maintenance schedule CHEVROLET EXPRESS 2010 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: EXPRESS, Model: CHEVROLET EXPRESS 2010Pages: 440, PDF Size: 2.42 MB

Page 291 of 440

To inspect or replace the engine air cleaner/filter, do the

following:

1. Unhook the retainer clips and remove the cover.

2. Lift the filter out of the engine air cleaner/filter

housing. Care should be taken to dislodge as

little dirt as possible.

3. Clean the engine air cleaner/filter housing.

4. Inspect or replace the engine air cleaner/filter.

Make sure that the filter fits properly into the

housing.

5. Reinstall the cover and fasten the retaining clips.

{WARNING:

Operating the engine with the air cleaner/filter off

can cause you or others to be burned. The air

cleaner not only cleans the air; it helps to stop

flames if the engine backfires. If it is not there and

the engine backfires, you could be burned. Do not

drive with it off, and be careful working on the

engine with the air cleaner/filter off.Notice:If the air cleaner/�lter is off, a back�re

can cause a damaging engine �re. And, dirt

can easily get into the engine, which will damage it.

Always have the air cleaner/�lter in place when

you are driving.

Automatic Transmission Fluid

(4-Speed Transmission)

If your vehicle has the DURAMAX Diesel engine, see

the DURAMAX Diesel manual for more information.

When to Check and Change Automatic

Transmission Fluid

A good time to check your automatic transmission fluid

level is when the engine oil is changed.

Change the fluid and filter at the intervals listed in

Scheduled Maintenance on page 7-3, and be sure to

use the transmission fluid listed inRecommended Fluids

and Lubricants on page 7-12.

6-21

Page 294 of 440

How to Add Automatic Transmission

Fluid

Refer to the Maintenance Schedule to determine what

kind of transmission fluid to use. SeeRecommended

Fluids and Lubricants on page 7-12.

Using a funnel, add fluid down the transmission dipstick

tube only after checking the transmission fluid while it is

hot. A cold check is used only as a reference. If the fluid

level is low, add only enough of the proper fluid to bring

the level up to the HOT area for a hot check. It does not

take much fluid, generally less than one pint (0.5 L).

Do not overfill.

Notice:Use of the incorrect automatic transmission

�uid may damage the vehicle, and the damages may

not be covered by the vehicle’s warranty. Always

use the automatic transmission �uid listed in

Recommended Fluids and Lubricants on page 7-12.

•After adding fluid, recheck the fluid level as described

under “How to Check Automatic Transmission Fluid,”

earlier in this section.

•When the correct fluid level is obtained, push the

dipstick back in all the way; then flip the handle down

to lock the dipstick in place.

Automatic Transmission Fluid

(6-Speed Transmission)

When to Check and Change Automatic

Transmission Fluid

It is usually not necessary to check the transmission fluid

level. The only reason for fluid loss is a transmission

leak or overheating the transmission. If a small leak is

suspected, use the following procedures to check the

fluid level. However, if there is a large leak, then it may be

necessary to have the vehicle towed to a dealer/retailer

service department and have it repaired before driving

the vehicle further.

Change the fluid and filter at the intervals listed in

Scheduled Maintenance on page 7-3, and be sure

to use the transmission fluid listed inRecommended

Fluids and Lubricants on page 7-12.

6-24

Page 297 of 440

How to Add Automatic Transmission

Fluid

Refer to the Maintenance Schedule to determine what

kind of transmission fluid to use. SeeRecommended

Fluids and Lubricants on page 7-12.

A. WARM Range

B. HOT Range

Using a funnel, add fluid down the transmission dipstick

tube only after checking the transmission fluid while it is

warm or hot. A cold check is used only as a reference.If the fluid level is low, add only enough of the proper fluid

to bring the level up to the middle of the WARM (A) or

HOT (B) range depending on the ambient temperature

and prior driving conditions. Refer to “How to Check

Automatic Transmission Fluid”, earlier in this section

for instructions on driving to achieve warm or hot

transmission fluid. It does not take much fluid, generally

less than 0.5 L (one pint). Do not overfill.

Notice:Use of the incorrect automatic transmission

�uid may damage the vehicle, and the damages may

not be covered by the vehicle’s warranty. Always

use the automatic transmission �uid listed in

Recommended Fluids and Lubricants on page 7-12.

•After adding fluid, recheck the fluid level as described

under “How to Check Automatic Transmission Fluid,”

earlier in this section.

•When the correct fluid level is obtained, push the

dipstick back in all the way; then flip the handle down

to lock the dipstick in place.

6-27

Page 310 of 440

Brakes

Brake Fluid

The brake master cylinder

reservoir is filled with

DOT 3 brake fluid. See

Engine Compartment

Overview on page 6-14for

the location of the reservoir.

