clock CHEVROLET HHR 2011 1.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2011, Model line: HHR, Model: CHEVROLET HHR 2011 1.GPages: 430, PDF Size: 4.57 MB

Page 287 of 430

Black plate (11,1)Chevrolet HHR Owner Manual - 2011

When replacing the fuel cap, turn it clockwise until it

clicks. Make sure the cap is fully installed. The

diagnostic system can determine if the fuel cap has

been left off or improperly installed. This would allow

fuel to evaporate into the atmosphere. SeeMalfunction

Indicator Lamp on page 4‑33.

The CHECK GAS CAP message displays on the Driver

Information Center (DIC) if the fuel cap is not properly

installed. See DIC Warnings and Messages

on

page 4‑40for more information.

To close the fuel door securely, push the door to the

closed position.

{WARNING:

If a fire starts while you are refueling, do not

remove the nozzle. Shut off the flow of fuel by

shutting off the pump or by notifying the station

attendant. Leave the area immediately.

Notice: If you need a new fuel cap, be sure to get

the right type. Your dealer can get one for you.

If you get the wrong type, it may not fit properly.

This may cause the malfunction indicator lamp to

light and may damage the fuel tank and emissions

system. See Malfunction Indicator Lamp

on

page 4‑33.

6-11

Page 303 of 430

Black plate (27,1)Chevrolet HHR Owner Manual - 2011

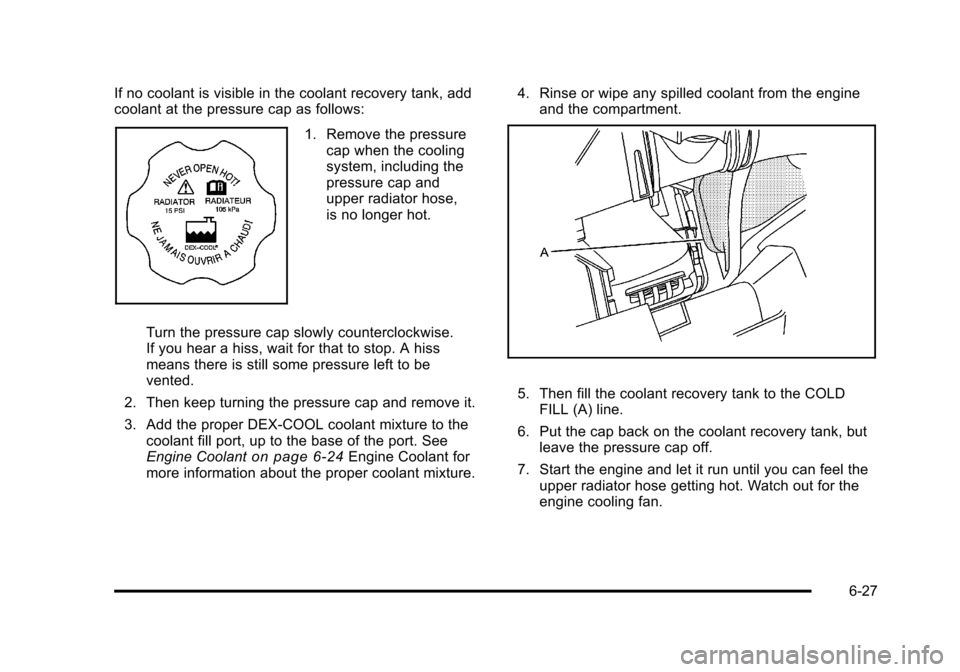

If no coolant is visible in the coolant recovery tank, add

coolant at the pressure cap as follows:

1. Remove the pressurecap when the cooling

system, including the

pressure cap and

upper radiator hose,

is no longer hot.

Turn the pressure cap slowly counterclockwise.

If you hear a hiss, wait for that to stop. A hiss

means there is still some pressure left to be

vented.

2. Then keep turning the pressure cap and remove it.

3. Add the proper DEX-COOL coolant mixture to the coolant fill port, up to the base of the port. See

Engine Coolant

on page 6‑24Engine Coolant for

more information about the proper coolant mixture. 4. Rinse or wipe any spilled coolant from the engine

and the compartment.

