headlamp CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 669 of 2438

CONCEALED HEADLAMPS INDEX

page page

Concealed Headlamp MotorÐAC-Body ........ 29

Diagnostic Procedures ..................... 27

General Information ....................... 27 Headlamp DoorÐAC-Body

................. 29

Headlamp DoorÐAY Body ................. 29

Headlamp Drive MotorÐAY Body ............ 30

GENERAL INFORMATION

For proper operation of the Concealed Headlamp

System, refer to the Owner's Manual provided with

the vehicle.

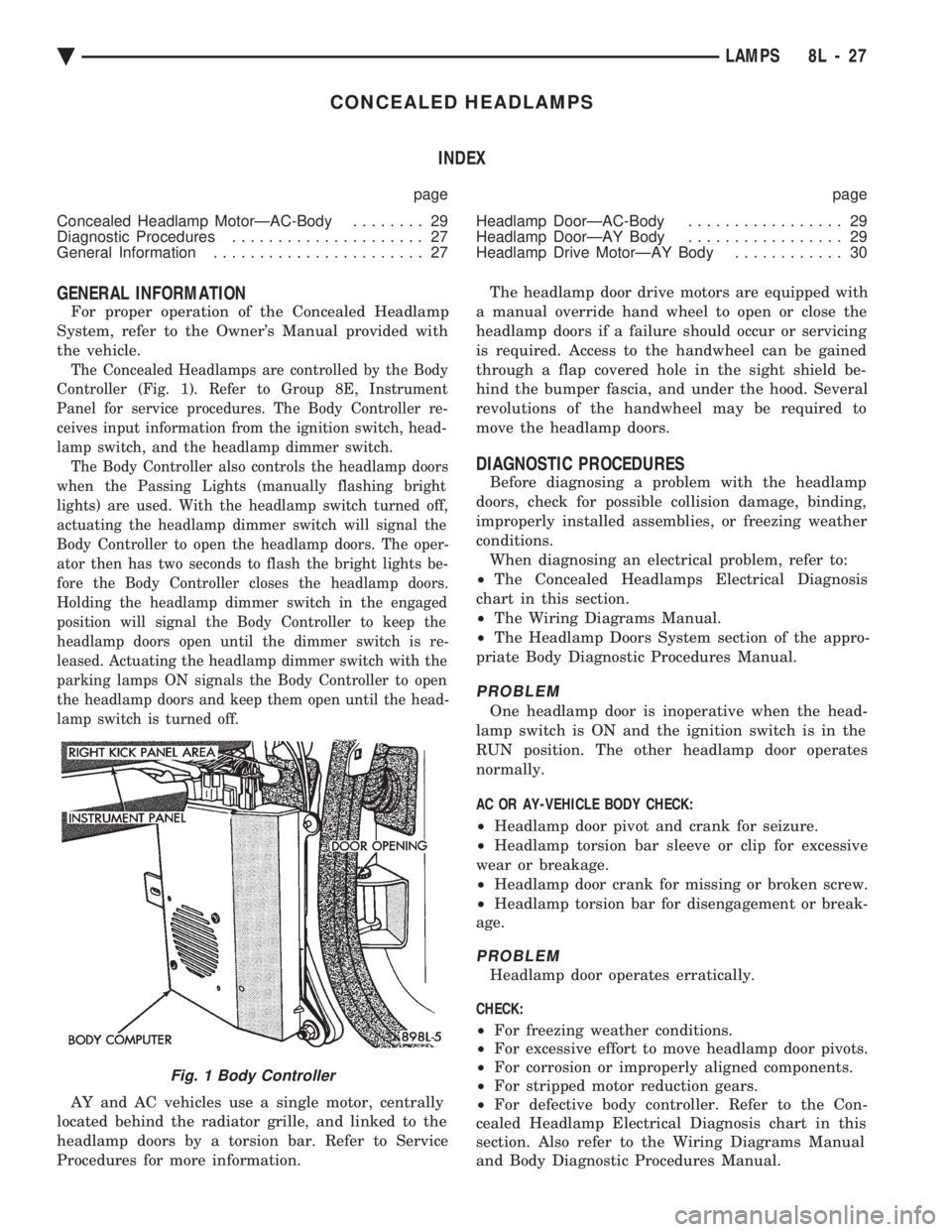

The Concealed Headlamps are controlled by the Body

Controller (Fig. 1). Refer to Group 8E, Instrument

Panel for service procedures. The Body Controller re-

ceives input information from the ignition switch, head-

lamp switch, and the headlamp dimmer switch. The Body Controller also controls the headlamp doors

when the Passing Lights (manually flashing bright

lights) are used. With the headlamp switch turned off,

actuating the headlamp dimmer switch will signal the

Body Controller to open the headlamp doors. The oper-

ator then has two seconds to flash the bright lights be-

fore the Body Controller closes the headlamp doors.

Holding the headlamp dimmer switch in the engaged

position will signal the Body Controller to keep the

headlamp doors open until the dimmer switch is re-

leased. Actuating the headlamp dimmer switch with the

parking lamps ON signals the Body Controller to open

the headlamp doors and keep them open until the head-

lamp switch is turned off.

AY and AC vehicles use a single motor, centrally

located behind the radiator grille, and linked to the

headlamp doors by a torsion bar. Refer to Service

Procedures for more information. The headlamp door drive motors are equipped with

a manual override hand wheel to open or close the

headlamp doors if a failure should occur or servicing

is required. Access to the handwheel can be gained

through a flap covered hole in the sight shield be-

hind the bumper fascia, and under the hood. Several

revolutions of the handwheel may be required to

move the headlamp doors.

