drain bolt CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1964 of 2438

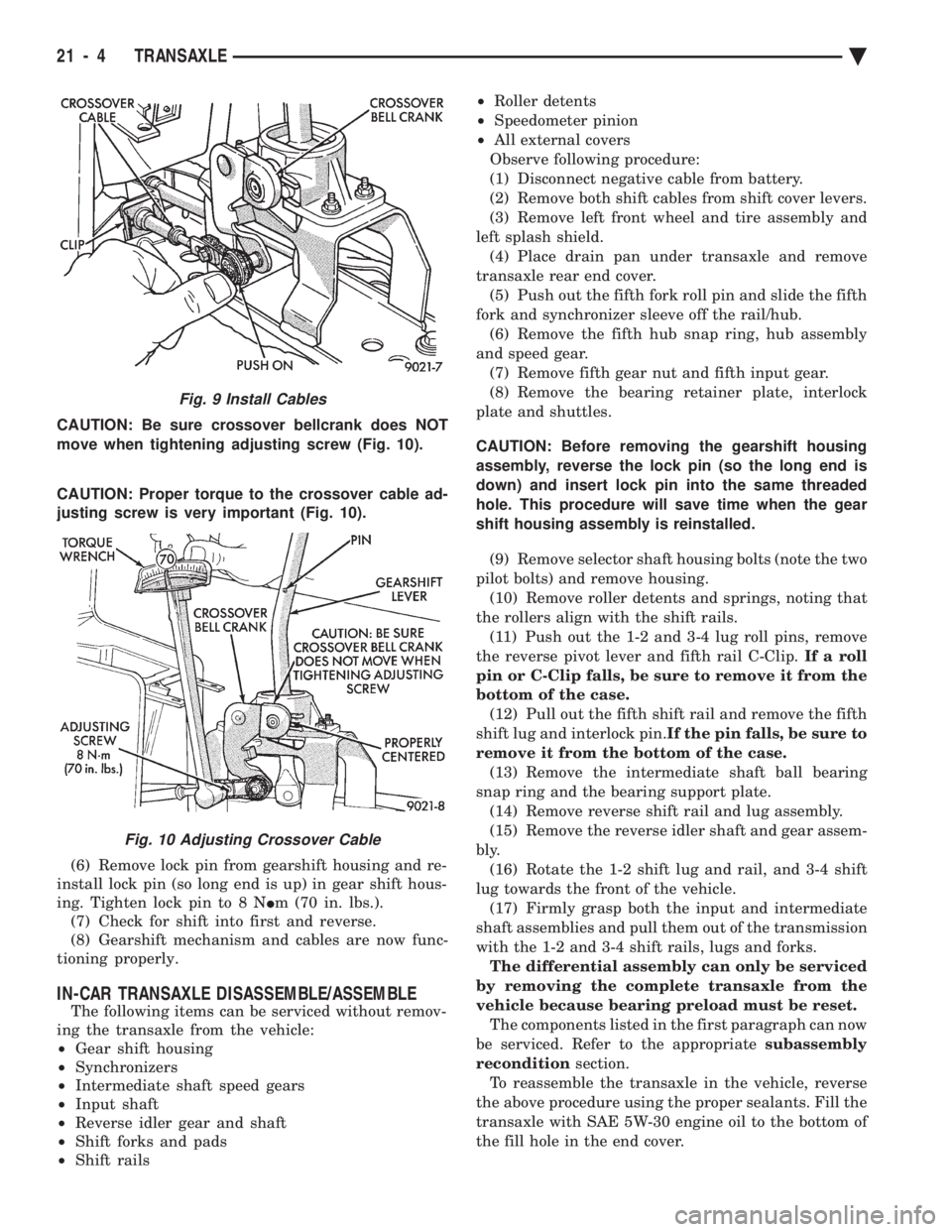

CAUTION: Be sure crossover bellcrank does NOT

move when tightening adjusting screw (Fig. 10).

CAUTION: Proper torque to the crossover cable ad-

justing screw is very important (Fig. 10).

(6) Remove lock pin from gearshift housing and re-

install lock pin (so long end is up) in gear shift hous-

ing. Tighten lock pin to 8 N Im (70 in. lbs.).

(7) Check for shift into first and reverse.

(8) Gearshift mechanism and cables are now func-

tioning properly.

IN-CAR TRANSAXLE DISASSEMBLE/ASSEMBLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

² Gear shift housing

² Synchronizers

² Intermediate shaft speed gears

² Input shaft

² Reverse idler gear and shaft

² Shift forks and pads

² Shift rails ²

Roller detents

² Speedometer pinion

² All external covers

Observe following procedure:

(1) Disconnect negative cable from battery.

(2) Remove both shift cables from shift cover levers.

(3) Remove left front wheel and tire assembly and

left splash shield. (4) Place drain pan under transaxle and remove

transaxle rear end cover. (5) Push out the fifth fork roll pin and slide the fifth

fork and synchronizer sleeve off the rail/hub. (6) Remove the fifth hub snap ring, hub assembly

and speed gear. (7) Remove fifth gear nut and fifth input gear.

(8) Remove the bearing retainer plate, interlock

plate and shuttles.

CAUTION: Before removing the gearshift housing

assembly, reverse the lock pin (so the long end is

down) and insert lock pin into the same threaded

hole. This procedure will save time when the gear

shift housing assembly is reinstalled. (9) Remove selector shaft housing bolts (note the two

pilot bolts) and remove housing. (10) Remove roller detents and springs, noting that

the rollers align with the shift rails. (11) Push out the 1-2 and 3-4 lug roll pins, remove

the reverse pivot lever and fifth rail C-Clip. If a roll

pin or C-Clip falls, be sure to remove it from the

bottom of the case. (12) Pull out the fifth shift rail and remove the fifth

shift lug and interlock pin. If the pin falls, be sure to

remove it from the bottom of the case. (13) Remove the intermediate shaft ball bearing

snap ring and the bearing support plate. (14) Remove reverse shift rail and lug assembly.

(15) Remove the reverse idler shaft and gear assem-

bly. (16) Rotate the 1-2 shift lug and rail, and 3-4 shift

lug towards the front of the vehicle. (17) Firmly grasp both the input and intermediate

shaft assemblies and pull them out of the transmission

with the 1-2 and 3-4 shift rails, lugs and forks. The differential assembly can only be serviced

by removing the complete transaxle from the

vehicle because bearing preload must be reset. The components listed in the first paragraph can now

be serviced. Refer to the appropriate subassembly

recondition section.

To reassemble the transaxle in the vehicle, reverse

the above procedure using the proper sealants. Fill the

transaxle with SAE 5W-30 engine oil to the bottom of

the fill hole in the end cover.

