6-67

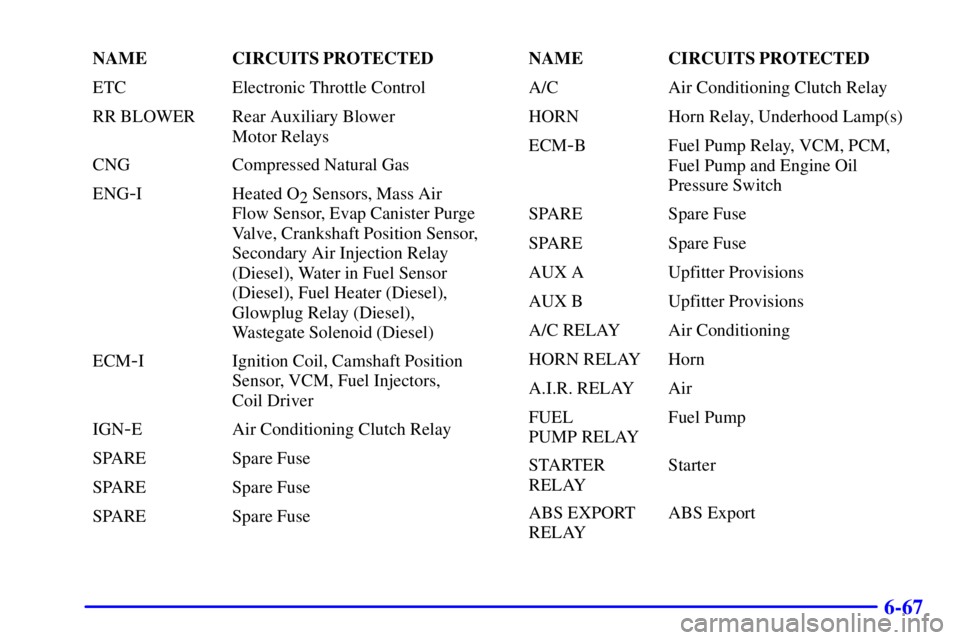

NAME CIRCUITS PROTECTED

ETC Electronic Throttle Control

RR BLOWER Rear Auxiliary Blower

Motor Relays

CNG Compressed Natural Gas

ENG

-I Heated O2 Sensors, Mass Air

Flow Sensor, Evap Canister Purge

Valve, Crankshaft Position Sensor,

Secondary Air Injection Relay

(Diesel), Water in Fuel Sensor

(Diesel), Fuel Heater (Diesel),

Glowplug Relay (Diesel),

Wastegate Solenoid (Diesel)

ECM

-I Ignition Coil, Camshaft Position

Sensor, VCM, Fuel Injectors,

Coil Driver

IGN

-E Air Conditioning Clutch Relay

SPARE Spare Fuse

SPARE Spare Fuse

SPARE Spare FuseNAME CIRCUITS PROTECTED

A/C Air Conditioning Clutch Relay

HORN Horn Relay, Underhood Lamp(s)

ECM

-B Fuel Pump Relay, VCM, PCM,

Fuel Pump and Engine Oil

Pressure Switch

SPARE Spare Fuse

SPARE Spare Fuse

AUX A Upfitter Provisions

AUX B Upfitter Provisions

A/C RELAY Air Conditioning

HORN RELAY Horn

A.I.R. RELAY Air

FUEL

PUMP RELAYFuel Pump

STARTER

RELAYStarter

ABS EXPORT

RELAYABS Export

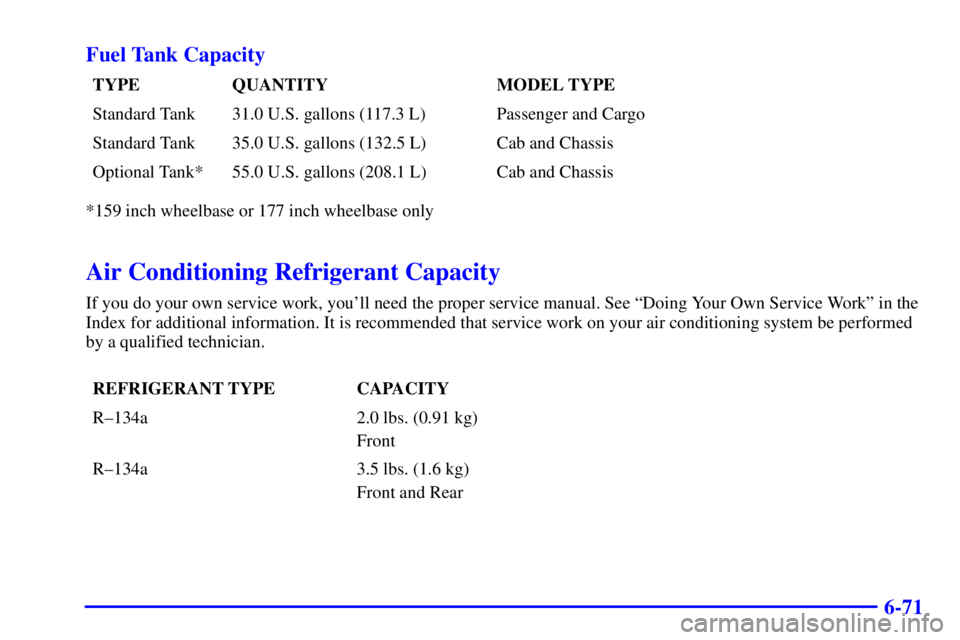

6-71 Fuel Tank Capacity

TYPE QUANTITY MODEL TYPE

Standard Tank 31.0 U.S. gallons (117.3 L) Passenger and Cargo

Standard Tank 35.0 U.S. gallons (132.5 L) Cab and Chassis

Optional Tank* 55.0 U.S. gallons (208.1 L) Cab and Chassis

*159 inch wheelbase or 177 inch wheelbase only

Air Conditioning Refrigerant Capacity

If you do your own service work, you'll need the proper service manual. See ªDoing Your Own Service Workº in the

Index for additional information. It is recommended that service work on your air conditioning system be performed

by a qualified technician.

REFRIGERANT TYPE CAPACITY

R±134a 2.0 lbs. (0.91 kg)

Front

R±134a 3.5 lbs. (1.6 kg)

Front and Rear

7-54 Fuel System Inspection

Inspect the complete fuel system for damage or leaks.

Engine Cooling System Inspection

Inspect the hoses and have them replaced if they are

cracked, swollen or deteriorated. Inspect all pipes,

fittings and clamps; replace as needed. Clean the outside

of the radiator and air conditioning condenser. To help

ensure proper operation, a pressure test of the cooling

system and pressure cap is recommended at least once

a year.

Throttle System Inspection

(Gasoline Engine)

Inspect the throttle system for interference or binding,

and for damaged or missing parts. Replace parts as

needed. Replace any components that have high effort

or excessive wear. Do not lubricate accelerator and

cruise control cables.

Rear Axle Service

Check the gear lubricant level in the rear axle and add

if needed. See ªRear Axleº in the Index. A fluid loss

may indicate a problem. Check the axle and repair it

if needed.

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses for proper hook

-up, binding, leaks, cracks,

chafing, etc. Inspect disc brake pads for wear and rotors

for surface condition. Also inspect drum brake linings

for wear and cracks. Inspect other brake parts, including

drums, wheel cylinders, calipers, parking brake, etc.

Check parking brake adjustment. You may need to have

your brakes inspected more often if your driving habits

or conditions result in frequent braking.