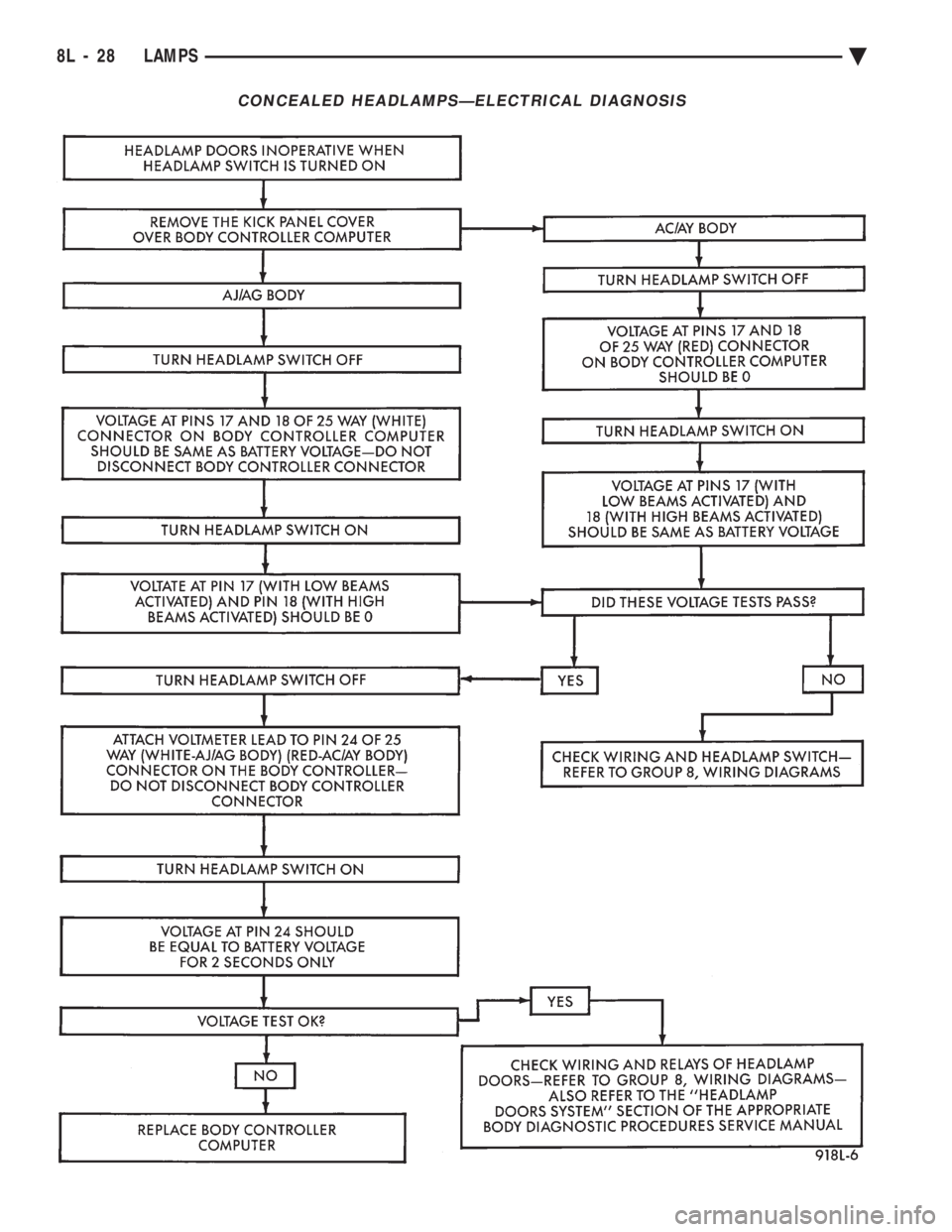

DIAGNOSTIC PROCEDURES

Before diagnosing a problem with the headlamp

doors, check for possible collision damage, binding,

improperly installed assemblies, or freezing weather

conditions. When diagnosing an electrical problem, refer to:

² The Concealed Headlamps Electrical Diagnosis

chart in this section.

² The Wiring Diagrams Manual.

² The Headlamp Doors System section of the appro-

priate Body Diagnostic Procedures Manual.

PROBLEM

One headlamp door is inoperative when the head-

lamp switch is ON and the ignition switch is in the

RUN position. The other headlamp door operates

normally.

AC OR AY-VEHICLE BODY CHECK:

² Headlamp door pivot and crank for seizure.

² Headlamp torsion bar sleeve or clip for excessive

wear or breakage.

² Headlamp door crank for missing or broken screw.

² Headlamp torsion bar for disengagement or break-

age.

PROBLEM

Headlamp door operates erratically.

CHECK:

² For freezing weather conditions.

² For excessive effort to move headlamp door pivots.

² For corrosion or improperly aligned components.

² For stripped motor reduction gears.

² For defective body controller. Refer to the Con-

cealed Headlamp Electrical Diagnosis chart in this

section. Also refer to the Wiring Diagrams Manual

and Body Diagnostic Procedures Manual.

Fig. 1 Body Controller

Ä LAMPS 8L - 27

Page 670 of 2438

CONCEALED HEADLAMPSÐELECTRICAL DIAGNOSIS

8L - 28 LAMPS Ä

Page 671 of 2438

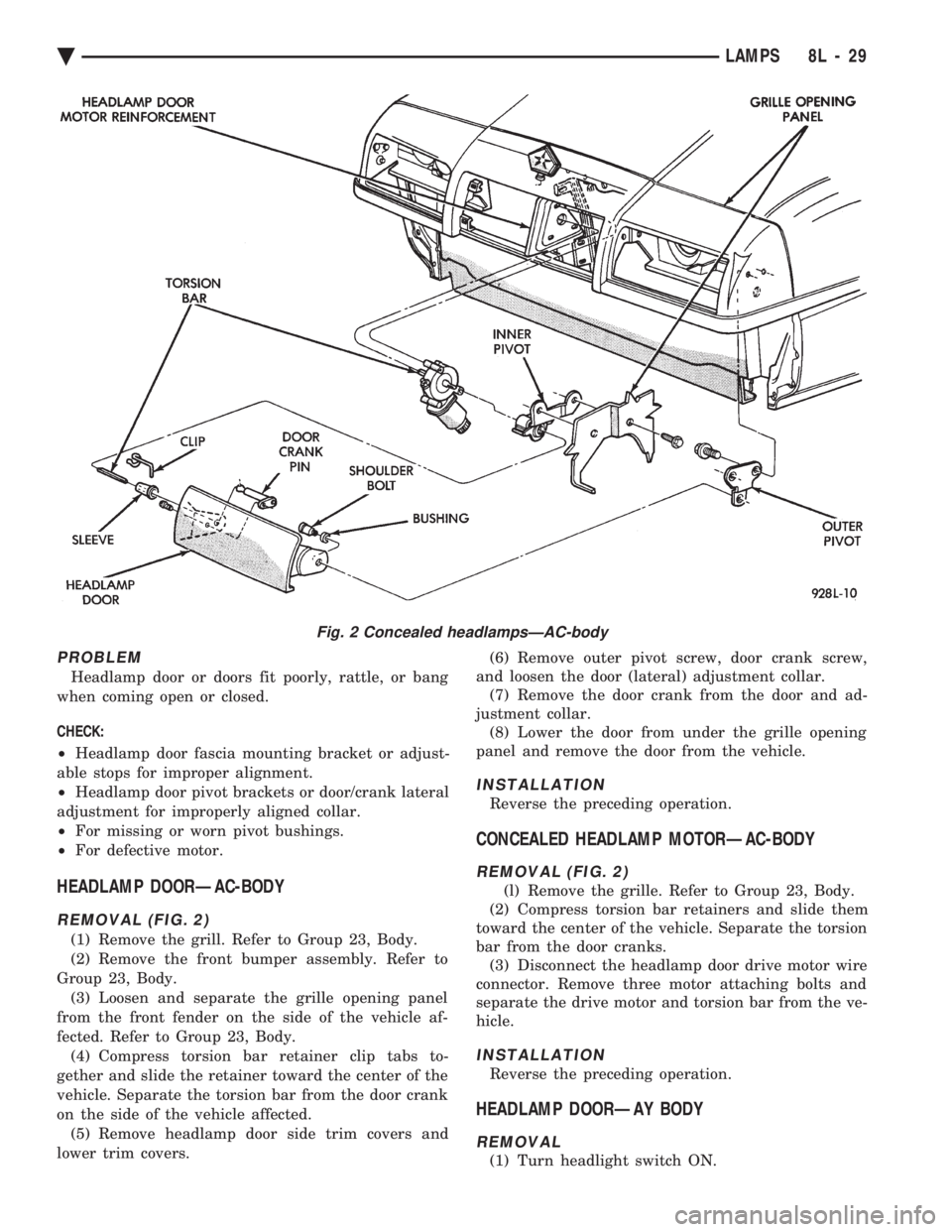

PROBLEM

Headlamp door or doors fit poorly, rattle, or bang

when coming open or closed.