Fig. 9 Install Cables

Fig. 10 Adjusting Crossover Cable

21 - 4 TRANSAXLE Ä

Page 2000 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle. The torque converter will fill in both the PPark or N

Neutral positions. Place the selector lever in PPark to

check fluid level. Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the addmark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOTregion.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR tATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex- ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR tATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan. (3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N Im (40

in. lbs.). (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive sealant. Tighten oil pan

bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the HOT

region (Fig. 1). To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40 TRANSAXLE Ä

Page 2005 of 2438

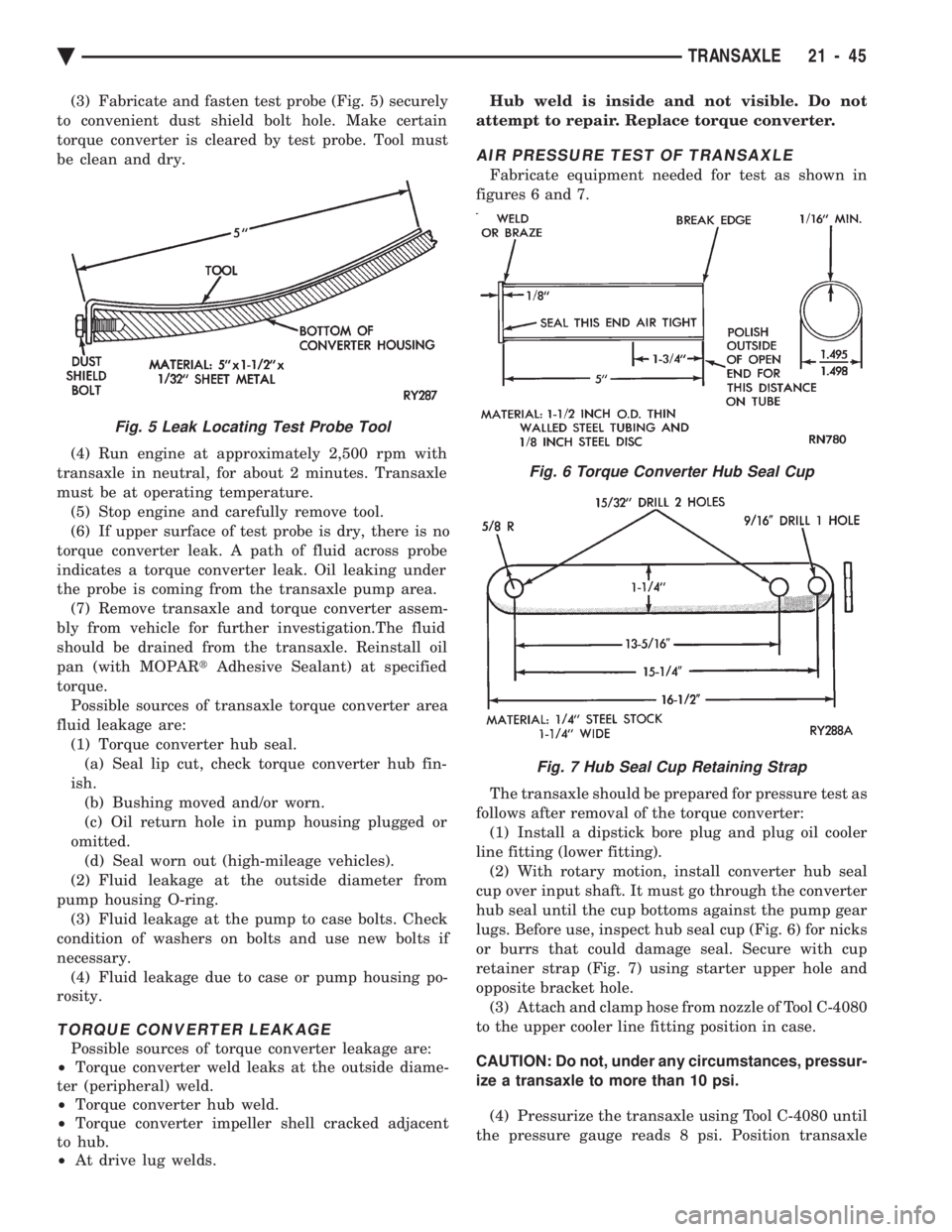

(3) Fabricate and fasten test probe (Fig. 5) securely

to convenient dust shield bolt hole. Make certain

torque converter is cleared by test probe. Tool must

be clean and dry.

(4) Run engine at approximately 2,500 rpm with

transaxle in neutral, for about 2 minutes. Transaxle

must be at operating temperature. (5) Stop engine and carefully remove tool.

(6) If upper surface of test probe is dry, there is no

torque converter leak. A path of fluid across probe

indicates a torque converter leak. Oil leaking under

the probe is coming from the transaxle pump area. (7) Remove transaxle and torque converter assem-

bly from vehicle for further investigation.The fluid

should be drained from the transaxle. Reinstall oil

pan (with MOPAR tAdhesive Sealant) at specified

torque. Possible sources of transaxle torque converter area

fluid leakage are: (1) Torque converter hub seal.(a) Seal lip cut, check torque converter hub fin-

ish. (b) Bushing moved and/or worn.

(c) Oil return hole in pump housing plugged or

omitted. (d) Seal worn out (high-mileage vehicles).

(2) Fluid leakage at the outside diameter from

pump housing O-ring. (3) Fluid leakage at the pump to case bolts. Check

condition of washers on bolts and use new bolts if

necessary. (4) Fluid leakage due to case or pump housing po-

rosity.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

² Torque converter weld leaks at the outside diame-

ter (peripheral) weld.

² Torque converter hub weld.

² Torque converter impeller shell cracked adjacent

to hub.

² At drive lug welds. Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter.

AIR PRESSURE TEST OF TRANSAXLE

Fabricate equipment needed for test as shown in

figures 6 and 7.

The transaxle should be prepared for pressure test as

follows after removal of the torque converter: (1) Install a dipstick bore plug and plug oil cooler

line fitting (lower fitting). (2) With rotary motion, install converter hub seal

cup over input shaft. It must go through the converter

hub seal until the cup bottoms against the pump gear

lugs. Before use, inspect hub seal cup (Fig. 6) for nicks

or burrs that could damage seal. Secure with cup

retainer strap (Fig. 7) using starter upper hole and

opposite bracket hole. (3) Attach and clamp hose from nozzle of Tool C-4080

to the upper cooler line fitting position in case.

CAUTION: Do not, under any circumstances, pressur-

ize a transaxle to more than 10 psi. (4) Pressurize the transaxle using Tool C-4080 until

the pressure gauge reads 8 psi. Position transaxle

Fig. 5 Leak Locating Test Probe Tool

Fig. 6 Torque Converter Hub Seal Cup

Fig. 7 Hub Seal Cup Retaining Strap

Ä TRANSAXLE 21 - 45

Page 2007 of 2438

BAND ADJUSTMENT

KICKDOWN BAND (FRONT)

The kickdown band adjusting screw is located on

left side (top front) of the transaxle case. (1) Loosen locknut and back off nut approximately

five turns. Test adjusting screw for free turning in

the transaxle case. (2) Using wrench, Tool C-3880-A with adapter Tool

C-3705, tighten band adjusting screw to 5 N Im (47 to

50 in. lbs.). If adapter C-3705 is not used, tighten ad-

justing screw to 8 N Im (72 in. lbs.) which is the true

torque. (3) Back off adjusting screw the number of turns

listed in Specifications . Hold adjusting screw in this

position and tighten locknut to 47 N Im (35 ft. lbs.)

