brake rotor CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 31 of 2438

COMPONENT AND SYSTEM INDEX

Name Group-page Name Group-page

BODY ................................... 23-1

AA-VEHICLE BODY COMPONENT SERVICE .......23-11

AC-VEHICLE BODY COMPONENT SERVICE .......23-37

AG-VEHICLE BODY COMPONENT SERVICE .......23-52

AJ/27-VEHICLE CONVERTIBLE BODY COMPONENT SERVICE ............................ 23-86

AJ-VEHICLE BODY COMPONENT SERVICE .......23-71

AP-VEHICLE BODY COMPONENT SERVICE .......23-97

AY-VEHICLE BODY COMPONENT SERVICE .......23-133

BODY DIAGNOSTIC PROCEDURES .............23-2

GENERAL SERVICE INFORMATION .............23-1

PAINT ................................. 23-4

POWER SUNROOF ........................ 23-6

WINDSHIELD ............................ 23-9

BRAKES ..................................5-1

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ......................... 5-72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY .................... 5-113

BRAKE DISC (ROTOR) ...................... 5-53

BRAKE SUPPORT ASSEMBLY .................5-25

FRONT DISC BRAKES ...................... 5-31

GENERAL INFORMATION .....................5-1

HYDRAULIC SYSTEM CONTROL VALVES .........5-26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER .....5-35

KELSEY HAYES DOUBLE PIN NON-FAMILY CALIPER ............................. 5-38

MASTER CYLINDER ....................... 5-66

PARKING BRAKES ........................ 5-57

POWER BRAKES ......................... 5-68

REAR DISC BRAKES ....................... 5-45

REAR WHEEL DRUM BRAKES ................5-18

SERVICE ADJUSTMENTS .....................5-4

WHEEL BEARINGS ........................ 5-70

WHEEL CYLINDERS ....................... 5-23

COOLING SYSTEM ...........................7-1

ACCESSORY DRIVE BELTS ................... 7-24

ENGINE BLOCK HEATER .................... 7-28

GENERAL INFORMATION .....................7-1

SERVICE PROCEDURES ..................... 7-10

SPECIFICATIONS ......................... 7-29

ENGINE ..................................9-1

2.2/2.5L ENGINES .........................9-8

3.0L ENGINE ............................ 9-66

3.3/3.8L ENGINE ......................... 9-98

STANDARD SERVICE PROCEDURES .............9-1

EXHAUST SYSTEM AND INTAKE MANIFOLD .........11-1

GENERAL INFORMATION .................... 11-1

SERVICE PROCEDURES ..................... 11-4

TORQUE SPECIFICATION ................... 11-25

FRAME AND BUMPERS ....................... 13-1

BUMPER AND FASCIA ...................... 13-1

FRAME ................................ 13-9

HEATING AND AIR CONDITIONING ...............24-1

AUTOMATIC TEMPERATURE CONTROL (ATC) .....24-66 COMPONENT SERVICE PROCEDURES

..........24-47

FIXED DISPLACEMENT COMPRESSORÐMODEL 10PA17............................. 24-24

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P ............................. 24-38

FIXED DISPLACEMENT COMPRESSORÐMODEL TR105 .............................. 24-32

GENERAL INFORMATION .................... 24-1

HEATER AND A/C PERFORMANCE TESTS .........24-6

REFRIGERANT SERVICE PROCEDURES ..........24-8

VACUUM CONTROL SYSTEM DIAGNOSIS .........24-4

VARIABLE DISPLACEMENT COMPRESSORÐMODEL 6C17 ............................... 24-13

INTRODUCTION .......................... Intro.-1

LUBRICATION AND MAINTENANCE ................0-1

CHASSIS AND BODY ....................... 0-19

DRIVETRAIN ............................ 0-16

ENGINE ................................0-8

GENERAL INFORMATION .....................0-1

MANUAL TRANSAXLE CLUTCH ...................6-1

STEERING ................................ 19-1

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 19-28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 19-36