5. Then fill the coolant recovery tank to the COLDFILL (A) line.

6. Put the cap back on the coolant recovery tank, but leave the pressure cap off.

7. Start the engine and let it run until you can feel the upper radiator hose getting hot. Watch out for the

engine cooling fan.

6-27

Page 316 of 430

Black plate (40,1)Chevrolet HHR Owner Manual - 2011

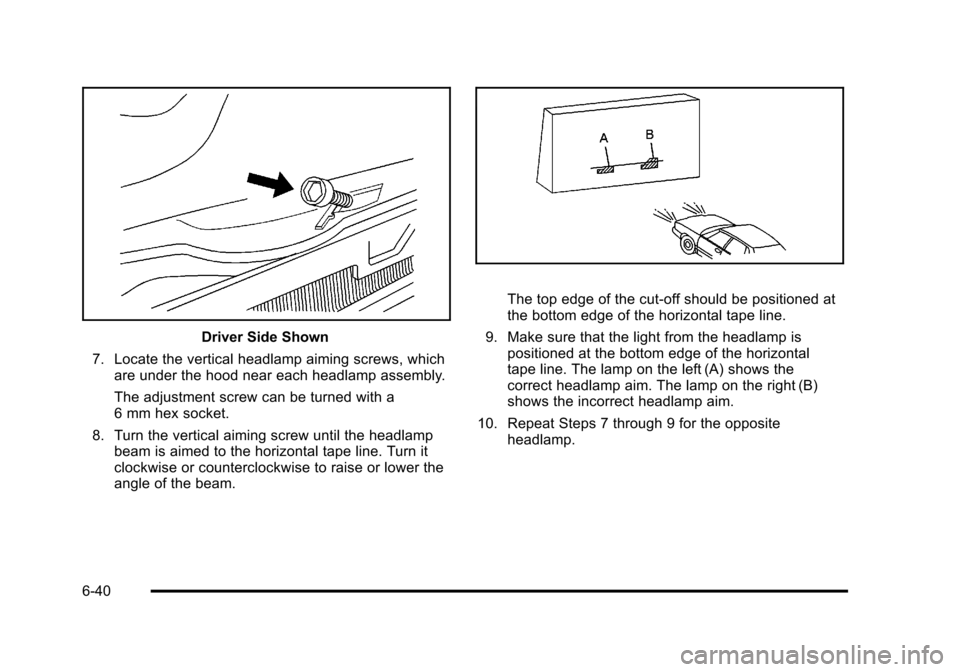

Driver Side Shown

7. Locate the vertical headlamp aiming screws, which are under the hood near each headlamp assembly.

The adjustment screw can be turned with a

6 mm hex socket.

8. Turn the vertical aiming screw until the headlamp beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

The top edge of the cut-off should be positioned at

the bottom edge of the horizontal tape line.

9. Make sure that the light from the headlamp is positioned at the bottom edge of the horizontal

tape line. The lamp on the left (A) shows the

correct headlamp aim. The lamp on the right (B)