CHECK:

² Headlamp door fascia mounting bracket or adjust-

able stops for improper alignment.

² Headlamp door pivot brackets or door/crank lateral

adjustment for improperly aligned collar.

² For missing or worn pivot bushings.

² For defective motor.

HEADLAMP DOORÐAC-BODY

REMOVAL (FIG. 2)

(1) Remove the grill. Refer to Group 23, Body.

(2) Remove the front bumper assembly. Refer to

Group 23, Body. (3) Loosen and separate the grille opening panel

from the front fender on the side of the vehicle af-

fected. Refer to Group 23, Body. (4) Compress torsion bar retainer clip tabs to-

gether and slide the retainer toward the center of the

vehicle. Separate the torsion bar from the door crank

on the side of the vehicle affected. (5) Remove headlamp door side trim covers and

lower trim covers. (6) Remove outer pivot screw, door crank screw,

and loosen the door (lateral) adjustment collar. (7) Remove the door crank from the door and ad-

justment collar. (8) Lower the door from under the grille opening

panel and remove the door from the vehicle.

INSTALLATION

Reverse the preceding operation.

CONCEALED HEADLAMP MOTORÐAC-BODY

REMOVAL (FIG. 2)

(l) Remove the grille. Refer to Group 23, Body.

(2) Compress torsion bar retainers and slide them

toward the center of the vehicle. Separate the torsion

bar from the door cranks. (3) Disconnect the headlamp door drive motor wire

connector. Remove three motor attaching bolts and

separate the drive motor and torsion bar from the ve-

hicle.

INSTALLATION

Reverse the preceding operation.

HEADLAMP DOORÐAY BODY

REMOVAL

(1) Turn headlight switch ON.

Fig. 2 Concealed headlampsÐAC-body

Ä LAMPS 8L - 29

Page 672 of 2438

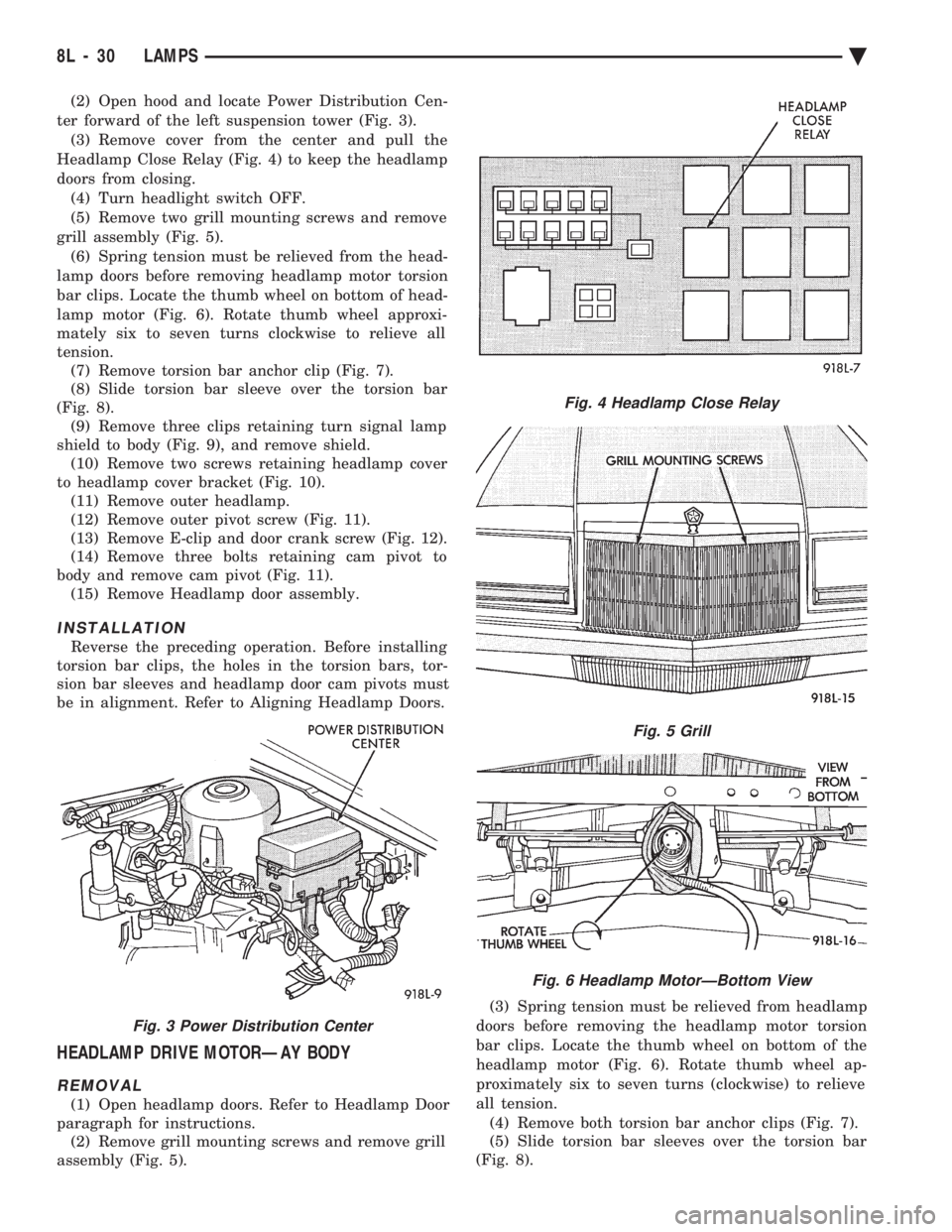

(2) Open hood and locate Power Distribution Cen-

ter forward of the left suspension tower (Fig. 3). (3) Remove cover from the center and pull the

Headlamp Close Relay (Fig. 4) to keep the headlamp

doors from closing. (4) Turn headlight switch OFF.