GENERAL INFORMATION .................... 19-1

POWER STEERING GEAR ................... 19-25

POWER STEERING PUMPS ..................19-1

SPECIFICATIONS AND TIGHTENING REFERENCE . . . 19-42

SUSPENSION AND DRIVESHAFTS .................2-1

AUTOMATIC AIR LOAD LEVELING SYSTEM ........2-59

AUTOMATIC AIR SUSPENSION ................2-73

DRIVESHAFTS ........................... 2-25

FRONT SUSPENSION .......................2-2

FRONT SUSPENSION SERVICE PROCEDURES .......2-5

GENERAL INFORMATION .....................2-1

REAR (STUB) AXLE ALIGNMENT ALL MODELS .....2-89

REAR SUSPENSION ....................... 2-50

SPECIFICATIONS ......................... 2-91

TRANSAXLE .............................. 21-85

41TE FOUR SPEED AUTOMATIC TRANSAXLE ......21-85

41TE FOUR SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 21-170

41TE ON-BOARD DIAGNOSTICS .............21-145

A-523, A-543, and A-568 MANUAL TRANSAXLE ....21-1

SPECIFICATIONS ........................ 21-183

THREE SPEED TORQUEFLITE AUTOMATIC TRANSAXLE .......................... 21-35

THREE SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 21-162

WHEELSÐTIRES ........................... 22-1

SPECIFICATIONS ......................... 22-8

TIRE SERVICE PROCEDURES .................22-1

WHEELS SERVICE PROCEDURES ..............22-6

Page 43 of 2438

TOWING RECOMMENDATIONS

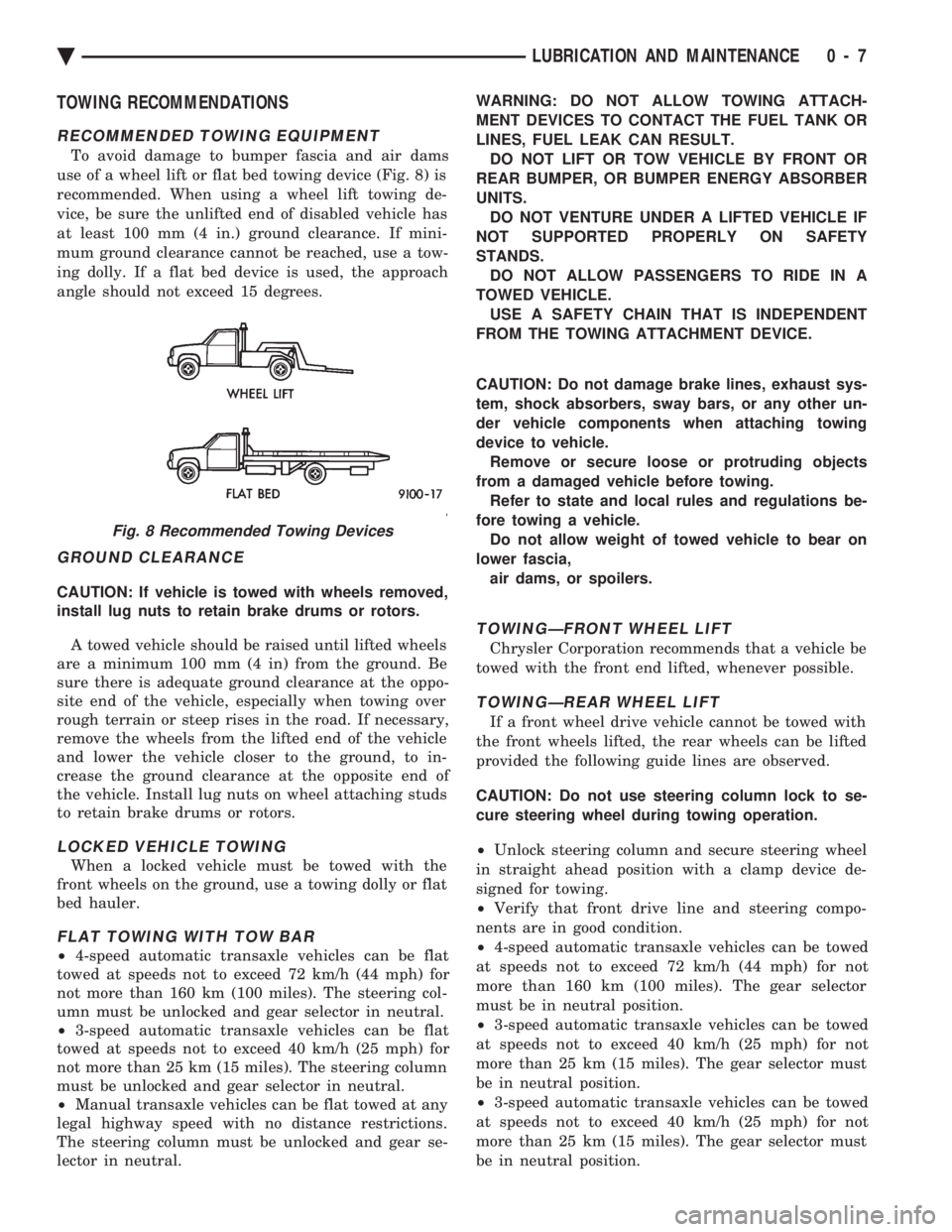

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use of a wheel lift or flat bed towing device (Fig. 8) is

recommended. When using a wheel lift towing de-

vice, be sure the unlifted end of disabled vehicle has

at least 100 mm (4 in.) ground clearance. If mini-

mum ground clearance cannot be reached, use a tow-

ing dolly. If a flat bed device is used, the approach

angle should not exceed 15 degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain or steep rises in the road. If necessary,

remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to in-

crease the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

² 4-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 72 km/h (44 mph) for

not more than 160 km (100 miles). The steering col-

umn must be unlocked and gear selector in neutral.

² 3-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 miles). The steering column

must be unlocked and gear selector in neutral.

² Manual transaxle vehicles can be flat towed at any

legal highway speed with no distance restrictions.

The steering column must be unlocked and gear se-

lector in neutral. WARNING: DO NOT ALLOW TOWING ATTACH-

MENT DEVICES TO CONTACT THE FUEL TANK OR

LINES, FUEL LEAK CAN RESULT. DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER, OR BUMPER ENERGY ABSORBER

UNITS. DO NOT VENTURE UNDER A LIFTED VEHICLE IF

NOT SUPPORTED PROPERLY ON SAFETY

STANDS. DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE. USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other un-

der vehicle components when attaching towing

device to vehicle. Remove or secure loose or protruding objects

from a damaged vehicle before towing. Refer to state and local rules and regulations be-

fore towing a vehicle. Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

TOWINGÐFRONT WHEEL LIFT

Chrysler Corporation recommends that a vehicle be

towed with the front end lifted, whenever possible.

TOWINGÐREAR WHEEL LIFT

If a front wheel drive vehicle cannot be towed with

the front wheels lifted, the rear wheels can be lifted

provided the following guide lines are observed.

CAUTION: Do not use steering column lock to se-

cure steering wheel during towing operation.

² Unlock steering column and secure steering wheel

in straight ahead position with a clamp device de-

signed for towing.

² Verify that front drive line and steering compo-

nents are in good condition.

² 4-speed automatic transaxle vehicles can be towed

at speeds not to exceed 72 km/h (44 mph) for not

more than 160 km (100 miles). The gear selector

must be in neutral position.

² 3-speed automatic transaxle vehicles can be towed

at speeds not to exceed 40 km/h (25 mph) for not

more than 25 km (15 miles). The gear selector must

be in neutral position.

² 3-speed automatic transaxle vehicles can be towed

at speeds not to exceed 40 km/h (25 mph) for not

more than 25 km (15 miles). The gear selector must

be in neutral position.

Fig. 8 Recommended Towing Devices

Ä LUBRICATION AND MAINTENANCE 0 - 7

Page 151 of 2438

BRAKES

CONTENTS

page page

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ............. 72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY ....... 113

BRAKE DISC (ROTOR) ................... 53

BRAKE SUPPORT ASSEMBLY ............. 25

FRONT DISC BRAKES ................... 31

GENERAL INFORMATION .................. 1

HYDRAULIC SYSTEM CONTROL VALVES . . . 26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER ............................ 35 KELSEY HAYES DOUBLE PIN NON-FAMILY

CALIPER ............................ 38

MASTER CYLINDER ..................... 66

PARKING BRAKES ...................... 57

POWER BRAKES ....................... 68

REAR DISC BRAKES .................... 45

REAR WHEEL DRUM BRAKES ............ 18

SERVICE ADJUSTMENTS .................. 4

WHEEL BEARINGS ...................... 70

WHEEL CYLINDERS ..................... 23

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the break down of these designa-

tions is included in the Introduction Section at the

front of this service manual. Standard brake equipment consists of:

² Double pin floating caliper disc front brakes.

² Rear automatic adjusting drum brakes.

² Differential valve with a brake warning switch.

² Master cylinder.

² Vacuum power booster.

² Double pin floating caliper rear disc brakes are

available on some models. The Bendix Anti-Lock 10 braking system, uses the

standard power brake system caliper assemblies,

braking discs, pedal assembly, brake lines and hoses.

The unique parts of the Bendix Anti-Lock 10 braking

system consists of the following components. Propor-

tioning valves, wheel speed sensors, tone wheels,

electronic control unit, modulator assembly and hy-

draulic assembly. These components replace the con-

ventional master cylinder and power booster. The

components will be described in detail in the Bendix

Anti-Lock 10 brake section in this group of the ser-

vice manual. The Bendix Anti-Lock 6 braking system, uses the

following standard brake system components. Master

cylinder, power booster, caliper assemblies, braking

discs, pedal assembly, brake lines and hoses. The

unique parts of the Bendix Anti-Lock 6 braking sys-

tem consists of the following components. Modulator

assembly, unique proportioning valves, wheel speed

sensors, tone wheels, and electronic control unit.

