wheel bolt torque CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1951 of 2438

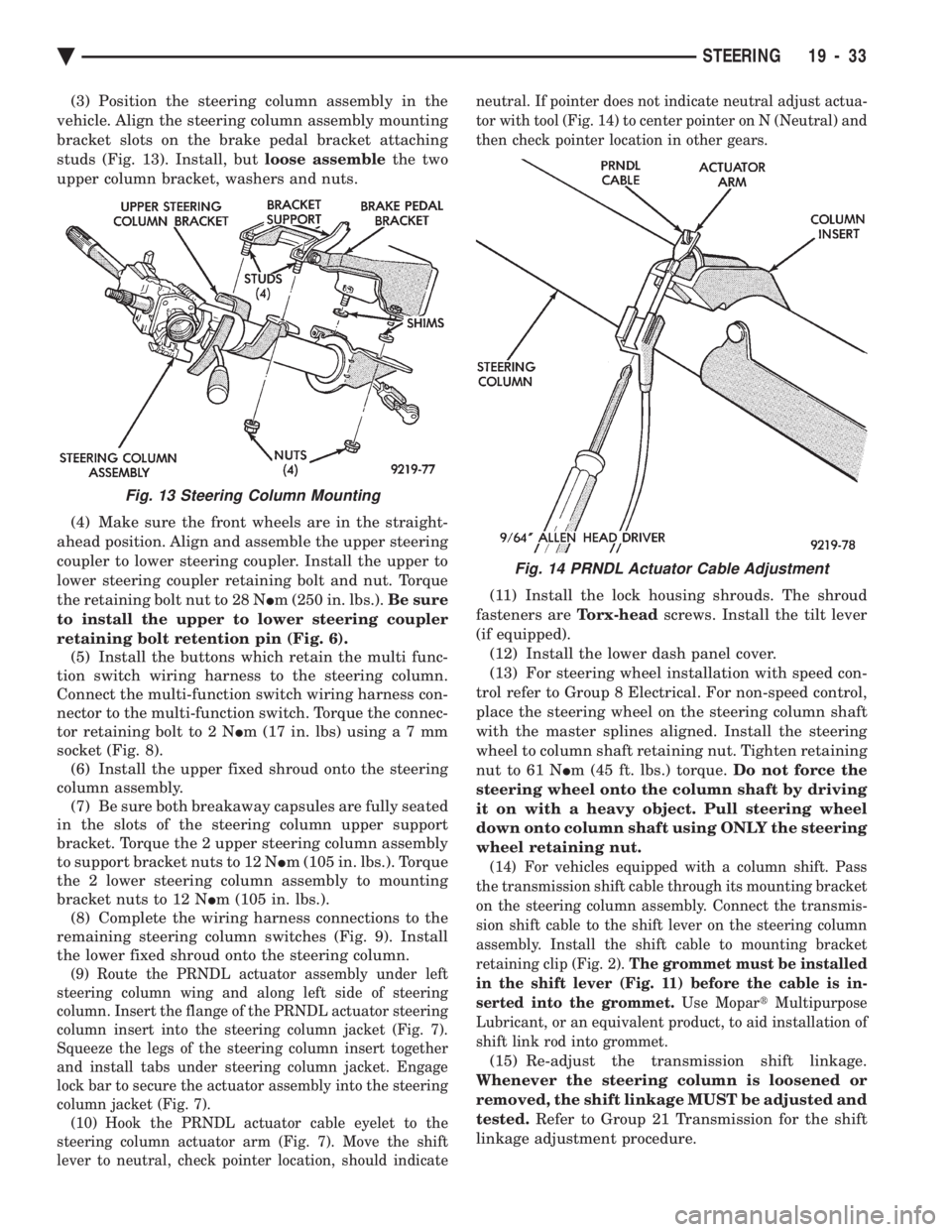

(3) Position the steering column assembly in the

vehicle. Align the steering column assembly mounting

bracket slots on the brake pedal bracket attaching

studs (Fig. 13). Install, but loose assemblethe two

upper column bracket, washers and nuts.