shows the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

6-40

Page 318 of 430

Black plate (42,1)Chevrolet HHR Owner Manual - 2011

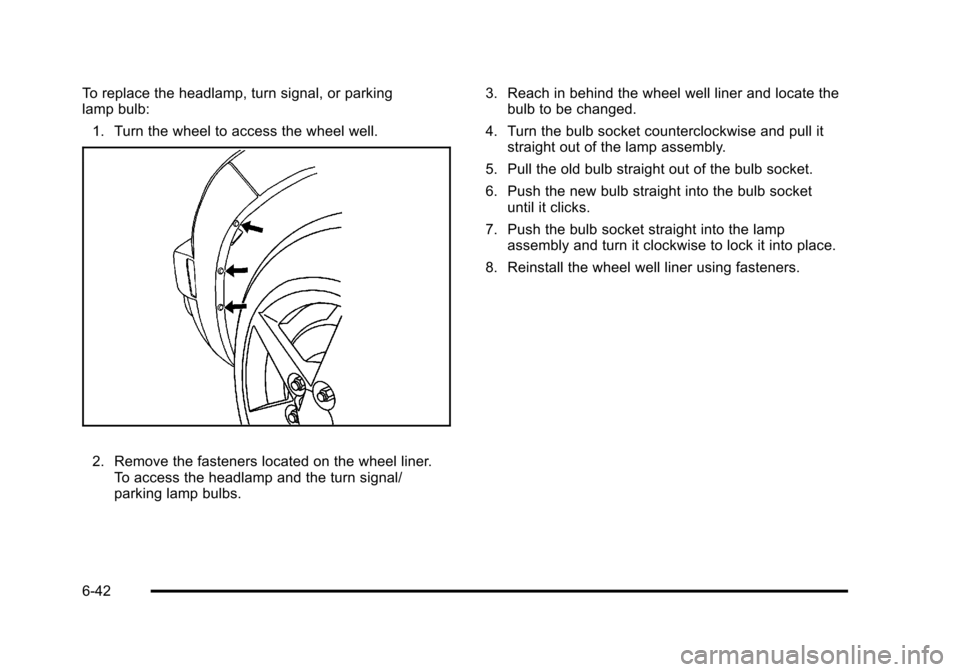

To replace the headlamp, turn signal, or parking

lamp bulb:1. Turn the wheel to access the wheel well.

2. Remove the fasteners located on the wheel liner. To access the headlamp and the turn signal/

parking lamp bulbs. 3. Reach in behind the wheel well liner and locate the

bulb to be changed.

4. Turn the bulb socket counterclockwise and pull it straight out of the lamp assembly.

5. Pull the old bulb straight out of the bulb socket.

6. Push the new bulb straight into the bulb socket until it clicks.

7. Push the bulb socket straight into the lamp assembly and turn it clockwise to lock it into place.

8. Reinstall the wheel well liner using fasteners.

6-42

Page 319 of 430

Black plate (43,1)Chevrolet HHR Owner Manual - 2011

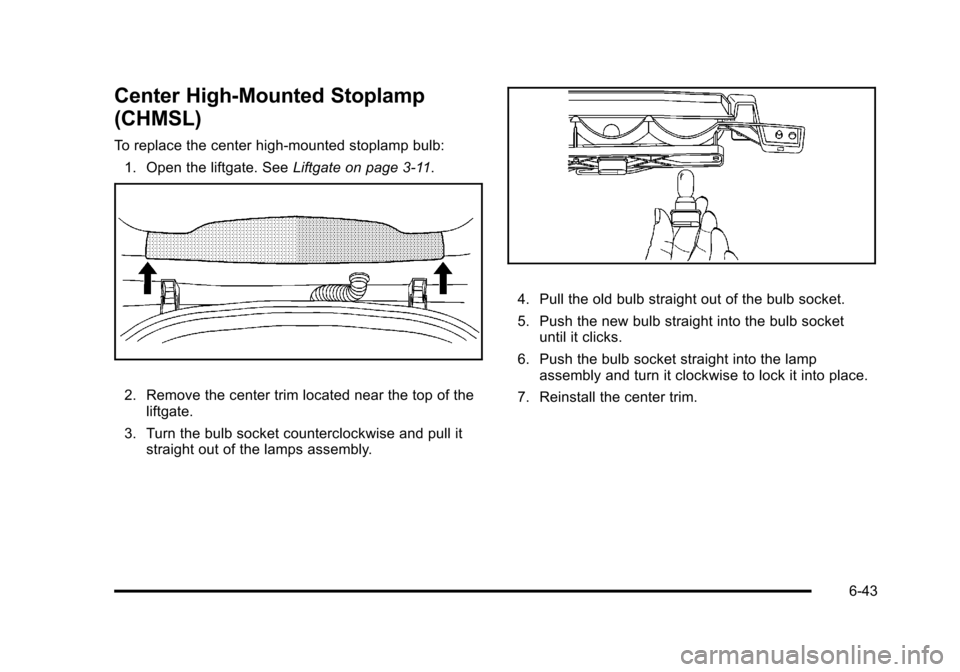

Center High-Mounted Stoplamp

(CHMSL)

To replace the center high-mounted stoplamp bulb:1. Open the liftgate. See Liftgate on page 3‑11.