These components will be described in detail in the

Bendix Anti-Lock 6 brake section in this group of the

service manual. The front disc brake shoes have semi-metallic lin-

ings. The hydraulic brake system (Fig .123and4)is

diagonally split on both the Non-ABS and ABS brak-

ing system. With the left front and right rear brakes

on one hydraulic system and the right front and left

rear on the other. The Non-ABS and ABS brake system may use dif-

ferent types of brake line fittings and tubing flares.

The Non-ABS brake system uses double wall tubing

flares and fittings at all tubing joint locations. Some

ABS brake systems use both ISO style tubing flares

and double wall tubing flares and corresponding fit-

tings at different joint locations. See (Figs . 2 3 and 4)

for specific joint locations and type of tubing flare. The front disc brakes consist of two different types

of caliper assemblies. A double pin Kelsey-Hayes cal-

iper (family caliper) with a bolt-on adapter attached

to the steering knuckle. Or a double pin Kelsey-

Hayes caliper (non-family caliper) which mounts di-

rectly to rails on the steering knuckle. The non-

family caliper is only used on the AY Body

(Imperials).

CAUTION: Caliper pistons, boots and seals for the

different caliper assemblies used on the front and

rear disc brake assemblies are not interchangeable.

Misusage could result in a complete brake system

failure. Be sure that the parts are replaced with the

correct replacement parts, refer to the parts book

for the type and model year of the vehicle being

worked on.

The master cylinder is anodized, lightweight alu-

minum, with a bore size of 24.0mm, 21.0mm or 7/8

inch.

Ä BRAKES 5 - 1

Page 181 of 2438

FRONT DISC BRAKES INDEX

page page

General Information ....................... 31

Service Precautions ....................... 34 Shoe and Lining Wear

.................... 33

GENERAL INFORMATION

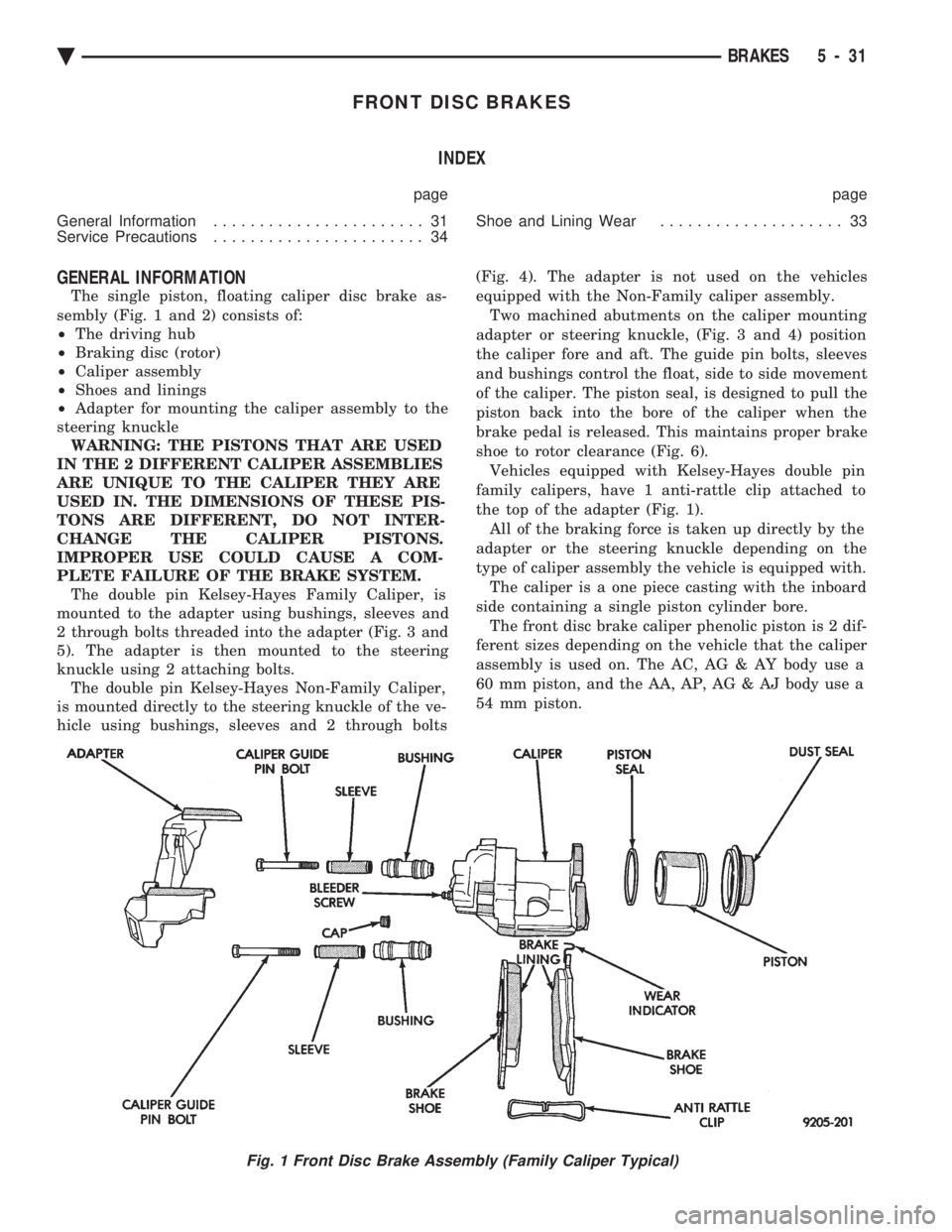

The single piston, floating caliper disc brake as-

sembly (Fig. 1 and 2) consists of:

² The driving hub

² Braking disc (rotor)

² Caliper assembly

² Shoes and linings

² Adapter for mounting the caliper assembly to the

steering knuckle WARNING: THE PISTONS THAT ARE USED

IN THE 2 DIFFERENT CALIPER ASSEMBLIES

ARE UNIQUE TO THE CALIPER THEY ARE

USED IN. THE DIMENSIONS OF THESE PIS-

TONS ARE DIFFERENT, DO NOT INTER-

CHANGE THE CALIPER PISTONS.

IMPROPER USE COULD CAUSE A COM-

PLETE FAILURE OF THE BRAKE SYSTEM. The double pin Kelsey-Hayes Family Caliper, is

mounted to the adapter using bushings, sleeves and

2 through bolts threaded into the adapter (Fig. 3 and

5). The adapter is then mounted to the steering

knuckle using 2 attaching bolts. The double pin Kelsey-Hayes Non-Family Caliper,

is mounted directly to the steering knuckle of the ve-

hicle using bushings, sleeves and 2 through bolts (Fig. 4). The adapter is not used on the vehicles

equipped with the Non-Family caliper assembly.

