86, 98, 99

Splice Z2-1 ...............................98

Splice Z2-2 ......................... .36, 39, 43

Splice Z12 ....................... .16, 22, 24, 35

Splice Z13 ............................7,9,35

Splice Z14 ...............................35

Stop Lamps .................... .161, 162, 163, 164

Stop Lamp Switch ......................... .38, 59

Switches A/C Ambient Temp ...................... .56, 114

A/C Cycling Switch ..........................54

A/C Fan Cutout ........................ .56, 114

A/C Defrost ........................... .53, 55

A/C Heater Blower ....................... .53, 55

A/C High Pressure Cutout ................54, 56, 114

A/C Low Pressure .................... .53, 55, 114

ATC Temp Control ......................... .116

Automatic Transmission Park/Neutral Position .........12

Backup Lamp ..............................12

Brake Warning Lamp .........................11

Deck Lid Release ......................... .111

Defrost .............................. .53, 55

Dimmer-Headlamp ..........................66

Door Ajar .......................... .92, 93, 94

Door Jamb ............................ .87, 88

Door Window-Left Front ..................... .157

Door Window-Left Rear ..................... .157

Door Window-Right Front .................... .158

Door Window-Right Rear .................... .158

Engine Oil Pressure .................... .30, 31, 32

Fuel Tank Level Gauge Sending Unit Switch ..........36

Glove Box Lamp .......................... .111

Hazard Flasher .............................60

Headlamp ..............................1,65

Headlamp Dimmer .........................1,66

Heated Rear Window ......................4,148

Heater Bi-Level Control Switch ...................51

Horn ...................................63Wiring Diagram

Name Sheet Number

Ignition ................................4,11

Illuminated Entry ...........................91

Illuminated Visor Vanity Mirror Switch ..............89

Intermittent Wiper ...........................61

Key-in .......................... .104, 107, 109

Left Rear Door Jamb Switch ....................87

Optical Horn .............................1,66

Park Brake ...............................11

Power Door Lock-Left Front ................... .139

Power Door Lock-Right Front ...................140

Power Mirrors ........................ .143, 145

Power Recliner Seat .................... .152, 155

Power Seat ................... .149, 150, 152, 155

Power Steering Switch .................... .19, 25

Seat Belt .................................67

Security Alarm-Hood ................. .128, 132, 136

Seat Memory Selector Switch ...................151

Sliding Roof Position ....................... .147

Stop Lamp w/Speed Control ..................38, 59

Stop Lamp w/o Speed Control ................38, 59

Sunroof ............................... .147

Transmission Range Switch .....................35

Turn Signal ...............................60

Vanity Lamp ..............................89

Vehicle Speed Control ........................37

Throttle Body Fuel Injection (TBI) Ignition System (2.5L) ....................... .14, 15, 16, 17, 18

Automatic Shut Down Relay ....................15

Data Link Connector .........................14

Distributor ...............................17

Engine Coolant Temperature Sensor ..........17, 19, 30

EVAP/Purge Solenoid .........................15

Exhaust Gas Recirculation Solenoid ................14

Heated Oxygen Sensor ........................14

Idle Air Control Motor ........................14

Ignition Coil ...............................15

Injector .................................15

MAP Sensor ..............................18

Powertrain Control Module ...........14, 15, 16, 17, 18

Throttle Position (Sensor) ......................18

Vehicle Speed Sensor ........................17

Throttle Position (Sensors) ..................18, 21, 26

Transmission Controller Connector .................177

Transmission Control Module ................33, 34, 35

Transmission Control System ................33, 34, 35

Back-Up Lamp Relay .........................33

Park/Neutral Position Switch ....................33

Safety Shut Down Relay .......................35

Transmission Control Module ...............33, 34, 35

Transmission Output Speed Sensor ................34

Transmission Range Switch .....................35

Transmission Solenoids and Pressure Switches ........35

Turbine Speed Sensor ........................34

Transmission Output Speed Sensor .................34

Transmission Range Lamp with Electronic Cluster ........85

Transmission Solenoid Connector ..................179

Transmission Solenoids and Pressure Switches ..........35

Ä WIRING DIAGRAMS AC-AY BODY 8W - 321

Page 1635 of 2438

LEFT SIDE MOUNT

(1) Raise vehicle on hoist and remove left front

wheel. (2) Remove inter splash shield.

(3) Support the transmission with a transmission

jack. (4) Remove the insulator thru bolt from the mount.

