wheel CHEVROLET EXPRESS 2006 Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2006, Model line: EXPRESS, Model: CHEVROLET EXPRESS 2006Pages: 440, PDF Size: 2.42 MB

Page 360 of 440

Removing the Flat Tire and

Installing the Spare Tire

If your vehicle has plastic wheel nut caps, loosen

them by turning the wheel wrench counterclockwise.

The wheel nut caps are designed to remain with

the center cap. Remove the center cap.

If the wheel has a smooth center piece, place the chisel

end of the wheel wrench in the slot on the wheel and

gently pry it out.

1. Do a safety check before proceeding. SeeChanging

a Flat Tire on page 6-86for more information.

2. Loosen all the wheel nuts with the wheel wrench.

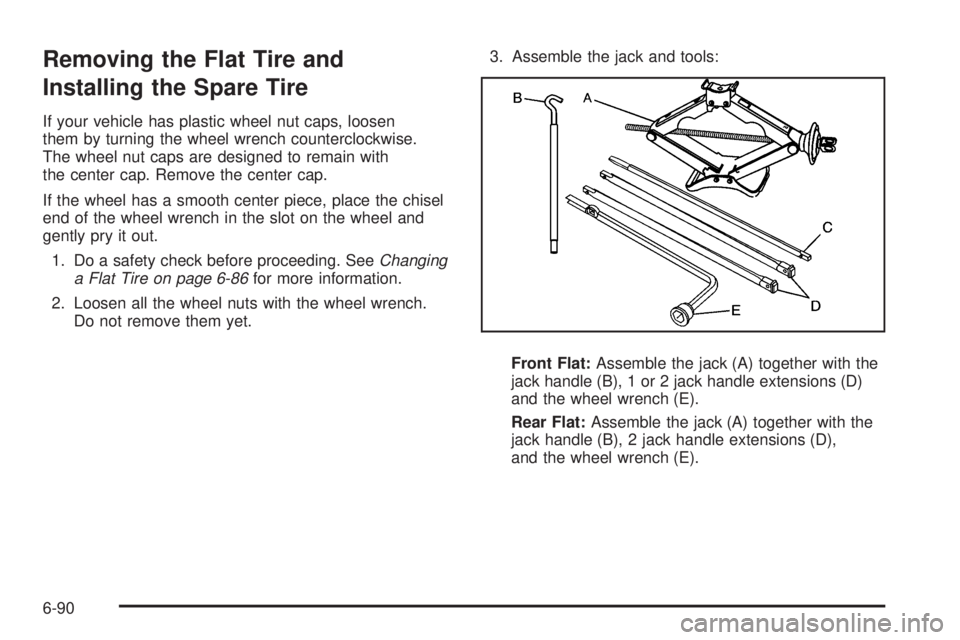

Do not remove them yet.3. Assemble the jack and tools:

Front Flat:Assemble the jack (A) together with the

jack handle (B), 1 or 2 jack handle extensions (D)

and the wheel wrench (E).

Rear Flat:Assemble the jack (A) together with the

jack handle (B), 2 jack handle extensions (D),

and the wheel wrench (E).

6-90

Page 363 of 440

{WARNING:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack you

could be badly injured or killed. Never get under

a vehicle when it is supported only by a jack.