LOW/REVERSE BAND-REAR

To adjust low-reverse band, proceed as follows:

(1) Loosen and back off locknut approximately 5

turns. (2) Using an inch-pound torque wrench, tighten

adjusting screw to 5 N Im (41 in. lbs.) true torque.

(3) Back off adjusting screw the number of turns

listed under Specifications in the rear of the Tran-

saxle Section in this service manual. (4) Tighten locknut to 14 N Im (10 ft. lbs.).

HYDRAULIC CONTROL PRESSURE ADJUSTMENTS

LINE PRESSURE

An incorrect throttle pressure setting will cause in-

correct line pressure readings even though line pres-

sure adjustment is correct. Always inspect and

correct throttle pressure adjustment before adjusting

the line pressure. The approximate adjustment for line pressure is

1-5/16 inches, measured from valve body to inner

edge of adjusting nut. However, due to manufactur-

ing tolerances, the adjustment can be varied to ob-

tain specified line pressure. The adjusting screw may be turned with an Allen

wrench. One complete turn of adjusting screw

changes closed throttle line pressure approximately

1-2/3 psi. Turning adjusting screw counterclockwise

increases pressure, and clockwise decreases pressure.

THROTTLE PRESSURE

Throttle pressures cannot be tested accurately;

therefore, the adjustment should be measured if a

malfunction is evident. (1) Insert gauge pin of Tool C-3763 between the

throttle lever cam and kickdown valve. (2) By pushing in on tool, compress kickdown

valve against its spring so throttle valve is com-

pletely bottomed inside the valve body. (3) While compressing spring, turn throttle lever

stop screw with adapter C-4553. Turn until head of screw touches throttle lever tang, with throttle lever

cam touching tool and throttle valve bottomed. Be sure

adjustment is made with spring fully compressed and

valve bottomed in the valve body.

VEHICLE SPEED SENSOR PINION GEAR

When the speed sensor is removed for any reason, a

NEW O-ring must be installed on its outside diameter.

REMOVAL AND INSTALLATION

(1) Remove speedometer cable (if so equipped).

(2) Remove harness connector from sensor. Make

sure weatherseal stays on harness connector. (3) Remove bolt securing the distance sensor in the

extension housing. (4) Carefully pull sensor and pinion gear assembly

out of extension housing. (5) Remove pinion gear from sensor.

(6) To install, reverse the above procedure. Make

sure extension housing and sensor flange are clean

prior to installation. Always use a NEW sensor O-ring. (7) Tighten securing bolt to 7 N Im (60 in. lbs.).

Tighten speedometer cable to 4 N Im (35 in. lbs.).

PARK/NEUTRAL POSITION AND BACK-UP LAMP

SWITCH

REPLACEMENT AND TEST

The Park/Neutral switch is the center terminal of the

3 terminal switch. It provides ground for the starter

solenoid circuit through the selector lever in only Park

and Neutral positions. (1) To test switch, remove wiring connector from

switch and test for continuity between center pin of

switch and transaxle case. Continuity should exist only

when transaxle is in Park or Neutral. (2) Check gearshift cable adjustment before replac-

ing a switch which tests bad. (3) Unscrew switch from transaxle case allowing

fluid to drain into a container. Move selector lever to

Park and then to Neutral positions. Inspect to see that

the switch operating lever fingers are centered in

switch opening in the case. (4) Screw the switch with a new seal into transaxle

case and tighten to 33 N Im (24 ft. lbs.). Retest switch

with the test lamp. (5) Add fluid to transaxle to bring up to proper level.

(6) The back-up lamp switch circuit is through the

two outside terminals of the 3 terminal switch. (7) To test switch, remove wiring connector from

switch and test for continuity between the two outside

pins. (8) Continuity should exist only with transaxle in

Reverse position. (9) No continuity should exist from either pin to the

case.

Ä TRANSAXLE 21 - 47

Page 2053 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. The torque converter fills in both the PPark and N

Neutral positions. Place the selector lever in PPark to

check the fluid level. The engine should be running

at idle speed for at least one minute, with the

vehicle on level ground. This will assure com-

plete oil level stabilization between differential

and transmission. The fluid should be at normal

operating temperature (approximately 82 C. or 180 F.).

The fluid level is correct if it is in the HOTregion

(cross-hatched area) on the oil level indicator. Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause over heat-

ing, fluid oxidation, and varnishing, which can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transaxle vent where it may be mistaken for a leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

the 41TE transaxle. MOPAR tATF PLUS (Automatic

Transmission FluidÐtype 7176) should be used to aid

in assuring optimum transmission performance. Flu-

ids of the type labeled DEXRON II Automatic Trans-

mission Fluid are not recommended . DEXRON II

can be used only if the recommended fluid is not

available. If more than a small amount of DEXRON II

is used shudder or shift quality problems may result. It

is important that the transmission fluid be maintained

at the prescribed level using the recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transaxle, other than the

automatic transmission fluid listed above. An excep- tion to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGES

When the factory fill fluid is changed, only fluids

labeled MOPAR tATF PLUS (Automatic Transmis-

sion fluid) Type 7176 should be used. A filter change

should be made at the time of the oil change. Also

the magnet (on the inside of the oil pan) should be

cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason, the

fluid and filter should be changed.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication,

Group 0). Place a drain container with a large open-

ing, under transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan. (3) Install a new filter and O-ring on bottom of the

valve body. (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive Sealant. Tighten oil