(5) Remove the transmission mount fasteners and

remove mount. (6) Reverse removal procedure for installation. En-

sure that the slide tube is seated into the rail

bracket guides. Refer to (Fig. 3) for bolt tightening

specifications. (7) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

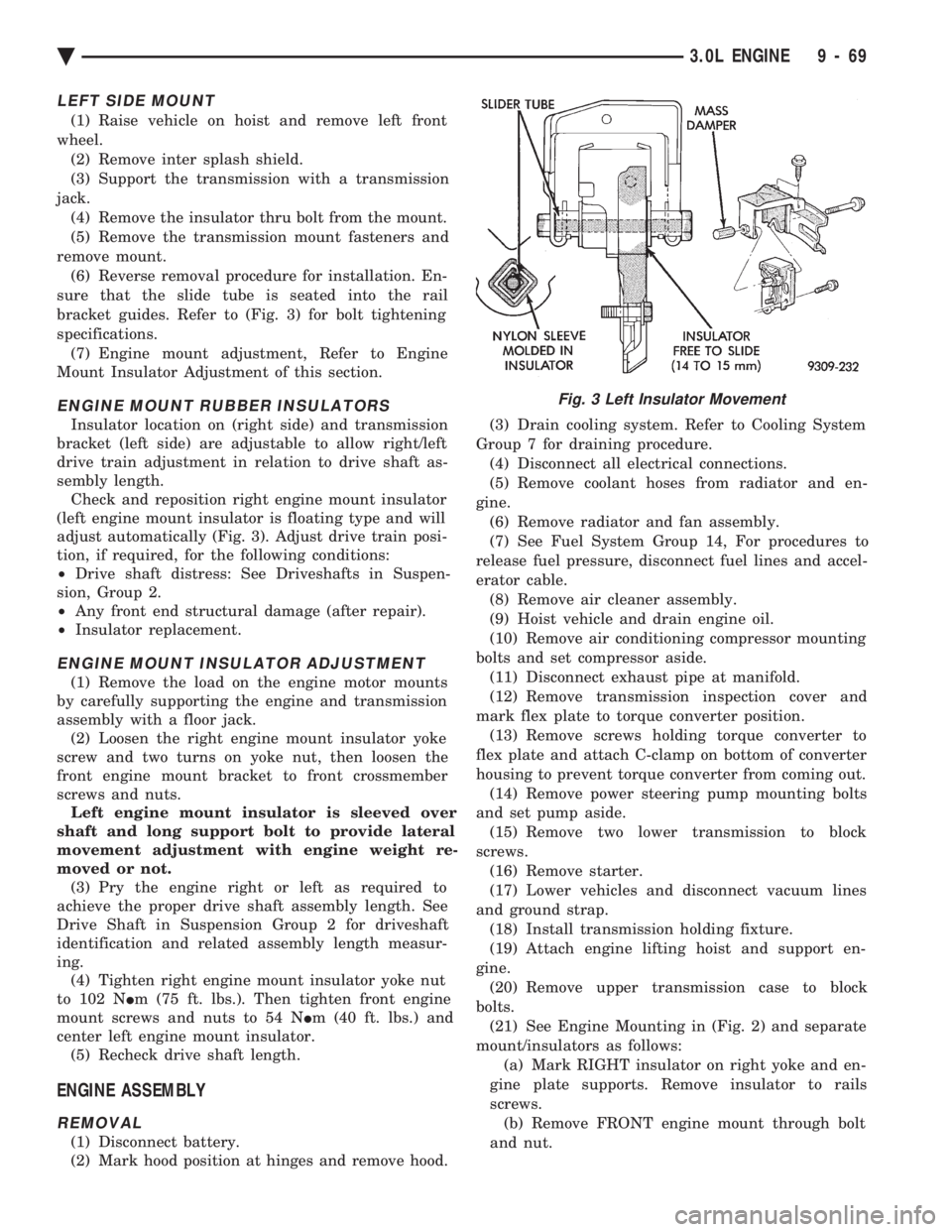

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) and transmission

bracket (left side) are adjustable to allow right/left

drive train adjustment in relation to drive shaft as-

sembly length. Check and reposition right engine mount insulator

(left engine mount insulator is floating type and will

adjust automatically (Fig. 3). Adjust drive train posi-

tion, if required, for the following conditions:

² Drive shaft distress: See Driveshafts in Suspen-

sion, Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack. (2) Loosen the right engine mount insulator yoke

screw and two turns on yoke nut, then loosen the

front engine mount bracket to front crossmember

screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. See

Drive Shaft in Suspension Group 2 for driveshaft

identification and related assembly length measur-

ing. (4) Tighten right engine mount insulator yoke nut

to 102 N Im (75 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood. (3) Drain cooling system. Refer to Cooling System

Group 7 for draining procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and en-

gine. (6) Remove radiator and fan assembly.

(7) See Fuel System Group 14, For procedures to

release fuel pressure, disconnect fuel lines and accel-

erator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from coming out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 2) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right yoke and en-

gine plate supports. Remove insulator to rails

screws. (b) Remove FRONT engine mount through bolt

and nut.