There are only two reasons why the brake fluid level in

the reservoir might go down:

•The brake fluid level goes down because of normal

brake lining wear. When new linings are installed,

the fluid level goes back up.

•A fluid leak in the brake hydraulic system can also

cause a low fluid level. Have the brake hydraulic

system fixed, since a leak means that sooner

or later the brakes will not work well.Do not top off the brake fluid. Adding fluid does not

correct a leak. If fluid is added when the linings are worn,

there will be too much fluid when new brake linings are

installed. Add or remove brake fluid, as necessary, only

when work is done on the brake hydraulic system.

{WARNING:

If too much brake fluid is added, it can spill on

the engine and/or fuel operated heater parts, if

equipped. If the vehicle has a diesel engine and a

fuel operated heater, see “Fuel Operated Heater

(FOH)” in the diesel engine supplement. The fluid

will burn if the engine is hot enough. You or others

could be burned, and the vehicle could be

damaged. Add brake fluid only when work is done

on the brake hydraulic system. See “Checking

Brake Fluid” in this section.

Refer to the Maintenance Schedule to determine when

to check the brake fluid. SeeScheduled Maintenance

on page 7-3.

6-40

Page 319 of 440

To disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the remote positive (+) terminal cover to its

original position.

All-Wheel Drive

Lubricant checks in this section also apply to these

vehicles. However, there are two additional systems

that need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance on page 7-3.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the filler plug hole,

you’ll need to add some lubricant. Add enough lubricant

to raise the level to the bottom of the filler plug hole.

Use care not to overtighten the plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 7-12.

6-49

Page 320 of 440

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance on page 7-3.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.If you have the 1500 Series, the proper level is from

5/8 inch (15 mm) to 1 5/8 inch (40 mm) below the bottom

of the filler plug hole. The proper level for the 2500 and

3500 Series is from 0 to 1/4 (6 mm) below the bottom of

the filler plug hole. Add only enough fluid to reach the

proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 7-12.

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it.

SeeScheduled Maintenance on page 7-3.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

6-50

Page 321 of 440

If the level is below the

bottom of the filler plug

hole, you may need to

add some lubricant.

When the differential is cold, add enough lubricant

to raise the level to 3/8 inch (10 mm) below the filler

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to

the bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 7-12.

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance with

federal noise emission standards for vehicles with a

Gross Vehicle Weight Rating (GVWR) of more than

10,000 lbs (4 536 kg). The Maintenance Schedule

provides information on maintaining the noise control

system to minimize degradation of the noise emission

control system during the life of your vehicle. The noise

control system warranty is given in your warranty booklet.

These standards apply only to vehicles sold in the

United States.

Federal law prohibits the following acts or the causing

thereof:

1. The removal or rendering inoperative by any person,

other than for purposes of maintenance, repair or

replacement, of any device or element of design

incorporated into any new vehicle for the purpose

of noise control, prior to its sale or delivery to the

ultimate purchaser or while it is in use; or

2. The use of the vehicle after such device or element

of design has been removed or rendered inoperative

by any person.

6-51

Page 329 of 440

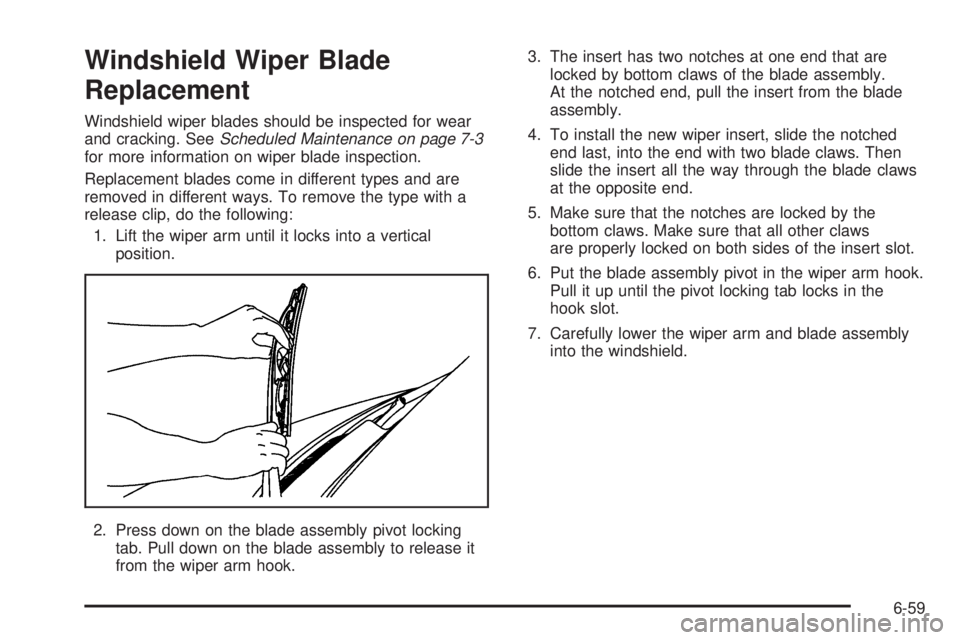

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

and cracking. SeeScheduled Maintenance on page 7-3

for more information on wiper blade inspection.