(5) Remove two grill mounting screws and remove

grill assembly (Fig. 5). (6) Spring tension must be relieved from the head-

lamp doors before removing headlamp motor torsion

bar clips. Locate the thumb wheel on bottom of head-

lamp motor (Fig. 6). Rotate thumb wheel approxi-

mately six to seven turns clockwise to relieve all

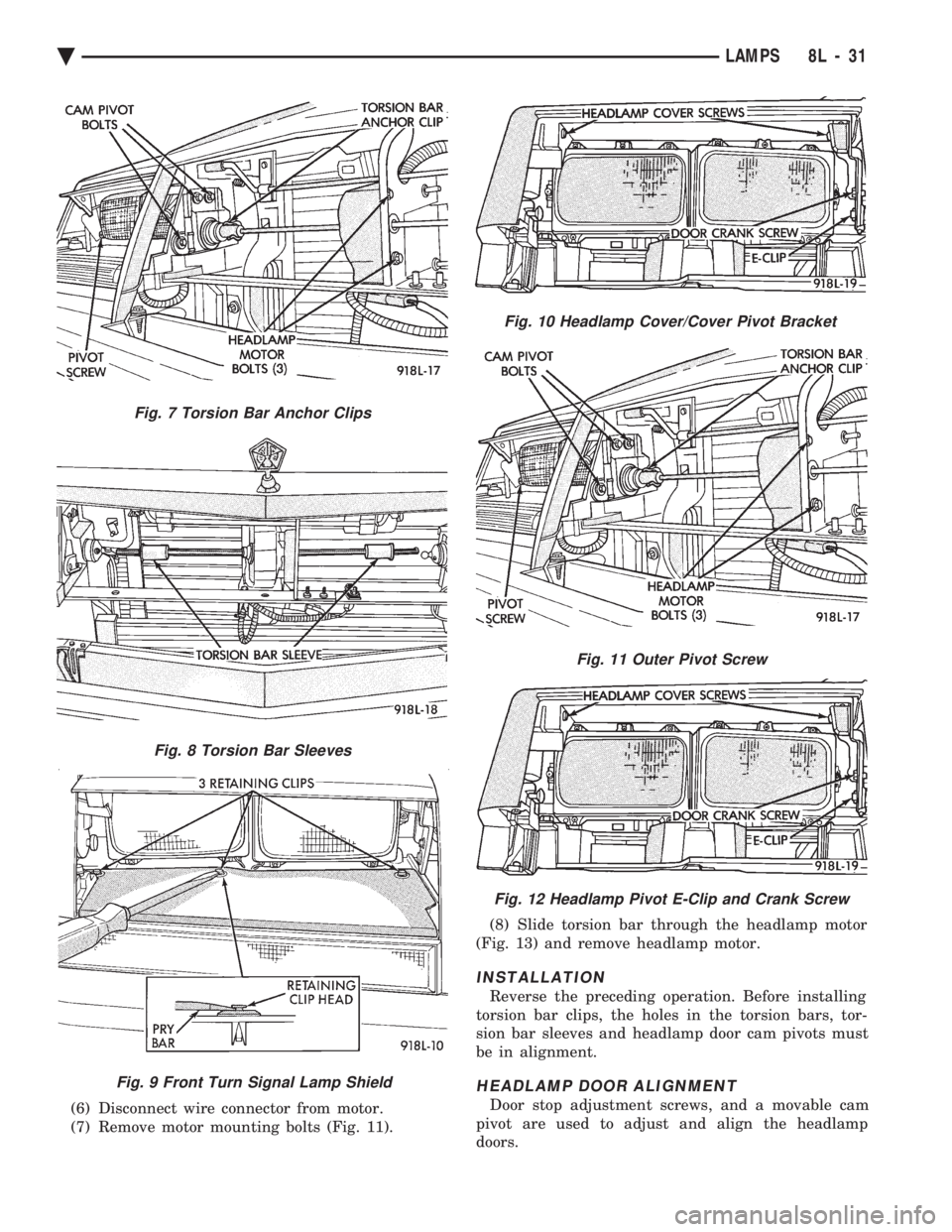

tension. (7) Remove torsion bar anchor clip (Fig. 7).

(8) Slide torsion bar sleeve over the torsion bar

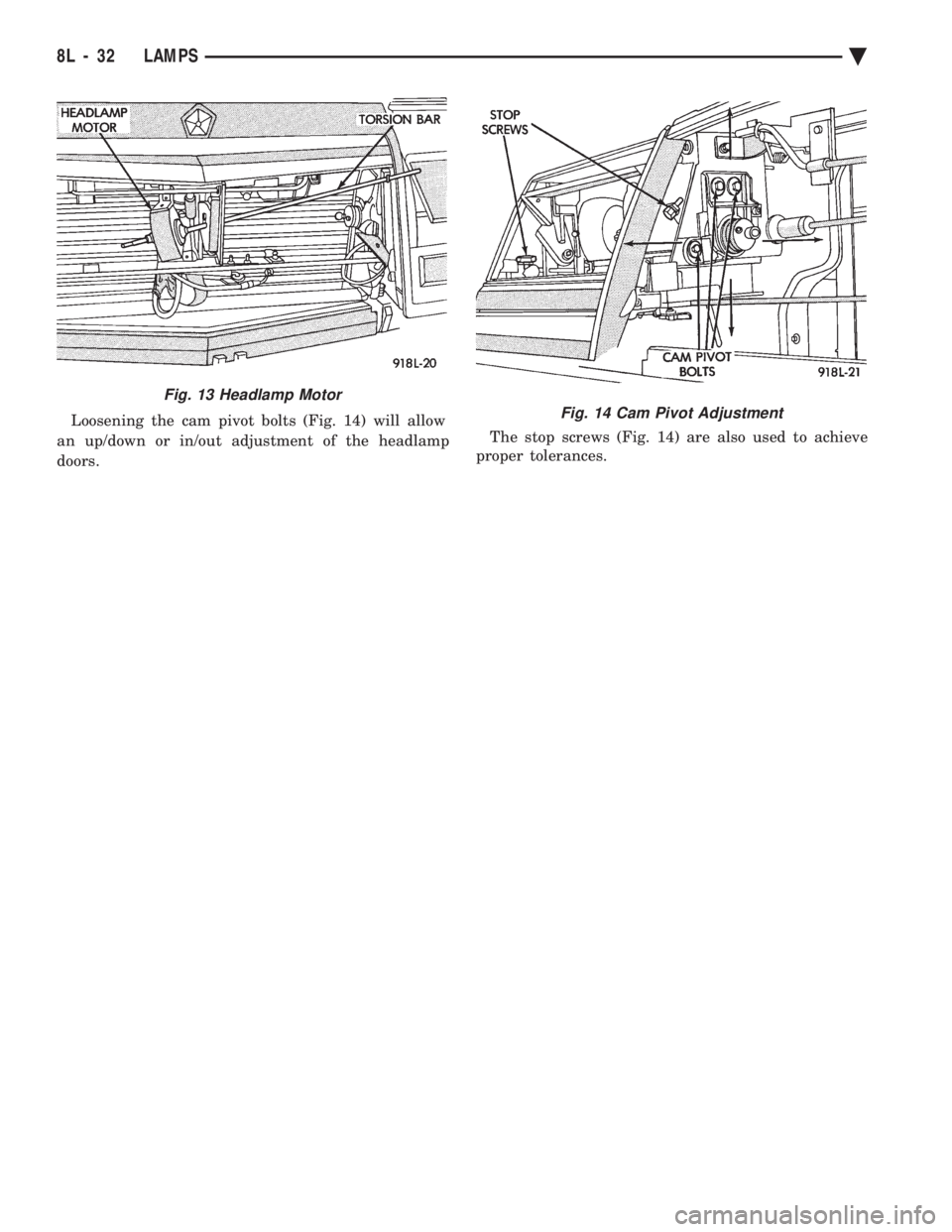

(Fig. 8). (9) Remove three clips retaining turn signal lamp

shield to body (Fig. 9), and remove shield. (10) Remove two screws retaining headlamp cover

to headlamp cover bracket (Fig. 10). (11) Remove outer headlamp.

