service interval CHEVROLET KODIAK 2006 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2006, Model line: KODIAK, Model: CHEVROLET KODIAK 2006Pages: 398, PDF Size: 5.72 MB

Page 281 of 398

Electric Air Compressor

Your vehicle may have an electric air compressor. This

compressor is used to run options that require

pressurized air, such as air horn, air seat, 7.8L engine

exhaust restrictor, or 7.8L engine exhaust brake.

The air compressor is used when vehicles are not

equipped with an air brake system.

The air supply for this

system must be

maintained by releasing

the drain valve to eject any

moisture that may have

built up in the system.

It is recommended that this system be drained on a

weekly basis.

Clutch Pedal Free Travel

If you have a V8 engine and a manual transmission,

your clutch will need adjustment when pedal free travel

gets down to about 1/4 inch (32 mm), as measured

at the clutch pedal pad. You should have 1 1/2 to

2 inches (38 to 51 mm) of clutch pedal free travel.

If your clutch ever needs service, be sure to use only

GM clutch replacement parts.

Chassis Lubrication

Your Maintenance Schedule provides all of the required

chassis lubrication intervals and identifies proper

lubricants to use. Be sure to see your Maintenance

Schedule before performing any chassis lubrication

service. To determine location of chassis lubrication

items, use the following charts.

5-53

Page 298 of 398

Other Service Items

Fuel Filter

Fuel Filter/Pressure Regulator

(Gasoline Engines)

The steel fuel filter/pressure regulator is located near

the engine compartment on the driver’s side frame rail.If your vehicle has a rear steel fuel tank, the fuel

filter/pressure regulator is located near the rear fuel

tank, on the driver’s side frame rail. SeeScheduled

Maintenance on page 6-5for recommended service

intervals.

If your vehicle is equipped with the optional Davco

spin-on type filter, it is located on the driver’s side

frame rail.

Fuel Filter (Diesel Engines)

If you have a diesel engine, your fuel filter is located in

the engine compartment on the driver’s side of the

vehicle, or along the driver’s side frame rail. See “Fuel

Filter Replacement” earlier in this section for further

information.

Also seeScheduled Maintenance on page 6-5for

recommended service intervals.

5-70

Page 338 of 398

Part A: Scheduled Maintenance

Services

In this part are scheduled maintenance services which

are to be performed at the mileage intervals specified.

Using the Maintenance Schedule

We at General Motors want to help keep your vehicle in

good working condition. But we do not know exactly

how you will drive it. You may drive very short distances

only a few times a week. Or you may drive long

distances all the time in very hot, dusty weather. You

may use your vehicle in making deliveries or in

many other ways.

Because of all the different ways people use their

vehicles, maintenance needs vary. You may need more

frequent checks and replacements. So please read

the following and note how you drive. If you have any

questions on how to keep your vehicle in good condition,

see your dealer.

This part tells you the maintenance services you should

have done and when to schedule them.

When you go to your dealer for your service needs, you

will know that GM-trained and supported service

people will perform the work using genuine GM parts.The proper fluids and lubricants to use are listed in

Part C. Make sure whoever services your vehicle uses

these. All parts should be replaced and all necessary

repairs done before you or anyone else drives the

vehicle.

This schedule is for vehicles that:

•carry passengers and cargo within recommended

limits. You will find limits on your vehicle’s GVW

Rating label. SeeLoading Your Vehicle on

page 4-34.

•are driven on reasonable road surfaces within legal

driving limits.

•use the recommended fuel. SeeGasoline Octane

on page 5-6for gasoline engine vehicles orWhat

Fuel to Use on page 5-8for diesel engine vehicles.

Scheduled Maintenance

Supplements

If your vehicle has a Caterpillar®diesel engine, your

owner’s manual is supplemented by the Caterpillar®

Diesel Engine Operation & Maintenance Manual. If your

vehicle has an Allison Transmission®, your owner’s

manual is supplemented by an Allison Transmission®

Operator’s Manual. Always refer to these manuals

for related maintenance services.

