warning CHEVROLET EXPRESS 2007 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2007, Model line: EXPRESS, Model: CHEVROLET EXPRESS 2007Pages: 440, PDF Size: 2.42 MB

Page 354 of 440

Tire Chains

{WARNING:

If your vehicle has dual wheels or P245/70R17 or

LT245/75R16 size tires, do not use tire chains.

They can damage your vehicle because there is not

enough clearance. Tire chains used on a vehicle

without the proper amount of clearance can cause

damage to the brakes, suspension, or other vehicle

parts. The area damaged by the tire chains could

cause you to lose control of your vehicle and you

or others may be injured in a crash.

Use another type of traction device only if its

manufacturer recommends it for use on your

vehicle and tire size combination and road

conditions. Follow that manufacturer’s instructions.

WARNING: (Continued)

WARNING: (Continued)

To help avoid damage to your vehicle, drive

slowly, readjust, or remove the device if it is

contacting your vehicle, and do not spin the

vehicle’s wheels.

If you do find traction devices that will fit, install

them on the rear tires.

Notice:If your vehicle does not have dual wheels

and has a tire size other than P245/70R17 or

LT245/75R16, use tire chains only where legal and

only when you must. Use chains that are the proper

size for your tires. Install them on the tires of the

rear axle. Do not use chains on the tires of the front

axle. Tighten them as tightly as possible with the

ends securely fastened. Drive slowly and follow the

chain manufacturer’s instructions. If you can

hear the chains contacting your vehicle, stop and

retighten them. If the contact continues, slow down

until it stops. Driving too fast or spinning the

wheels with chains on will damage your vehicle.

6-84

Page 355 of 440

If a Tire Goes Flat

It is unusual for a tire to blowout while you are driving,

especially if you maintain your vehicle’s tires properly.

If air goes out of a tire, it is much more likely to leak out

slowly. But if you should ever have a blowout, here

are a few tips about what to expect and what to do:

If a front tire fails, the flat tire creates a drag that pulls

the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake

to a stop well out of the traffic lane.

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you would use

in a skid. In any rear blowout remove your foot from the

accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.{WARNING:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without the

appropriate safety equipment and training. If a jack

is provided with the vehicle, it is designed only for

changing a flat tire. If it is used for anything else,

you or others could be badly injured or killed if the

vehicle slips off the jack. If a jack is provided with

the vehicle, only use it for changing a flat tire.

If a tire goes flat, the next part shows how to use the

jacking equipment to change a flat tire safely.

6-85

Page 356 of 440

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on the hazard

warning flashers. SeeHazard Warning Flashers

on page 4-3.

{WARNING:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you or

other people. You and they could be badly injured

or even killed. Find a level place to change your

tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put the shift lever in P (Park).

3. Turn off the engine and do not restart while

the vehicle is raised.

4. Do not allow passengers to remain in the

vehicle.

WARNING: (Continued)

WARNING: (Continued)