(4) Make sure the front wheels are in the straight-

ahead position. Align and assemble the upper steering

coupler to lower steering coupler. Install the upper to

lower steering coupler retaining bolt and nut. Torque

the retaining bolt nut to 28 N Im (250 in. lbs.). Be sure

to install the upper to lower steering coupler

retaining bolt retention pin (Fig. 6). (5) Install the buttons which retain the multi func-

tion switch wiring harness to the steering column.

Connect the multi-function switch wiring harness con-

nector to the multi-function switch. Torque the connec-

tor retaining bolt to 2 N Im (17 in. lbs) usin ga7mm

socket (Fig. 8). (6) Install the upper fixed shroud onto the steering

column assembly. (7) Be sure both breakaway capsules are fully seated

in the slots of the steering column upper support

bracket. Torque the 2 upper steering column assembly

to support bracket nuts to 12 N Im (105 in. lbs.). Torque

the 2 lower steering column assembly to mounting

bracket nuts to 12 N Im (105 in. lbs.).

(8) Complete the wiring harness connections to the

remaining steering column switches (Fig. 9). Install

the lower fixed shroud onto the steering column.

(9) Route the PRNDL actuator assembly under left

steering column wing and along left side of steering

column. Insert the flange of the PRNDL actuator steering

column insert into the steering column jacket (Fig. 7).