Replacement blades come in different types and are

removed in different ways. To remove the type with a

release clip, do the following:

1. Lift the wiper arm until it locks into a vertical

position.

2. Press down on the blade assembly pivot locking

tab. Pull down on the blade assembly to release it

from the wiper arm hook.3. The insert has two notches at one end that are

locked by bottom claws of the blade assembly.

At the notched end, pull the insert from the blade

assembly.

4. To install the new wiper insert, slide the notched

end last, into the end with two blade claws. Then

slide the insert all the way through the blade claws

at the opposite end.

5. Make sure that the notches are locked by the

bottom claws. Make sure that all other claws

are properly locked on both sides of the insert slot.

6. Put the blade assembly pivot in the wiper arm hook.

Pull it up until the pivot locking tab locks in the

hook slot.

7. Carefully lower the wiper arm and blade assembly

into the windshield.

6-59

Page 340 of 440

Dual Tire Operation

When the vehicle is new, or whenever a wheel, wheel bolt

or wheel nut is replaced, check the wheel nut torque after

100, 1,000 and 6,000 miles (160, 1 600 and 10 000 km)

of driving. For proper wheel nut tightening information,

see “Removing the Flat Tire and Installing the Spare

Tire” later in this section, underChanging a Flat Tire

on page 6-86. Also see “Wheel Nut Torque” under

Capacities and Speci�cations on page 6-116.

The outer tire on a dual wheel setup generally wears

faster than the inner tire. Your tires will wear more

evenly and last longer if you rotate the tires periodically.

SeeTire Inspection and Rotation on page 6-75. Also

seeScheduled Maintenance on page 7-3.

{WARNING:

If you operate your vehicle with a tire that is badly

underinflated, the tire can overheat. An overheated

tire can lose air suddenly or catch fire. You or

others could be injured. Be sure all tires (including

the spare) are properly inflated.

SeeTires on page 6-60andIn�ation - Tire Pressure on

page 6-68for more information on proper tire inflation.

Tire Pressure Monitor System

The Tire Pressure Monitor System (TPMS) uses radio

and sensor technology to check tire pressure levels.

The TPMS sensors monitor the air pressure in

your vehicle’s tires and transmit tire pressure readings

to a receiver located in the vehicle.

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer

on the vehicle placard or tire inflation pressure label.

(If your vehicle has tires of a different size than the

size indicated on the vehicle placard or tire inflation

pressure label, you should determine the proper

tire inflation pressure for those tires.)

As an added safety feature, your vehicle has been

equipped with a tire pressure monitoring system (TPMS)

that illuminates a low tire pressure telltale when one

or more of your tires is significantly under-inflated.

6-70

Page 345 of 440

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPMS sensor by increasing or

decreasing the tire’s air pressure for five seconds,

or until a horn chirp sounds. The horn chirp, which

may take up to 30 seconds to sound, confirms that

the sensor identification code has been matched to

this tire and wheel position.

6. Proceed to the passenger side front tire, and repeat

the procedure in Step 5.

7. Proceed to the passenger side rear tire, and repeat

the procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the

procedure in Step 5. The horn sounds two times to

indicate the sensor identification code has been

matched to the driver side rear tire, and that the

TPMS sensor matching process is no longer active.

The TIRE LEARNING ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Tire and Loading

Information label.

11. Put the valve caps back on the valve stems.Tire Inspection and Rotation

Inspect tires regularly for signs of wear or damage.

Also inspect the spare tire. For more information

on tire inspection, seeWhen It Is Time for

New Tires on page 6-78.

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km). SeeScheduled Maintenance

on page 7-3.

The purpose of a regular tire rotation is to achieve

a uniform wear for all tires on the vehicle. This will

ensure that the vehicle continues to perform most

like it did when the tires were new. The first rotation

is the most important. SeeScheduled Maintenance

on page 7-3.

Any time you notice unusual wear, rotate the tires

as soon as possible and check wheel alignment.

Also check for damaged tires or wheels. SeeWhen

It Is Time for New Tires on page 6-78andWheel

Replacement on page 6-82.

6-75