Two machined abutments on the caliper mounting

adapter or steering knuckle, (Fig. 3 and 4) position

the caliper fore and aft. The guide pin bolts, sleeves

and bushings control the float, side to side movement

of the caliper. The piston seal, is designed to pull the

piston back into the bore of the caliper when the

brake pedal is released. This maintains proper brake

shoe to rotor clearance (Fig. 6). Vehicles equipped with Kelsey-Hayes double pin

family calipers, have 1 anti-rattle clip attached to

the top of the adapter (Fig. 1). All of the braking force is taken up directly by the

adapter or the steering knuckle depending on the

type of caliper assembly the vehicle is equipped with. The caliper is a one piece casting with the inboard

side containing a single piston cylinder bore. The front disc brake caliper phenolic piston is 2 dif-

ferent sizes depending on the vehicle that the caliper

assembly is used on. The AC, AG & AY body use a

60 mm piston, and the AA, AP, AG & AJ body use a

54 mm piston.

Fig. 1 Front Disc Brake Assembly (Family Caliper Typical)

Ä BRAKES 5 - 31

Page 185 of 2438

KELSEY HAYES DOUBLE PIN FAMILY CALIPER

BRAKE SHOE SERVICE PROCEDURES

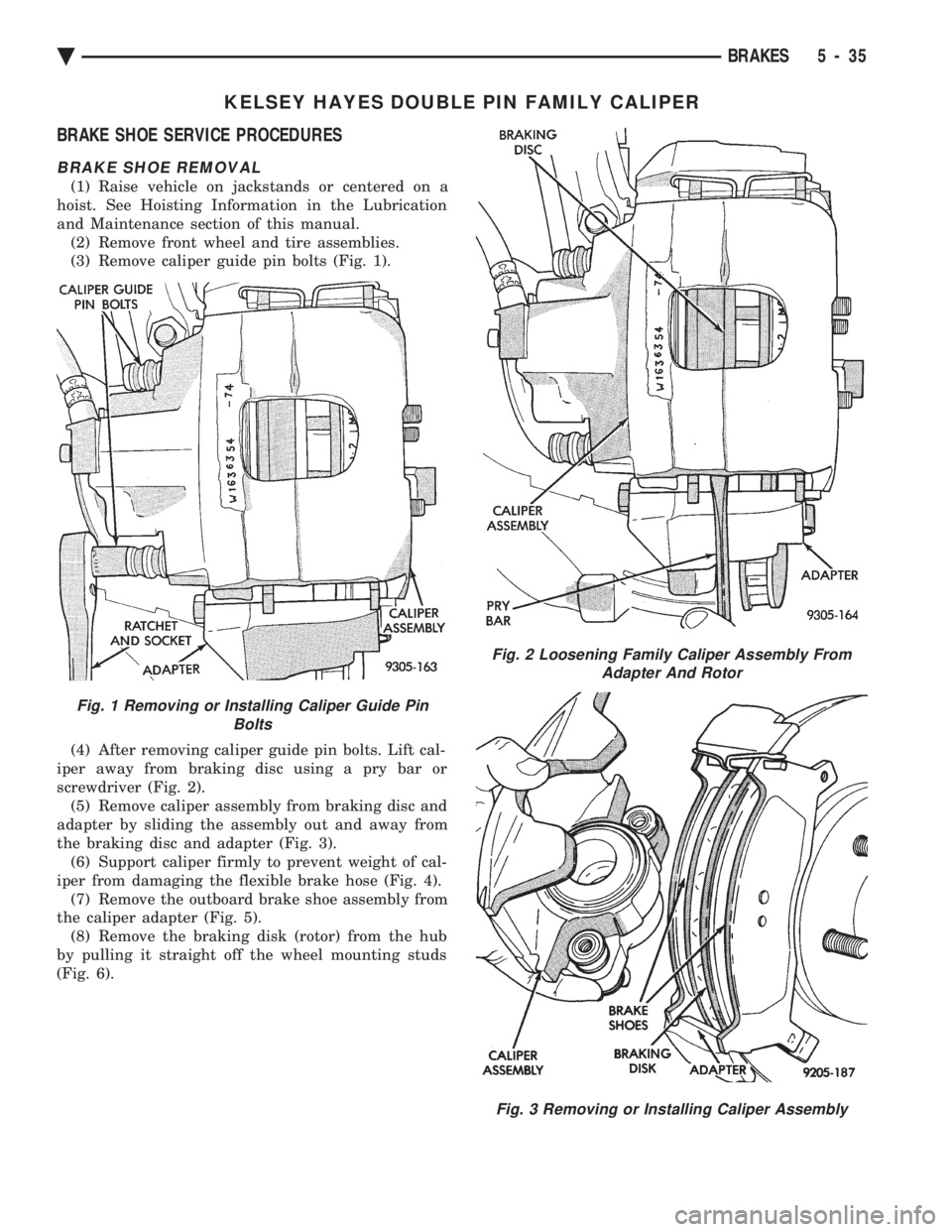

BRAKE SHOE REMOVAL

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting Information in the Lubrication

and Maintenance section of this manual. (2) Remove front wheel and tire assemblies.

(3) Remove caliper guide pin bolts (Fig. 1).

(4) After removing caliper guide pin bolts. Lift cal-

iper away from braking disc using a pry bar or

screwdriver (Fig. 2). (5) Remove caliper assembly from braking disc and

adapter by sliding the assembly out and away from

the braking disc and adapter (Fig. 3). (6) Support caliper firmly to prevent weight of cal-

iper from damaging the flexible brake hose (Fig. 4). (7) Remove the outboard brake shoe assembly from

the caliper adapter (Fig. 5). (8) Remove the braking disk (rotor) from the hub

by pulling it straight off the wheel mounting studs

(Fig. 6).