2. Remove the center trim located near the top of the

liftgate.

3. Turn the bulb socket counterclockwise and pull it straight out of the lamps assembly.

4. Pull the old bulb straight out of the bulb socket.

5. Push the new bulb straight into the bulb socketuntil it clicks.

6. Push the bulb socket straight into the lamp assembly and turn it clockwise to lock it into place.

7. Reinstall the center trim.

6-43

Page 320 of 430

Black plate (44,1)Chevrolet HHR Owner Manual - 2011

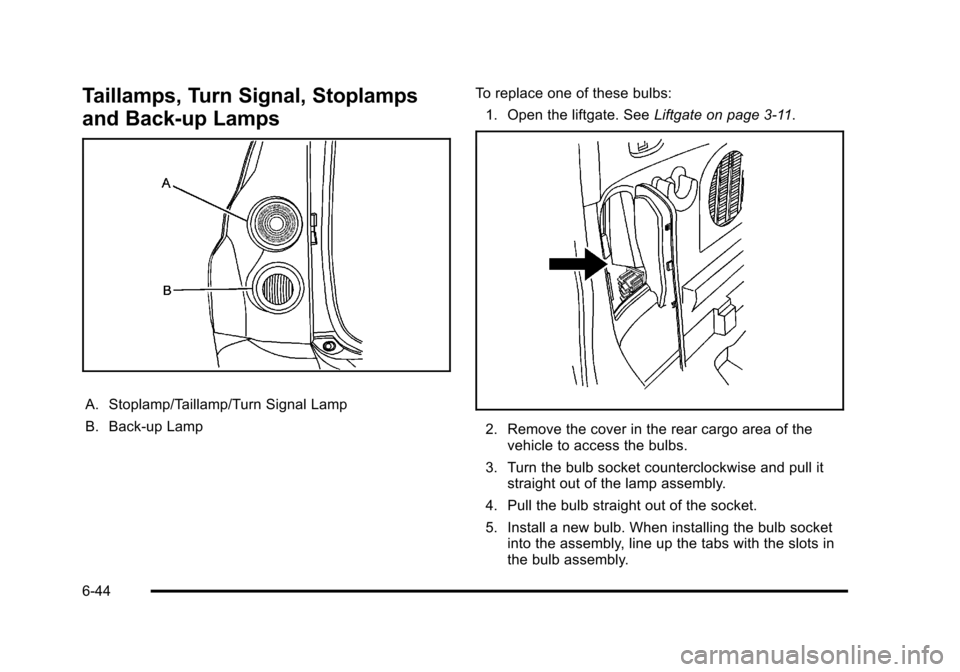

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps

A. Stoplamp/Taillamp/Turn Signal Lamp

B. Back-up LampTo replace one of these bulbs:

1. Open the liftgate. See Liftgate on page 3‑11.

2. Remove the cover in the rear cargo area of the

vehicle to access the bulbs.

3. Turn the bulb socket counterclockwise and pull it straight out of the lamp assembly.

4. Pull the bulb straight out of the socket.

5. Install a new bulb. When installing the bulb socket into the assembly, line up the tabs with the slots in

the bulb assembly.