(12) Remove outer pivot screw (Fig. 11).

(13) Remove E-clip and door crank screw (Fig. 12).

(14) Remove three bolts retaining cam pivot to

body and remove cam pivot (Fig. 11). (15) Remove Headlamp door assembly.

INSTALLATION

Reverse the preceding operation. Before installing

torsion bar clips, the holes in the torsion bars, tor-

sion bar sleeves and headlamp door cam pivots must

be in alignment. Refer to Aligning Headlamp Doors.

HEADLAMP DRIVE MOTORÐAY BODY

REMOVAL

(1) Open headlamp doors. Refer to Headlamp Door

paragraph for instructions. (2) Remove grill mounting screws and remove grill

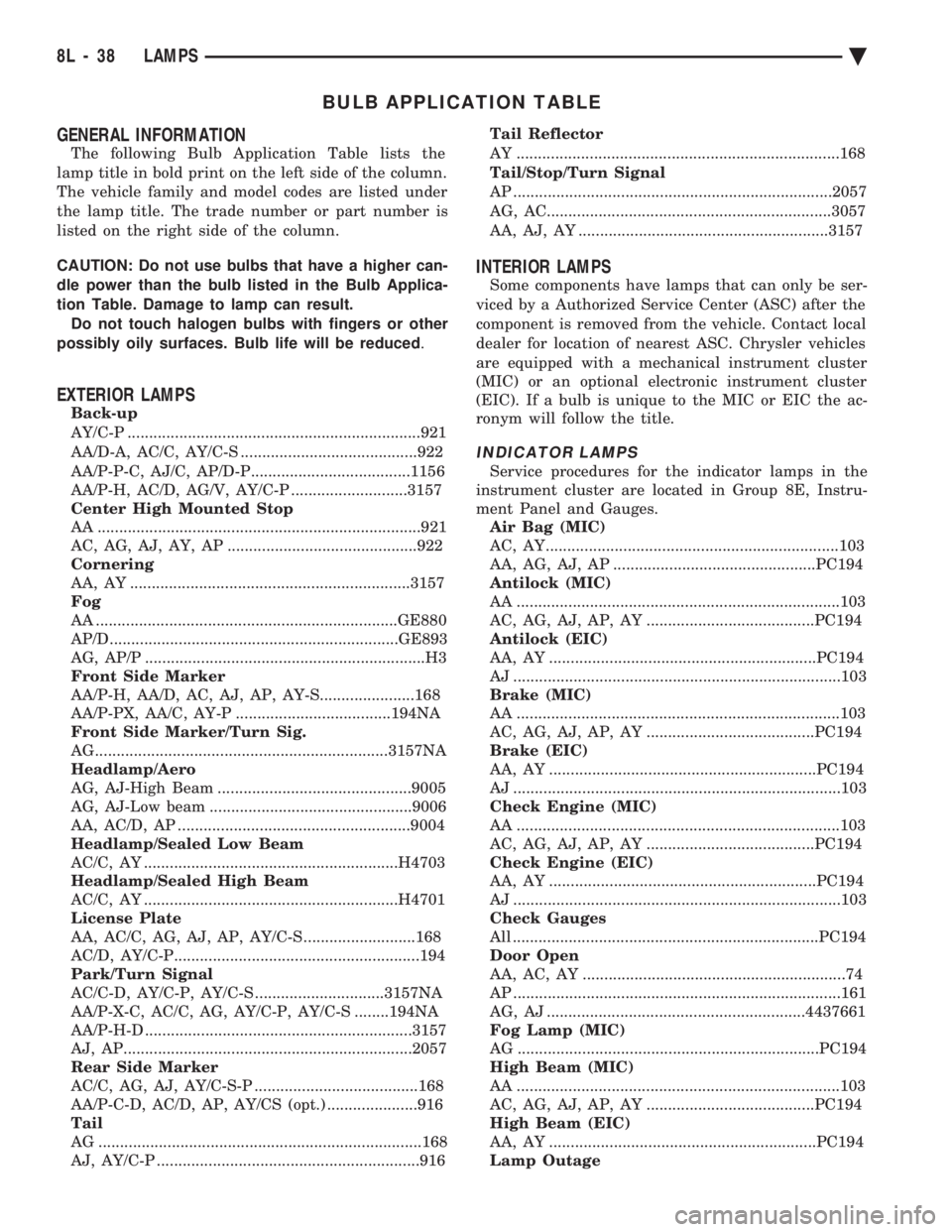

assembly (Fig. 5). (3) Spring tension must be relieved from headlamp

doors before removing the headlamp motor torsion

bar clips. Locate the thumb wheel on bottom of the

headlamp motor (Fig. 6). Rotate thumb wheel ap-

proximately six to seven turns (clockwise) to relieve

all tension. (4) Remove both torsion bar anchor clips (Fig. 7).

(5) Slide torsion bar sleeves over the torsion bar

(Fig. 8).

Fig. 3 Power Distribution Center

Fig. 4 Headlamp Close Relay

Fig. 5 Grill

Fig. 6 Headlamp MotorÐBottom View

8L - 30 LAMPS Ä

Page 673 of 2438

(6) Disconnect wire connector from motor.

(7) Remove motor mounting bolts (Fig. 11). (8) Slide torsion bar through the headlamp motor

(Fig. 13) and remove headlamp motor.

INSTALLATION

Reverse the preceding operation. Before installing

torsion bar clips, the holes in the torsion bars, tor-

sion bar sleeves and headlamp door cam pivots must

be in alignment.

HEADLAMP DOOR ALIGNMENT

Door stop adjustment screws, and a movable cam

pivot are used to adjust and align the headlamp

doors.

Fig. 9 Front Turn Signal Lamp Shield

Fig. 10 Headlamp Cover/Cover Pivot Bracket

Fig. 7 Torsion Bar Anchor Clips

Fig. 8 Torsion Bar Sleeves

Fig. 11 Outer Pivot Screw

Fig. 12 Headlamp Pivot E-Clip and Crank Screw

Ä LAMPS 8L - 31

Page 674 of 2438

Loosening the cam pivot bolts (Fig. 14) will allow

an up/down or in/out adjustment of the headlamp

doors. The stop screws (Fig. 14) are also used to achieve

proper tolerances.

