engine CHEVROLET EXPRESS PASSANGER 2006 1.G Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2006, Model line: EXPRESS PASSANGER, Model: CHEVROLET EXPRESS PASSANGER 2006 1.GPages: 406, PDF Size: 2.51 MB

Page 300 of 406

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance (Gasoline Engine) on page 6-4.

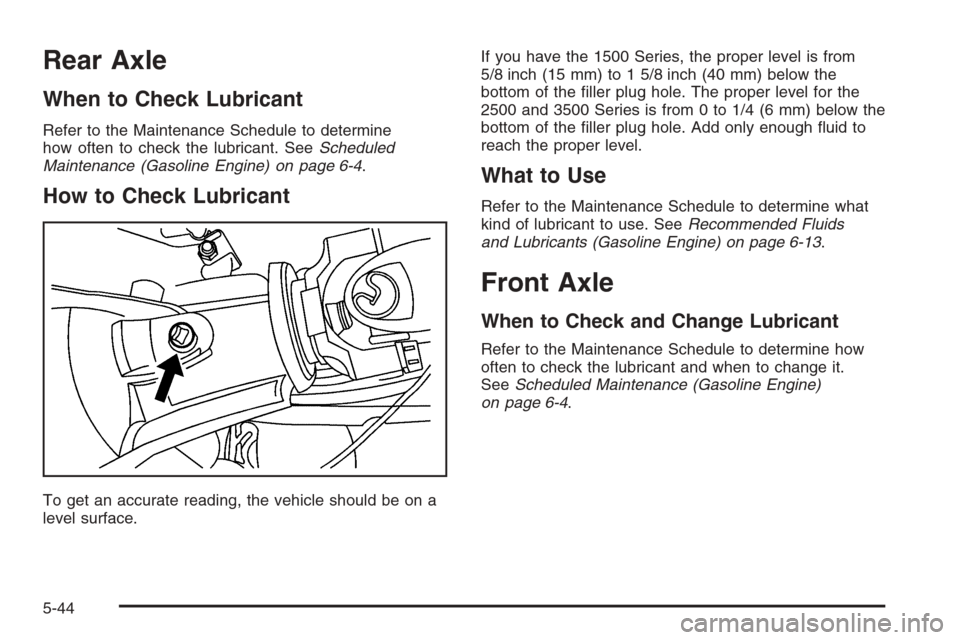

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.If you have the 1500 Series, the proper level is from

5/8 inch (15 mm) to 1 5/8 inch (40 mm) below the

bottom of the filler plug hole. The proper level for the

2500 and 3500 Series is from 0 to 1/4 (6 mm) below the

bottom of the filler plug hole. Add only enough fluid to

reach the proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants (Gasoline Engine) on page 6-13.

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it.

SeeScheduled Maintenance (Gasoline Engine)

on page 6-4.

5-44

Page 301 of 406

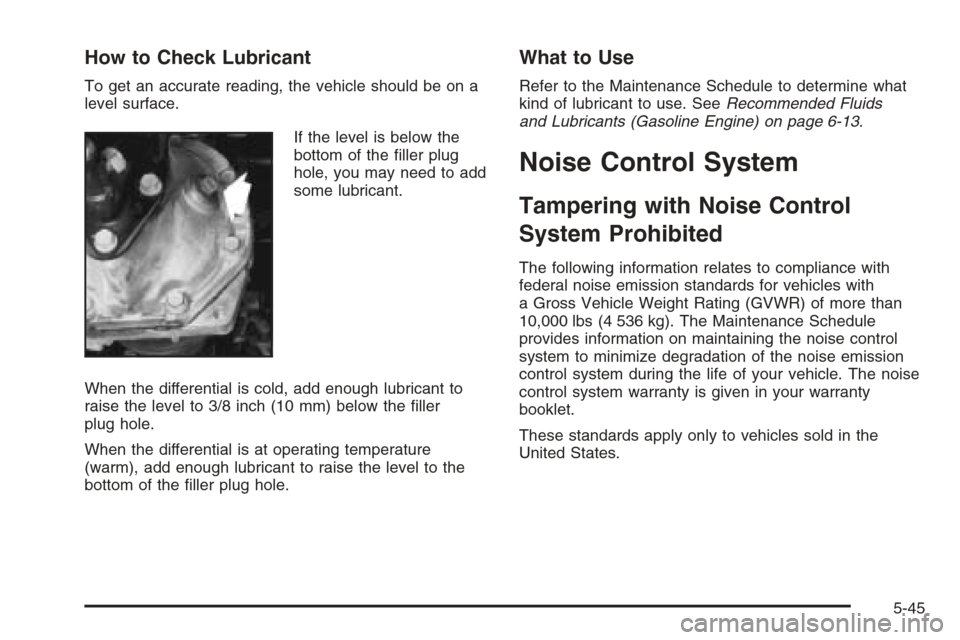

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the

bottom of the filler plug

hole, you may need to add

some lubricant.