Squeeze the legs of the steering column insert together

and install tabs under steering column jacket. Engage

lock bar to secure the actuator assembly into the steering

column jacket (Fig. 7). (10) Hook the PRNDL actuator cable eyelet to the

steering column actuator arm (Fig. 7). Move the shift

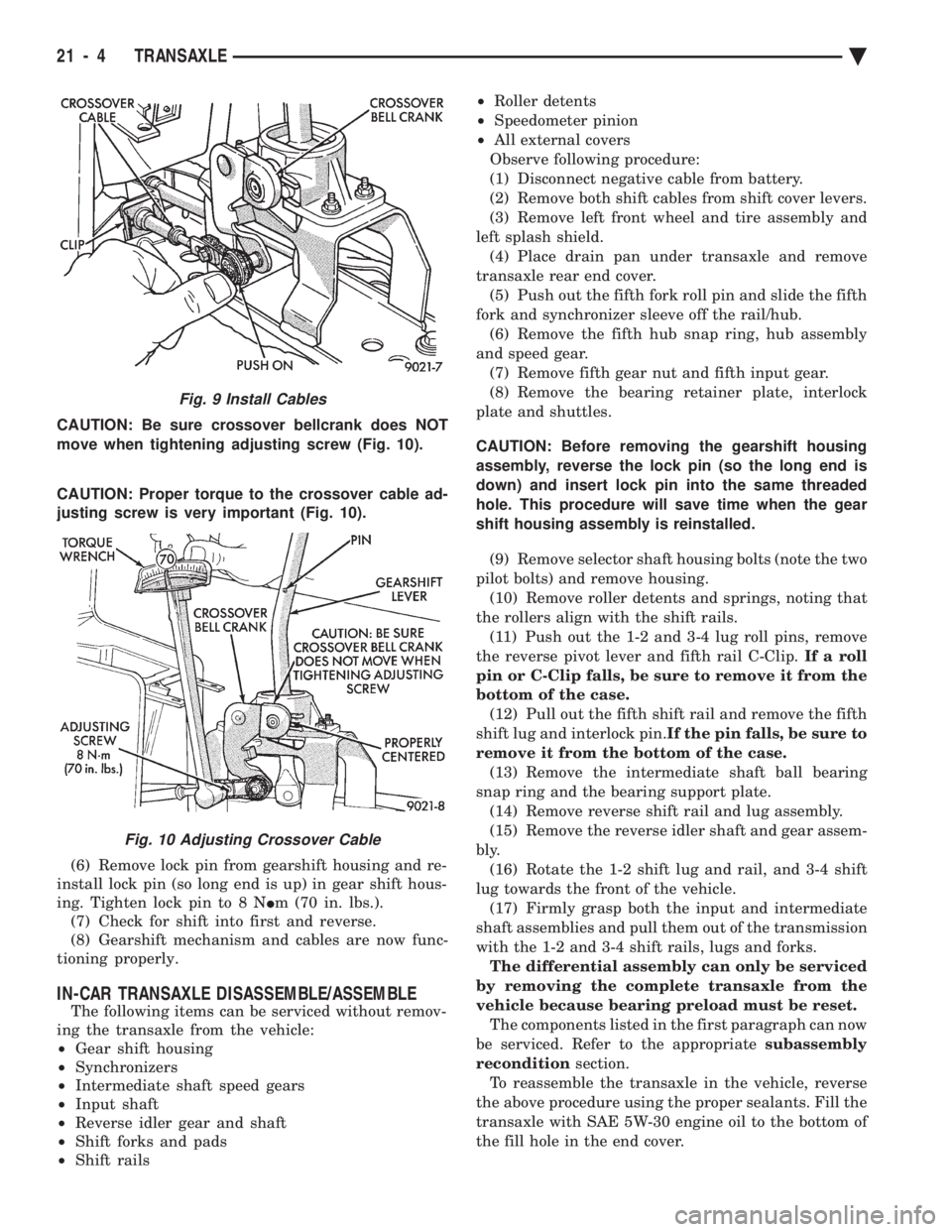

lever to neutral, check pointer location, should indicate neutral. If pointer does not indicate neutral adjust actua-

tor with tool (Fig. 14) to center pointer on N (Neutral) and

then check pointer location in other gears.

(11) Install the lock housing shrouds. The shroud

fasteners are Torx-headscrews. Install the tilt lever

(if equipped). (12) Install the lower dash panel cover.

(13) For steering wheel installation with speed con-

trol refer to Group 8 Electrical. For non-speed control,

place the steering wheel on the steering column shaft

with the master splines aligned. Install the steering

wheel to column shaft retaining nut. Tighten retaining

nut to 61 N Im (45 ft. lbs.) torque. Do not force the

steering wheel onto the column shaft by driving

it on with a heavy object. Pull steering wheel

down onto column shaft using ONLY the steering

wheel retaining nut.

(14) For vehicles equipped with a column shift. Pass

the transmission shift cable through its mounting bracket

on the steering column assembly. Connect the transmis-

sion shift cable to the shift lever on the steering column

assembly. Install the shift cable to mounting bracket

retaining clip (Fig. 2). The grommet must be installed

in the shift lever (Fig. 11) before the cable is in-

serted into the grommet. Use MopartMultipurpose

Lubricant, or an equivalent product, to aid installation of

shift link rod into grommet.

(15) Re-adjust the transmission shift linkage.

Whenever the steering column is loosened or

removed, the shift linkage MUST be adjusted and

tested. Refer to Group 21 Transmission for the shift

linkage adjustment procedure.