Fig. 13 Headlamp Motor

Fig. 14 Cam Pivot Adjustment

8L - 32 LAMPS Ä

Page 680 of 2438

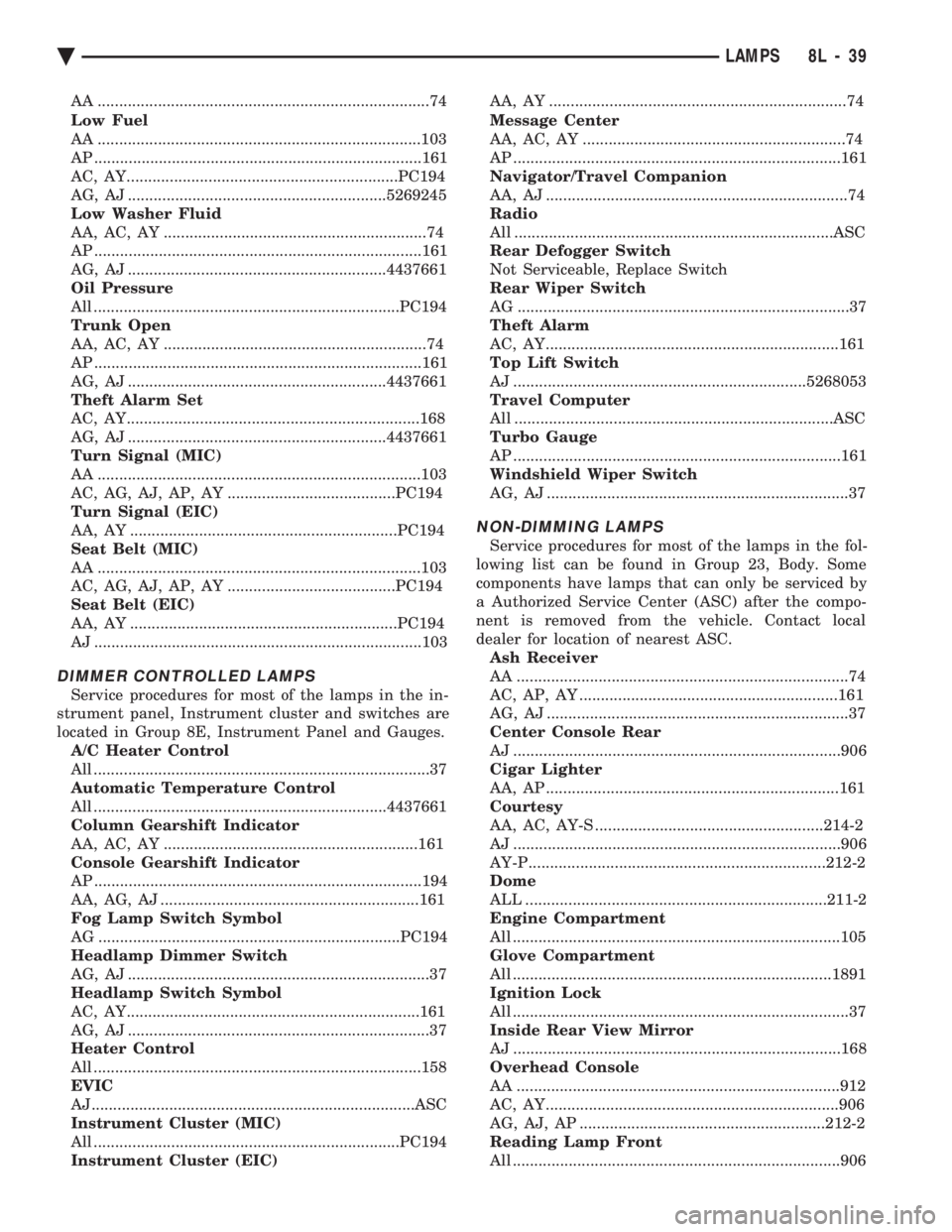

BULB APPLICATION TABLE

GENERAL INFORMATION

The following Bulb Application Table lists the

lamp title in bold print on the left side of the column.

The vehicle family and model codes are listed under

the lamp title. The trade number or part number is

listed on the right side of the column.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result. Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced .

EXTERIOR LAMPS

Back-up

AY/C-P ....................................................................921

AA/D-A, AC/C, AY/C-S .........................................922

AA/P-P-C, AJ/C, AP/D-P.....................................1156

AA/P-H, AC/D, AG/V, AY/C-P ...........................3157

Center High Mounted Stop

AA ...........................................................................921

AC, AG, AJ, AY, AP ............................................922

Cornering

AA, AY .................................................................3157

Fog

AA ......................................................................GE880

AP/D...................................................................GE893

AG, AP/P .................................................................H3

Front Side Marker

AA/P-H, AA/D, AC, AJ, AP, AY-S......................168

AA/P-PX, AA/C, AY-P ....................................194NA

Front Side Marker/Turn Sig.

AG....................................................................3157NA

Headlamp/Aero

AG, AJ-High Beam .............................................9005

AG, AJ-Low beam ...............................................9006

AA, AC/D, AP ......................................................9004

Headlamp/Sealed Low Beam

AC/C, AY ...........................................................H4703

Headlamp/Sealed High Beam

AC/C, AY ...........................................................H4701

License Plate

AA, AC/C, AG, AJ, AP, AY/C-S ..........................168

AC/D, AY/C-P.........................................................194

Park/Turn Signal

AC/C-D, AY/C-P, AY/C-S ..............................3157NA

AA/P-X-C, AC/C, AG, AY/C-P, AY/C-S ........194NA

AA/P-H-D ..............................................................3157

AJ, AP...................................................................2057

Rear Side Marker

AC/C, AG, AJ, AY/C-S-P ......................................168

AA/P-C-D, AC/D, AP, AY/CS (opt.) .....................916

Tail

AG ...........................................................................168

AJ, AY/C-P .............................................................916 Tail Reflector

AY ...........................................................................168

Tail/Stop/Turn Signal

AP ..........................................................................2057

AG, AC..................................................................3057

AA, AJ, AY ..........................................................3157

INTERIOR LAMPS

Some components have lamps that can only be ser-

viced by a Authorized Service Center (ASC) after the

component is removed from the vehicle. Contact local

dealer for location of nearest ASC. Chrysler vehicles

are equipped with a mechanical instrument cluster

(MIC) or an optional electronic instrument cluster

(EIC). If a bulb is unique to the MIC or EIC the ac-

ronym will follow the title.