When the differential is cold, add enough lubricant to

raise the level to 3/8 inch (10 mm) below the filler

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants (Gasoline Engine) on page 6-13.

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance with

federal noise emission standards for vehicles with

a Gross Vehicle Weight Rating (GVWR) of more than

10,000 lbs (4 536 kg). The Maintenance Schedule

provides information on maintaining the noise control

system to minimize degradation of the noise emission

control system during the life of your vehicle. The noise

control system warranty is given in your warranty

booklet.

These standards apply only to vehicles sold in the

United States.

5-45

Page 302 of 406

Federal law prohibits the following acts or the causing

thereof:

1. The removal or rendering inoperative by any

person, other than for purposes of maintenance,

repair or replacement, of any device or element of

design incorporated into any new vehicle for

the purpose of noise control, prior to its sale or

delivery to the ultimate purchaser or while it is in

use; or

2. The use of the vehicle after such device or element

of design has been removed or rendered inoperative

by any person.

Among those acts presumed to constitute tampering are

the acts listed below.

Insulation:

•

Removal of the noise shields or any underhood

insulation.

Engine:

•

Removal or rendering engine speed governor

(if equipped) inoperative so as to allow engine

speed to exceed manufacturer specifications.

Fan and Drive:

•

Removal of fan clutch (if equipped) or rendering

clutch inoperative.

•Removal of the fan shroud (if equipped).

Air Intake:

•

Removal of the air cleaner silencer.

•Modification of the air cleaner.

Exhaust:

•

Removal of the muffler and/or resonator.

•Removal of the exhaust pipes and exhaust pipe

clamps.

Bulb Replacement

For the proper type of replacement bulbs, see

Replacement Bulbs on page 5-51.

For any bulb changing procedure not listed in this

section, contact your dealer.

5-46

Page 308 of 406

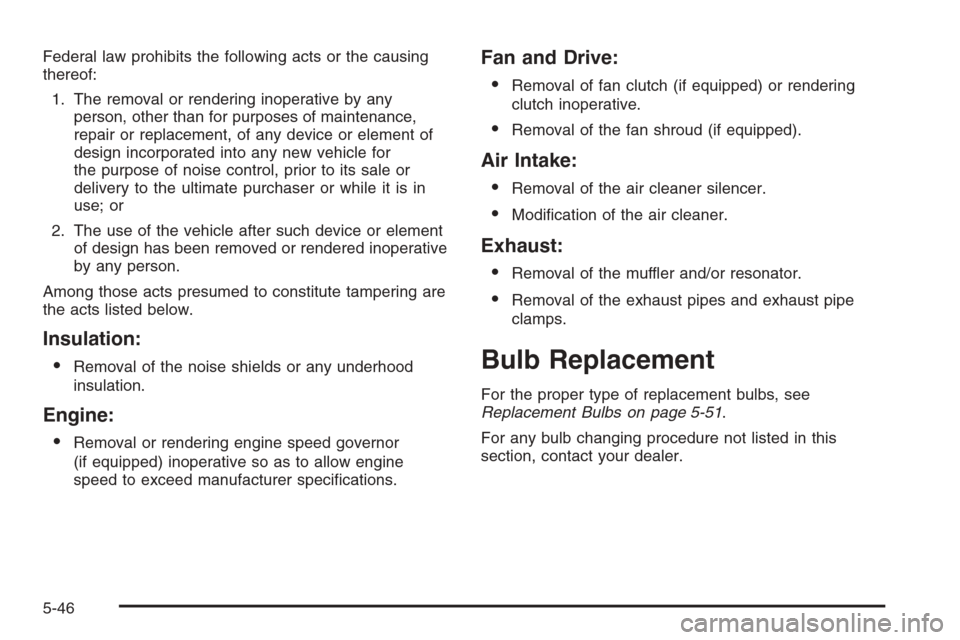

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

and cracking. SeeScheduled Maintenance (Gasoline

Engine) on page 6-4for more information on wiper blade

inspection.