Fig. 3 Left Insulator Movement

Ä 3.0L ENGINE 9 - 69

Page 1667 of 2438

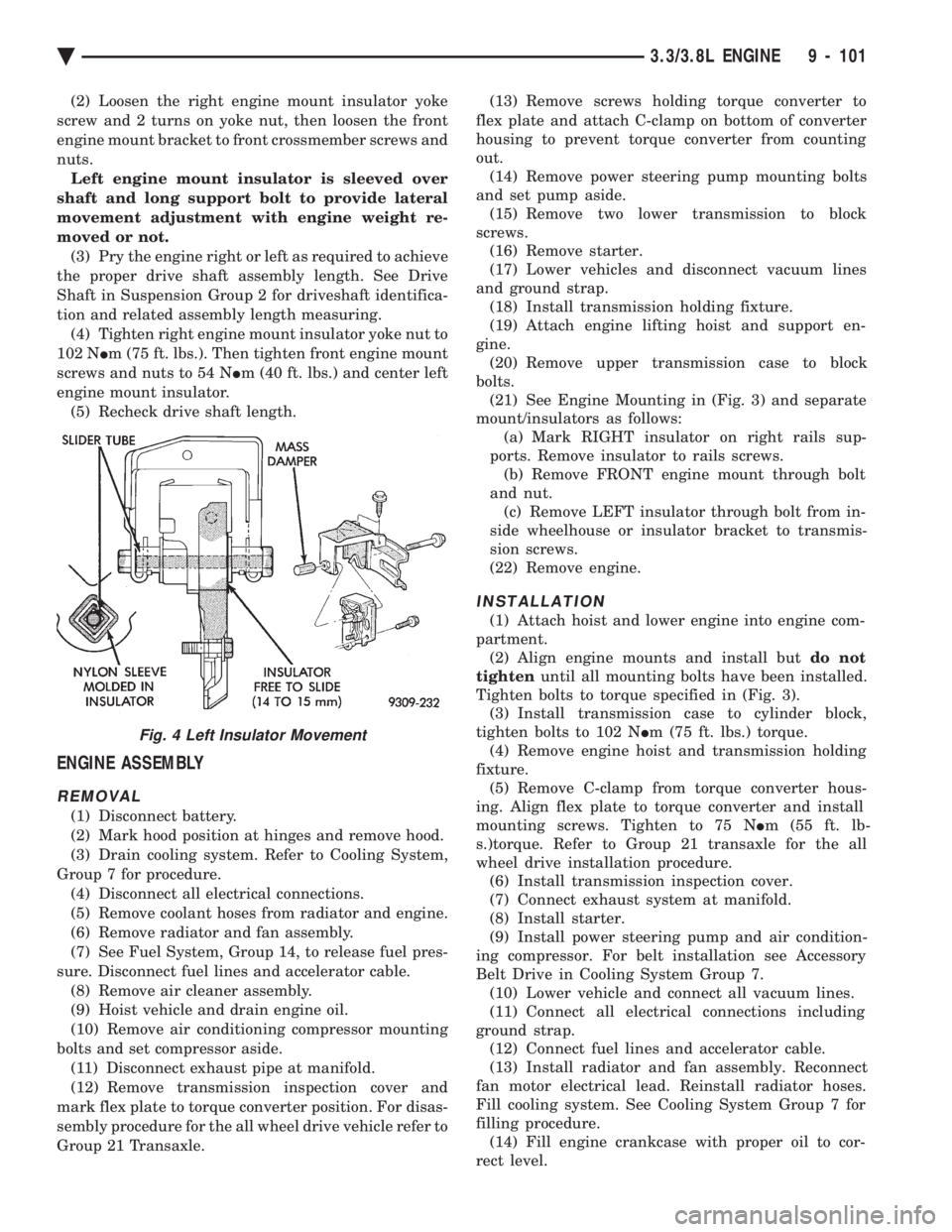

(2) Loosen the right engine mount insulator yoke

screw and 2 turns on yoke nut, then loosen the front

engine mount bracket to front crossmember screws and

nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to achieve

the proper drive shaft assembly length. See Drive

Shaft in Suspension Group 2 for driveshaft identifica-

tion and related assembly length measuring. (4) Tighten right engine mount insulator yoke nut to

102 N Im (75 ft. lbs.). Then tighten front engine mount

screws and nuts to 54 N Im (40 ft. lbs.) and center left

engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood.

(3) Drain cooling system. Refer to Cooling System,

Group 7 for procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and engine.

(6) Remove radiator and fan assembly.

(7) See Fuel System, Group 14, to release fuel pres-

sure. Disconnect fuel lines and accelerator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. For disas-

sembly procedure for the all wheel drive vehicle refer to

Group 21 Transaxle. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from counting

out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 3) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right rails sup-

ports. Remove insulator to rails screws. (b) Remove FRONT engine mount through bolt

and nut. (c) Remove LEFT insulator through bolt from in-

side wheelhouse or insulator bracket to transmis-

sion screws.

(22) Remove engine.

INSTALLATION

(1) Attach hoist and lower engine into engine com-

partment. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

Tighten bolts to torque specified in (Fig. 3). (3) Install transmission case to cylinder block,

tighten bolts to 102 N Im (75 ft. lbs.) torque.

(4) Remove engine hoist and transmission holding

fixture. (5) Remove C-clamp from torque converter hous-

ing. Align flex plate to torque converter and install

mounting screws. Tighten to 75 N Im (55 ft. lb-

s.)torque. Refer to Group 21 transaxle for the all

wheel drive installation procedure. (6) Install transmission inspection cover.

(7) Connect exhaust system at manifold.

(8) Install starter.

(9) Install power steering pump and air condition-

ing compressor. For belt installation see Accessory

Belt Drive in Cooling System Group 7. (10) Lower vehicle and connect all vacuum lines.

(11) Connect all electrical connections including

ground strap. (12) Connect fuel lines and accelerator cable.

(13) Install radiator and fan assembly. Reconnect

fan motor electrical lead. Reinstall radiator hoses.

Fill cooling system. See Cooling System Group 7 for

filling procedure. (14) Fill engine crankcase with proper oil to cor-

rect level.

Fig. 4 Left Insulator Movement

Ä 3.3/3.8L ENGINE 9 - 101

Page 1937 of 2438

(18) Lower vehicle.

(19) Install the serpentine drive belt. Refer to (Fig.

10) for correct serpentine belt routing. See Cooling,

Group 7 for detailed installation procedure.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(20) Fill power steering pump reservoir to correct

