fuel cap CHEVROLET KODIAK 2008 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2008, Model line: KODIAK, Model: CHEVROLET KODIAK 2008Pages: 384, PDF Size: 5.4 MB

Page 315 of 384

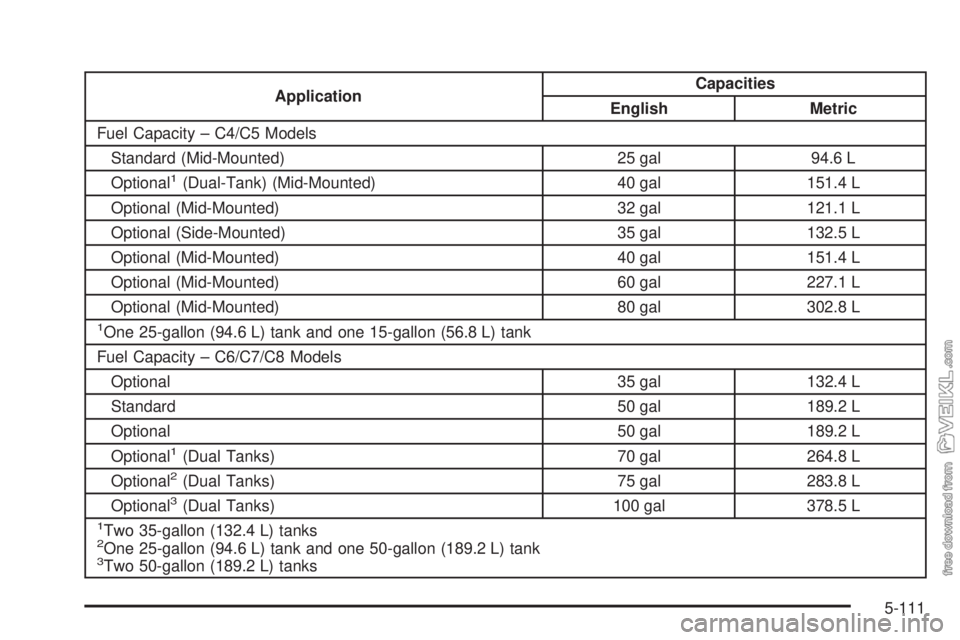

ApplicationCapacities

English Metric

Fuel Capacity – C4/C5 Models

Standard (Mid-Mounted) 25 gal 94.6 L

Optional

1(Dual-Tank) (Mid-Mounted) 40 gal 151.4 L

Optional (Mid-Mounted) 32 gal 121.1 L

Optional (Side-Mounted) 35 gal 132.5 L

Optional (Mid-Mounted) 40 gal 151.4 L

Optional (Mid-Mounted) 60 gal 227.1 L

Optional (Mid-Mounted) 80 gal 302.8 L

1One 25-gallon (94.6 L) tank and one 15-gallon (56.8 L) tank

Fuel Capacity – C6/C7/C8 Models

Optional 35 gal 132.4 L

Standard 50 gal 189.2 L

Optional 50 gal 189.2 L

Optional

1(Dual Tanks) 70 gal 264.8 L

Optional

2(Dual Tanks) 75 gal 283.8 L

Optional

3(Dual Tanks) 100 gal 378.5 L

1Two 35-gallon (132.4 L) tanks2One 25-gallon (94.6 L) tank and one 50-gallon (189.2 L) tank3Two 50-gallon (189.2 L) tanks