6-44

Page 321 of 430

Black plate (45,1)Chevrolet HHR Owner Manual - 2011

6. Push the bulb socket straight into the lampassembly and turn it clockwise to lock it into place.

7. Reinstall the cover.

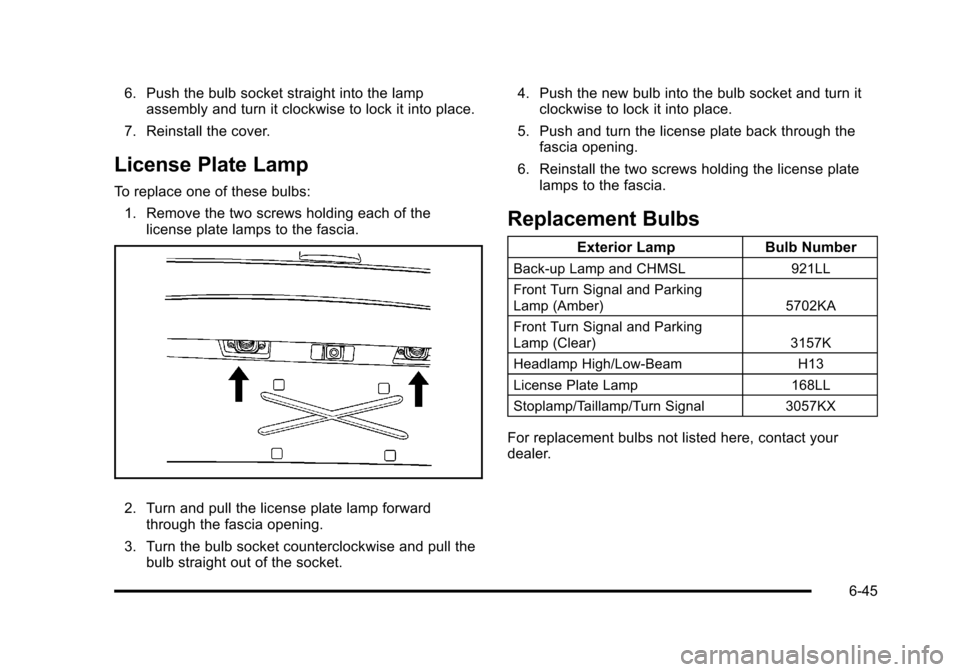

License Plate Lamp

To replace one of these bulbs: 1. Remove the two screws holding each of the license plate lamps to the fascia.

2. Turn and pull the license plate lamp forwardthrough the fascia opening.

3. Turn the bulb socket counterclockwise and pull the bulb straight out of the socket. 4. Push the new bulb into the bulb socket and turn it

clockwise to lock it into place.

5. Push and turn the license plate back through the fascia opening.

6. Reinstall the two screws holding the license plate lamps to the fascia.

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up Lamp and CHMSL 921LL

Front Turn Signal and Parking

Lamp (Amber) 5702KA

Front Turn Signal and Parking

Lamp (Clear) 3157K

Headlamp High/Low-Beam H13

License Plate Lamp 168LL

Stoplamp/Taillamp/Turn Signal 3057KX

For replacement bulbs not listed here, contact your

dealer.