pan bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Au-

tomatic Transmission Fluid) Type 7176 through the

fill tube. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

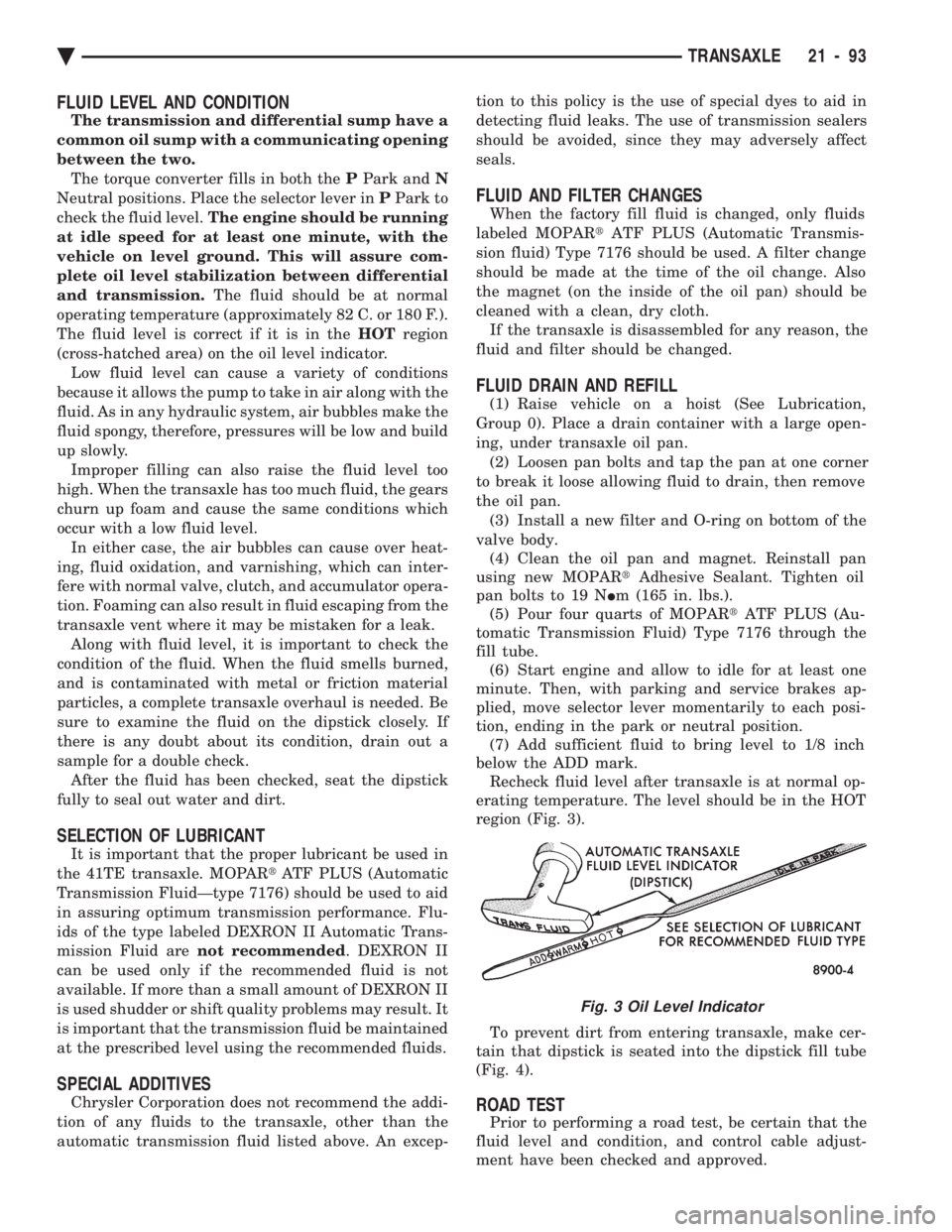

below the ADD mark. Recheck fluid level after transaxle is at normal op-

erating temperature. The level should be in the HOT

region (Fig. 3).

To prevent dirt from entering transaxle, make cer-

tain that dipstick is seated into the dipstick fill tube

(Fig. 4).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjust-

ment have been checked and approved.

Fig. 3 Oil Level Indicator

Ä TRANSAXLE 21 - 93

Page 2057 of 2438

first separator plate and watch carefully for the pis-

ton to move forward. The piston should return to its

original position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks

the output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not ro-

tate with hand torque. Release the air pressure and

confirm that the input shaft will rotate.

FLUID LEAKAGE-TORQUE CONVERTER HOUSING

AREA

(1) Check for source of leakage.

Since fluid leakage at or around the torque con-

verter area may originate from an engine oil leak,

the area should be examined closely. Factory fill

fluid is dyed red and, therefore, can be distinguished

from engine oil. (2) Prior to removing the transaxle, perform the

following checks: When leakage is determined to originate from the

transaxle, check fluid level prior to removal of the

transaxle and torque converter. High oil level can result in oil leakage out the vent

in the manual shaft. If the fluid level is high, adjust

to proper level. After performing this operation, inspect for leak-

age. If a leak persists, perform the following opera-

tion on the vehicle to determine if it is the torque

converter or transaxle that is leaking.

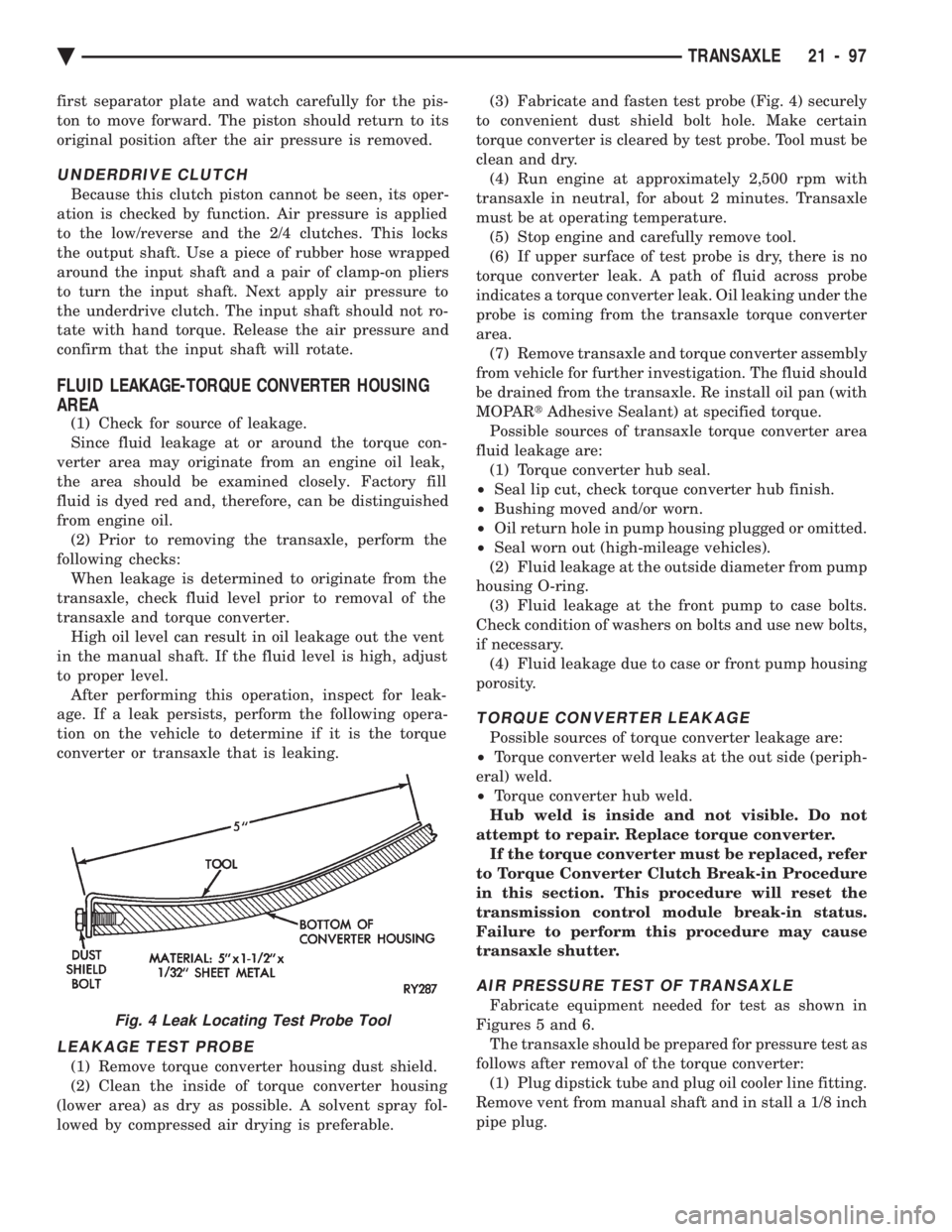

LEAKAGE TEST PROBE

(1) Remove torque converter housing dust shield.