5-111

Page 318 of 384

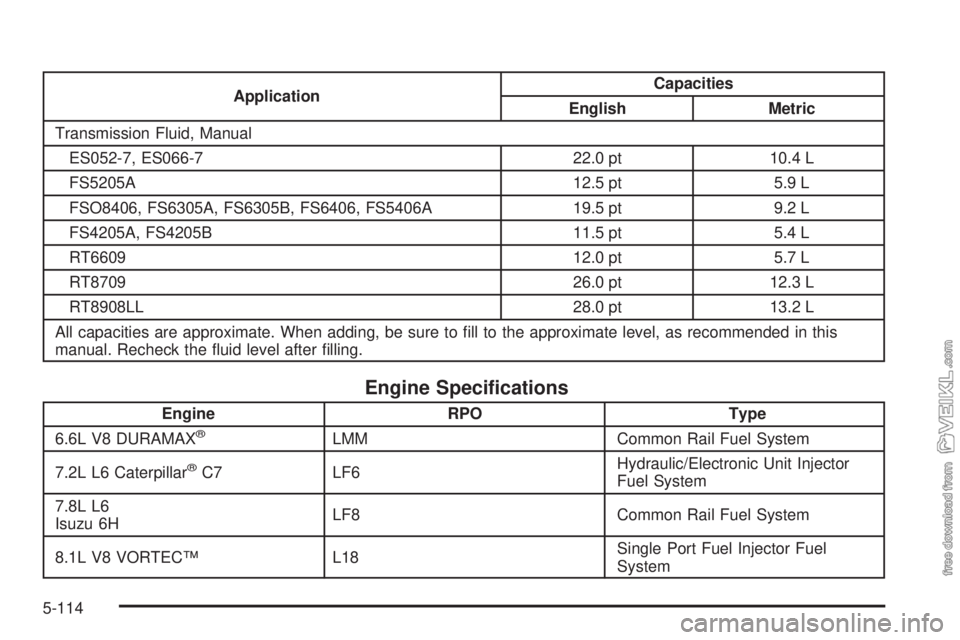

ApplicationCapacities

English Metric

Transmission Fluid, Manual

ES052-7, ES066-7 22.0 pt 10.4 L

FS5205A 12.5 pt 5.9 L

FSO8406, FS6305A, FS6305B, FS6406, FS5406A 19.5 pt 9.2 L

FS4205A, FS4205B 11.5 pt 5.4 L

RT6609 12.0 pt 5.7 L

RT8709 26.0 pt 12.3 L

RT8908LL 28.0 pt 13.2 L

All capacities are approximate. When adding, be sure to fill to the approximate level, as recommended in this

manual. Recheck the fluid level after filling.

Engine Speci�cations

Engine RPO Type

6.6L V8 DURAMAX

®LMM Common Rail Fuel System

7.2L L6 Caterpillar

®C7 LF6Hydraulic/Electronic Unit Injector

Fuel System

7.8L L6

Isuzu 6HLF8 Common Rail Fuel System

8.1L V8 VORTEC™ L18Single Port Fuel Injector Fuel

System

5-114

Page 334 of 384

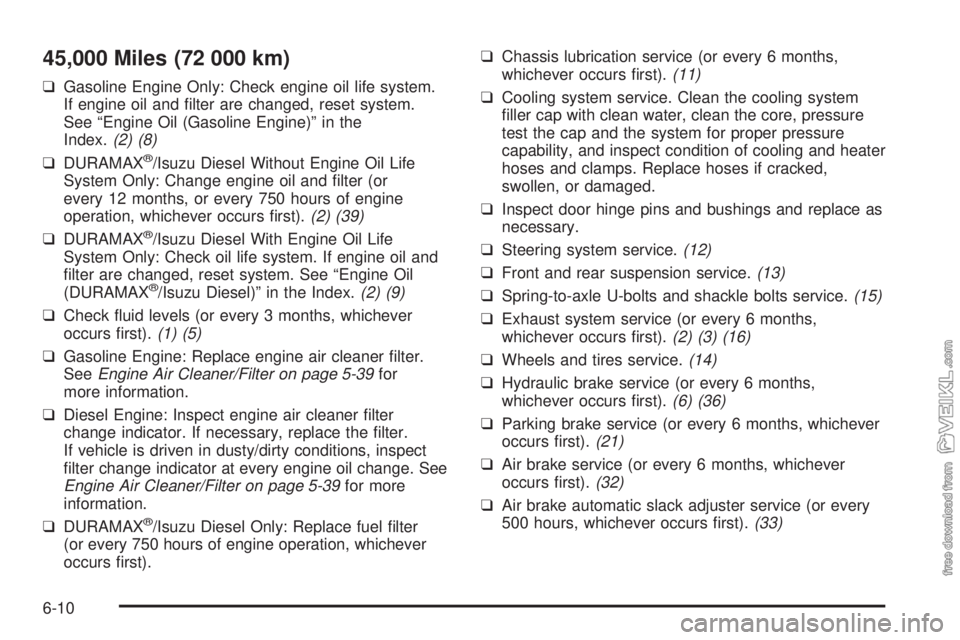

45,000 Miles (72 000 km)

❑Gasoline Engine Only: Check engine oil life system.

If engine oil and filter are changed, reset system.