fluid level. (21) Connect the negative battery cable on the

negative battery post. (22) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

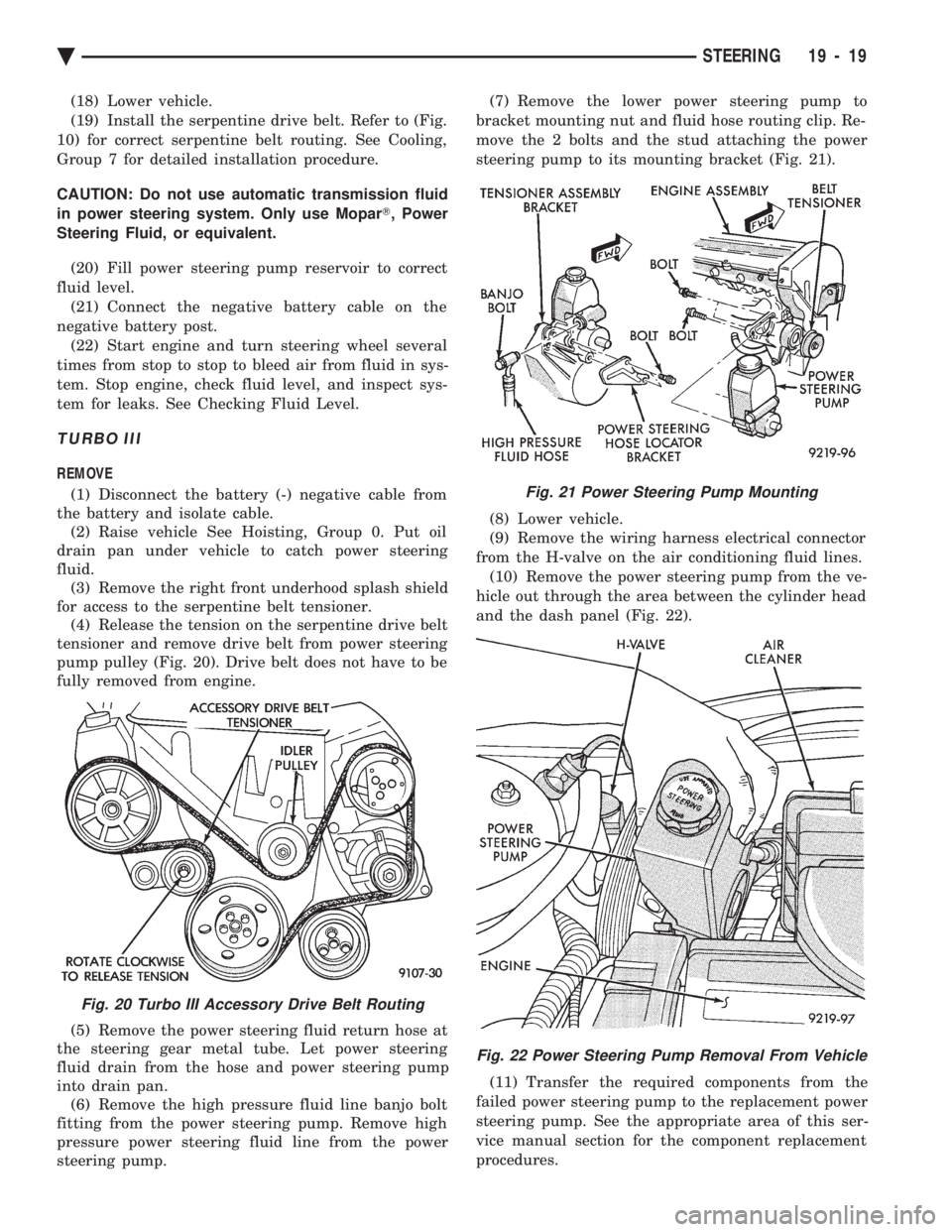

TURBO III

REMOVE

(1) Disconnect the battery (-) negative cable from

the battery and isolate cable. (2) Raise vehicle See Hoisting, Group 0. Put oil

drain pan under vehicle to catch power steering

fluid. (3) Remove the right front underhood splash shield

for access to the serpentine belt tensioner. (4) Release the tension on the serpentine drive belt

tensioner and remove drive belt from power steering

pump pulley (Fig. 20). Drive belt does not have to be

fully removed from engine.