(2) Clean the inside of torque converter housing

(lower area) as dry as possible. A solvent spray fol-

lowed by compressed air drying is preferable. (3) Fabricate and fasten test probe (Fig. 4) securely

to convenient dust shield bolt hole. Make certain

torque converter is cleared by test probe. Tool must be

clean and dry. (4) Run engine at approximately 2,500 rpm with

transaxle in neutral, for about 2 minutes. Transaxle

must be at operating temperature. (5) Stop engine and carefully remove tool.

(6) If upper surface of test probe is dry, there is no

torque converter leak. A path of fluid across probe

indicates a torque converter leak. Oil leaking under the

probe is coming from the transaxle torque converter

area. (7) Remove transaxle and torque converter assembly

from vehicle for further investigation. The fluid should

be drained from the transaxle. Re install oil pan (with

MOPAR tAdhesive Sealant) at specified torque.

Possible sources of transaxle torque converter area

fluid leakage are: (1) Torque converter hub seal.

² Seal lip cut, check torque converter hub finish.

² Bushing moved and/or worn.

² Oil return hole in pump housing plugged or omitted.

² Seal worn out (high-mileage vehicles).

(2) Fluid leakage at the outside diameter from pump

housing O-ring. (3) Fluid leakage at the front pump to case bolts.

Check condition of washers on bolts and use new bolts,

if necessary. (4) Fluid leakage due to case or front pump housing

porosity.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

² Torque converter weld leaks at the out side (periph-

eral) weld.

² Torque converter hub weld.

Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter. If the torque converter must be replaced, refer

to Torque Converter Clutch Break-in Procedure

in this section. This procedure will reset the

transmission control module break-in status.

Failure to perform this procedure may cause

transaxle shutter.

AIR PRESSURE TEST OF TRANSAXLE

Fabricate equipment needed for test as shown in

Figures 5 and 6. The transaxle should be prepared for pressure test as

follows after removal of the torque converter: (1) Plug dipstick tube and plug oil cooler line fitting.

Remove vent from manual shaft and in stall a 1/8 inch

pipe plug.Fig. 4 Leak Locating Test Probe Tool

Ä TRANSAXLE 21 - 97

Page 2059 of 2438

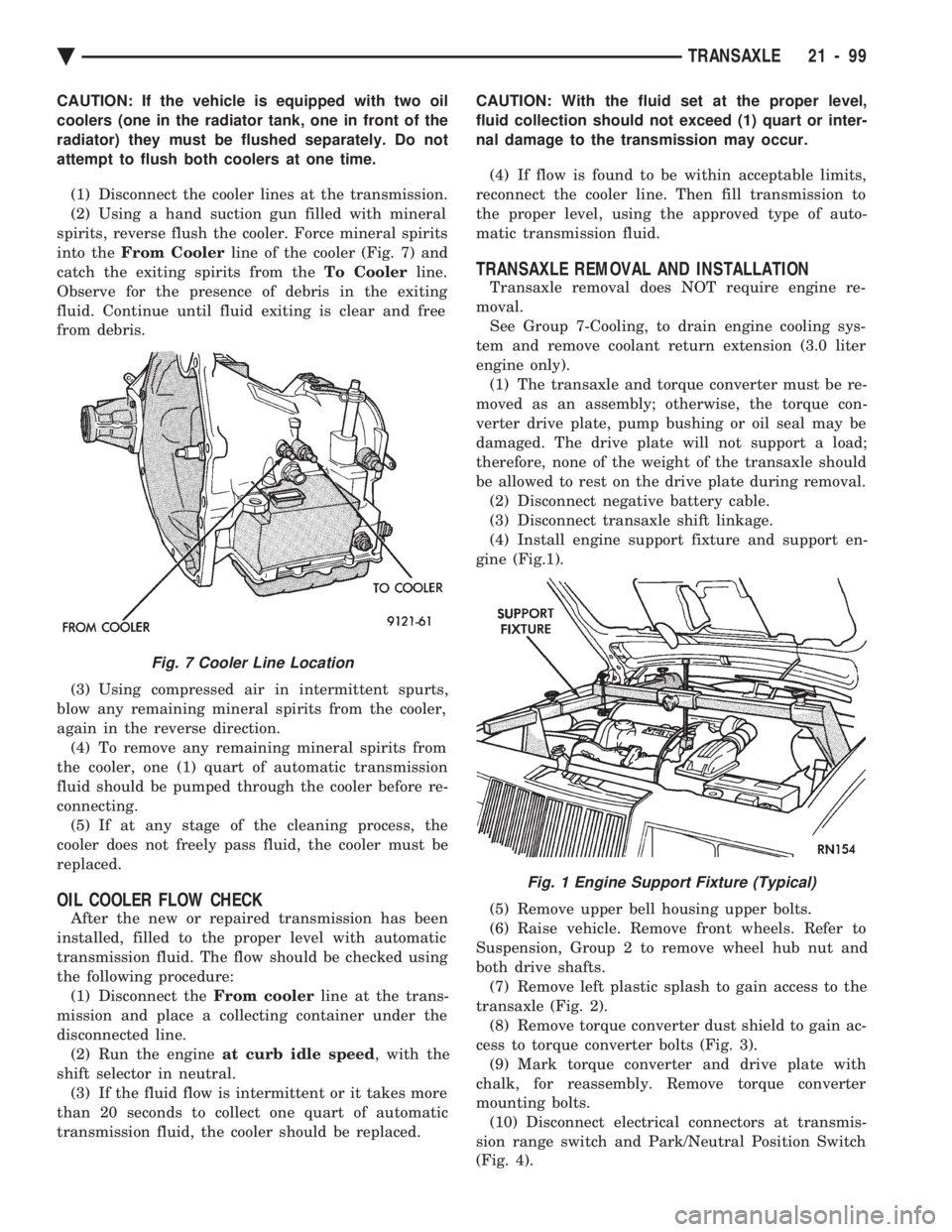

CAUTION: If the vehicle is equipped with two oil

coolers (one in the radiator tank, one in front of the

radiator) they must be flushed separately. Do not

attempt to flush both coolers at one time. (1) Disconnect the cooler lines at the transmission.

