CHEVROLET EXPRESS CARGO VAN 2009 1.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2009, Model line: EXPRESS CARGO VAN, Model: CHEVROLET EXPRESS CARGO VAN 2009 1.GPages: 408, PDF Size: 2.36 MB

Page 281 of 408

Checking Brake Fluid

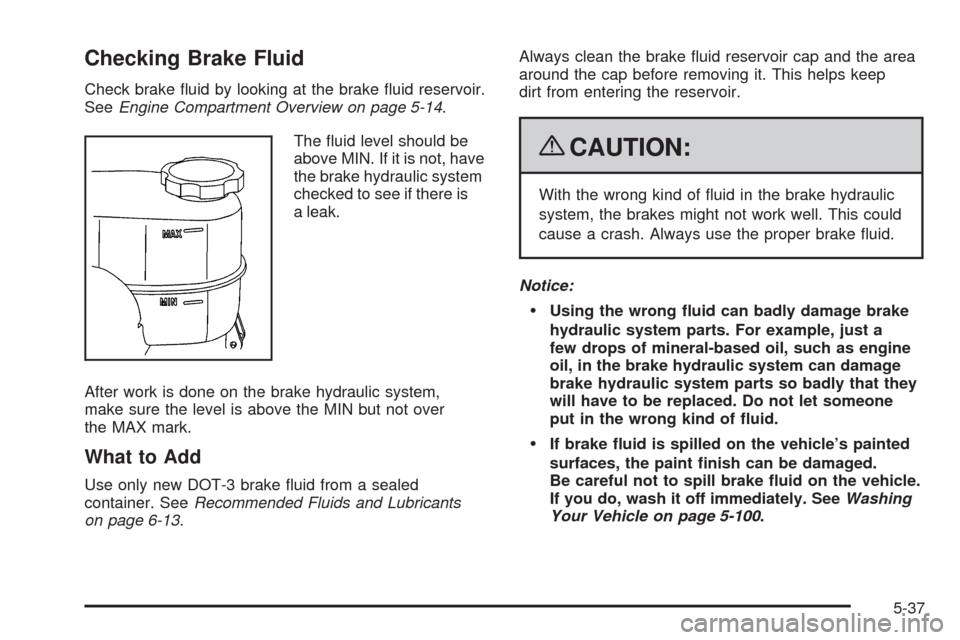

Check brake fluid by looking at the brake fluid reservoir.

SeeEngine Compartment Overview on page 5-14.

The fluid level should be

above MIN. If it is not, have

the brake hydraulic system

checked to see if there is

a leak.

After work is done on the brake hydraulic system,

make sure the level is above the MIN but not over

the MAX mark.

What to Add

Use only new DOT-3 brake fluid from a sealed

container. SeeRecommended Fluids and Lubricants

on page 6-13.Always clean the brake fluid reservoir cap and the area

around the cap before removing it. This helps keep

dirt from entering the reservoir.

{CAUTION:

With the wrong kind of fluid in the brake hydraulic

system, the brakes might not work well. This could

cause a crash. Always use the proper brake fluid.

Notice:

Using the wrong �uid can badly damage brake

hydraulic system parts. For example, just a

few drops of mineral-based oil, such as engine

oil, in the brake hydraulic system can damage

brake hydraulic system parts so badly that they

will have to be replaced. Do not let someone

put in the wrong kind of �uid.

If brake �uid is spilled on the vehicle’s painted

surfaces, the paint �nish can be damaged.

Be careful not to spill brake �uid on the vehicle.

If you do, wash it off immediately. SeeWashing

Your Vehicle on page 5-100.

5-37

Page 282 of 408

Brake Wear

This vehicle has disc brakes. Disc brake pads have

built-in wear indicators that make a high-pitched warning

sound when the brake pads are worn and new pads

are needed. The sound can come and go or be heard

all the time the vehicle is moving, except when applying

the brake pedal firmly.

{CAUTION:

The brake wear warning sound means that soon

the brakes will not work well. That could lead to an

accident. When the brake wear warning sound is

heard, have the vehicle serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.Some driving conditions or climates can cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong

with the brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts

in the proper sequence to torque specifications

inCapacities and Specifications on page 5-111.

Brake linings should always be replaced as complete

axle sets.Brake Pedal Travel

See your dealer/retailer if the brake pedal does not

return to normal height, or if there is a rapid increase in

pedal travel. This could be a sign that brake service

might be required.