Fig. 13 Steering Column Mounting

Fig. 14 PRNDL Actuator Cable Adjustment

Ä STEERING 19 - 33

Page 1964 of 2438

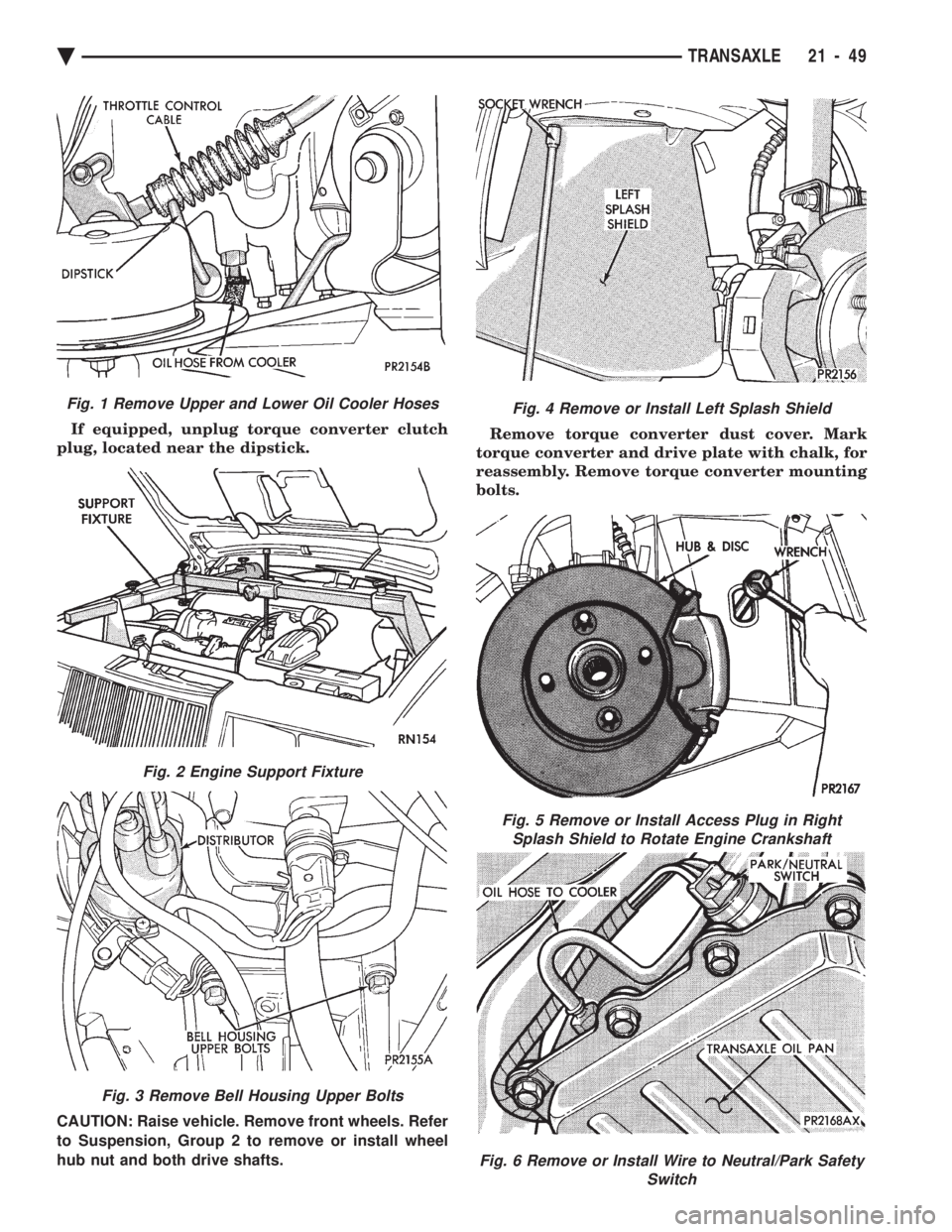

CAUTION: Be sure crossover bellcrank does NOT

move when tightening adjusting screw (Fig. 10).

CAUTION: Proper torque to the crossover cable ad-

justing screw is very important (Fig. 10).

(6) Remove lock pin from gearshift housing and re-

install lock pin (so long end is up) in gear shift hous-

ing. Tighten lock pin to 8 N Im (70 in. lbs.).

(7) Check for shift into first and reverse.

(8) Gearshift mechanism and cables are now func-

tioning properly.

IN-CAR TRANSAXLE DISASSEMBLE/ASSEMBLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

² Gear shift housing

² Synchronizers

² Intermediate shaft speed gears

² Input shaft

² Reverse idler gear and shaft

² Shift forks and pads

² Shift rails ²

Roller detents

² Speedometer pinion

² All external covers

Observe following procedure:

(1) Disconnect negative cable from battery.

(2) Remove both shift cables from shift cover levers.

(3) Remove left front wheel and tire assembly and

left splash shield. (4) Place drain pan under transaxle and remove

transaxle rear end cover. (5) Push out the fifth fork roll pin and slide the fifth

fork and synchronizer sleeve off the rail/hub. (6) Remove the fifth hub snap ring, hub assembly

and speed gear. (7) Remove fifth gear nut and fifth input gear.

(8) Remove the bearing retainer plate, interlock

plate and shuttles.

CAUTION: Before removing the gearshift housing

assembly, reverse the lock pin (so the long end is

down) and insert lock pin into the same threaded

hole. This procedure will save time when the gear

shift housing assembly is reinstalled. (9) Remove selector shaft housing bolts (note the two

pilot bolts) and remove housing. (10) Remove roller detents and springs, noting that

the rollers align with the shift rails. (11) Push out the 1-2 and 3-4 lug roll pins, remove

the reverse pivot lever and fifth rail C-Clip. If a roll

pin or C-Clip falls, be sure to remove it from the

bottom of the case. (12) Pull out the fifth shift rail and remove the fifth

shift lug and interlock pin. If the pin falls, be sure to

remove it from the bottom of the case. (13) Remove the intermediate shaft ball bearing

snap ring and the bearing support plate. (14) Remove reverse shift rail and lug assembly.

