wheel bolts CHEVROLET HHR 2010 1.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: HHR, Model: CHEVROLET HHR 2010 1.GPages: 480, PDF Size: 5.25 MB

Page 378 of 480

Wheel Alignment and Tire Balance

The tires and wheels on your vehicle were aligned and

balanced carefully at the factory to give you the longest

tire life and best overall performance. Adjustments

to wheel alignment and tire balancing will not be

necessary on a regular basis. However, if you notice

unusual tire wear or your vehicle pulling to one side or

the other, the alignment might need to be checked.

If you notice your vehicle vibrating when driving on a

smooth road, the tires and wheels might need to be

rebalanced. See your dealer/retailer for proper

diagnosis.

Wheel Replacement

Replace any wheel that is bent, cracked, or badly

rusted or corroded. If wheel nuts keep coming loose,

the wheel, wheel bolts, and wheel nuts should be

replaced. If the wheel leaks air, replace it (except some

aluminum wheels, which can sometimes be repaired).

See your dealer/retailer if any of these conditions exist.

Your dealer/retailer will know the kind of wheel

you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset, and be mounted the

same way as the one it replaces.If you need to replace any of your wheels, wheel bolts,

wheel nuts, or Tire Pressure Monitor System (TPMS)

sensors, replace them only with new GM original

equipment parts. This way, you will be sure to have the

right wheel, wheel bolts, wheel nuts, and TPMS sensors

for your vehicle.

{WARNING:

Using the wrong replacement wheels, wheel bolts,

or wheel nuts on your vehicle can be dangerous.

It could affect the braking and handling of your

vehicle, make your tires lose air and make you

lose control. You could have a collision in which

you or others could be injured. Always use the

correct wheel, wheel bolts, and wheel nuts for

replacement.

Notice: The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance, and tire or tire chain

clearance to the body and chassis.

See Changing a Flat Tire

on page 6‑88for more

information.

6-76

Page 397 of 480

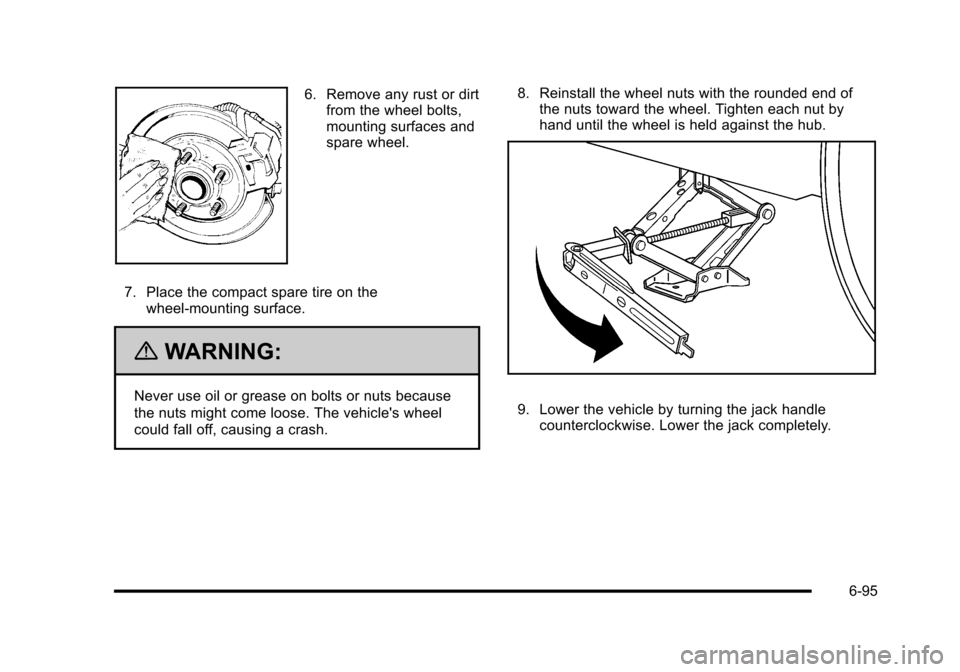

6. Remove any rust or dirtfrom the wheel bolts,

mounting surfaces and

spare wheel.

7. Place the compact spare tire on the wheel-mounting surface.

{WARNING:

Never use oil or grease on bolts or nuts because

the nuts might come loose. The vehicle's wheel

could fall off, causing a crash. 8. Reinstall the wheel nuts with the rounded end of

the nuts toward the wheel. Tighten each nut by

hand until the wheel is held against the hub.9. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