(5) Remove the power steering fluid return hose at

the steering gear metal tube. Let power steering

fluid drain from the hose and power steering pump

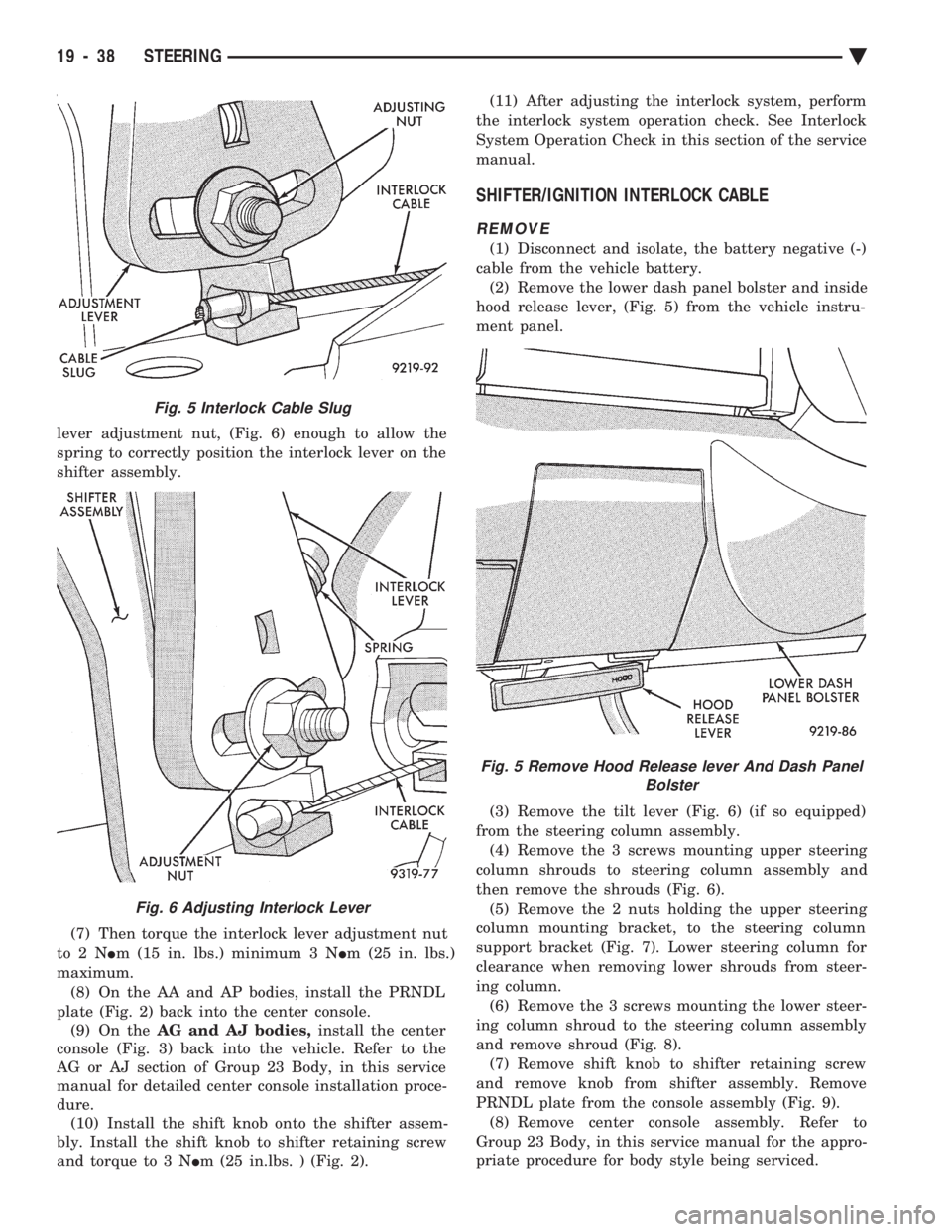

into drain pan. (6) Remove the high pressure fluid line banjo bolt

fitting from the power steering pump. Remove high

pressure power steering fluid line from the power

steering pump. (7) Remove the lower power steering pump to

bracket mounting nut and fluid hose routing clip. Re-

move the 2 bolts and the stud attaching the power

steering pump to its mounting bracket (Fig. 21).

(8) Lower vehicle.

(9) Remove the wiring harness electrical connector

from the H-valve on the air conditioning fluid lines. (10) Remove the power steering pump from the ve-

hicle out through the area between the cylinder head

and the dash panel (Fig. 22).

(11) Transfer the required components from the

failed power steering pump to the replacement power

steering pump. See the appropriate area of this ser-

vice manual section for the component replacement

procedures.

Fig. 20 Turbo III Accessory Drive Belt Routing

Fig. 21 Power Steering Pump Mounting

Fig. 22 Power Steering Pump Removal From Vehicle

Ä STEERING 19 - 19

Page 1956 of 2438

lever adjustment nut, (Fig. 6) enough to allow the

spring to correctly position the interlock lever on the

shifter assembly.

(7) Then torque the interlock lever adjustment nut

to2N Im (15 in. lbs.) minimum 3 N Im (25 in. lbs.)

maximum. (8) On the AA and AP bodies, install the PRNDL

plate (Fig. 2) back into the center console. (9) On the AG and AJ bodies, install the center

console (Fig. 3) back into the vehicle. Refer to the

AG or AJ section of Group 23 Body, in this service

manual for detailed center console installation proce-

dure. (10) Install the shift knob onto the shifter assem-

bly. Install the shift knob to shifter retaining screw

and torque to 3 N Im (25 in.lbs. ) (Fig. 2). (11) After adjusting the interlock system, perform

the interlock system operation check. See Interlock

System Operation Check in this section of the service

manual.