Fig. 1 Removing or Installing Caliper Guide Pin Bolts

Fig. 2 Loosening Family Caliper Assembly FromAdapter And Rotor

Fig. 3 Removing or Installing Caliper Assembly

Ä BRAKES 5 - 35

Page 195 of 2438

REAR DISC BRAKES INDEX

page page

Assembling Rear Disc Brake Caliper .......... 49

Brake Shoe Removal ..................... 46

Cleaning and Inspection ................... 49

Disassembling Rear Caliper Assembly ......... 48 General Information

....................... 45

Lining Wear ............................. 45

Service Precautions ....................... 46

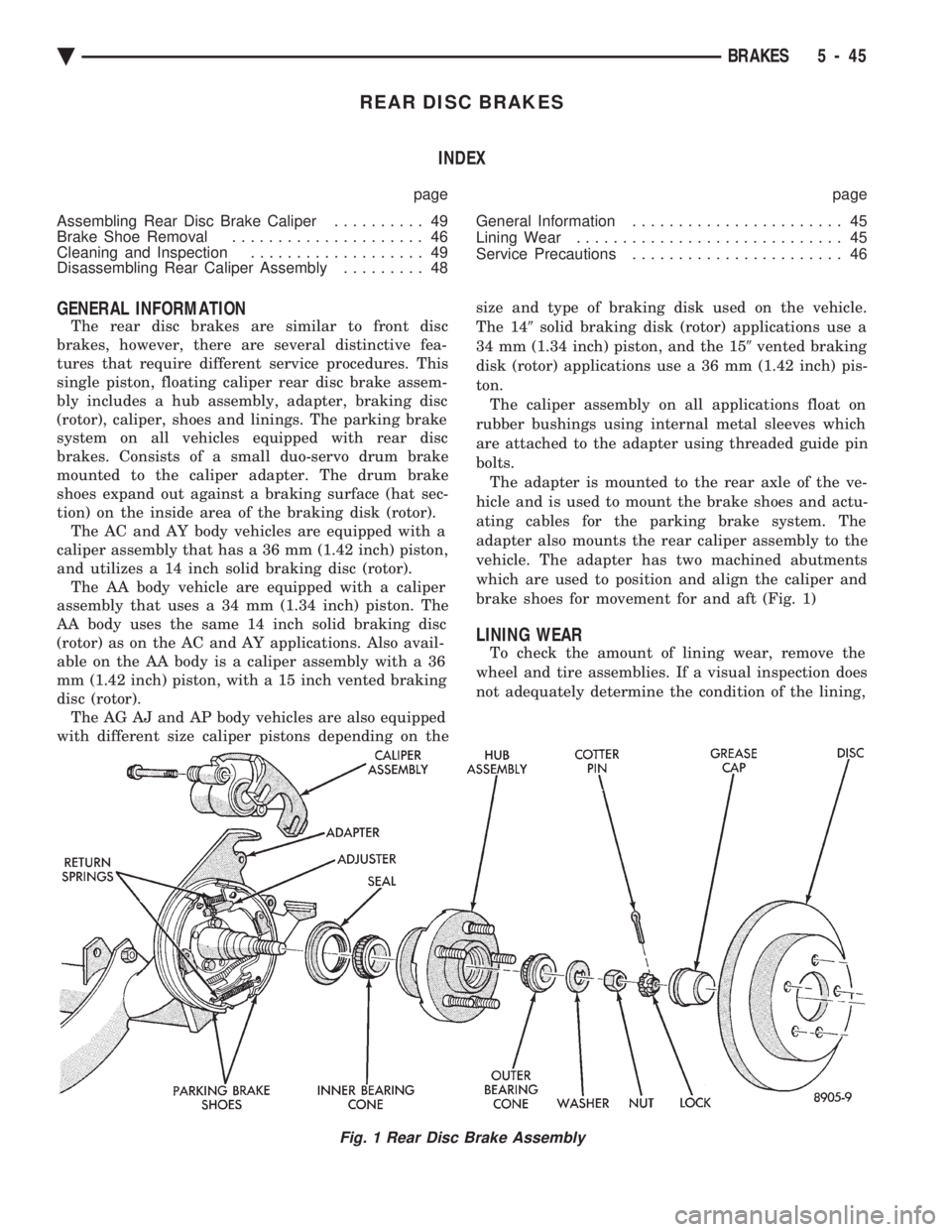

GENERAL INFORMATION

The rear disc brakes are similar to front disc

brakes, however, there are several distinctive fea-

tures that require different service procedures. This

single piston, floating caliper rear disc brake assem-

bly includes a hub assembly, adapter, braking disc

(rotor), caliper, shoes and linings. The parking brake

system on all vehicles equipped with rear disc

brakes. Consists of a small duo-servo drum brake

mounted to the caliper adapter. The drum brake

shoes expand out against a braking surface (hat sec-

tion) on the inside area of the braking disk (rotor). The AC and AY body vehicles are equipped with a

caliper assembly that has a 36 mm (1.42 inch) piston,

and utilizes a 14 inch solid braking disc (rotor). The AA body vehicle are equipped with a caliper

assembly that uses a 34 mm (1.34 inch) piston. The

AA body uses the same 14 inch solid braking disc

(rotor) as on the AC and AY applications. Also avail-

able on the AA body is a caliper assembly with a 36

mm (1.42 inch) piston, with a 15 inch vented braking

disc (rotor). The AG AJ and AP body vehicles are also equipped

with different size caliper pistons depending on the size and type of braking disk used on the vehicle.

The 14 9solid braking disk (rotor) applications use a

34 mm (1.34 inch) piston, and the 15 9vented braking

disk (rotor) applications use a 36 mm (1.42 inch) pis-

ton. The caliper assembly on all applications float on

rubber bushings using internal metal sleeves which

are attached to the adapter using threaded guide pin

bolts. The adapter is mounted to the rear axle of the ve-

hicle and is used to mount the brake shoes and actu-

ating cables for the parking brake system. The

adapter also mounts the rear caliper assembly to the

vehicle. The adapter has two machined abutments

which are used to position and align the caliper and

brake shoes for movement for and aft (Fig. 1)