Replacement blades come in different types and are

removed in different ways. To remove the type with a

release clip, do the following:

1. Lift the wiper arm until it locks into a vertical

position.

2. Press down on the blade assembly pivot locking

tab. Pull down on the blade assembly to release it

from the wiper arm hook.

3. The insert has two notches at one end that are

locked by bottom claws of the blade assembly.

At the notched end, pull the insert from the blade

assembly.

4. To install the new wiper insert, slide the notched

end last, into the end with two blade claws. Then

slide the insert all the way through the blade claws

at the opposite end.

5-52

Page 312 of 406

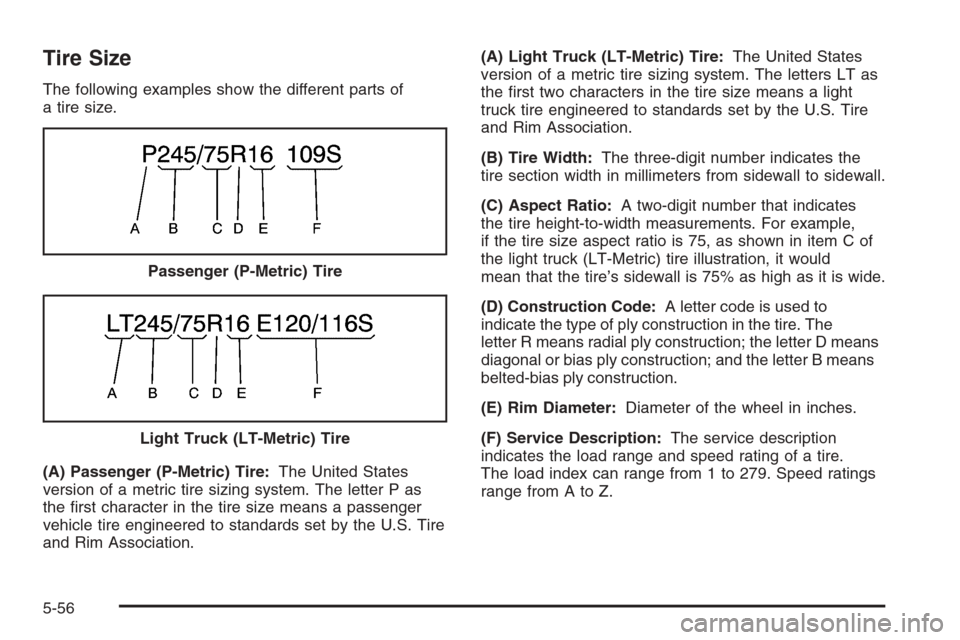

Tire Size

The following examples show the different parts of

a tire size.

(A) Passenger (P-Metric) Tire:The United States

version of a metric tire sizing system. The letter P as

the first character in the tire size means a passenger

vehicle tire engineered to standards set by the U.S. Tire

and Rim Association.(A) Light Truck (LT-Metric) Tire:The United States

version of a metric tire sizing system. The letters LT as

the first two characters in the tire size means a light

truck tire engineered to standards set by the U.S. Tire

and Rim Association.

(B) Tire Width:The three-digit number indicates the

tire section width in millimeters from sidewall to sidewall.

(C) Aspect Ratio:A two-digit number that indicates

the tire height-to-width measurements. For example,

if the tire size aspect ratio is 75, as shown in item C of

the light truck (LT-Metric) tire illustration, it would

mean that the tire’s sidewall is 75% as high as it is wide.

(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire. The

letter R means radial ply construction; the letter D means

diagonal or bias ply construction; and the letter B means

belted-bias ply construction.

(E) Rim Diameter:Diameter of the wheel in inches.

(F) Service Description:The service description

indicates the load range and speed rating of a tire.

The load index can range from 1 to 279. Speed ratings

range from A to Z. Passenger (P-Metric) Tire

Light Truck (LT-Metric) Tire

5-56

Page 317 of 406

Dual Tire Operation

When the vehicle is new, or whenever a wheel, wheel bolt

or wheel nut is replaced, check the wheel nut torque after

100, 1,000 and 6,000 miles (160, 1 600 and 10 000 km)

of driving. For proper wheel nut tightening information,

see “Removing the Flat Tire and Installing the Spare

Tire” later in this section, underChanging a Flat Tire

on page 5-71. Also see “Wheel Nut Torque” under

Capacities and Speci�cations on page 5-99.