(2) Using a hand suction gun filled with mineral

spirits, reverse flush the cooler. Force mineral spirits

into the From Cooler line of the cooler (Fig. 7) and

catch the exiting spirits from the To Coolerline.

Observe for the presence of debris in the exiting

fluid. Continue until fluid exiting is clear and free

from debris.

(3) Using compressed air in intermittent spurts,

blow any remaining mineral spirits from the cooler,

again in the reverse direction. (4) To remove any remaining mineral spirits from

the cooler, one (1) quart of automatic transmission

fluid should be pumped through the cooler before re-

connecting. (5) If at any stage of the cleaning process, the

cooler does not freely pass fluid, the cooler must be

replaced.

OIL COOLER FLOW CHECK

After the new or repaired transmission has been

installed, filled to the proper level with automatic

transmission fluid. The flow should be checked using

the following procedure: (1) Disconnect the From coolerline at the trans-

mission and place a collecting container under the

disconnected line. (2) Run the engine at curb idle speed , with the

shift selector in neutral. (3) If the fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of automatic

transmission fluid, the cooler should be replaced. CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(4) If flow is found to be within acceptable limits,

reconnect the cooler line. Then fill transmission to

the proper level, using the approved type of auto-

matic transmission fluid.

TRANSAXLE REMOVAL AND INSTALLATION

Transaxle removal does NOT require engine re-

moval. See Group 7-Cooling, to drain engine cooling sys-

tem and remove coolant return extension (3.0 liter

engine only). (1) The transaxle and torque converter must be re-

moved as an assembly; otherwise, the torque con-

verter drive plate, pump bushing or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the drive plate during removal. (2) Disconnect negative battery cable.

(3) Disconnect transaxle shift linkage.

(4) Install engine support fixture and support en-

gine (Fig.1).

(5) Remove upper bell housing upper bolts.

(6) Raise vehicle. Remove front wheels. Refer to

Suspension, Group 2 to remove wheel hub nut and

both drive shafts. (7) Remove left plastic splash to gain access to the

transaxle (Fig. 2). (8) Remove torque converter dust shield to gain ac-

cess to torque converter bolts (Fig. 3). (9) Mark torque converter and drive plate with

chalk, for reassembly. Remove torque converter

mounting bolts. (10) Disconnect electrical connectors at transmis-

sion range switch and Park/Neutral Position Switch

(Fig. 4).

Fig. 7 Cooler Line Location

Fig. 1 Engine Support Fixture (Typical)

Ä TRANSAXLE 21 - 99

Page 2162 of 2438

POWER SUNROOF INDEX

page page

Adjustment Bracket ........................ 7

Drain Channel ............................ 7

Drive Cable Locators ....................... 7

Drive Cables ............................. 8

General Information ........................ 6

Glass Panel ............................. 7 Glass Vertical Height Adjustment

.............. 6

Guide Assembly .......................... 8

Motor and Drive Gears ..................... 7

Sunshade ............................... 8

Wind Deflector ........................... 6

GENERAL INFORMATION

All sunroofs are equipped with drain tubes that are

located in the A, B or C-pillars. The drain tubes

must be kept open to prevent water from entering

the passenger compartment.

LUBRICATION

(1) Lubricate cables with Lubriplate or equivalent

when cables are replaced. (2) Periodically clean dirt from guide rail covers.

DRAIN TUBES

² Inspect the drain holes, located in the trough

around the sunroof opening to verify they are clear.

Inspection should be performed at least once a year

or when problems are suspected. If drain hose or

tubes are plugged, use compressed air or blunt flexi-

ble wire to clear them. If tubes cannot be cleared,

they must be repaired.

² The lower ends of the rear drain tubes are located

in the rear quarter panel drop wells. To clear rear

drain tubes, use compressed air or blunt flexible wire

from the lower ends of the tubes.