6-45

Page 348 of 430

Black plate (72,1)Chevrolet HHR Owner Manual - 2011

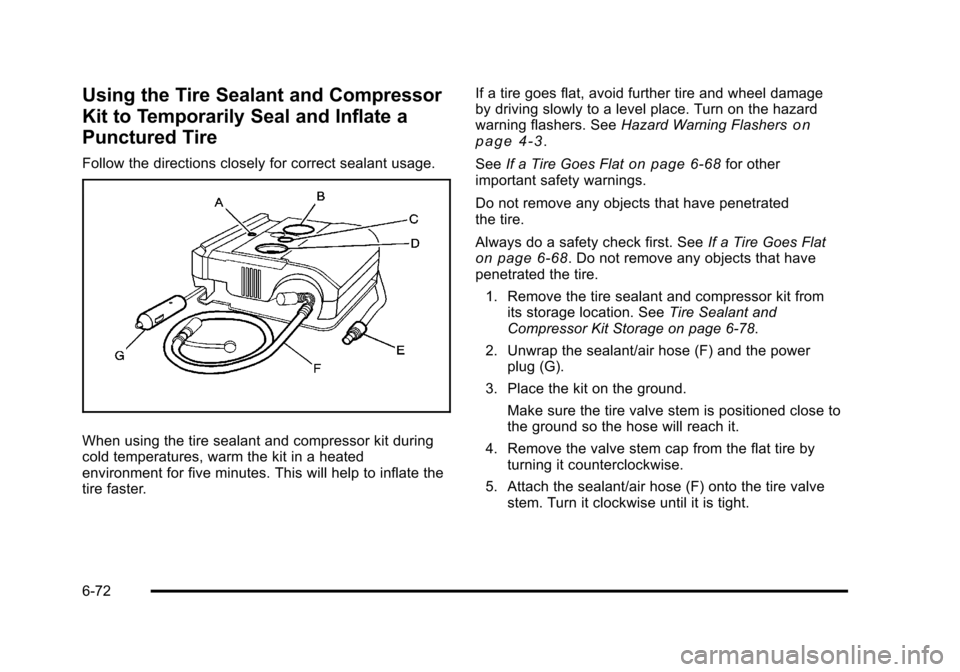

Using the Tire Sealant and Compressor

Kit to Temporarily Seal and Inflate a

Punctured Tire

Follow the directions closely for correct sealant usage.

When using the tire sealant and compressor kit during

cold temperatures, warm the kit in a heated

environment for five minutes. This will help to inflate the

tire faster.If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on the hazard

warning flashers. See

Hazard Warning Flashers

on

page 4‑3.

See If a Tire Goes Flat

on page 6‑68for other

important safety warnings.

Do not remove any objects that have penetrated

the tire.

Always do a safety check first. See If a Tire Goes Flat

on page 6‑68. Do not remove any objects that have

penetrated the tire.

1. Remove the tire sealant and compressor kit from its storage location. See Tire Sealant and

Compressor Kit Storage on page 6‑78.

2. Unwrap the sealant/air hose (F) and the power plug (G).

3. Place the kit on the ground.

Make sure the tire valve stem is positioned close to

the ground so the hose will reach it.

4. Remove the valve stem cap from the flat tire by turning it counterclockwise.

5. Attach the sealant/air hose (F) onto the tire valve stem. Turn it clockwise until it is tight.

6-72

Page 349 of 430

Black plate (73,1)Chevrolet HHR Owner Manual - 2011

6. Plug the power plug (G) into the accessory poweroutlet in the vehicle. Unplug all items from other

accessory power outlets. See Accessory Power

Outlet(s) on page 4‑15.

If the vehicle has an accessory power outlet, do

not use the cigarette lighter.

If the vehicle only has a cigarette lighter, use the

cigarette lighter.

Do not pinch the power plug cord in the door or

window.

7. Start the vehicle. The vehicle must be running while using the air compressor.

8. Turn the selector switch (B) clockwise to the Sealant + Air position.

9. Press the on/off (A) button to turn the tire sealant and compressor kit on.

The compressor will inject sealant and air into

the tire.

The pressure gauge (D) will initially show a high

pressure while the compressor pushes the sealant

into the tire. Once the sealant is completely

dispersed into the tire, the pressure will quickly

drop and start to rise again as the tire inflates with

air only. 10. Inflate the tire to the recommended inflation

pressure using the pressure gauge (D). The

recommended inflation pressure can be found on

the Tire and Loading Information label. See

Inflation - Tire Pressure on page 6‑54.

The pressure gauge (D) may read higher than the

actual tire pressure while the compressor is on.

Turn the compressor off to get an accurate

pressure reading. The compressor may be turned

on/off until the correct pressure is reached.

Notice: If the recommended pressure cannot be

reached after approximately 25 minutes, the vehicle

should not be driven farther. The tire is too severely

damaged and the tire sealant and compressor kit

cannot inflate the tire. Remove the power plug from

the accessory power outlet and unscrew the

inflating hose from the tire valve. See Roadside

Assistance Program on page 8‑6.

11. Press the on/off button (A) to turn the tire sealant and compressor kit off.

The tire is not sealed and will continue to leak air

until the vehicle is driven and the sealant is

distributed in the tire, therefore, Steps 12 through

18 must be done immediately after Step 11.