LINING WEAR

To check the amount of lining wear, remove the

wheel and tire assemblies. If a visual inspection does

not adequately determine the condition of the lining,

Fig. 1 Rear Disc Brake Assembly

Ä BRAKES 5 - 45

Page 197 of 2438

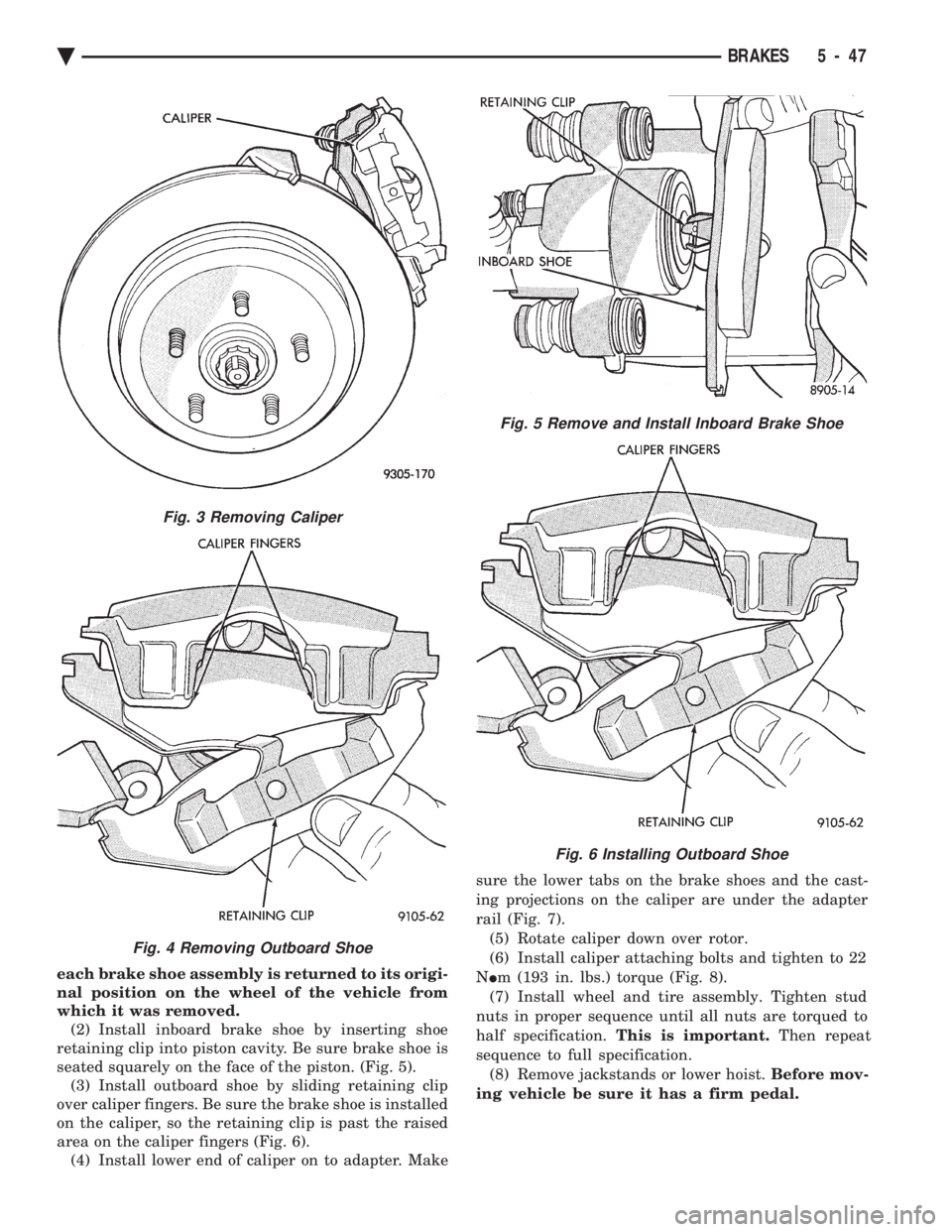

each brake shoe assembly is returned to its origi-

nal position on the wheel of the vehicle from

which it was removed. (2) Install inboard brake shoe by inserting shoe

retaining clip into piston cavity. Be sure brake shoe is

seated squarely on the face of the piston. (Fig. 5). (3) Install outboard shoe by sliding retaining clip

over caliper fingers. Be sure the brake shoe is installed

on the caliper, so the retaining clip is past the raised

area on the caliper fingers (Fig. 6). (4) Install lower end of caliper on to adapter. Make sure the lower tabs on the brake shoes and the cast-

ing projections on the caliper are under the adapter

rail (Fig. 7). (5) Rotate caliper down over rotor.

(6) Install caliper attaching bolts and tighten to 22

N Im (193 in. lbs.) torque (Fig. 8).

(7) Install wheel and tire assembly. Tighten stud

nuts in proper sequence until all nuts are torqued to

half specification. This is important. Then repeat

sequence to full specification. (8) Remove jackstands or lower hoist. Before mov-

ing vehicle be sure it has a firm pedal.

Fig. 5 Remove and Install Inboard Brake Shoe

Fig. 6 Installing Outboard Shoe

Fig. 3 Removing Caliper

Fig. 4 Removing Outboard Shoe

Ä BRAKES 5 - 47

Page 203 of 2438

BRAKE DISC (ROTOR) INDEX

page page

Braking Disc Removal ..................... 54

General Information ....................... 53

Inspection Diagnosis ...................... 53 Installing Braking Disc

..................... 54

Refinishing Braking Disc ................... 55

Service Procedures ....................... 53

GENERAL INFORMATION

Any servicing of the braking disc requires extreme

care to maintain the braking disc within service toler-

ances to ensure proper brake action.

CAUTION: If the braking disk (rotor) needs to be

replaced with a new part. The protective coating on

the braking surfaces of the rotor MUST BE REMOVED

with an appropriate solvent, to avoid contamination

of the brake shoe linings.

When replacing a rotor with a new part do NOT

reface the new rotor. Rotor already has the re-

quired micro finish when manufactured, only

remove the protective coating.

INSPECTION DIAGNOSIS

Before refinishing or refacing a braking disc, the disc

should be checked and inspected for the following

conditions: Braking surface scoring, rust, impregnation of lining

material and worn ridges. Excessive lateral rotor runout or wobble.

Thickness variation (Parallelism).

Dishing or distortion (Flatness).

If a vehicle has not been driven for a period of time.

The discs will rust in the area not covered by the brake

lining and cause noise and chatter when the brakes are

applied. Excessive wear and scoring of the disc can cause

temporary improper lining contact if ridges are not

removed before installation of new brake shoe assem-

blies. Some discoloration or wear of the disc surface is

normal and does not require resurfacing when linings

are replaced. Excessive runout or wobble in a disc can increase

pedal travel due to piston knock back. This will in-

crease guide pin bushing wear due to tendency of

caliper to follow disc wobble. Thickness variation in a disc can also result in pedal

pulsation, chatter and surge due to variation in brake

output. This can also be caused by excessive runout in

braking disc or hub. Dishing or distortion can be caused by extreme heat

and abuse of the brakes.