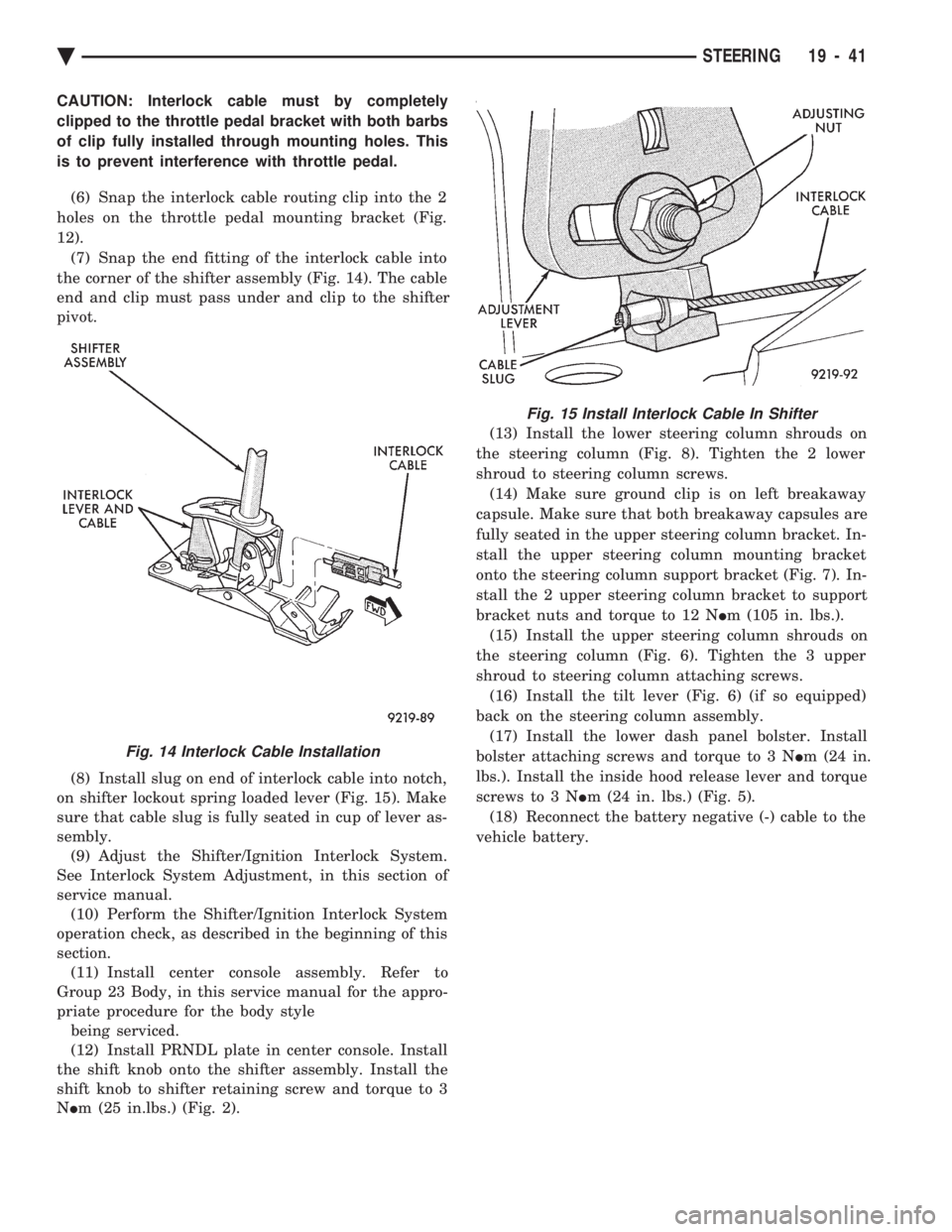

SHIFTER/IGNITION INTERLOCK CABLE

REMOVE

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery. (2) Remove the lower dash panel bolster and inside

hood release lever, (Fig. 5) from the vehicle instru-

ment panel.

(3) Remove the tilt lever (Fig. 6) (if so equipped)

from the steering column assembly. (4) Remove the 3 screws mounting upper steering

column shrouds to steering column assembly and

then remove the shrouds (Fig. 6). (5) Remove the 2 nuts holding the upper steering

column mounting bracket, to the steering column

support bracket (Fig. 7). Lower steering column for

clearance when removing lower shrouds from steer-

ing column. (6) Remove the 3 screws mounting the lower steer-

ing column shroud to the steering column assembly

and remove shroud (Fig. 8). (7) Remove shift knob to shifter retaining screw

and remove knob from shifter assembly. Remove

PRNDL plate from the console assembly (Fig. 9). (8) Remove center console assembly. Refer to

Group 23 Body, in this service manual for the appro-

priate procedure for body style being serviced.

Fig. 5 Interlock Cable Slug

Fig. 6 Adjusting Interlock Lever

Fig. 5 Remove Hood Release lever And Dash Panel Bolster

19 - 38 STEERING Ä

Page 1959 of 2438

CAUTION: Interlock cable must by completely

clipped to the throttle pedal bracket with both barbs

of clip fully installed through mounting holes. This

is to prevent interference with throttle pedal.

(6) Snap the interlock cable routing clip into the 2

holes on the throttle pedal mounting bracket (Fig.

12). (7) Snap the end fitting of the interlock cable into

the corner of the shifter assembly (Fig. 14). The cable

end and clip must pass under and clip to the shifter

pivot.

(8) Install slug on end of interlock cable into notch,

on shifter lockout spring loaded lever (Fig. 15). Make

sure that cable slug is fully seated in cup of lever as-

sembly. (9) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section of

service manual. (10) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section. (11) Install center console assembly. Refer to

Group 23 Body, in this service manual for the appro-

priate procedure for the body style being serviced.

(12) Install PRNDL plate in center console. Install

the shift knob onto the shifter assembly. Install the

shift knob to shifter retaining screw and torque to 3

N Im (25 in.lbs.) (Fig. 2). (13) Install the lower steering column shrouds on

the steering column (Fig. 8). Tighten the 2 lower

shroud to steering column screws. (14) Make sure ground clip is on left breakaway

capsule. Make sure that both breakaway capsules are

fully seated in the upper steering column bracket. In-

stall the upper steering column mounting bracket

onto the steering column support bracket (Fig. 7). In-

stall the 2 upper steering column bracket to support

bracket nuts and torque to 12 N Im (105 in. lbs.).

(15) Install the upper steering column shrouds on

the steering column (Fig. 6). Tighten the 3 upper

shroud to steering column attaching screws. (16) Install the tilt lever (Fig. 6) (if so equipped)

back on the steering column assembly. (17) Install the lower dash panel bolster. Install

bolster attaching screws and torque to 3 N Im (24 in.

lbs.). Install the inside hood release lever and torque

screws to 3 N Im (24 in. lbs.) (Fig. 5).

(18) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 14 Interlock Cable Installation