6-4

Page 339 of 398

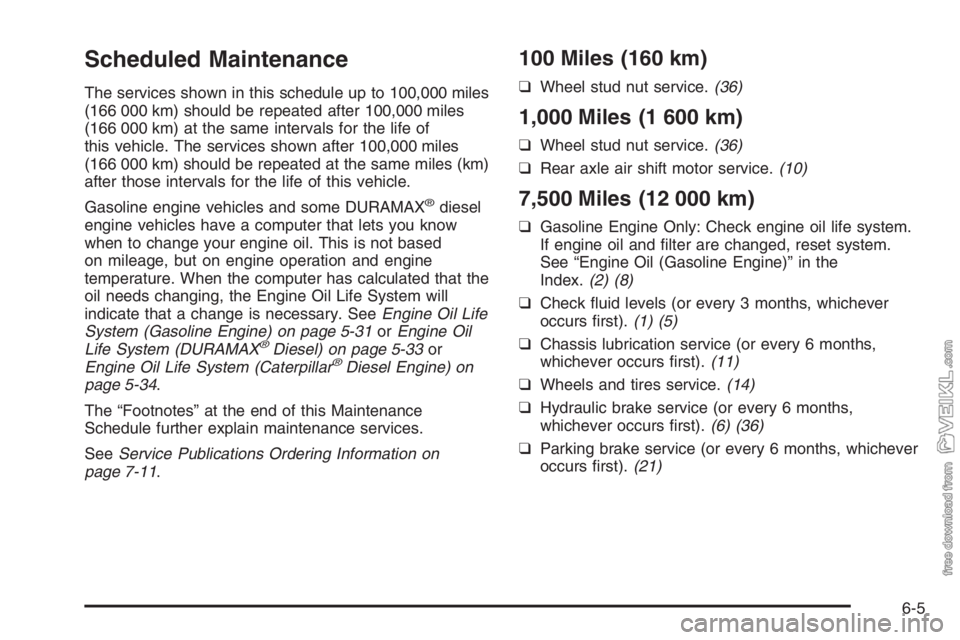

Scheduled Maintenance

The services shown in this schedule up to 100,000 miles

(166 000 km) should be repeated after 100,000 miles

(166 000 km) at the same intervals for the life of

this vehicle. The services shown after 100,000 miles

(166 000 km) should be repeated at the same miles (km)

after those intervals for the life of this vehicle.

Gasoline engine vehicles and some DURAMAX

®diesel

engine vehicles have a computer that lets you know

when to change your engine oil. This is not based

on mileage, but on engine operation and engine

temperature. When the computer has calculated that the

oil needs changing, the Engine Oil Life System will

indicate that a change is necessary. SeeEngine Oil Life

System (Gasoline Engine) on page 5-31orEngine Oil

Life System (DURAMAX

®Diesel) on page 5-33or

Engine Oil Life System (Caterpillar®Diesel Engine) on

page 5-34.

The “Footnotes” at the end of this Maintenance

Schedule further explain maintenance services.

SeeService Publications Ordering Information on

page 7-11.

100 Miles (160 km)

❑Wheel stud nut service.(36)

1,000 Miles (1 600 km)

❑Wheel stud nut service.(36)

❑Rear axle air shift motor service.(10)

7,500 Miles (12 000 km)

❑Gasoline Engine Only: Check engine oil life system.

If engine oil and filter are changed, reset system.

See “Engine Oil (Gasoline Engine)” in the

Index.(2) (8)

❑Check fluid levels (or every 3 months, whichever

occurs first).(1) (5)

❑Chassis lubrication service (or every 6 months,

whichever occurs first).(11)

❑Wheels and tires service.(14)

❑Hydraulic brake service (or every 6 months,

whichever occurs first).(6) (36)

❑Parking brake service (or every 6 months, whichever

occurs first).(21)

6-5

Page 356 of 398

Footnotes

† = The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

(1)= If your vehicle has an Allison Transmission

®, your

GM owner manual is supplemented by an Allison

Transmission

®Operator’s Manual. Always refer to these

manuals for related maintenance services.

(2)= An Emission Control Service.

(3)= A Noise Emission Control Device.

(4)= Applies to vehicles sold in the United States and is

recommended for vehicles sold in Canada.(5)= Check fluid level in brake master cylinder, power

steering pump, axle, transmission, and hydraulic

spring parking brake pump (if equipped). A low fluid

level in the brake master cylinder can indicate

worn brake linings and should be checked accordingly.

(6)= Inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, chafing, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect caliper assemblies. Check brake

pedal for excessive free play or travel (or every

6 months, whichever occurs first) and have serviced if

needed. Check brakes more often if driving habits

and conditions result in frequent braking.

(7)= This vehicle has the Engine Oil Life System. This

system will show you when to change the engine oil

and filter — usually between 3,000 miles (5 000 km) and

12,000 miles (20 000 km) since your last oil change.

Under severe conditions, the indicator may come

on before 3,000 miles (5 000 km). Never drive your

7.8L diesel engine vehicle more than 12,000 miles

(20 000 km), or 12 months, or 600 engine hours, without

an oil and filter change.

6-22

Page 359 of 398

(14)= Adjust tire pressures as indicated on the Gross

Vehicle Weight (GVW) Rating label for optimum tire life.

SeeTires on page 5-74for further details. Check

tires for excessive or abnormal wear or damage. Also

check for damaged wheels. Replace wheels and/or tires

as needed.

(15)= Check spring-to-axle U-bolts and shackle bolts

for proper torque. See the service manual for torque

sequence and specifications. When parts are replaced,

the torque must be checked and adjusted more often

during the first 6,000 miles (10 000 km). Check torque at

500 miles (800 km) and 2,000 miles (3 000 km) after

first use of parts.

(16)= Check complete exhaust system and cab areas

near the exhaust system for broken, damaged,

missing, or out-of-position parts. Also inspect for open

seams, holes, loose connections, or other conditions

which could let exhaust fumes seep into the driver

compartment. Needed repairs should be made at once.