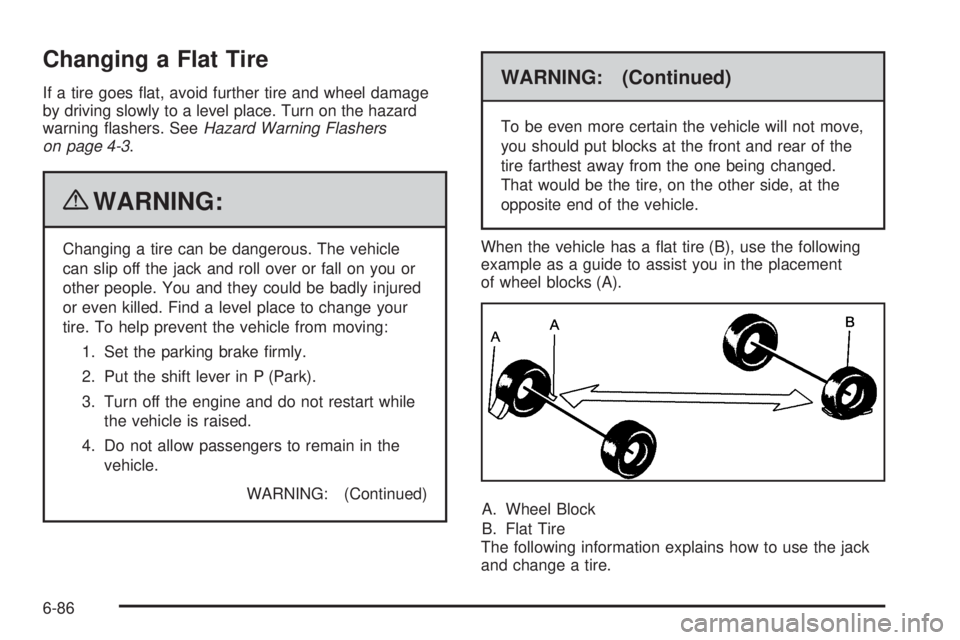

To be even more certain the vehicle will not move,

you should put blocks at the front and rear of the

tire farthest away from the one being changed.

That would be the tire, on the other side, at the

opposite end of the vehicle.

When the vehicle has a flat tire (B), use the following

example as a guide to assist you in the placement

of wheel blocks (A).

A. Wheel Block

B. Flat Tire

The following information explains how to use the jack

and change a tire.

6-86

Page 363 of 440

{WARNING:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack you

could be badly injured or killed. Never get under

a vehicle when it is supported only by a jack.

{WARNING:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even make

the vehicle fall. To help avoid personal injury and

vehicle damage, be sure to fit the jack lift head into

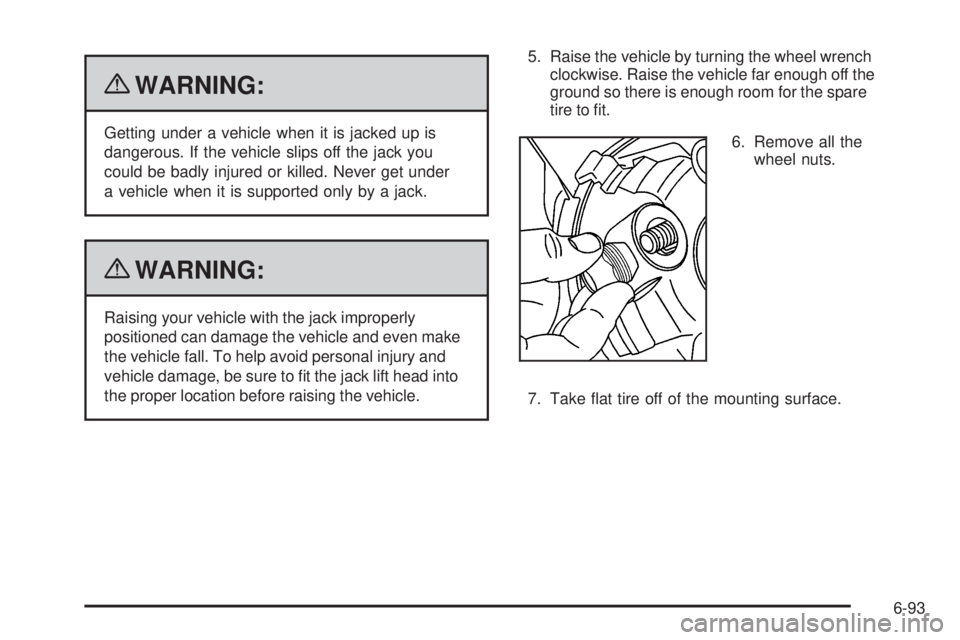

the proper location before raising the vehicle.5. Raise the vehicle by turning the wheel wrench

clockwise. Raise the vehicle far enough off the

ground so there is enough room for the spare

tire to fit.

6. Remove all the

wheel nuts.