The outer tire on a dual wheel setup generally wears

faster than the inner tire. Your tires will wear more evenly

and last longer if you rotate the tires periodically. See

Tire Inspection and Rotation on page 5-61. Also see

Scheduled Maintenance (Gasoline Engine) on page 6-4.

{CAUTION:

If you operate your vehicle with a tire that is

badly underin�ated, the tire can overheat. An

overheated tire can lose air suddenly or catch

�re. You or others could be injured. Be sure all

tires (including the spare) are properly in�ated.

SeeTires on page 5-53andIn�ation - Tire Pressure on

page 5-59for more information on proper tire inflation.

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).

Any time you notice unusual wear, rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. SeeWhen It Is Time

for New Tires on page 5-63andWheel Replacement

on page 5-67for more information.

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves,

use the ratchet/wheel wrench to tighten the cable.

SeeChanging a Flat Tire on page 5-71.

If your vehicle has dual rear wheels, also seeDual Tire

Operation on page 5-61.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The first rotation

is the most important. SeeScheduled Maintenance

(Gasoline Engine) on page 6-4.

5-61

Page 327 of 406

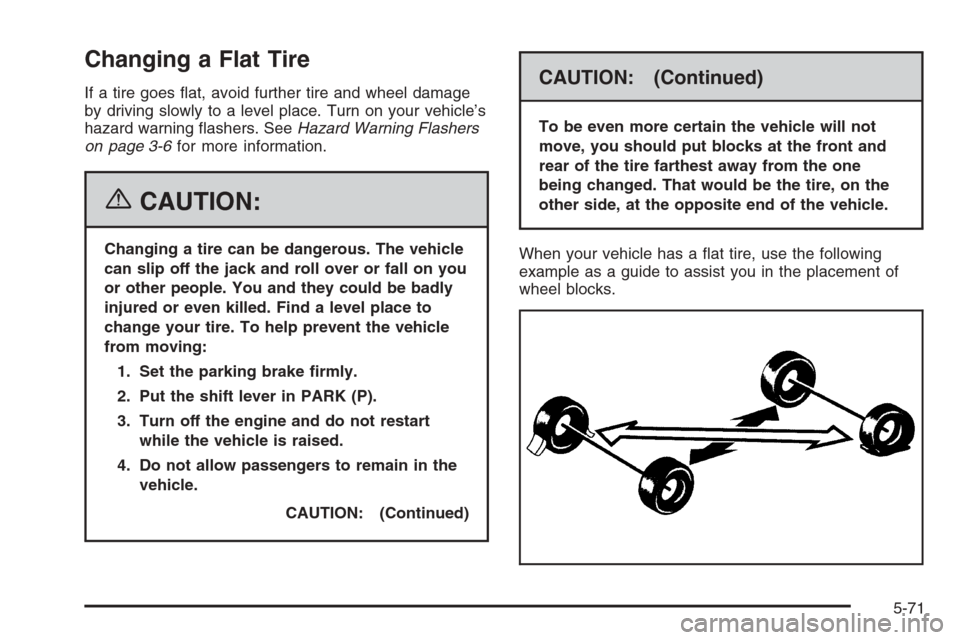

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your vehicle’s

hazard warning flashers. SeeHazard Warning Flashers

on page 3-6for more information.

{CAUTION:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you

or other people. You and they could be badly

injured or even killed. Find a level place to

change your tire. To help prevent the vehicle

from moving:

1. Set the parking brake �rmly.

2. Put the shift lever in PARK (P).

3. Turn off the engine and do not restart

while the vehicle is raised.

4. Do not allow passengers to remain in the

vehicle.

CAUTION: (Continued)

CAUTION: (Continued)

To be even more certain the vehicle will not

move, you should put blocks at the front and

rear of the tire farthest away from the one

being changed. That would be the tire, on the

other side, at the opposite end of the vehicle.

When your vehicle has a flat tire, use the following

example as a guide to assist you in the placement of

wheel blocks.

5-71

Page 343 of 406

Instrument Panel, Vinyl, and

Other Plastic Surfaces

A soft cloth dampened with water may be used to

remove dust. If a more thorough cleaning is necessary,

a clean soft cloth dampened with a mild soap solution

can be used to gently remove dust and dirt. Never use

spot lifters or removers on plastic surfaces. Many

commercial cleaners and coatings that are sold to

preserve and protect soft plastic surfaces may

permanently change the appearance and feel of your

interior and are not recommended. Do not use silicone

or wax-based products, or those containing organic

solvents to clean your vehicle’s interior because

they can alter the appearance by increasing the gloss in

a non-uniform manner.