Brake Adjustment

Every brake stop, the brakes adjust for wear.

5-38

Page 283 of 408

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have to be of top quality and work well together if

the vehicle is to have really good braking. The vehicle

was designed and tested with top-quality brake parts.

When parts of the braking system are replaced — for

example, when the brake linings wear down and new

ones are installed — be sure to get new approved

replacement parts. If this is not done, the brakes might

not work properly. For example, if someone puts in

brake linings that are wrong for the vehicle, the balance

between the front and rear brakes can change — for the

worse. The braking performance expected can change in

many other ways if the wrong replacement brake parts

are installed.

Battery

This vehicle has a maintenance free battery. When it is

time for a new battery, see your dealer/retailer for one

that has the replacement number shown on the original

battery’s label. SeeEngine Compartment Overview on

page 5-14for battery location.

Warning:Battery posts, terminals, and related

accessories contain lead and lead compounds,

chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

Vehicle Storage

{CAUTION:

Batteries have acid that can burn you and gas that

can explode. You can be badly hurt if you are not

careful. SeeJump Starting on page 5-40for tips

on working around a battery without getting hurt.

Infrequent Usage: If the vehicle is driven infrequently,

remove the black, negative (−) cable from the battery.

This helps keep the battery from running down.

Extended Storage: For extended storage of the vehicle,

remove the black, negative (−) cable from the battery or

use a battery trickle charger. This helps maintain the

charge of the battery over an extended period of time.

5-39

Page 284 of 408

Jump Starting

If the vehicle battery has run down, you may want to

use another vehicle and some jumper cables to start your

vehicle. Be sure to use the following steps to do it safely.

{CAUTION:

Batteries can hurt you. They can be dangerous

because:

•They contain acid that can burn you.

•They contain gas that can explode or ignite.

•They contain enough electricity to burn you.

If you do not follow these steps exactly, some or

all of these things can hurt you.Notice:Ignoring these steps could result in costly

damage to your vehicle that would not be covered

by your warranty.

Trying to start your vehicle by pushing or pulling it

will not work, and it could damage your vehicle.

1. Check the other vehicle. It must have a 12-volt

battery with a negative ground system.

Notice:If the other vehicle’s system is not a 12-volt

system with a negative ground, both vehicles can

be damaged. Only use vehicles with 12-volt systems

with negative grounds to jump start your vehicle.

2. Get the vehicles close enough so the jumper cables

can reach, but be sure the vehicles are not touching

each other. If they are, it could cause a ground

connection you do not want. You would not be

able to start your vehicle, and the bad grounding

could damage the electrical systems.

To avoid the possibility of the vehicles rolling,

set the parking brake firmly on both vehicles

involved in the jump start procedure. Put an

automatic transmission in P (PARK) or a manual

transmission in NEUTRAL before setting the

parking brake.

5-40

Page 285 of 408

Notice:If you leave the radio or other accessories

on during the jump starting procedure, they could

be damaged. The repairs would not be covered by

the warranty. Always turn off the radio and other

accessories when jump starting the vehicle.

3. Turn off the ignition on both vehicles. Unplug

unnecessary accessories plugged into the cigarette

lighter or the accessory power outlet. Turn off

the radio and all lamps that are not needed.

This will avoid sparks and help save both

batteries. And it could save the radio!

4. Open the hoods and locate the positive (+) and

negative (−) terminal locations of the other vehicle.

Your vehicle has a remote positive (+) jump

starting terminal and a remote negative (−) jump

starting terminal. You should always use these

remote terminals instead of the terminals on the

battery.The remote positive (+) terminal is located

behind a red plastic cover near the engine accessory

drive bracket on the driver’s side of the engine

compartment, below the alternator. To uncover

the remote positive (+) terminal, open the red

plastic cover.

The remote negative (−) terminal is located on

the engine drive bracket on all V8 engines and is

marked GND (Ground).

On V6 engines the remote negative (−) terminal is

located on a tab attached to the engine accessory

drive bracket and is marked GND (Ground).

5-41

Page 286 of 408

{CAUTION:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing this,

and some have been blinded. Use a flashlight if

you need more light.

Be sure the battery has enough water. You do not

need to add water to the battery installed in your

new vehicle. But if a battery has filler caps, be

sure the right amount of fluid is there. If it is low,

add water to take care of that first. If you do not,

explosive gas could be present.

Battery fluid contains acid that can burn you.