7. Take flat tire off of the mounting surface.

6-93

Page 364 of 440

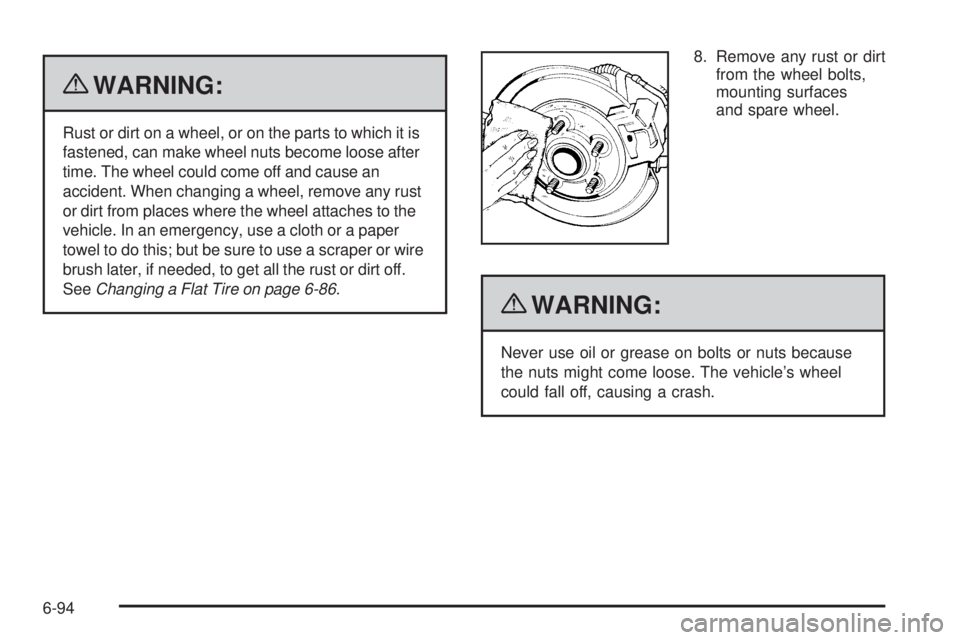

{WARNING:

Rust or dirt on a wheel, or on the parts to which it is

fastened, can make wheel nuts become loose after

time. The wheel could come off and cause an

accident. When changing a wheel, remove any rust

or dirt from places where the wheel attaches to the

vehicle. In an emergency, use a cloth or a paper

towel to do this; but be sure to use a scraper or wire

brush later, if needed, to get all the rust or dirt off.

SeeChanging a Flat Tire on page 6-86.8. Remove any rust or dirt

from the wheel bolts,

mounting surfaces

and spare wheel.

{WARNING:

Never use oil or grease on bolts or nuts because

the nuts might come loose. The vehicle’s wheel

could fall off, causing a crash.