{WARNING:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even make

the vehicle fall. To help avoid personal injury and

vehicle damage, be sure to fit the jack lift head into

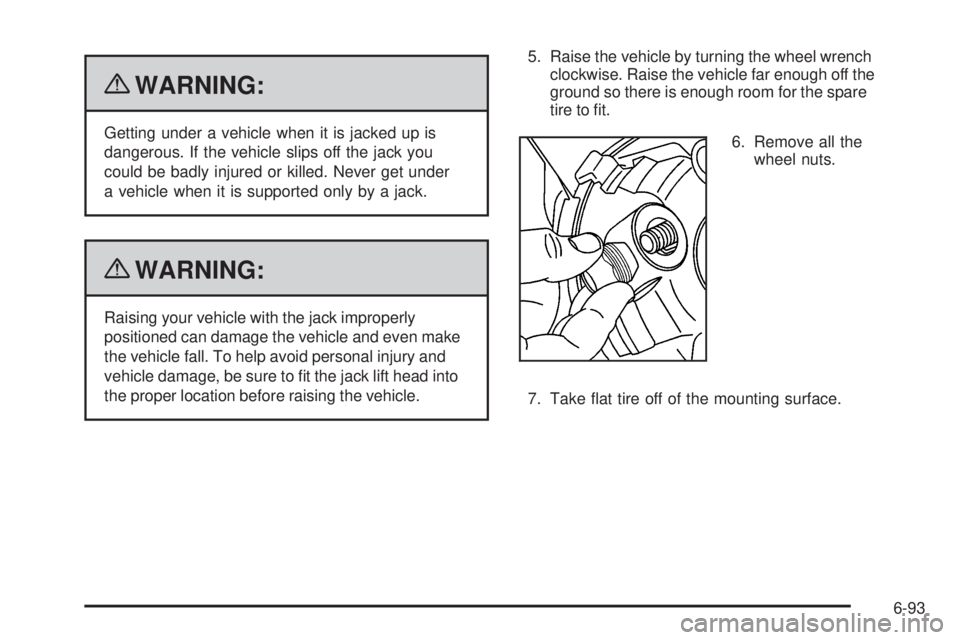

the proper location before raising the vehicle.5. Raise the vehicle by turning the wheel wrench

clockwise. Raise the vehicle far enough off the

ground so there is enough room for the spare

tire to fit.

6. Remove all the

wheel nuts.

7. Take flat tire off of the mounting surface.

6-93

Page 364 of 440

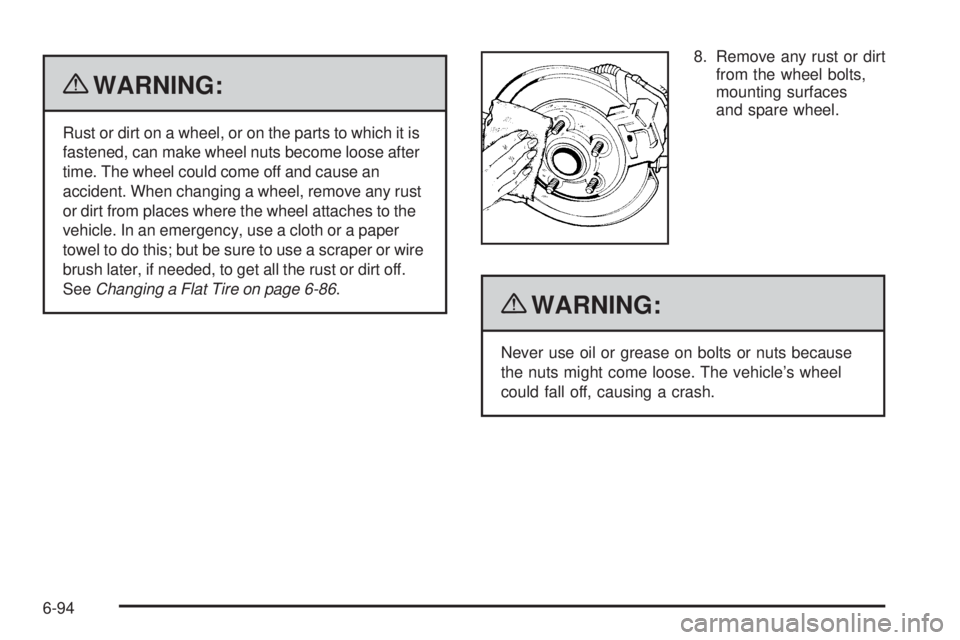

{WARNING:

Rust or dirt on a wheel, or on the parts to which it is

fastened, can make wheel nuts become loose after

time. The wheel could come off and cause an

accident. When changing a wheel, remove any rust

or dirt from places where the wheel attaches to the

vehicle. In an emergency, use a cloth or a paper

towel to do this; but be sure to use a scraper or wire

brush later, if needed, to get all the rust or dirt off.

SeeChanging a Flat Tire on page 6-86.8. Remove any rust or dirt

from the wheel bolts,

mounting surfaces

and spare wheel.

{WARNING:

Never use oil or grease on bolts or nuts because

the nuts might come loose. The vehicle’s wheel

could fall off, causing a crash.