Do not get it on you. If you accidentally get it in

your eyes or on your skin, flush the place with

water and get medical help immediately.

{CAUTION:

Fans or other moving engine parts can injure you

badly. Keep your hands away from moving parts

once the engine is running.

5. Check that the jumper cables do not have loose

or missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go

to positive (+) or to a remote positive (+) terminal

if the vehicle has one. Negative (−) will go to a

heavy, unpainted metal engine part or to a remote

negative (−) terminal if the vehicle has one.

Do not connect positive (+) to negative (−)oryou

will get a short that would damage the battery

and maybe other parts too. And do not connect the

negative (−) cable to the negative (−) terminal on

the dead battery because this can cause sparks.

5-42

Page 287 of 408

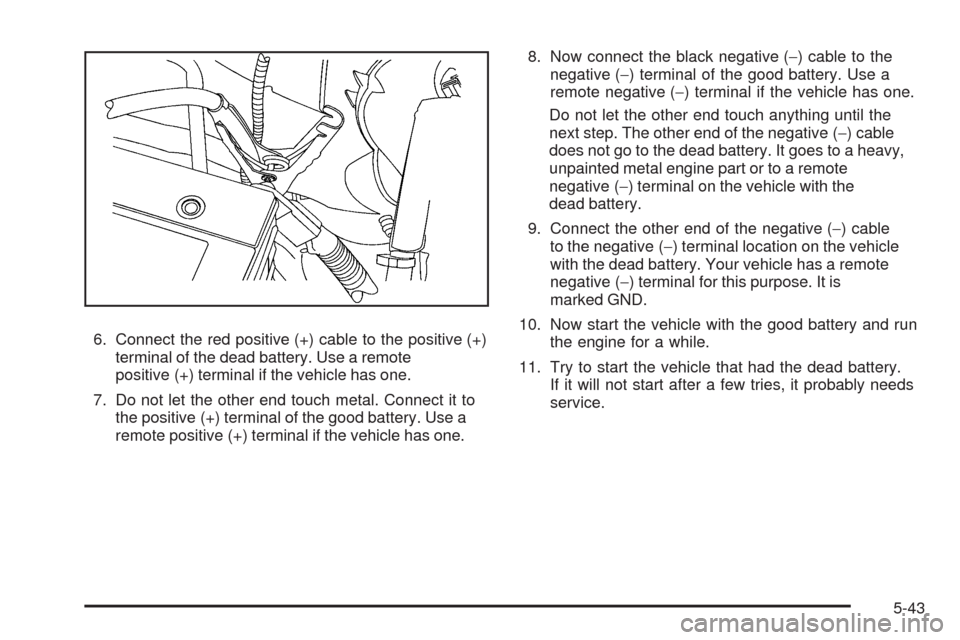

6. Connect the red positive (+) cable to the positive (+)

terminal of the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

7. Do not let the other end touch metal. Connect it to

the positive (+) terminal of the good battery. Use a

remote positive (+) terminal if the vehicle has one.8. Now connect the black negative (−) cable to the

negative (−) terminal of the good battery. Use a

remote negative (−) terminal if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does not go to the dead battery. It goes to a heavy,

unpainted metal engine part or to a remote

negative (−) terminal on the vehicle with the

dead battery.

9. Connect the other end of the negative (−) cable

to the negative (−) terminal location on the vehicle

with the dead battery. Your vehicle has a remote

negative (−) terminal for this purpose. It is

marked GND.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably needs

service.