(15) Remove the reverse idler shaft and gear assem-

bly. (16) Rotate the 1-2 shift lug and rail, and 3-4 shift

lug towards the front of the vehicle. (17) Firmly grasp both the input and intermediate

shaft assemblies and pull them out of the transmission

with the 1-2 and 3-4 shift rails, lugs and forks. The differential assembly can only be serviced

by removing the complete transaxle from the

vehicle because bearing preload must be reset. The components listed in the first paragraph can now

be serviced. Refer to the appropriate subassembly

recondition section.

To reassemble the transaxle in the vehicle, reverse

the above procedure using the proper sealants. Fill the

transaxle with SAE 5W-30 engine oil to the bottom of

the fill hole in the end cover.

Fig. 9 Install Cables

Fig. 10 Adjusting Crossover Cable

21 - 4 TRANSAXLE Ä

Page 2009 of 2438

If equipped, unplug torque converter clutch

plug, located near the dipstick.

CAUTION: Raise vehicle. Remove front wheels. Refer

to Suspension, Group 2 to remove or install wheel

hub nut and both drive shafts. Remove torque converter dust cover. Mark

torque converter and drive plate with chalk, for

reassembly. Remove torque converter mounting

bolts.

Fig. 1 Remove Upper and Lower Oil Cooler Hoses

Fig. 2 Engine Support Fixture

Fig. 3 Remove Bell Housing Upper Bolts

Fig. 4 Remove or Install Left Splash Shield

Fig. 5 Remove or Install Access Plug in Right Splash Shield to Rotate Engine Crankshaft