6-94

Page 365 of 440

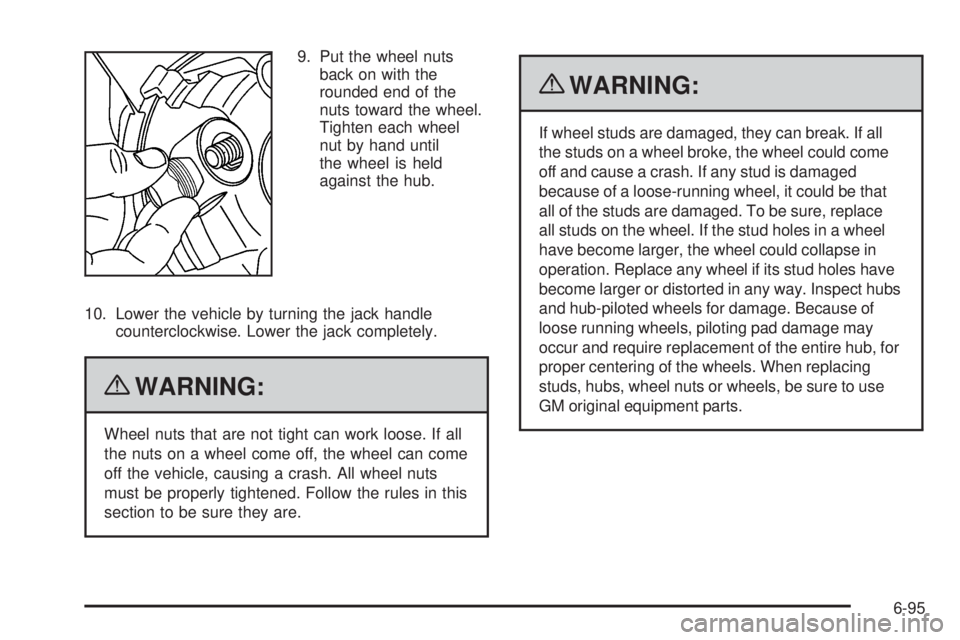

9. Put the wheel nuts

back on with the

rounded end of the

nuts toward the wheel.

Tighten each wheel

nut by hand until

the wheel is held

against the hub.

10. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

{WARNING:

Wheel nuts that are not tight can work loose. If all

the nuts on a wheel come off, the wheel can come

off the vehicle, causing a crash. All wheel nuts

must be properly tightened. Follow the rules in this

section to be sure they are.

{WARNING:

If wheel studs are damaged, they can break. If all

the studs on a wheel broke, the wheel could come

off and cause a crash. If any stud is damaged

because of a loose-running wheel, it could be that

all of the studs are damaged. To be sure, replace

all studs on the wheel. If the stud holes in a wheel

have become larger, the wheel could collapse in

operation. Replace any wheel if its stud holes have

become larger or distorted in any way. Inspect hubs

and hub-piloted wheels for damage. Because of

loose running wheels, piloting pad damage may

occur and require replacement of the entire hub, for

proper centering of the wheels. When replacing

studs, hubs, wheel nuts or wheels, be sure to use

GM original equipment parts.