6-94

Page 365 of 440

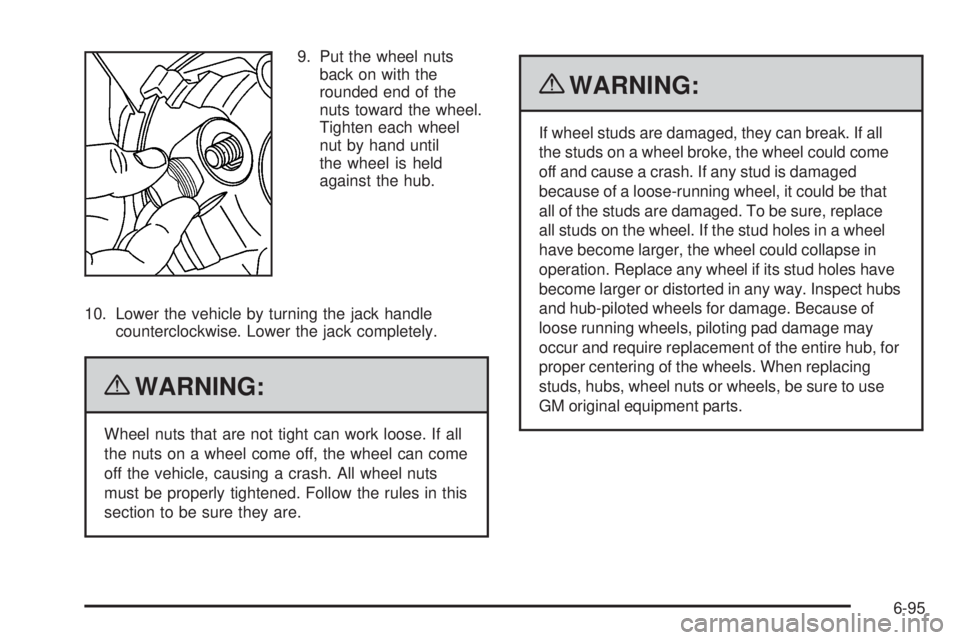

9. Put the wheel nuts

back on with the

rounded end of the

nuts toward the wheel.

Tighten each wheel

nut by hand until

the wheel is held

against the hub.

10. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

{WARNING:

Wheel nuts that are not tight can work loose. If all

the nuts on a wheel come off, the wheel can come

off the vehicle, causing a crash. All wheel nuts

must be properly tightened. Follow the rules in this

section to be sure they are.

{WARNING:

If wheel studs are damaged, they can break. If all

the studs on a wheel broke, the wheel could come

off and cause a crash. If any stud is damaged

because of a loose-running wheel, it could be that

all of the studs are damaged. To be sure, replace

all studs on the wheel. If the stud holes in a wheel

have become larger, the wheel could collapse in

operation. Replace any wheel if its stud holes have

become larger or distorted in any way. Inspect hubs

and hub-piloted wheels for damage. Because of

loose running wheels, piloting pad damage may

occur and require replacement of the entire hub, for

proper centering of the wheels. When replacing

studs, hubs, wheel nuts or wheels, be sure to use

GM original equipment parts.

6-95

Page 366 of 440

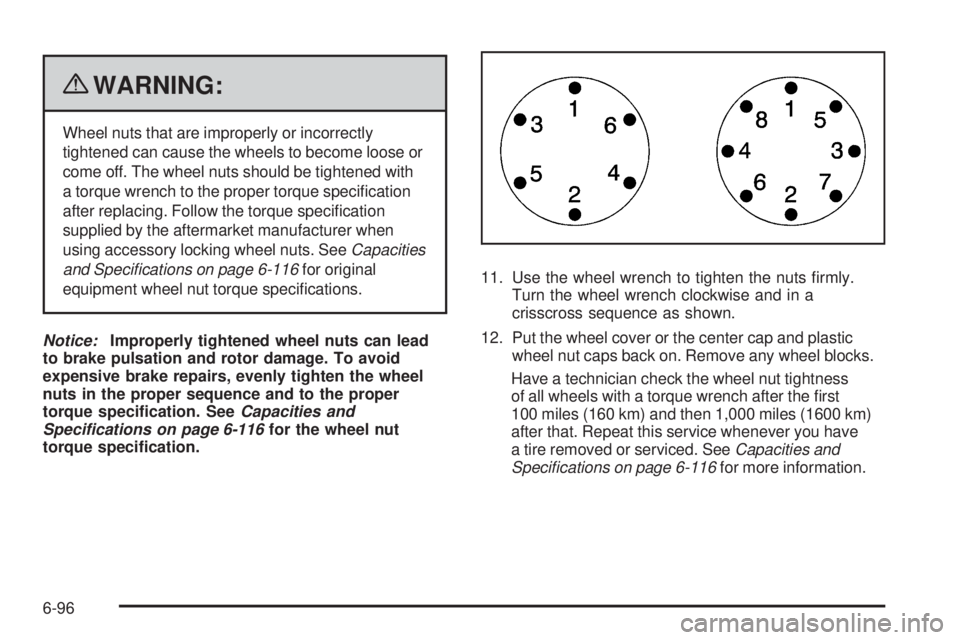

{WARNING:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose or

come off. The wheel nuts should be tightened with

a torque wrench to the proper torque specification

after replacing. Follow the torque specification

supplied by the aftermarket manufacturer when

using accessory locking wheel nuts. SeeCapacities

and Speci�cations on page 6-116for original

equipment wheel nut torque specifications.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci�cation. SeeCapacities and

Specifications on page 6-116for the wheel nut

torque speci�cation.11. Use the wheel wrench to tighten the nuts firmly.