5-43

Page 288 of 408

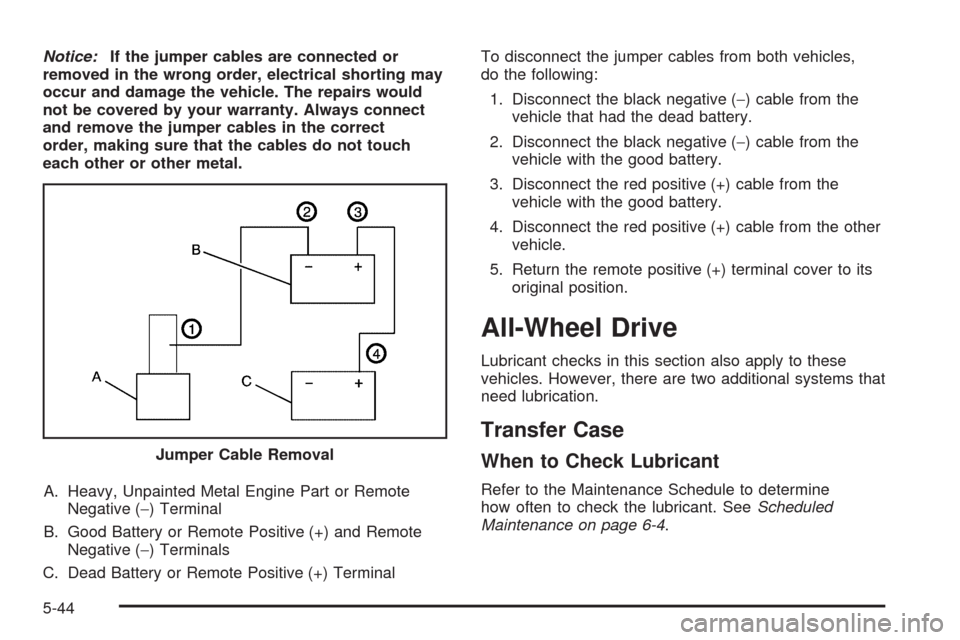

Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by your warranty. Always connect

and remove the jumper cables in the correct

order, making sure that the cables do not touch

each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both vehicles,

do the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the remote positive (+) terminal cover to its

original position.

All-Wheel Drive

Lubricant checks in this section also apply to these

vehicles. However, there are two additional systems that

need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance on page 6-4. Jumper Cable Removal

5-44

Page 289 of 408

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 6-13.

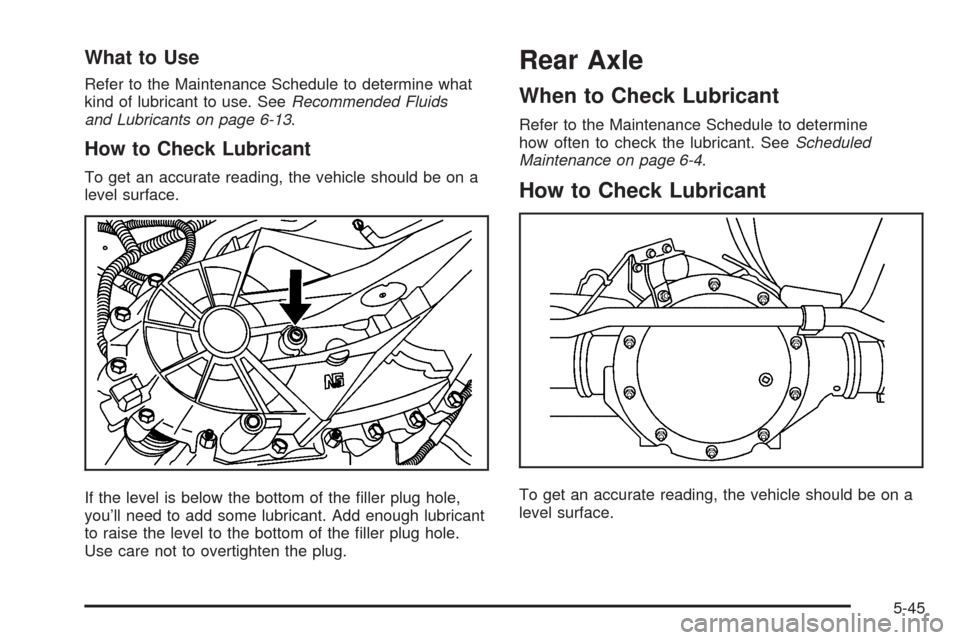

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the filler plug hole,

you’ll need to add some lubricant. Add enough lubricant

to raise the level to the bottom of the filler plug hole.

Use care not to overtighten the plug.

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

5-45

Page 290 of 408

If you have the 1500 Series, the proper level is from

5/8 inch (15 mm) to 1 5/8 inch (40 mm) below the

bottom of the filler plug hole. The proper level for the

2500 and 3500 Series is from 0 to 1/4 (6 mm) below the

bottom of the filler plug hole. Add only enough fluid to

reach the proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 6-13.

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it.

SeeScheduled Maintenance on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.If the level is below the

bottom of the filler plug

hole, you may need to

add some lubricant.

When the differential is cold, add enough lubricant

to raise the level to 3/8 inch (10 mm) below the filler

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to

the bottom of the filler plug hole.What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 6-13.

5-46