Some commercial products may increase gloss on your

instrument panel. The increase in gloss may cause

annoying reflections in the windshield and even make it

difficult to see through the windshield under certain

conditions.

Care of Safety Belts

Keep belts clean and dry.

{CAUTION:

Do not bleach or dye safety belts. If you do,

it may severely weaken them. In a crash,

they might not be able to provide adequate

protection. Clean safety belts only with mild

soap and lukewarm water.

Weatherstrips

Silicone grease on weatherstrips will make them last

longer, seal better, and not stick or squeak. Apply

silicone grease with a clean cloth. During very cold,

damp weather frequent application may be required.

SeeRecommended Fluids and Lubricants (Gasoline

Engine) on page 6-13.

5-87

Page 349 of 406

Vehicle Identi�cation

Vehicle Identi�cation Number (VIN)

This is the legal identifier for your vehicle. It appears on

a plate in the front corner of the instrument panel, on

the driver’s side. You can see it if you look through the

windshield from outside your vehicle. The VIN also

appears on the Vehicle Certification and Service Parts

labels and the certificates of title and registration.

Engine Identi�cation

The eighth character in the VIN is the engine code.

This code will help you identify your vehicle’s engine,

specifications, and replacement parts.

Service Parts Identi�cation Label

You will find this label on the front passenger door

frame. It is very helpful if you ever need to order parts.

On this label you will find the following:

•VIN

•Model designation

•Paint information

•Production options and special equipment

Do not remove this label from the vehicle.

5-93

Page 352 of 406

Relays Usage

23 Window Retained Accessory Power

24 Auxiliary

25 Rear Window Defogger

26 Courtesy Lamp

27 Cargo Unlock

28 Driver Unlock

29 Park Lamp

30 Door Locks

31 Passenger Unlock

Circuit Breaker Usage

34 Power Window

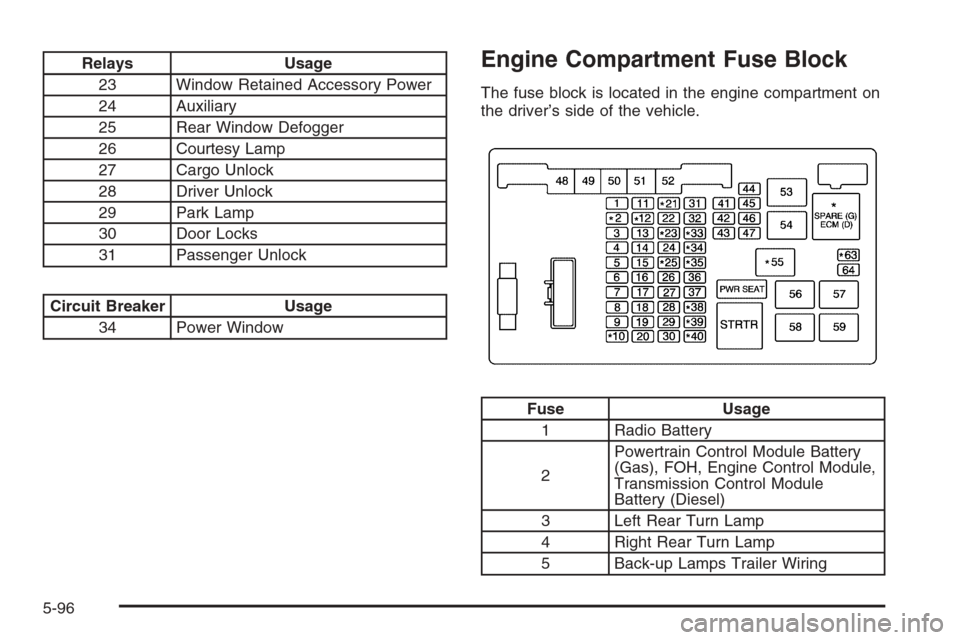

Engine Compartment Fuse Block

The fuse block is located in the engine compartment on

the driver’s side of the vehicle.

Fuse Usage

1 Radio Battery

2Powertrain Control Module Battery

(Gas), FOH, Engine Control Module,

Transmission Control Module

Battery (Diesel)

3 Left Rear Turn Lamp

4 Right Rear Turn Lamp

5 Back-up Lamps Trailer Wiring

5-96