Fig. 6 Remove or Install Wire to Neutral/Park Safety Switch

Ä TRANSAXLE 21 - 49

Page 2059 of 2438

CAUTION: If the vehicle is equipped with two oil

coolers (one in the radiator tank, one in front of the

radiator) they must be flushed separately. Do not

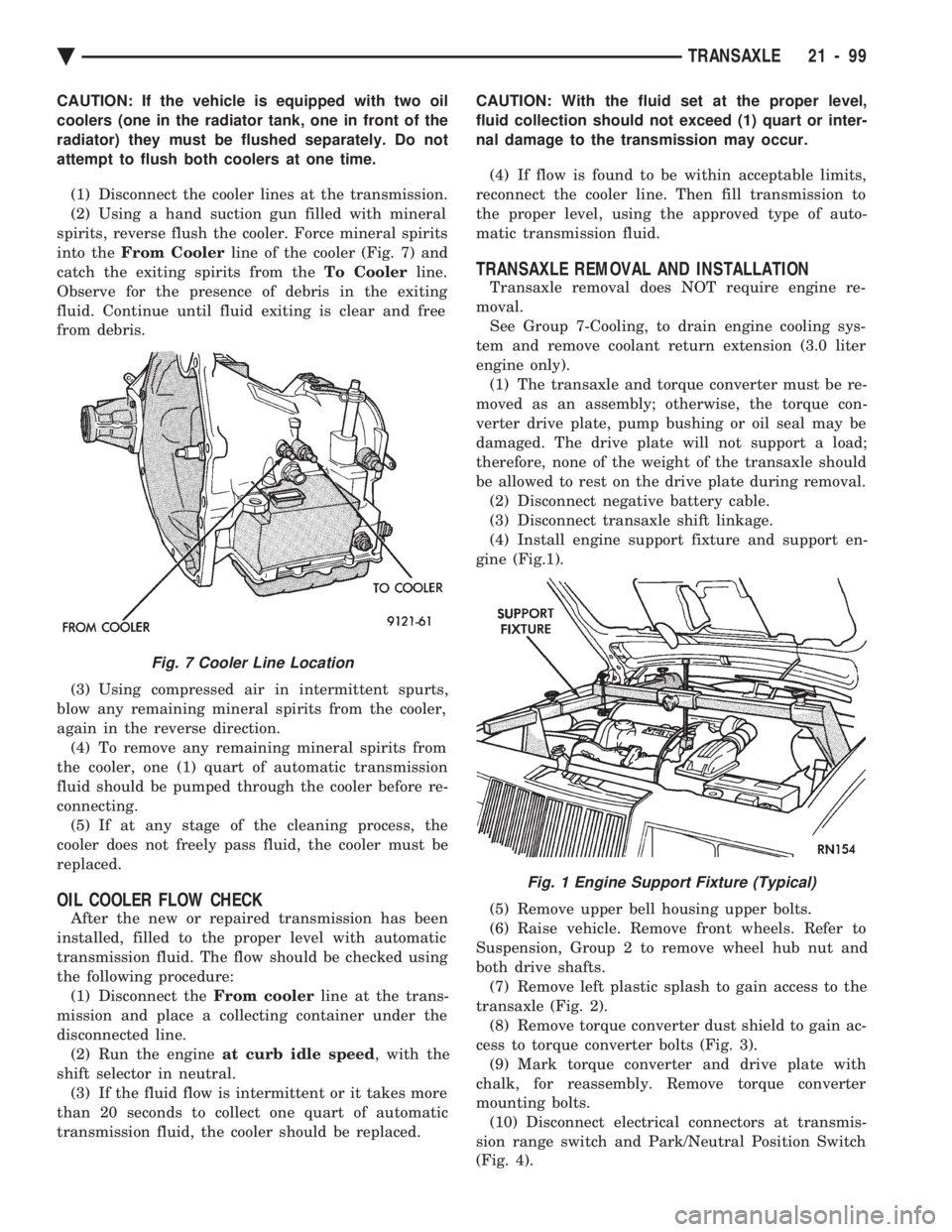

attempt to flush both coolers at one time. (1) Disconnect the cooler lines at the transmission.

(2) Using a hand suction gun filled with mineral

spirits, reverse flush the cooler. Force mineral spirits

into the From Cooler line of the cooler (Fig. 7) and

catch the exiting spirits from the To Coolerline.

Observe for the presence of debris in the exiting

fluid. Continue until fluid exiting is clear and free

from debris.

(3) Using compressed air in intermittent spurts,

blow any remaining mineral spirits from the cooler,

again in the reverse direction. (4) To remove any remaining mineral spirits from

the cooler, one (1) quart of automatic transmission

fluid should be pumped through the cooler before re-

connecting. (5) If at any stage of the cleaning process, the

cooler does not freely pass fluid, the cooler must be

replaced.

OIL COOLER FLOW CHECK

After the new or repaired transmission has been

installed, filled to the proper level with automatic

transmission fluid. The flow should be checked using

the following procedure: (1) Disconnect the From coolerline at the trans-

mission and place a collecting container under the

disconnected line. (2) Run the engine at curb idle speed , with the

shift selector in neutral. (3) If the fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of automatic

transmission fluid, the cooler should be replaced. CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(4) If flow is found to be within acceptable limits,

reconnect the cooler line. Then fill transmission to

the proper level, using the approved type of auto-

matic transmission fluid.

TRANSAXLE REMOVAL AND INSTALLATION

Transaxle removal does NOT require engine re-

moval. See Group 7-Cooling, to drain engine cooling sys-

tem and remove coolant return extension (3.0 liter

engine only). (1) The transaxle and torque converter must be re-

moved as an assembly; otherwise, the torque con-

verter drive plate, pump bushing or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the drive plate during removal. (2) Disconnect negative battery cable.

(3) Disconnect transaxle shift linkage.

(4) Install engine support fixture and support en-

gine (Fig.1).

(5) Remove upper bell housing upper bolts.

(6) Raise vehicle. Remove front wheels. Refer to

Suspension, Group 2 to remove wheel hub nut and

both drive shafts. (7) Remove left plastic splash to gain access to the

transaxle (Fig. 2). (8) Remove torque converter dust shield to gain ac-

cess to torque converter bolts (Fig. 3). (9) Mark torque converter and drive plate with

chalk, for reassembly. Remove torque converter

mounting bolts. (10) Disconnect electrical connectors at transmis-

sion range switch and Park/Neutral Position Switch

(Fig. 4).

Fig. 7 Cooler Line Location

Fig. 1 Engine Support Fixture (Typical)

Ä TRANSAXLE 21 - 99