See “Engine Oil (Gasoline Engine)” in the

Index.(2) (8)

❑DURAMAX

®/Isuzu Diesel Without Engine Oil Life

System Only: Change engine oil and filter (or

every 12 months, or every 750 hours of engine

operation, whichever occurs first).(2) (39)

❑DURAMAX

®/Isuzu Diesel With Engine Oil Life

System Only: Check oil life system. If engine oil and

filter are changed, reset system. See “Engine Oil

(DURAMAX

®/Isuzu Diesel)” in the Index.(2) (9)

❑Check fluid levels (or every 3 months, whichever

occurs first).(1) (5)

❑Gasoline Engine: Replace engine air cleaner filter.

SeeEngine Air Cleaner/Filter on page 5-39for

more information.

❑Diesel Engine: Inspect engine air cleaner filter

change indicator. If necessary, replace the filter.

If vehicle is driven in dusty/dirty conditions, inspect

filter change indicator at every engine oil change. See

Engine Air Cleaner/Filter on page 5-39for more

information.

❑DURAMAX

®/Isuzu Diesel Only: Replace fuel filter

(or every 750 hours of engine operation, whichever

occurs first).❑Chassis lubrication service (or every 6 months,

whichever occurs first).(11)

❑Cooling system service. Clean the cooling system

filler cap with clean water, clean the core, pressure

test the cap and the system for proper pressure

capability, and inspect condition of cooling and heater

hoses and clamps. Replace hoses if cracked,

swollen, or damaged.

❑Inspect door hinge pins and bushings and replace as

necessary.

❑Steering system service.(12)

❑Front and rear suspension service.(13)

❑Spring-to-axle U-bolts and shackle bolts service.(15)

❑Exhaust system service (or every 6 months,

whichever occurs first).(2) (3) (16)

❑Wheels and tires service.(14)

❑Hydraulic brake service (or every 6 months,

whichever occurs first).(6) (36)

❑Parking brake service (or every 6 months, whichever

occurs first).(21)

❑Air brake service (or every 6 months, whichever

occurs first).(32)

❑Air brake automatic slack adjuster service (or every

500 hours, whichever occurs first).(33)

6-10

Page 339 of 384

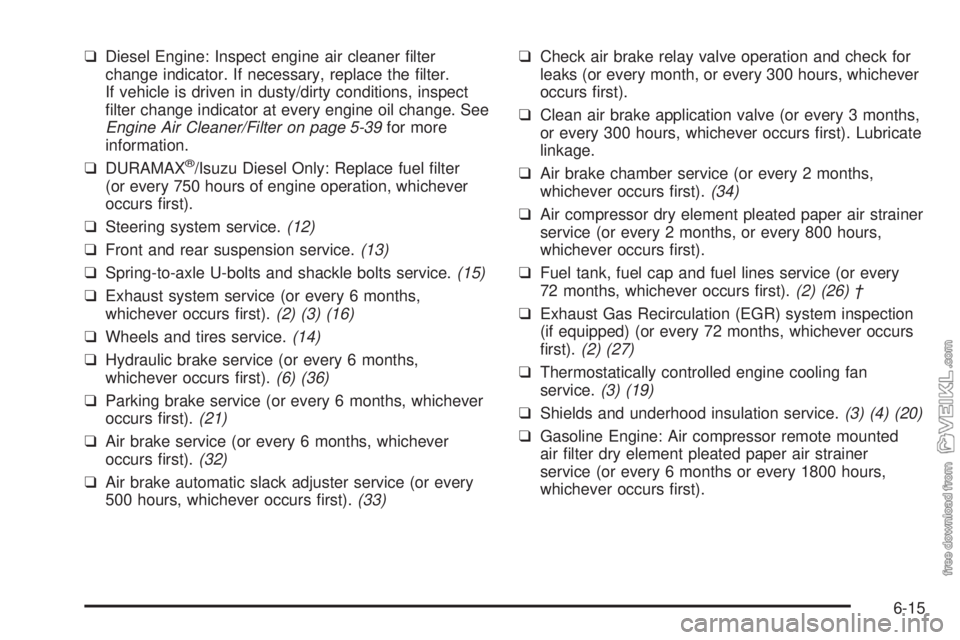

❑Diesel Engine: Inspect engine air cleaner filter

change indicator. If necessary, replace the filter.