Be careful while handling the tire sealant and

compressor kit as it could be warm after usage.

6-73

Page 350 of 430

Black plate (74,1)Chevrolet HHR Owner Manual - 2011

12. Unplug the power plug (G) from the accessorypower outlet in the vehicle.

13. Turn the sealant/air hose (F) counterclockwise to remove it from the tire valve stem.

14. Replace the tire valve stem cap.

15. Replace the sealant/air hose (F), and the power plug (G) back in their original location.

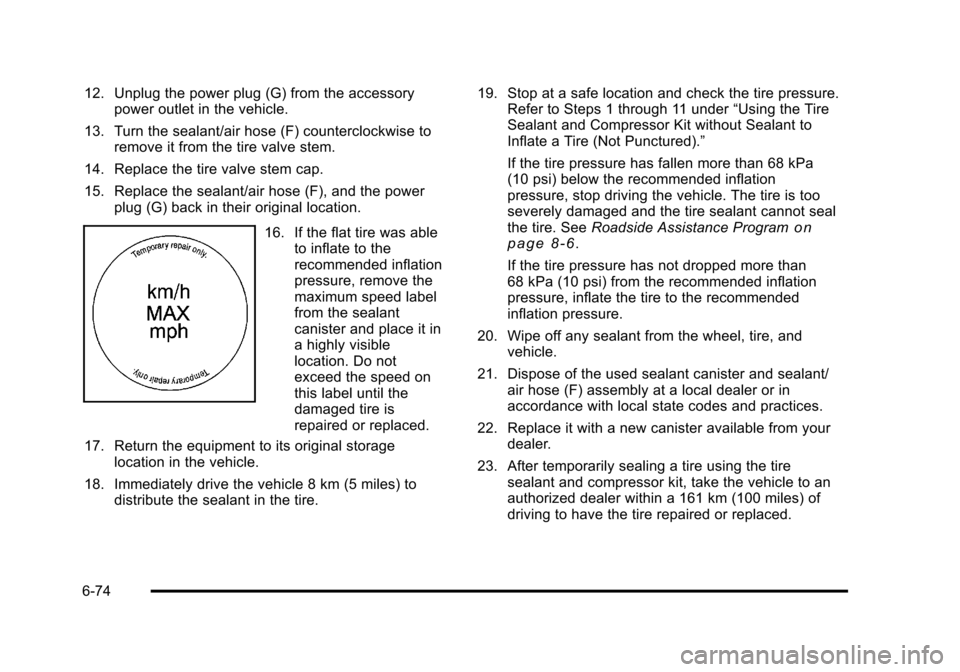

16. If the flat tire was ableto inflate to the

recommended inflation

pressure, remove the

maximum speed label

from the sealant

canister and place it in

a highly visible

location. Do not

exceed the speed on

this label until the

damaged tire is

repaired or replaced.

17. Return the equipment to its original storage location in the vehicle.

18. Immediately drive the vehicle 8 km (5 miles) to distribute the sealant in the tire. 19. Stop at a safe location and check the tire pressure.

Refer to Steps 1 through 11 under “Using the Tire

Sealant and Compressor Kit without Sealant to

Inflate a Tire (Not Punctured).”

If the tire pressure has fallen more than 68 kPa

(10 psi) below the recommended inflation

pressure, stop driving the vehicle. The tire is too

severely damaged and the tire sealant cannot seal

the tire. See Roadside Assistance Programon

page 8‑6.

If the tire pressure has not dropped more than

68 kPa (10 psi) from the recommended inflation

pressure, inflate the tire to the recommended

inflation pressure.

20. Wipe off any sealant from the wheel, tire, and vehicle.

21. Dispose of the used sealant canister and sealant/ air hose (F) assembly at a local dealer or in

accordance with local state codes and practices.

22. Replace it with a new canister available from your dealer.

23. After temporarily sealing a tire using the tire sealant and compressor kit, take the vehicle to an

authorized dealer within a 161 km (100 miles) of

driving to have the tire repaired or replaced.

6-74