SERVICE PROCEDURES

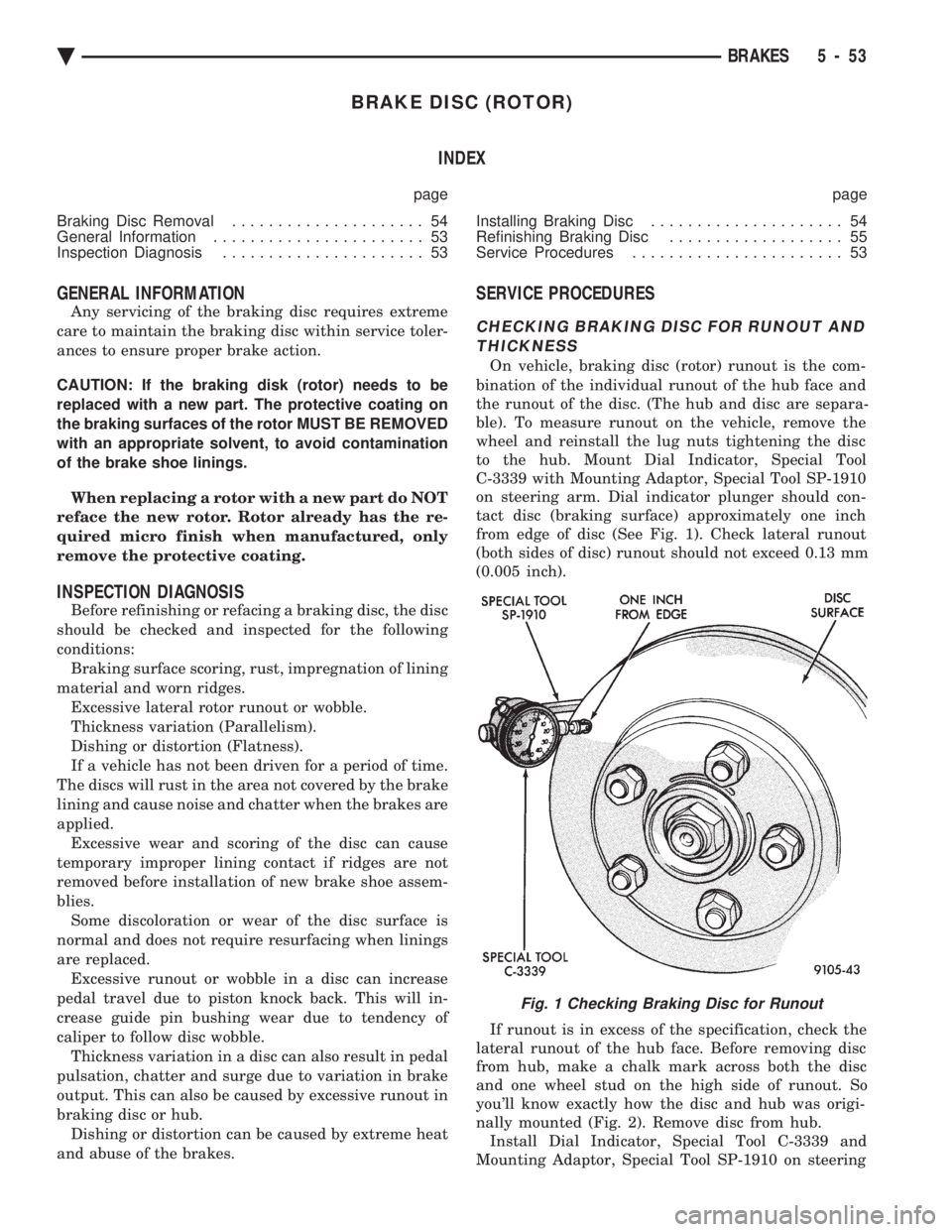

CHECKING BRAKING DISC FOR RUNOUT AND THICKNESS

On vehicle, braking disc (rotor) runout is the com-

bination of the individual runout of the hub face and

the runout of the disc. (The hub and disc are separa-

ble). To measure runout on the vehicle, remove the

wheel and reinstall the lug nuts tightening the disc

to the hub. Mount Dial Indicator, Special Tool

C-3339 with Mounting Adaptor, Special Tool SP-1910

on steering arm. Dial indicator plunger should con-

tact disc (braking surface) approximately one inch

from edge of disc (See Fig. 1). Check lateral runout

(both sides of disc) runout should not exceed 0.13 mm

(0.005 inch).

If runout is in excess of the specification, check the

lateral runout of the hub face. Before removing disc

from hub, make a chalk mark across both the disc

and one wheel stud on the high side of runout. So

you'll know exactly how the disc and hub was origi-

nally mounted (Fig. 2). Remove disc from hub. Install Dial Indicator, Special Tool C-3339 and

Mounting Adaptor, Special Tool SP-1910 on steering

Fig. 1 Checking Braking Disc for Runout

Ä BRAKES 5 - 53

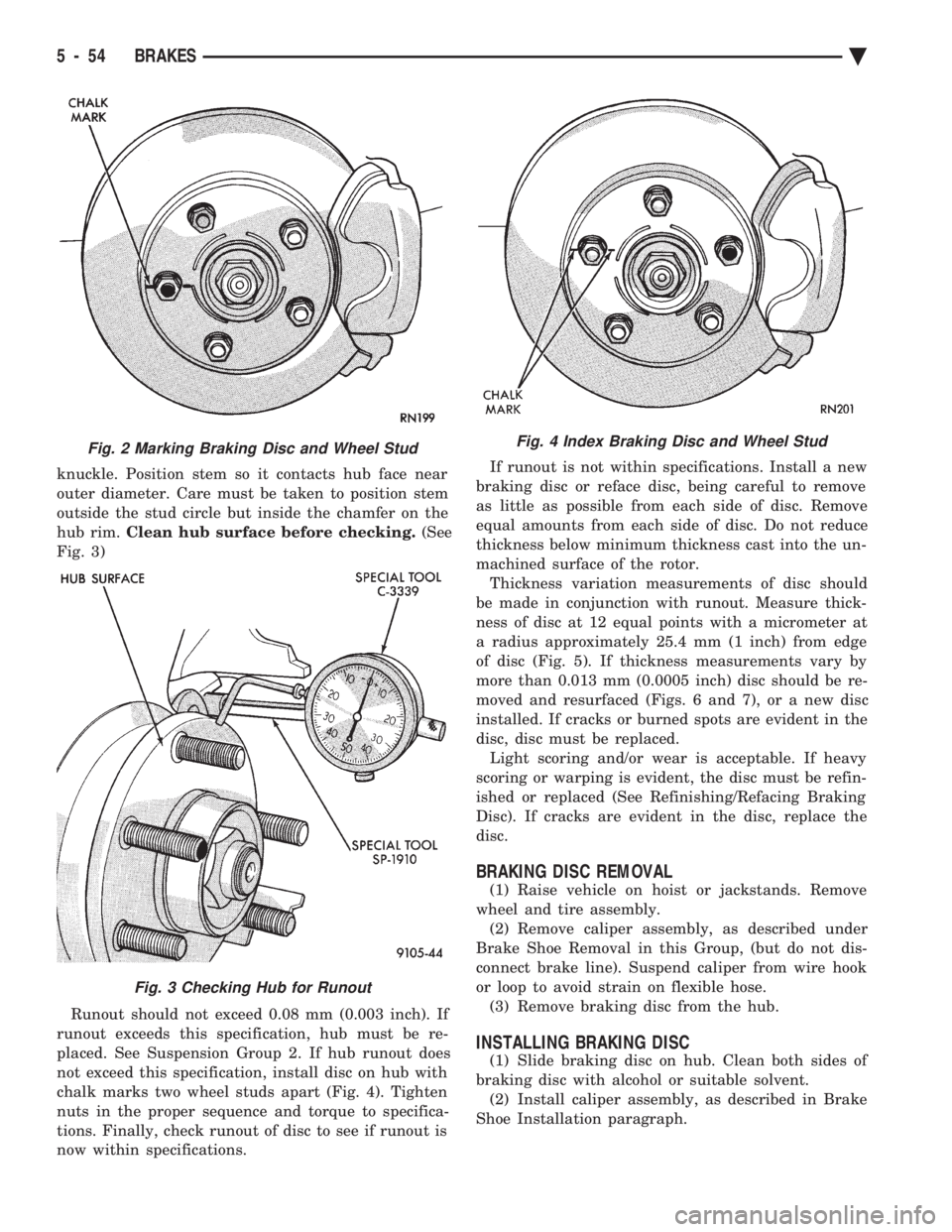

Page 204 of 2438

knuckle. Position stem so it contacts hub face near

outer diameter. Care must be taken to position stem

outside the stud circle but inside the chamfer on the

hub rim. Clean hub surface before checking. (See

Fig. 3)