6-95

Page 366 of 440

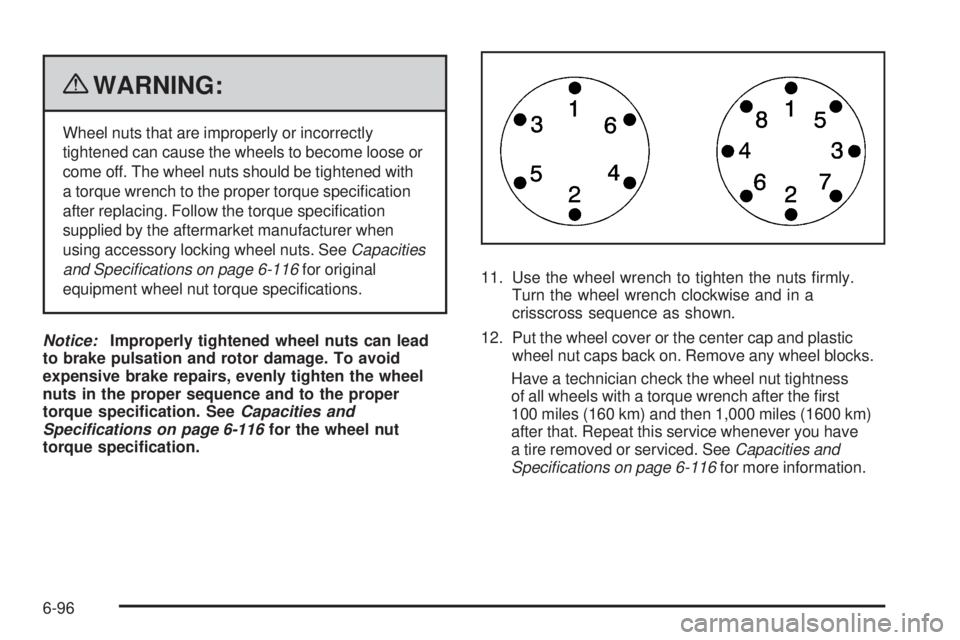

{WARNING:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose or

come off. The wheel nuts should be tightened with

a torque wrench to the proper torque specification

after replacing. Follow the torque specification

supplied by the aftermarket manufacturer when

using accessory locking wheel nuts. SeeCapacities

and Speci�cations on page 6-116for original

equipment wheel nut torque specifications.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci�cation. SeeCapacities and

Specifications on page 6-116for the wheel nut

torque speci�cation.11. Use the wheel wrench to tighten the nuts firmly.

Turn the wheel wrench clockwise and in a

crisscross sequence as shown.

12. Put the wheel cover or the center cap and plastic

wheel nut caps back on. Remove any wheel blocks.

Have a technician check the wheel nut tightness

of all wheels with a torque wrench after the first

100 miles (160 km) and then 1,000 miles (1600 km)

after that. Repeat this service whenever you have

a tire removed or serviced. SeeCapacities and

Speci�cations on page 6-116for more information.

6-96

Page 368 of 440

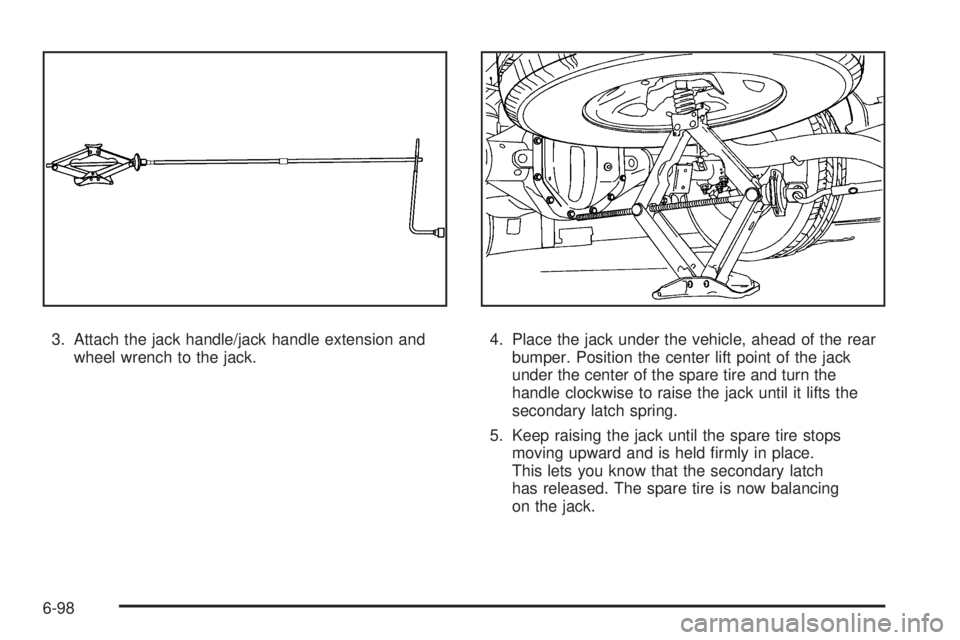

3. Attach the jack handle/jack handle extension and

wheel wrench to the jack.4. Place the jack under the vehicle, ahead of the rear

bumper. Position the center lift point of the jack

under the center of the spare tire and turn the

handle clockwise to raise the jack until it lifts the

secondary latch spring.

5. Keep raising the jack until the spare tire stops

moving upward and is held firmly in place.

This lets you know that the secondary latch

has released. The spare tire is now balancing

on the jack.

6-98

Page 369 of 440

6. Lower the jack by turning the wheel wrench

counterclockwise. Keep lowering the jack until

the spare tire slides off the jack or is hanging

by the cable.

7. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push

against the spare while firmly pulling the jack out

from under the spare tire with the other hand.