Fig. 15 Install Interlock Cable In Shifter

Ä STEERING 19 - 41

Page 2167 of 2438

AA-VEHICLE BODY COMPONENT SERVICE INDEX

page page

A-Pillar and Roof Rail Mouldings ............. 25

B-Pillar Trim Panel ....................... 25

Body Side Moulding and Applique ............ 24

Cowl Cover ............................. 13

Cowl Panel Trim and Scuff Plates ............ 25

Door Opening Weatherstrips ................ 24

Floor Carpet ............................ 30

Front Center Console ..................... 29

Front Door and Hinge ..................... 15

Front Door Belt Moulding and Weatherstrip ..... 17

Front Door Glass ........................ 17

Front Door Glass Channel and Run Weatherstrip . 18

Front Door Glass Run Lower Channel ......... 18

Front Door Latch ......................... 16

Front Door Side View Mirror ................ 17

Front Door Silencer and Water Shield ......... 15

Front Door Trim Panel .................... 14

Front Door Window Regulator/Manual ......... 18

Front Door Window Regulator/Power .......... 19

Front End Splash Shields .................. 13

Front Fender ............................ 14

Front Power Door Lock Actuator ............. 19

Front Seat Belts ......................... 27

Front Seats ............................. 28

Fuel Fill Door ........................... 36

Grille .................................. 11

Head Lining ............................. 30

Hood and Hinges ........................ 11

Hood Latch and Release Cable .............. 12

Outside Front Door Latch Release Handle ..... 16

Outside Rear Door Latch Release Handle ...... 21 Overhead Console

........................ 30

Quarter Extension Trim Panel ............... 27

Quarter Trim Panel ....................... 27

Rear Deck Filler Panel .................... 31

Rear Door and Hinge ..................... 20

Rear Door Belt Moulding and Weatherstrip ..... 22

Rear Door Glass ......................... 22

Rear Door Glass Run Weatherstrip ........... 22

Rear Door Glass Stationary Glass Module ..... 23

Rear Door Latch ......................... 21

Rear Door Silencer and Water Shield ......... 20

Rear Door Trim Panel ..................... 20

Rear Door Window Regulator/Manual ......... 23

Rear Door Window Regulator/Power .......... 23

Rear Power Door Lock Actuator ............. 22

Rear Seat Belts .......................... 28

Rear Seats ............................. 28

Rear Shelf Trim Panel ..................... 27

Rear Window Glass ...................... 32

Sun Roof Air Deflector .................... 31

Sun Roof Drain Tubes .................... 31

Sun Roof Weatherstrip .................... 31

Trunk Lid .............................. 33

Trunk Lid Hinge ......................... 34

Trunk Lid Latch .......................... 34

Trunk Lid Lock .......................... 34

Trunk Lid Luggage Rack ................... 35

Trunk Lid Torsion Bar ..................... 34

Trunk Lining ............................ 35

Trunk Opening Weatherstrip ................ 35

Vinyl Roof Bonnet ........................ 31

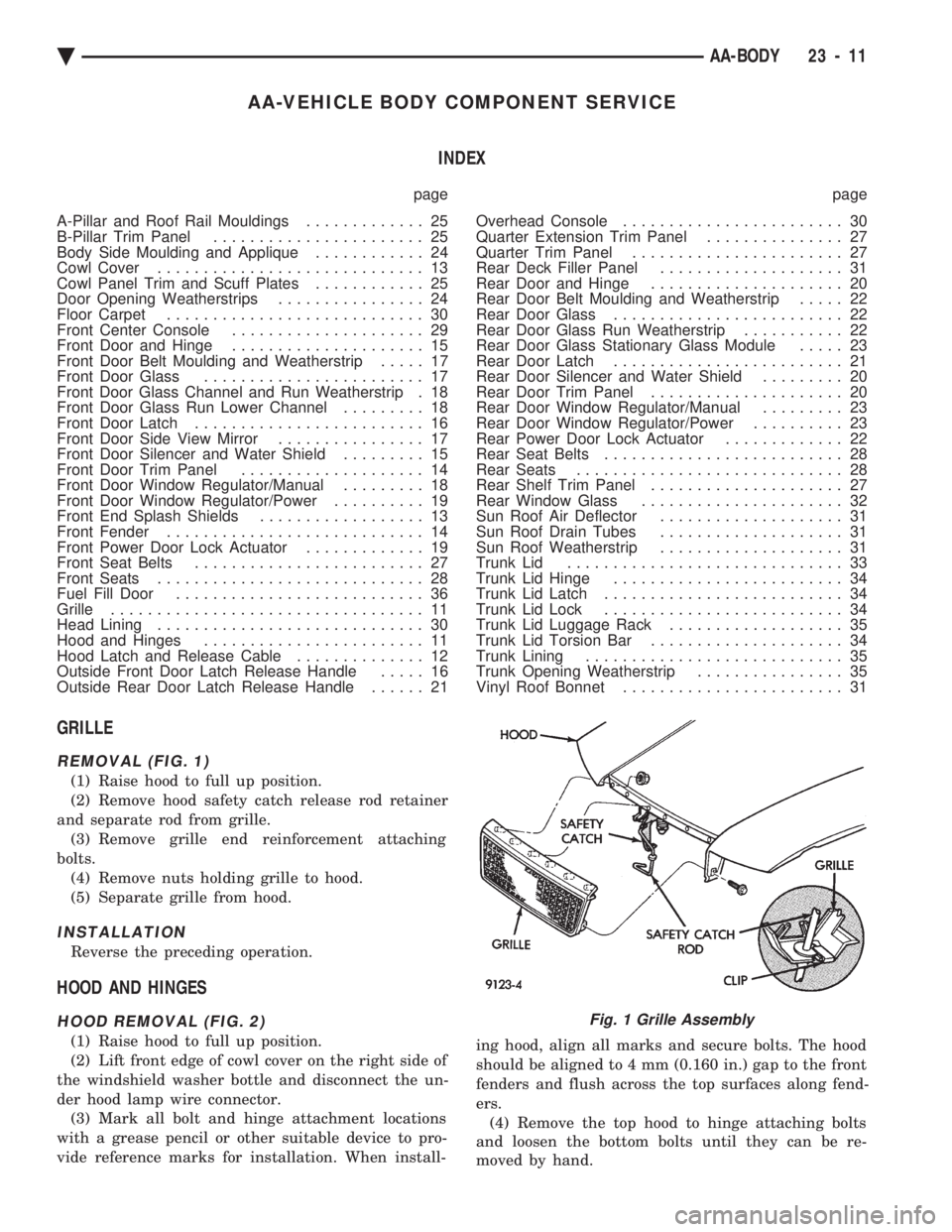

GRILLE

REMOVAL (FIG. 1)

(1) Raise hood to full up position.

(2) Remove hood safety catch release rod retainer

and separate rod from grille. (3) Remove grille end reinforcement attaching

bolts. (4) Remove nuts holding grille to hood.