Runout should not exceed 0.08 mm (0.003 inch). If

runout exceeds this specification, hub must be re-

placed. See Suspension Group 2. If hub runout does

not exceed this specification, install disc on hub with

chalk marks two wheel studs apart (Fig. 4). Tighten

nuts in the proper sequence and torque to specifica-

tions. Finally, check runout of disc to see if runout is

now within specifications. If runout is not within specifications. Install a new

braking disc or reface disc, being careful to remove

as little as possible from each side of disc. Remove

equal amounts from each side of disc. Do not reduce

thickness below minimum thickness cast into the un-

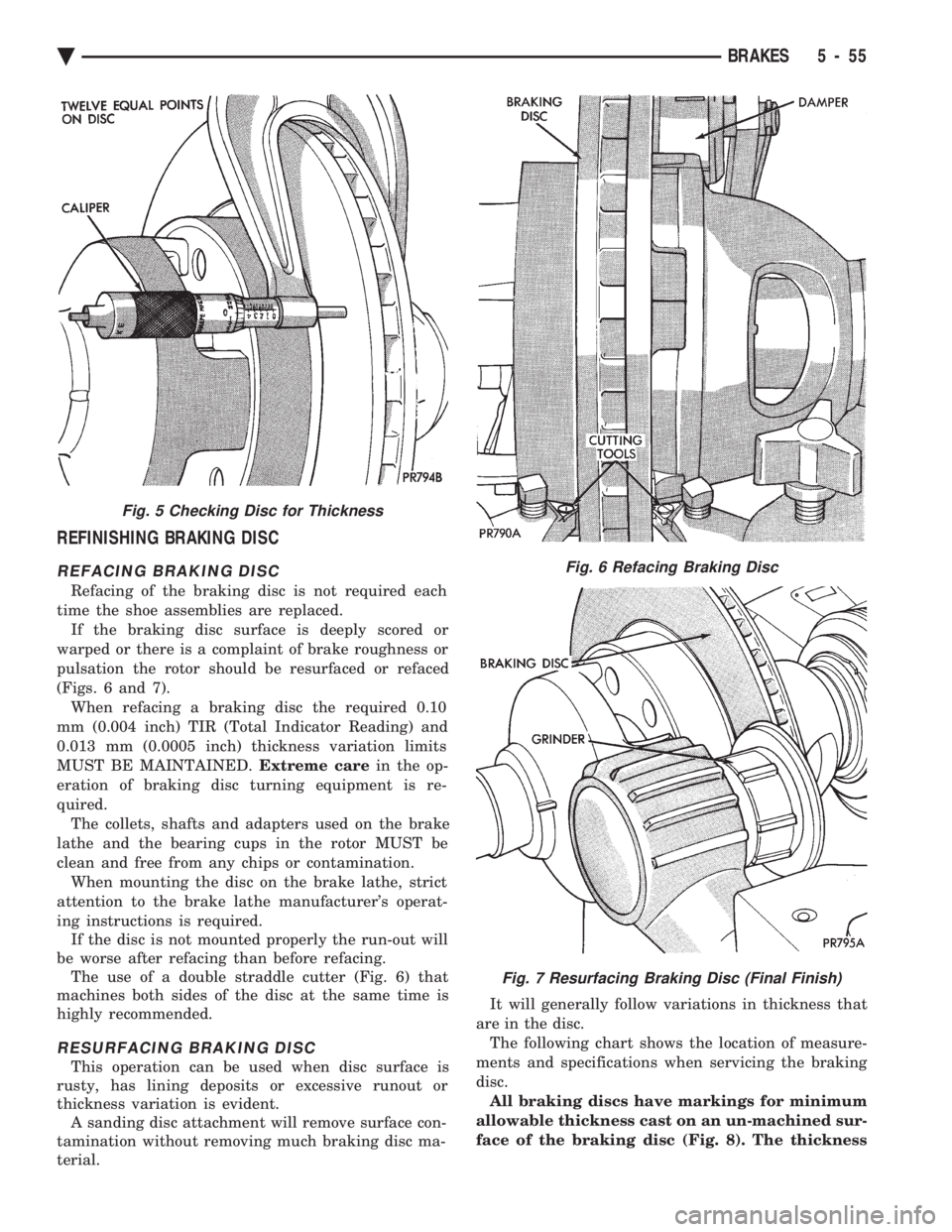

machined surface of the rotor. Thickness variation measurements of disc should

be made in conjunction with runout. Measure thick-

ness of disc at 12 equal points with a micrometer at

a radius approximately 25.4 mm (1 inch) from edge

of disc (Fig. 5). If thickness measurements vary by

more than 0.013 mm (0.0005 inch) disc should be re-

moved and resurfaced (Figs. 6 and 7), or a new disc

installed. If cracks or burned spots are evident in the

disc, disc must be replaced. Light scoring and/or wear is acceptable. If heavy

scoring or warping is evident, the disc must be refin-

ished or replaced (See Refinishing/Refacing Braking

Disc). If cracks are evident in the disc, replace the

disc.

BRAKING DISC REMOVAL

(1) Raise vehicle on hoist or jackstands. Remove

wheel and tire assembly. (2) Remove caliper assembly, as described under

Brake Shoe Removal in this Group, (but do not dis-

connect brake line). Suspend caliper from wire hook

or loop to avoid strain on flexible hose. (3) Remove braking disc from the hub.

INSTALLING BRAKING DISC

(1) Slide braking disc on hub. Clean both sides of

braking disc with alcohol or suitable solvent. (2) Install caliper assembly, as described in Brake

Shoe Installation paragraph.

Fig. 2 Marking Braking Disc and Wheel Stud

Fig. 3 Checking Hub for Runout

Fig. 4 Index Braking Disc and Wheel Stud

5 - 54 BRAKES Ä

Page 205 of 2438

REFINISHING BRAKING DISC

REFACING BRAKING DISC

Refacing of the braking disc is not required each

time the shoe assemblies are replaced. If the braking disc surface is deeply scored or

warped or there is a complaint of brake roughness or

pulsation the rotor should be resurfaced or refaced

(Figs. 6 and 7). When refacing a braking disc the required 0.10

mm (0.004 inch) TIR (Total Indicator Reading) and

0.013 mm (0.0005 inch) thickness variation limits

MUST BE MAINTAINED. Extreme carein the op-

eration of braking disc turning equipment is re-

quired. The collets, shafts and adapters used on the brake

lathe and the bearing cups in the rotor MUST be

clean and free from any chips or contamination. When mounting the disc on the brake lathe, strict

attention to the brake lathe manufacturer's operat-

ing instructions is required. If the disc is not mounted properly the run-out will

be worse after refacing than before refacing. The use of a double straddle cutter (Fig. 6) that

machines both sides of the disc at the same time is

highly recommended.

RESURFACING BRAKING DISC

This operation can be used when disc surface is

rusty, has lining deposits or excessive runout or

thickness variation is evident. A sanding disc attachment will remove surface con-

tamination without removing much braking disc ma-

terial. It will generally follow variations in thickness that

are in the disc. The following chart shows the location of measure-

ments and specifications when servicing the braking

disc. All braking discs have markings for minimum

allowable thickness cast on an un-machined sur-

face of the braking disc (Fig. 8). The thickness

Fig. 5 Checking Disc for Thickness

Fig. 6 Refacing Braking Disc

Fig. 7 Resurfacing Braking Disc (Final Finish)

Ä BRAKES 5 - 55