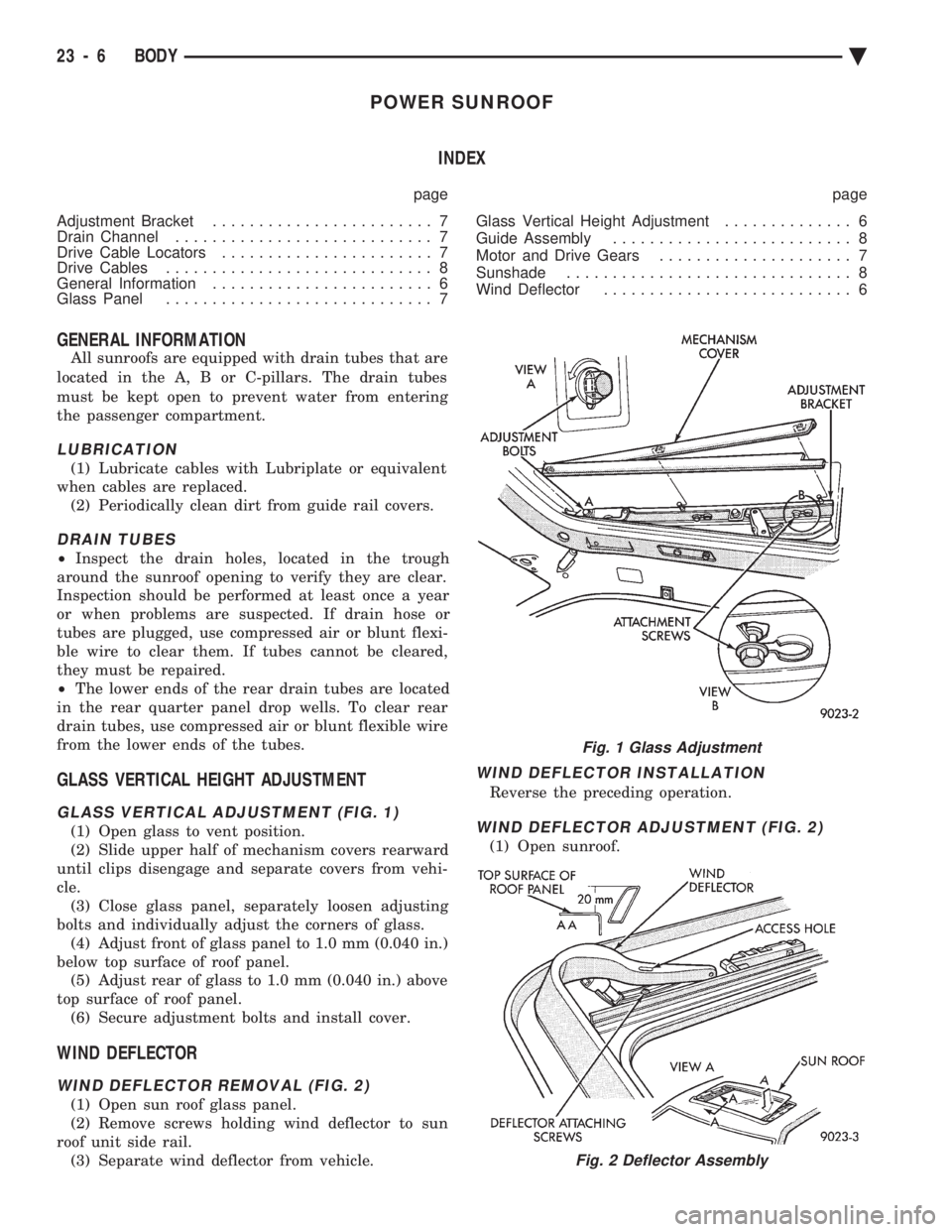

GLASS VERTICAL HEIGHT ADJUSTMENT

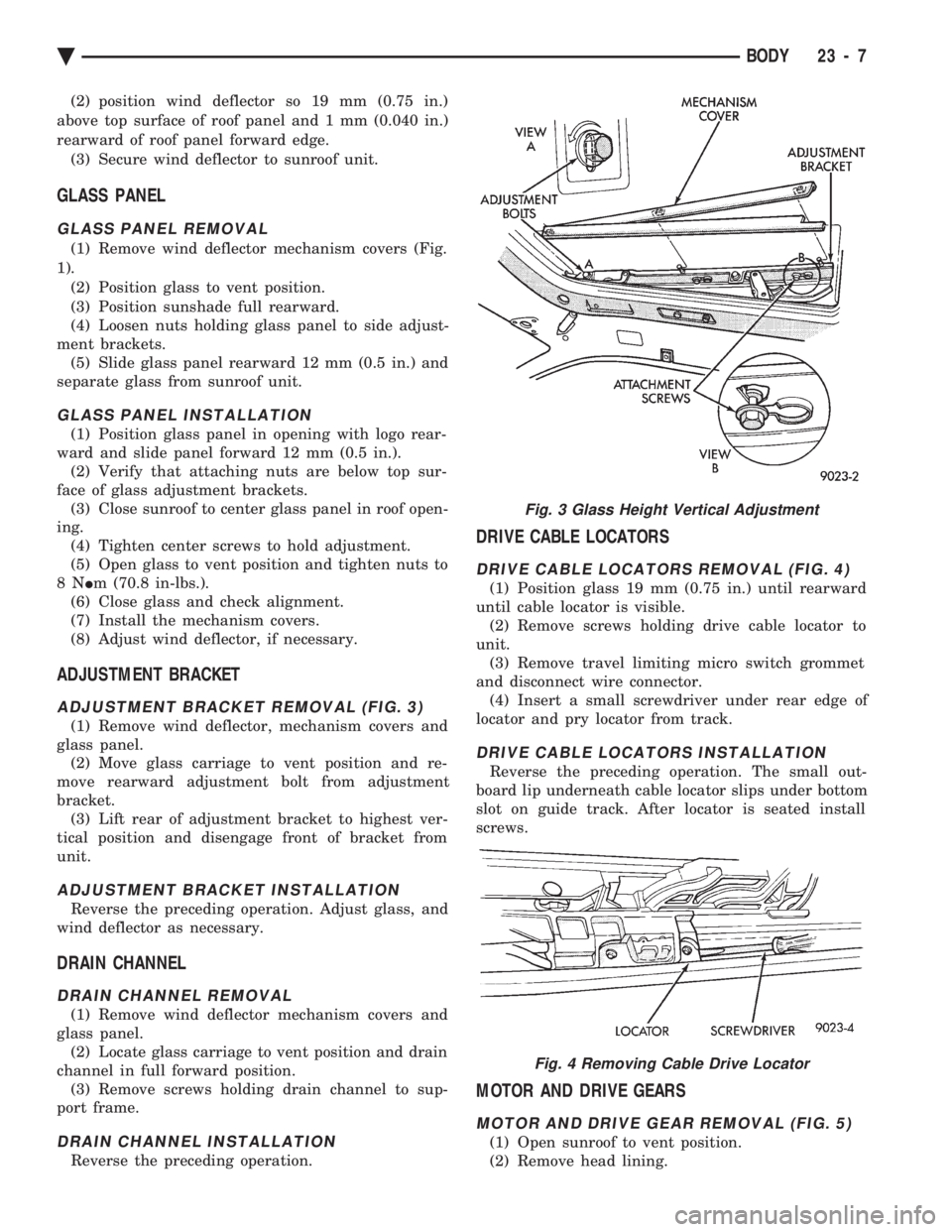

GLASS VERTICAL ADJUSTMENT (FIG. 1)

(1) Open glass to vent position.

(2) Slide upper half of mechanism covers rearward

until clips disengage and separate covers from vehi-

cle. (3) Close glass panel, separately loosen adjusting

bolts and individually adjust the corners of glass. (4) Adjust front of glass panel to 1.0 mm (0.040 in.)

below top surface of roof panel. (5) Adjust rear of glass to 1.0 mm (0.040 in.) above

top surface of roof panel. (6) Secure adjustment bolts and install cover.

WIND DEFLECTOR

WIND DEFLECTOR REMOVAL (FIG. 2)

(1) Open sun roof glass panel.

(2) Remove screws holding wind deflector to sun

roof unit side rail. (3) Separate wind deflector from vehicle.

WIND DEFLECTOR INSTALLATION

Reverse the preceding operation.

WIND DEFLECTOR ADJUSTMENT (FIG. 2)

(1) Open sunroof.

Fig. 1 Glass Adjustment

Fig. 2 Deflector Assembly

23 - 6 BODY Ä

Page 2163 of 2438

(2) position wind deflector so 19 mm (0.75 in.)

above top surface of roof panel and 1 mm (0.040 in.)

rearward of roof panel forward edge. (3) Secure wind deflector to sunroof unit.

GLASS PANEL

GLASS PANEL REMOVAL

(1) Remove wind deflector mechanism covers (Fig.

1). (2) Position glass to vent position.

(3) Position sunshade full rearward.

(4) Loosen nuts holding glass panel to side adjust-

ment brackets. (5) Slide glass panel rearward 12 mm (0.5 in.) and

separate glass from sunroof unit.

GLASS PANEL INSTALLATION

(1) Position glass panel in opening with logo rear-

ward and slide panel forward 12 mm (0.5 in.). (2) Verify that attaching nuts are below top sur-

face of glass adjustment brackets. (3) Close sunroof to center glass panel in roof open-

ing. (4) Tighten center screws to hold adjustment.

(5) Open glass to vent position and tighten nuts to

8N Im (70.8 in-lbs.).

(6) Close glass and check alignment.

(7) Install the mechanism covers.

(8) Adjust wind deflector, if necessary.

ADJUSTMENT BRACKET

ADJUSTMENT BRACKET REMOVAL (FIG. 3)

(1) Remove wind deflector, mechanism covers and

glass panel. (2) Move glass carriage to vent position and re-

move rearward adjustment bolt from adjustment

bracket. (3) Lift rear of adjustment bracket to highest ver-

tical position and disengage front of bracket from

unit.

ADJUSTMENT BRACKET INSTALLATION

Reverse the preceding operation. Adjust glass, and

wind deflector as necessary.