Turn the wheel wrench clockwise and in a

crisscross sequence as shown.

12. Put the wheel cover or the center cap and plastic

wheel nut caps back on. Remove any wheel blocks.

Have a technician check the wheel nut tightness

of all wheels with a torque wrench after the first

100 miles (160 km) and then 1,000 miles (1600 km)

after that. Repeat this service whenever you have

a tire removed or serviced. SeeCapacities and

Speci�cations on page 6-116for more information.

6-96

Page 367 of 440

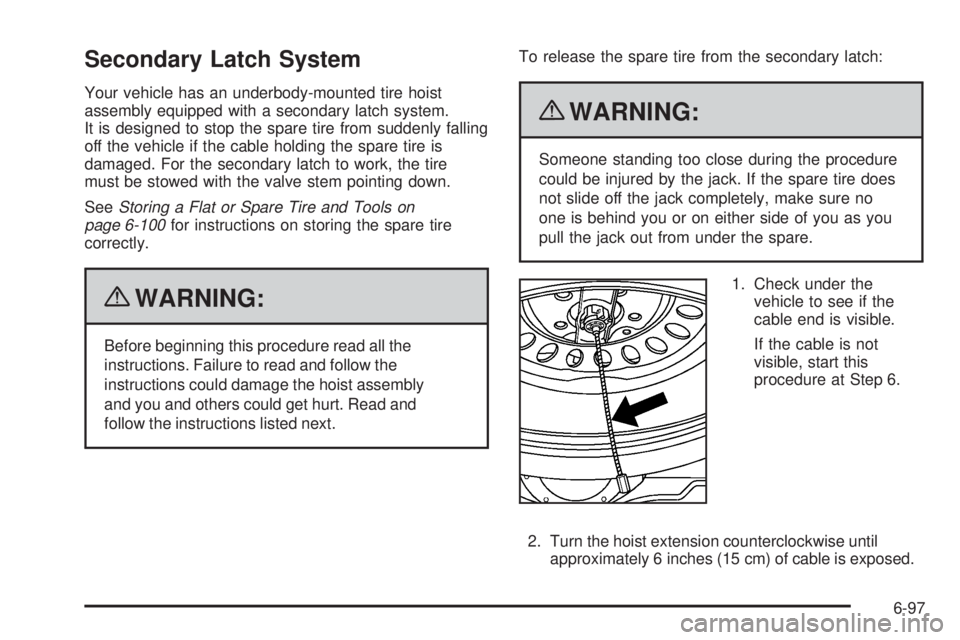

Secondary Latch System

Your vehicle has an underbody-mounted tire hoist

assembly equipped with a secondary latch system.

It is designed to stop the spare tire from suddenly falling

off the vehicle if the cable holding the spare tire is

damaged. For the secondary latch to work, the tire

must be stowed with the valve stem pointing down.

SeeStoring a Flat or Spare Tire and Tools on

page 6-100for instructions on storing the spare tire

correctly.

{WARNING:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed next.To release the spare tire from the secondary latch:

{WARNING:

Someone standing too close during the procedure

could be injured by the jack. If the spare tire does

not slide off the jack completely, make sure no

one is behind you or on either side of you as you

pull the jack out from under the spare.

1. Check under the

vehicle to see if the

cable end is visible.

If the cable is not

visible, start this

procedure at Step 6.

2. Turn the hoist extension counterclockwise until

approximately 6 inches (15 cm) of cable is exposed.