(5) Separate grille from hood.

INSTALLATION

Reverse the preceding operation.

HOOD AND HINGES

HOOD REMOVAL (FIG. 2)

(1) Raise hood to full up position.

(2) Lift front edge of cowl cover on the right side of

the windshield washer bottle and disconnect the un-

der hood lamp wire connector. (3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install- ing hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. (4) Remove the top hood to hinge attaching bolts

and loosen the bottom bolts until they can be re-

moved by hand.

Fig. 1 Grille Assembly

Ä AA-BODY 23 - 11

Page 2168 of 2438

(5) With assistance of a helper at the opposite side

of the vehicle to support the hood, remove the bottom

hood to hinge attaching bolts. Separate the hood

from the vehicle.

HOOD INSTALLATION

Reverse the preceding operation.

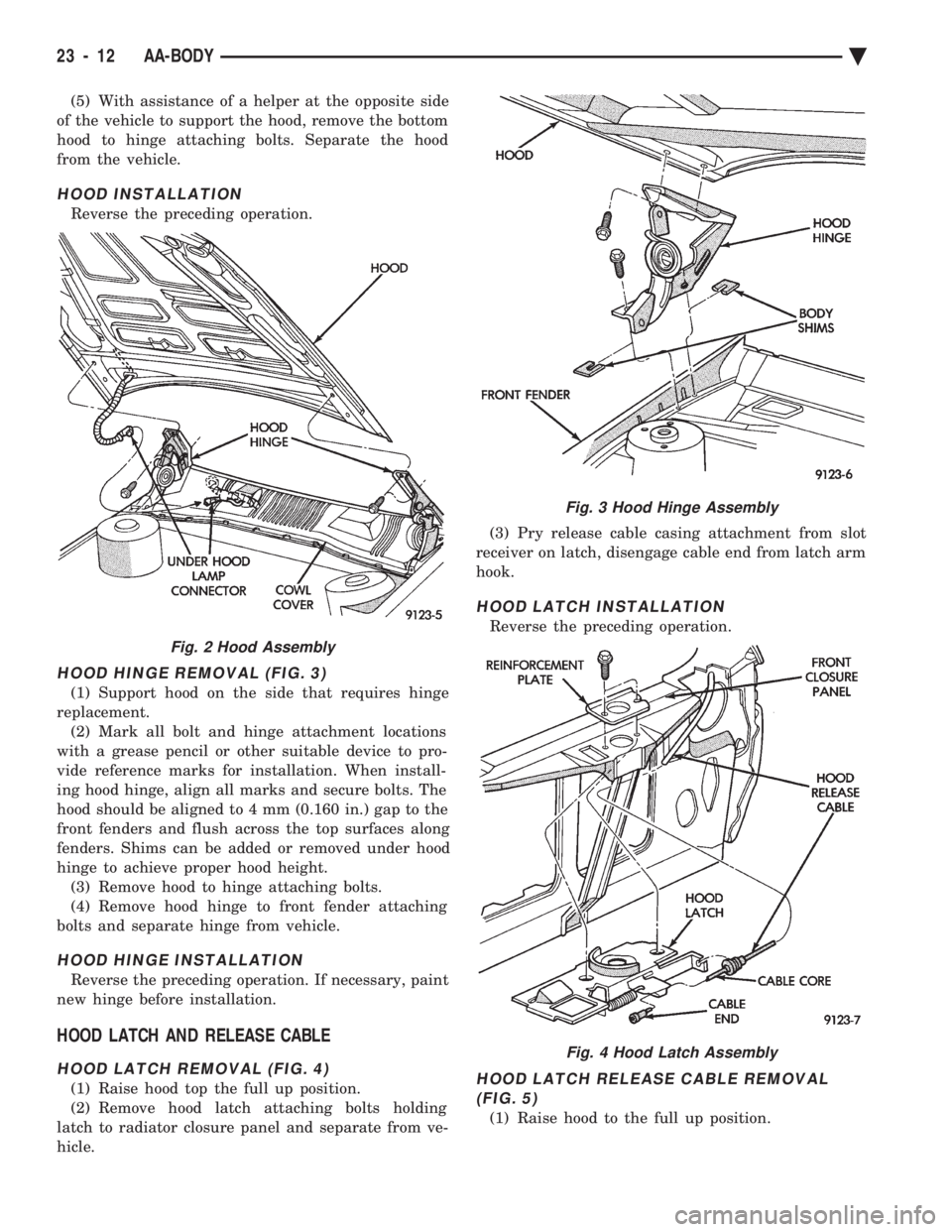

HOOD HINGE REMOVAL (FIG. 3)

(1) Support hood on the side that requires hinge

replacement. (2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install-

ing hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height. (3) Remove hood to hinge attaching bolts.

(4) Remove hood hinge to front fender attaching

bolts and separate hinge from vehicle.

HOOD HINGE INSTALLATION

Reverse the preceding operation. If necessary, paint

new hinge before installation.

HOOD LATCH AND RELEASE CABLE

HOOD LATCH REMOVAL (FIG. 4)

(1) Raise hood top the full up position.

(2) Remove hood latch attaching bolts holding

latch to radiator closure panel and separate from ve-

hicle. (3) Pry release cable casing attachment from slot

receiver on latch, disengage cable end from latch arm

hook.

HOOD LATCH INSTALLATION

Reverse the preceding operation.

HOOD LATCH RELEASE CABLE REMOVAL (FIG. 5)

(1) Raise hood to the full up position.

Fig. 2 Hood Assembly

Fig. 3 Hood Hinge Assembly

Fig. 4 Hood Latch Assembly

23 - 12 AA-BODY Ä