DRAIN CHANNEL

DRAIN CHANNEL REMOVAL

(1) Remove wind deflector mechanism covers and

glass panel. (2) Locate glass carriage to vent position and drain

channel in full forward position. (3) Remove screws holding drain channel to sup-

port frame.

DRAIN CHANNEL INSTALLATION

Reverse the preceding operation.

DRIVE CABLE LOCATORS

DRIVE CABLE LOCATORS REMOVAL (FIG. 4)

(1) Position glass 19 mm (0.75 in.) until rearward

until cable locator is visible. (2) Remove screws holding drive cable locator to

unit. (3) Remove travel limiting micro switch grommet

and disconnect wire connector. (4) Insert a small screwdriver under rear edge of

locator and pry locator from track.

DRIVE CABLE LOCATORS INSTALLATION

Reverse the preceding operation. The small out-

board lip underneath cable locator slips under bottom

slot on guide track. After locator is seated install

screws.

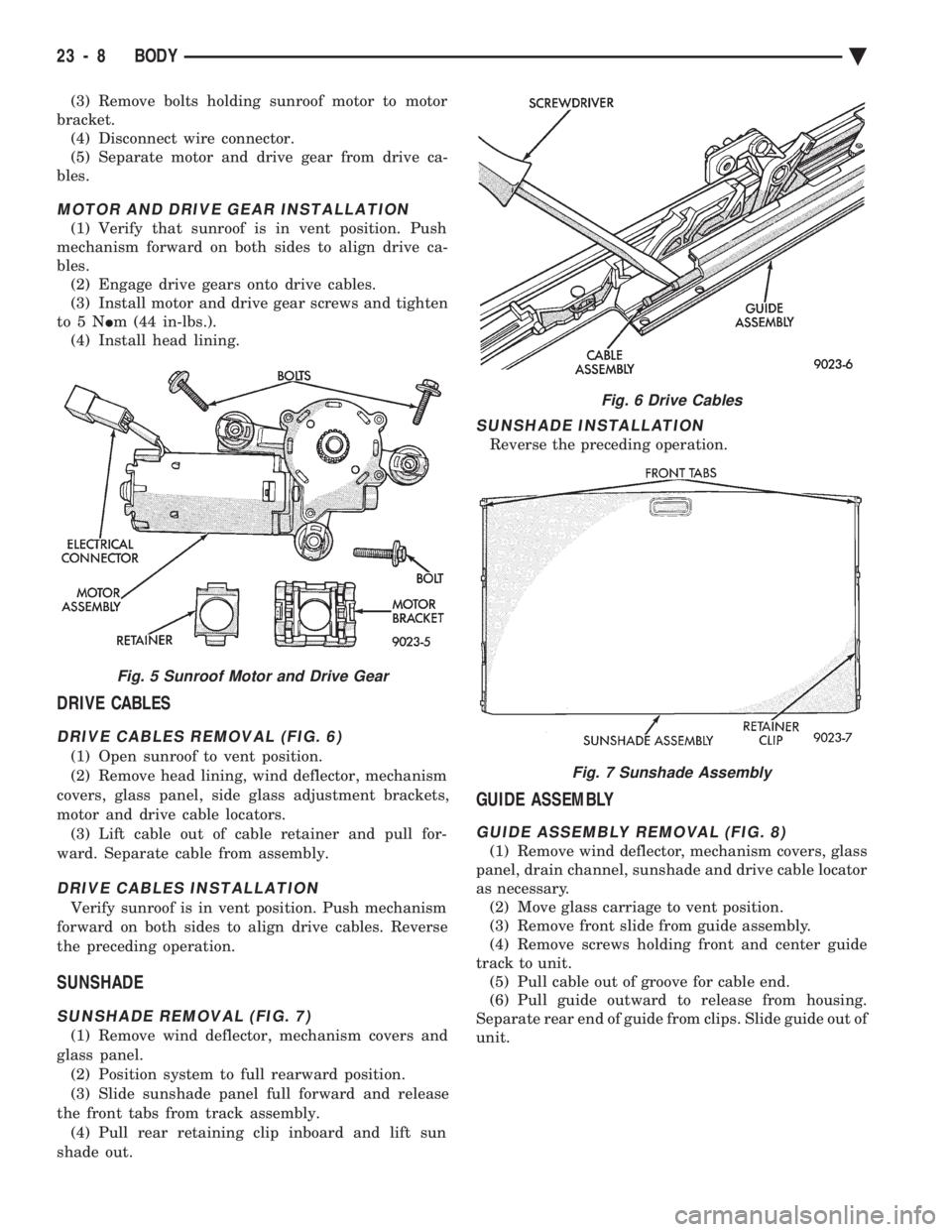

MOTOR AND DRIVE GEARS

MOTOR AND DRIVE GEAR REMOVAL (FIG. 5)

(1) Open sunroof to vent position.

(2) Remove head lining.

Fig. 3 Glass Height Vertical Adjustment

Fig. 4 Removing Cable Drive Locator

Ä BODY 23 - 7

Page 2164 of 2438

(3) Remove bolts holding sunroof motor to motor

bracket. (4) Disconnect wire connector.

(5) Separate motor and drive gear from drive ca-

bles.

MOTOR AND DRIVE GEAR INSTALLATION

(1) Verify that sunroof is in vent position. Push

mechanism forward on both sides to align drive ca-

bles. (2) Engage drive gears onto drive cables.

(3) Install motor and drive gear screws and tighten

to5N Im (44 in-lbs.).

(4) Install head lining.

DRIVE CABLES

DRIVE CABLES REMOVAL (FIG. 6)

(1) Open sunroof to vent position.

(2) Remove head lining, wind deflector, mechanism

covers, glass panel, side glass adjustment brackets,

motor and drive cable locators. (3) Lift cable out of cable retainer and pull for-

ward. Separate cable from assembly.

DRIVE CABLES INSTALLATION

Verify sunroof is in vent position. Push mechanism

forward on both sides to align drive cables. Reverse

the preceding operation.

SUNSHADE

SUNSHADE REMOVAL (FIG. 7)

(1) Remove wind deflector, mechanism covers and

glass panel. (2) Position system to full rearward position.

(3) Slide sunshade panel full forward and release

the front tabs from track assembly. (4) Pull rear retaining clip inboard and lift sun

shade out.

SUNSHADE INSTALLATION

Reverse the preceding operation.

GUIDE ASSEMBLY

GUIDE ASSEMBLY REMOVAL (FIG. 8)

(1) Remove wind deflector, mechanism covers, glass

panel, drain channel, sunshade and drive cable locator

as necessary. (2) Move glass carriage to vent position.

(3) Remove front slide from guide assembly.

(4) Remove screws holding front and center guide

track to unit. (5) Pull cable out of groove for cable end.

(6) Pull guide outward to release from housing.

Separate rear end of guide from clips. Slide guide out of

unit.

Fig. 5 Sunroof Motor and Drive Gear

Fig. 6 Drive Cables

Fig. 7 Sunshade Assembly

23 - 8 BODY Ä