6-97

Page 370 of 440

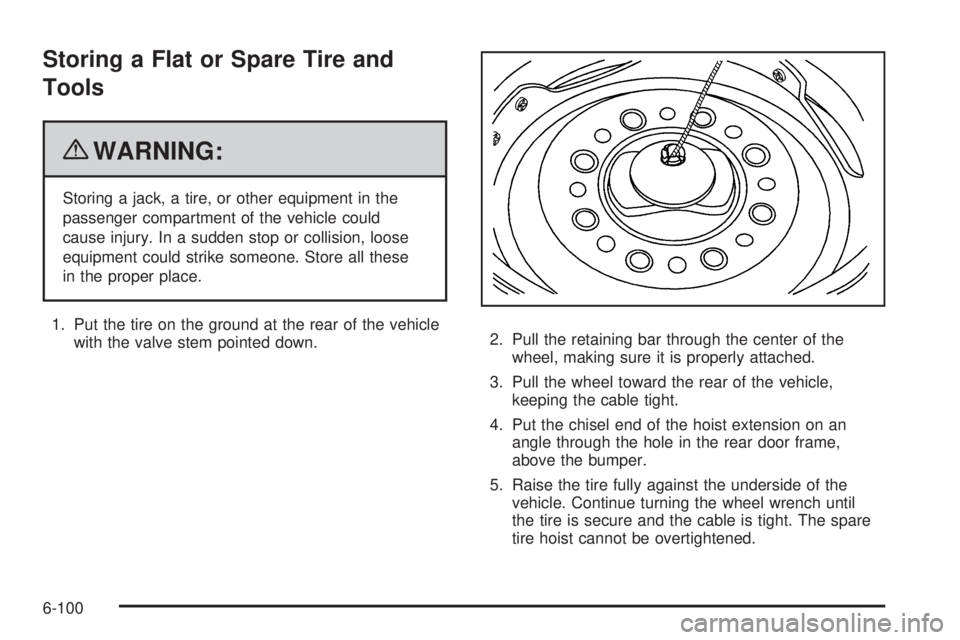

Storing a Flat or Spare Tire and

Tools

{WARNING:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision, loose

equipment could strike someone. Store all these

in the proper place.

1. Put the tire on the ground at the rear of the vehicle

with the valve stem pointed down.2. Pull the retaining bar through the center of the

wheel, making sure it is properly attached.

3. Pull the wheel toward the rear of the vehicle,

keeping the cable tight.

4. Put the chisel end of the hoist extension on an

angle through the hole in the rear door frame,

above the bumper.

5. Raise the tire fully against the underside of the

vehicle. Continue turning the wheel wrench until

the tire is secure and the cable is tight. The spare

tire hoist cannot be overtightened.

6-100

Page 374 of 440

If any of the soil remains, a commercial fabric cleaner

or spot lifter may be necessary. When a commercial

upholstery cleaner or spot lifter is to be used, test

a small hidden area for colorfastness first. If the

locally cleaned area gives any impression that a

ring formation may result, clean the entire surface.

After the cleaning process has been completed, a paper

towel can be used to blot excess moisture from the

fabric or carpet.

Instrument Panel, Vinyl, and Other

Plastic Surfaces

A soft cloth dampened with water may be used to remove

dust. If a more thorough cleaning is necessary, a clean

soft cloth dampened with a mild soap solution can be

used to gently remove dust and dirt. Never use spot lifters

or removers on plastic surfaces. Many commercial

cleaners and coatings that are sold to preserve and

protect soft plastic surfaces may permanently change

the appearance and feel of the interior and are not

recommended. Do not use silicone or wax-basedproducts, or those containing organic solvents to

clean the vehicle’s interior because they can alter the

appearance by increasing the gloss in a non-uniform

manner.

Some commercial products may increase gloss on the

instrument panel. The increase in gloss may cause

annoying reflections in the windshield and even make

it difficult to see through the windshield under certain

conditions.

Care of Safety Belts

Keep belts clean and dry.

{WARNING:

Do not bleach or dye safety belts. It may severely

weaken them. In a crash, they might not be able

to provide adequate protection. Clean safety belts

only with mild soap and lukewarm water.

6-104