INDICATOR LAMPS

Service procedures for the indicator lamps in the

instrument cluster are located in Group 8E, Instru-

ment Panel and Gauges. Air Bag (MIC)

AC, AY....................................................................103

AA, AG, AJ, AP ...............................................PC194

Antilock (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Antilock (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Brake (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Brake (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Check Engine (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Check Engine (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Check Gauges

All .......................................................................PC194

Door Open

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Fog Lamp (MIC)

AG ......................................................................PC194

High Beam (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

High Beam (EIC)

AA, AY ..............................................................PC194

Lamp Outage

8L - 38 LAMPS Ä

Page 681 of 2438

AA .............................................................................74

Low Fuel

AA ...........................................................................103

AP ............................................................................161

AC, AY...............................................................PC194

AG, AJ ............................................................5269245

Low Washer Fluid

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Oil Pressure

All .......................................................................PC194

Trunk Open

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Theft Alarm Set

AC, AY....................................................................168

AG, AJ ............................................................4437661

Turn Signal (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Turn Signal (EIC)

AA, AY ..............................................................PC194

Seat Belt (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Seat Belt (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

DIMMER CONTROLLED LAMPS

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges. A/C Heater Control

All ..............................................................................37

Automatic Temperature Control

All ....................................................................4437661

Column Gearshift Indicator

AA, AC, AY ...........................................................161

Console Gearshift Indicator

AP ............................................................................194

AA, AG, AJ ............................................................161

Fog Lamp Switch Symbol

AG ......................................................................PC194

Headlamp Dimmer Switch

AG, AJ ......................................................................37

Headlamp Switch Symbol

AC, AY....................................................................161

AG, AJ ......................................................................37

Heater Control

All ............................................................................158

EVIC

AJ...........................................................................ASC

Instrument Cluster (MIC)

All .......................................................................PC194

Instrument Cluster (EIC) AA, AY .....................................................................74

Message Center

AA, AC, AY .............................................................74

AP ............................................................................161

Navigator/Travel Companion

AA, AJ ......................................................................74

Radio

All ..........................................................................ASC

Rear Defogger Switch

Not Serviceable, Replace Switch

Rear Wiper Switch

AG .............................................................................37

Theft Alarm

AC, AY....................................................................161

Top Lift Switch

AJ ....................................................................5268053

Travel Computer

All ..........................................................................ASC

Turbo Gauge

AP ............................................................................161

Windshield Wiper Switch

AG, AJ ......................................................................37

NON-DIMMING LAMPS

Service procedures for most of the lamps in the fol-

lowing list can be found in Group 23, Body. Some

components have lamps that can only be serviced by

a Authorized Service Center (ASC) after the compo-

nent is removed from the vehicle. Contact local

dealer for location of nearest ASC. Ash Receiver

AA .............................................................................74

AC, AP, AY ............................................................161

AG, AJ ......................................................................37

Center Console Rear

AJ ............................................................................906

Cigar Lighter

AA, AP ....................................................................161

Courtesy

AA, AC, AY-S .....................................................214-2

AJ ............................................................................906

AY-P.....................................................................212-2

Dome

ALL ......................................................................211-2

Engine Compartment

All ............................................................................105

Glove Compartment

All ..........................................................................1891

Ignition Lock

All ..............................................................................37

Inside Rear View Mirror

AJ ............................................................................168

Overhead Console

AA ...........................................................................912

AC, AY....................................................................906

AG, AJ, AP .........................................................212-2

Reading Lamp Front

All ............................................................................906

Ä LAMPS 8L - 39

Page 702 of 2438

AA BODY

Uses a power door lock inhibit relay. The relay is

located above the glove box compartment.

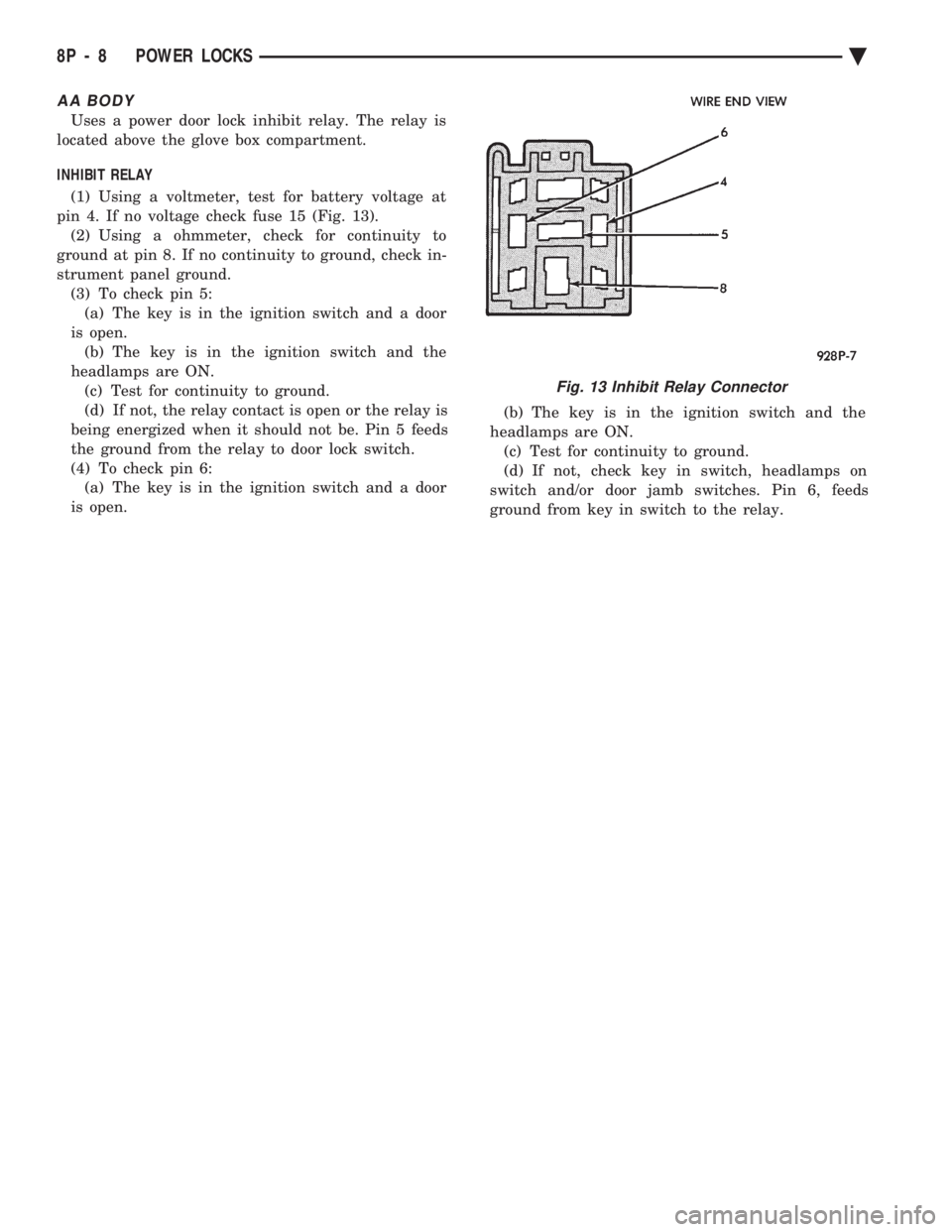

INHIBIT RELAY

(1) Using a voltmeter, test for battery voltage at

pin 4. If no voltage check fuse 15 (Fig. 13). (2) Using a ohmmeter, check for continuity to

ground at pin 8. If no continuity to ground, check in-

strument panel ground. (3) To check pin 5:(a) The key is in the ignition switch and a door

is open. (b) The key is in the ignition switch and the

headlamps are ON. (c) Test for continuity to ground.