If the spare tire is hanging from the cable, assembly

the wheel wrench onto the hoist extension and insert

the chisel end of the hoist extension into the hoist

shaft hole above the bumper. Turn the wheel wrench

counterclockwise to lower the spare the rest of

the way.8. Tilt the retainer at the end of the cable and pull it

through the wheel opening. Pull the tire out from

under the vehicle.

Notice:If you drive away before the spare tire or

secondary latch system cable has been reinstalled,

you could damage your vehicle. Always reinstall

this cable before driving your vehicle.

9. If the cable is hanging under the vehicle, turn the

wheel wrench in the hoist shaft hole in the bumper

clockwise to raise the cable back up.

Have the hoist assembly inspected as soon as you can.

You will not be able to store a spare or flat tire using

the hoist assembly until it has been repaired or replaced.

To continue changing the flat tire, return to Step 4 of

Removing the Flat Tire and Installing the Spare Tire on

page 6-90.

6-99

Page 370 of 440

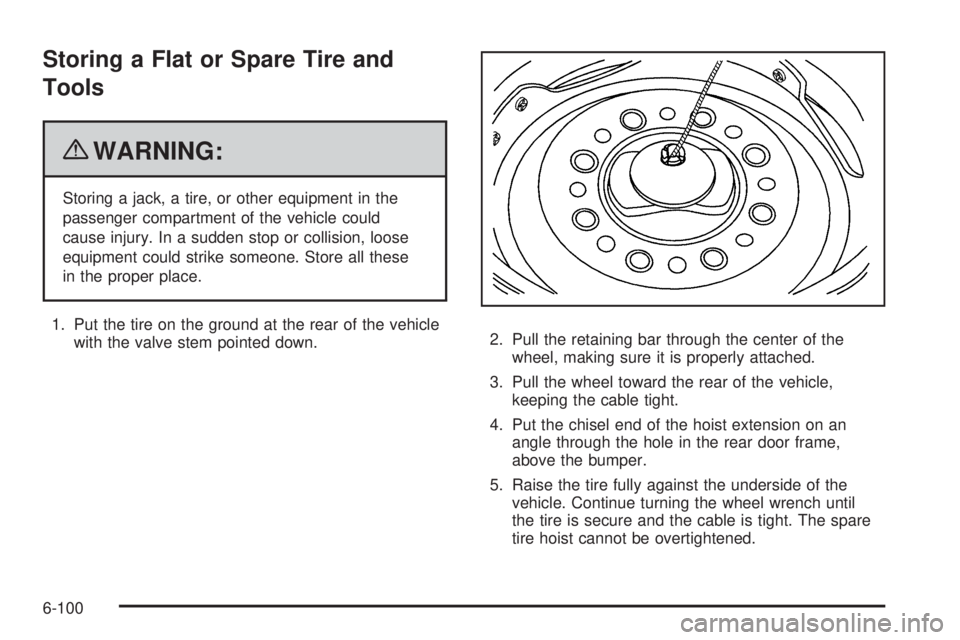

Storing a Flat or Spare Tire and

Tools

{WARNING:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision, loose

equipment could strike someone. Store all these

in the proper place.

1. Put the tire on the ground at the rear of the vehicle

with the valve stem pointed down.2. Pull the retaining bar through the center of the

wheel, making sure it is properly attached.

3. Pull the wheel toward the rear of the vehicle,

keeping the cable tight.

4. Put the chisel end of the hoist extension on an

angle through the hole in the rear door frame,

above the bumper.

5. Raise the tire fully against the underside of the

vehicle. Continue turning the wheel wrench until

the tire is secure and the cable is tight. The spare

tire hoist cannot be overtightened.