6-95

Page 401 of 480

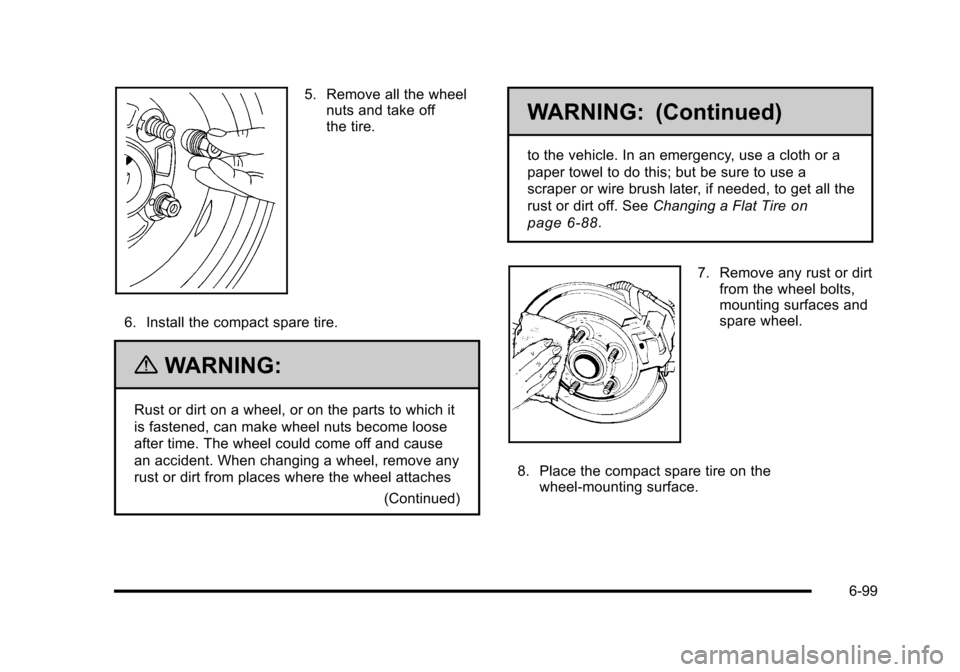

5. Remove all the wheelnuts and take off

the tire.

6. Install the compact spare tire.

{WARNING:

Rust or dirt on a wheel, or on the parts to which it

is fastened, can make wheel nuts become loose

after time. The wheel could come off and cause

an accident. When changing a wheel, remove any

rust or dirt from places where the wheel attaches (Continued)

WARNING: (Continued)

to the vehicle. In an emergency, use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if needed, to get all the

rust or dirt off. SeeChanging a Flat Tire

on

page 6‑88

.

7. Remove any rust or dirt from the wheel bolts,

mounting surfaces and

spare wheel.

8. Place the compact spare tire on the wheel-mounting surface.

6-99

Page 402 of 480

{WARNING:

Never use oil or grease on bolts or nuts because

the nuts might come loose. The vehicle's wheel

could fall off, causing a crash.

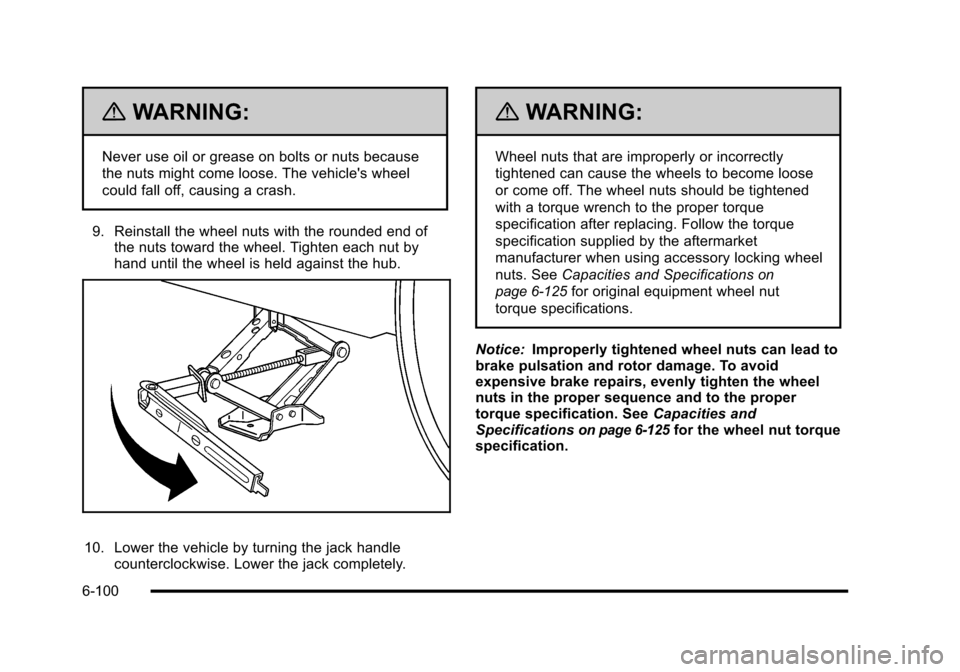

9. Reinstall the wheel nuts with the rounded end of the nuts toward the wheel. Tighten each nut by

hand until the wheel is held against the hub.

10. Lower the vehicle by turning the jack handle counterclockwise. Lower the jack completely.

{WARNING:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose

or come off. The wheel nuts should be tightened

with a torque wrench to the proper torque

specification after replacing. Follow the torque

specification supplied by the aftermarket

manufacturer when using accessory locking wheel

nuts. See Capacities and Specifications

on

page 6‑125

for original equipment wheel nut

torque specifications.

Notice: Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification. See Capacities and

Specifications

on page 6‑125for the wheel nut torque

specification.

6-100

Page 406 of 480

{WARNING:

Rust or dirt on a wheel, or on the parts to which it

is fastened, can make wheel nuts become loose

after time. The wheel could come off and cause

an accident. When changing a wheel, remove any

rust or dirt from places where the wheel attaches

to the vehicle. In an emergency, use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if needed, to get all the

rust or dirt off. SeeChanging a Flat Tire

on

page 6‑88

.

7. Remove any rust or dirt from the wheel bolts,

mounting surfaces, and

wheel.

8. Place the tire on the wheel mounting surface.

9. Reinstall the wheel nuts with the rounded end of the nuts toward the wheel. Tighten each by hand

until the wheel is held against the hub.

{WARNING:

Never use oil or grease on bolts or nuts because

the nuts might come loose. The vehicle's wheel

could fall off, causing a crash.

6-104