(d) If not, the relay contact is open or the relay is

being energized when it should not be. Pin 5 feeds

the ground from the relay to door lock switch.

(4) To check pin 6: (a) The key is in the ignition switch and a door

is open. (b) The key is in the ignition switch and the

headlamps are ON. (c) Test for continuity to ground.

(d) If not, check key in switch, headlamps on

switch and/or door jamb switches. Pin 6, feeds

ground from key in switch to the relay.

Fig. 13 Inhibit Relay Connector

8P - 8 POWER LOCKS Ä

Page 737 of 2438

POWER MIRRORS

CONTENTS

page page

AUTOMATIC DAY/NIGHT INSIDE MIRROR .... 7

AUTOMATIC DAY/NIGHT INSIDE MIRROR WITH ULTRALIGHT HEADLAMP CONTROL ....... 7

GENERAL INFORMATION .................. 1

HEATED MIRROR ........................ 2

INSIDE MIRROR/READING LAMPS BULB/LENS REPLACEMENT ........................ 6

INSIDE MIRROR/READING LAMPS REPLACEMENT ........................ 6

MIRROR ASSEMBLY REPLACEMENTÐAA BODY.5

MIRROR ASSEMBLY REPLACEMENTÐ AC AND AY BODIES .................... 5

MIRROR ASSEMBLY REPLACEMENTÐAG BODY.5

MIRROR ASSEMBLY REPLACEMENTÐAJ BODY.5

MIRROR ASSEMBLY REPLACEMENTÐAP BODY.5

MIRROR MOTOR TEST PROCEDURE ........ 2

MIRROR SWITCH REPLACEMENTÐAA BODY . 3

MIRROR SWITCH REPLACEMENTÐAC AND AY BODIES .............................. 4

MIRROR SWITCH REPLACEMENTÐAG AND AJ BODIES .............................. 3

MIRROR SWITCH REPLACEMENTÐAP BODY . 4

MIRROR SWITCH TEST PROCEDURE ....... 2

TEST PROCEDURES ...................... 2

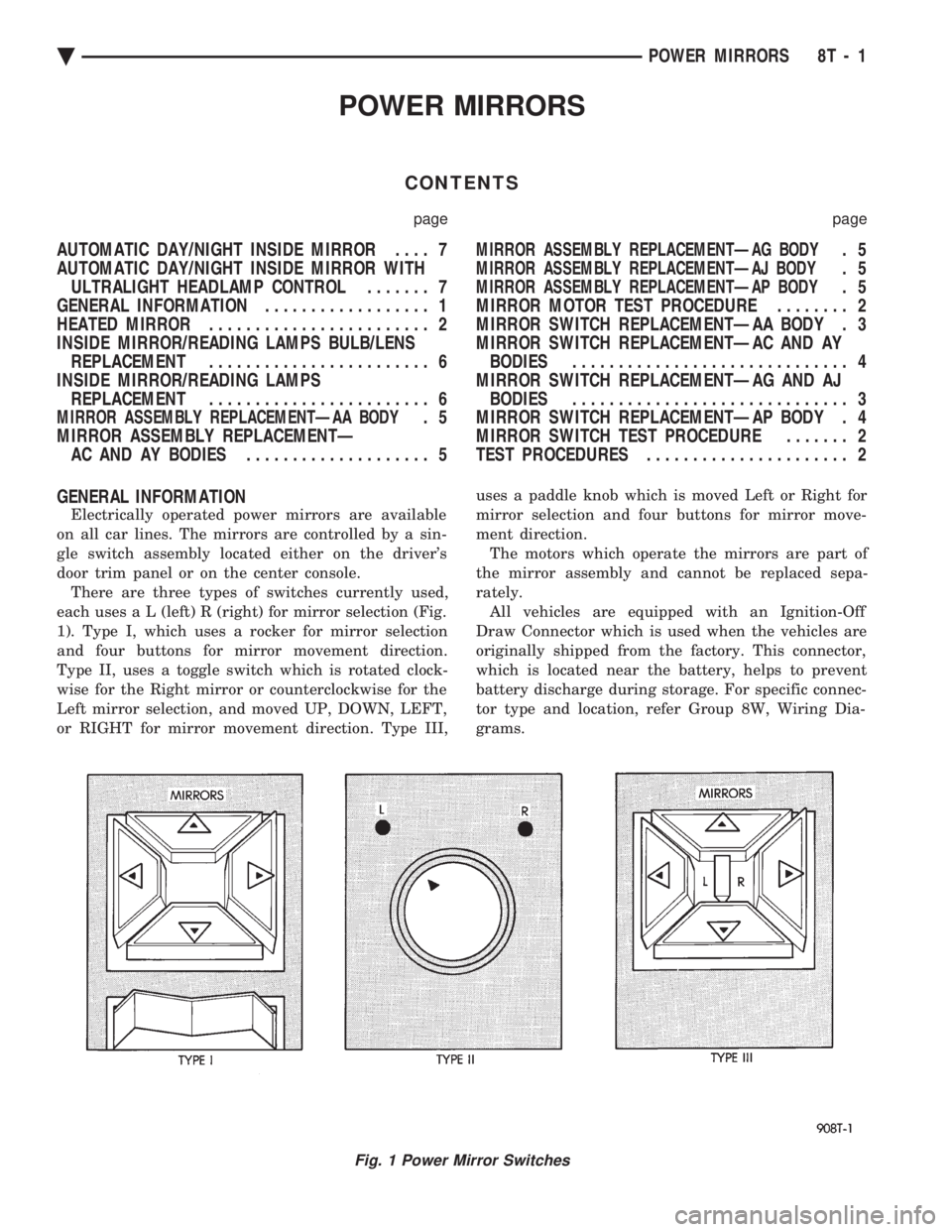

GENERAL INFORMATION

Electrically operated power mirrors are available

on all car lines. The mirrors are controlled by a sin-

gle switch assembly located either on the driver's

door trim panel or on the center console. There are three types of switches currently used,

each use s a L (left) R (right) for mirror selection (Fig.

1). Type I, which uses a rocker for mirror selection

and four buttons for mirror movement direction.

Type II, uses a toggle switch which is rotated clock-

wise for the Right mirror or counterclockwise for the

Left mirror selection, and moved UP, DOWN, LEFT,

or RIGHT for mirror movement direction. Type III, uses a paddle knob which is moved Left or Right for

mirror selection and four buttons for mirror move-

ment direction.

The motors which operate the mirrors are part of

the mirror assembly and cannot be replaced sepa-

rately. All vehicles are equipped with an Ignition-Off

Draw Connector which is used when the vehicles are

originally shipped from the factory. This connector,

which is located near the battery, helps to prevent

battery discharge during storage. For specific connec-

tor type and location, refer Group 8W, Wiring Dia-

grams.

Fig. 1 Power Mirror Switches

Ä POWER MIRRORS 8T - 1