To help maintain system integrity, replace exhaust

pipes whenever a new muffler is put on.

(17)= Check all gasoline engine drive belts for cracks,

fraying, and wear. Replace as needed.

(18)= Adjust valve lash. Incorrect valve clearance will

result in increased engine noise and reduced engine

output.(19)= With the engine off and below normal operating

temperature, check to see that the thermostatically

controlled engine cooling fan can be rotated by hand on

viscous-operated drives. Replace as needed.

(20)= Check shields and underhood insulation for

damage or looseness. Adjust or replace as needed.

(21)= Inspect parking brake drum and linings for wear

or cracks and check linkage and adjustment.

(22)= Wheel bearing service:

•Grease type — Clean, inspect, and lubricate with

the proper wheel bearing grease at designated

intervals or when hubs are removed. See

Part C: Recommended Fluids and Lubricants on

page 6-33.

•Oil-filled type — Some wheel bearings are

lubricated by axle lubricant. When you have oil-filled

hubs, use lubricant identical to that used in the

axle. Lubricant change intervals are the same for

front and rear axles. However, you must maintain

the proper oil level between change intervals.

SeeFront Wheel Bearings with Oil-Filled Hubs on

page 5-73andPart C: Recommended Fluids

and Lubricants on page 6-33.

6-25

Page 360 of 398

(23)= Check the air intake system installation to see

that gaskets are seated properly and all hose

connections, fasteners, and other components are tight.

Tighten connections and fasteners or replace parts

as required.

(24)= Evaporative Control System Service, if

equipped: Check all fuel and vapor lines and hoses

for proper connections and correct routing (or every

24 months, whichever occurs first). Replace parts

as needed.

(25)= Replace spark plugs. Inspect wires for damage.

Check the wire boot and boot heat shield fit at spark

plugs and coil. Replace parts as needed.

(26)= Check the fuel tank, fuel cap and fuel lines for

damage which could cause leakage. Inspect fuel cap for

correct sealing ability and any indications of damage.

Check fuel cap gasket for even filler neck imprint.

Replace parts as needed.

(27)= Check Exhaust Gas Recirculation (EGR) system

as described in the service manual. SeeService

Publications Ordering Information on page 7-11.

(28)= Inspect Electronic Vacuum Regulator Valve

(EVRV) filter for excessive contamination or plugging.

If needed, clean filter with solution of soap and water, let

dry and install.(29)= Drain, flush, and refill cooling system. This

service can be complex; you should have your dealer

perform this service. SeePart C: Recommended Fluids

and Lubricants on page 6-33for what to use. Inspect

hoses. Clean radiator, condenser, pressure cap,

and neck. Pressure test cooling system and pressure

cap. For Caterpillar

®diesel engines, always refer to the

Caterpillar®Diesel Engine Operation & Maintenance

Manual for coolant recommendations and change

intervals.

(30)= Change the lubricant. SeePart C: Recommended

Fluids and Lubricants on page 6-33.

(31)= Front axle service: Re-pack upper kingpin roller

bearing.

(32)= Air brake service:

•Inspect brake lines and hoses for proper hook-up,

binding, leaks, cracks, chafing, etc. Inspect drum

brake linings for wear or cracks. Inspect other brake

parts at each wheel, including drums and wheel

speed sensor wiring. Check brake pedal for

excessive free play or travel (or every 6 months,

whichever occurs first) and have serviced if needed.

Check brakes more often if driving habits and

conditions result in frequent braking. Replace air

dryer cartridge only if excessive oil or moisture

is present. A small amount of oil in the system is

normal and should not be considered as a reason to

replace the cartridge.

6-26

Page 362 of 398

Part B: Owner Checks and Services

Listed in this part are owner checks and services

which should be performed at the intervals specified to

help ensure the safety, dependability and emission

control performance of your vehicle.

For your safety and that of others, any of the

safety-related components that may have been

damaged in an accident should be checked and any

needed repairs made before operating the vehicle.

At the minimum, these routine checks should be made

every 6 months or 6,000 miles (10 000 km), whichever

occurs first. Whenever repairs are needed, have

them completed before operating the vehicle.

At Each Fuel Fill

It is important for you or a service station attendant to

perform these underhood checks at each fuel �ll.

Engine Oil Level Check

Check the engine oil level and add the proper oil if

necessary. SeeEngine Oil (Caterpillar®Diesel Engine)

on page 5-24orEngine Oil (DURAMAX®Diesel) on

page 5-24orEngine Oil (Gasoline Engine) on page 5-28

for further details.

Engine Coolant Level Check

Check the engine coolant level and add DEX-COOL®

coolant mixture if necessary. SeeEngine Coolant

(Gas and DURAMAX®Engines) on page 5-38orEngine

Coolant (Caterpillar®Diesel Engines) on page 5-40

for further details.

Windshield Washer Fluid Level Check

Check the windshield washer fluid level in the windshield

washer fluid reservoir and add the proper fluid if

necessary. SeeWindshield Washer Fluid on page 5-48

for further details.

6-28