6-100

Page 371 of 440

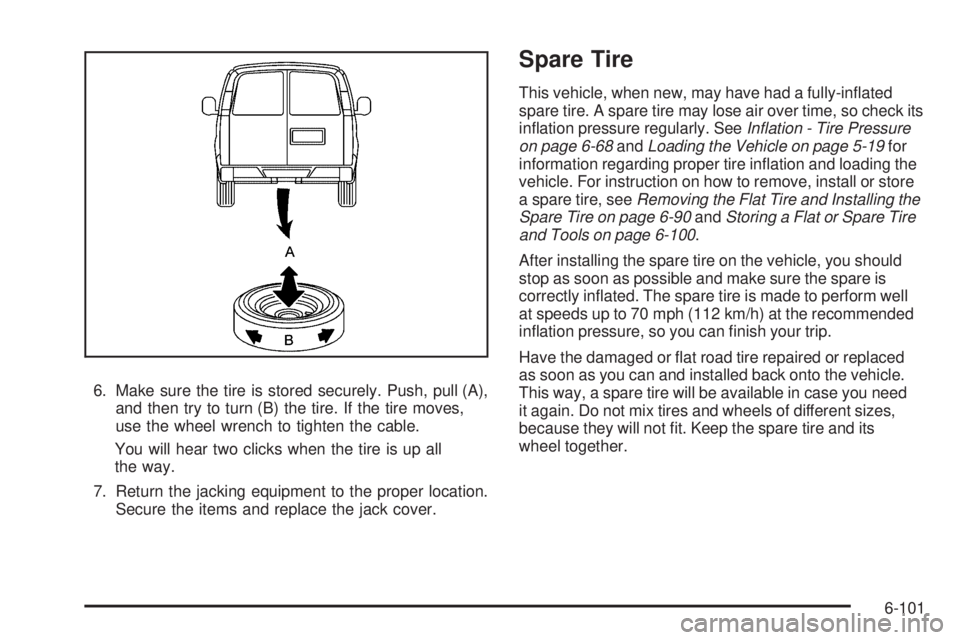

6. Make sure the tire is stored securely. Push, pull (A),

and then try to turn (B) the tire. If the tire moves,

use the wheel wrench to tighten the cable.

You will hear two clicks when the tire is up all

the way.

7. Return the jacking equipment to the proper location.

Secure the items and replace the jack cover.

Spare Tire

This vehicle, when new, may have had a fully-inflated

spare tire. A spare tire may lose air over time, so check its

inflation pressure regularly. SeeIn�ation - Tire Pressure

on page 6-68andLoading the Vehicle on page 5-19for

information regarding proper tire inflation and loading the

vehicle. For instruction on how to remove, install or store

a spare tire, seeRemoving the Flat Tire and Installing the

Spare Tire on page 6-90andStoring a Flat or Spare Tire

and Tools on page 6-100.

After installing the spare tire on the vehicle, you should

stop as soon as possible and make sure the spare is

correctly inflated. The spare tire is made to perform well

at speeds up to 70 mph (112 km/h) at the recommended

inflation pressure, so you can finish your trip.

Have the damaged or flat road tire repaired or replaced

as soon as you can and installed back onto the vehicle.

This way, a spare tire will be available in case you need

it again. Do not mix tires and wheels of different sizes,

because they will not fit. Keep the spare tire and its

wheel together.

6-101

Page 377 of 440

Aluminum Wheels

Notice:Using strong soaps, chemicals, abrasive

polishes, cleaners, brushes, or cleaners that contain

acid on aluminum or chrome-plated wheels, could

damage the surface of the wheel(s). The repairs

would not be covered by the vehicle warranty.

Use only approved cleaners on aluminum or

chrome-plated wheels.

Keep the wheels clean using a soft clean cloth with mild

soap and water. Rinse with clean water. After rinsing

thoroughly, dry with a soft clean towel. A wax may then

be applied.

Notice:Using chrome polish on aluminum wheels

could damage the wheels. The repairs would not

be covered by the vehicle warranty. Use chrome

polish on chrome wheels only.

The surface of these wheels is similar to the painted

surface of the vehicle. Do not use strong soaps,

chemicals, abrasive polishes, abrasive cleaners,

cleaners with acid, or abrasive cleaning brushes

on them because the surface could be damaged.

Do not use chrome polish on aluminum wheels.Notice:Driving the vehicle through an automatic car

wash that has silicone carbide tire cleaning brushes,

could damage the aluminum or chrome-plated

wheels. The repairs would not be covered by the

vehicle warranty. Never drive a vehicle that has

aluminum or chrome-plated wheels through an

automatic car wash that uses silicone carbide tire

cleaning brushes.

Tires

To clean the tires, use a stiff brush with tire cleaner.

Notice:Using petroleum-based tire dressing

products on the vehicle may damage the paint �nish

and/or tires. When applying a tire dressing, always

wipe off any overspray from all painted surfaces

on the vehicle.

Sheet Metal Damage

If the vehicle is damaged and requires sheet metal

repair or replacement, make sure the body repair shop

applies anti-corrosion material to parts repaired or

replaced to restore corrosion protection.

Original manufacturer replacement parts will provide

the corrosion protection while maintaining the vehicle

warranty.

6-107