If vehicle is driven in dusty/dirty conditions, inspect

filter change indicator at every engine oil change. See

Engine Air Cleaner/Filter on page 5-39for more

information.

❑DURAMAX

®/Isuzu Diesel Only: Replace fuel filter

(or every 750 hours of engine operation, whichever

occurs first).

❑Steering system service.(12)

❑Front and rear suspension service.(13)

❑Spring-to-axle U-bolts and shackle bolts service.(15)

❑Exhaust system service (or every 6 months,

whichever occurs first).(2) (3) (16)

❑Wheels and tires service.(14)

❑Hydraulic brake service (or every 6 months,

whichever occurs first).(6) (36)

❑Parking brake service (or every 6 months, whichever

occurs first).(21)

❑Air brake service (or every 6 months, whichever

occurs first).(32)

❑Air brake automatic slack adjuster service (or every

500 hours, whichever occurs first).(33)❑Check air brake relay valve operation and check for

leaks (or every month, or every 300 hours, whichever

occurs first).

❑Clean air brake application valve (or every 3 months,

or every 300 hours, whichever occurs first). Lubricate

linkage.

❑Air brake chamber service (or every 2 months,

whichever occurs first).(34)

❑Air compressor dry element pleated paper air strainer

service (or every 2 months, or every 800 hours,

whichever occurs first).

❑Fuel tank, fuel cap and fuel lines service (or every

72 months, whichever occurs first).(2) (26) †

❑Exhaust Gas Recirculation (EGR) system inspection

(if equipped) (or every 72 months, whichever occurs

first).(2) (27)

❑Thermostatically controlled engine cooling fan

service.(3) (19)

❑Shields and underhood insulation service.(3) (4) (20)

❑Gasoline Engine: Air compressor remote mounted

air filter dry element pleated paper air strainer

service (or every 6 months or every 1800 hours,

whichever occurs first).

6-15

Page 341 of 384

❑Chassis lubrication service (or every 6 months,

whichever occurs first).(11)

❑Cooling system service. Clean the cooling system

filler cap with clean water, clean the core, pressure

test the cap and the system for proper pressure

capability, and inspect condition of cooling and heater

hoses and clamps. Replace hoses if cracked,

swollen, or damaged.

❑Replace fuel filter(s) (or every 12 months, whichever

occurs first).(2)

❑Check restraint system.(40)

❑Steering system service.(12)

❑Front and rear suspension service.(13)

❑Spring-to-axle U-bolts and shackle bolts service.(15)

❑Exhaust system service (or every 6 months,

whichever occurs first).(2) (3) (16)

❑Inspect door hinge pins and bushings and replace as

necessary.

❑Wheel bearing (grease type) service (and whenever

hubs are removed).(22) (36)

❑Wheels and tires service.(14)

❑Hydraulic brake service (or every 6 months,

whichever occurs first).(6) (36)

❑Parking brake service (or every 6 months, whichever

occurs first).(21)❑Air brake service (or every 6 months, whichever

occurs first).(32)

❑Air brake automatic slack adjuster service (or every

500 hours, whichever occurs first).(33)

❑Check air brake relay valve operation and check for

leaks (or every month, or every 300 hours, whichever

occurs first).

❑Clean air brake application valve (or every 3 months,

or every 300 hours, whichever occurs first). Lubricate

linkage.

❑Air brake chamber service (or every 2 months,

whichever occurs first).(34)

❑Air brake system valve service (or every 3 months,

or every 900 hours, whichever occurs first).(37)

❑Air compressor dry element pleated paper air strainer

service (or every 2 months, or every 800 hours,

whichever occurs first).

❑C600, C700, and C800 Gasoline Engines Only:

Engine drive belts service (or every 12 months,

whichever occurs first).(17)

❑Thermostatically controlled engine cooling fan

service.(3) (19)

❑Shields and underhood insulation service.(3) (4) (20)

❑Rear axle air shift motor service.(10)

❑Air intake system service (or every 24 months,

whichever occurs first).(3) (4) (23)

6-17

Page 347 of 384

(21)= Inspect parking brake drum and linings for wear

or cracks and check linkage and adjustment.

(22)= Wheel bearing service:

•Grease type — Clean, inspect, and lubricate with

the proper wheel bearing grease at designated

intervals or when hubs are removed. SeePart C:

Recommended Fluids and Lubricants on page 6-31.

•Oil-filled type — Some wheel bearings are

lubricated by axle lubricant. When you have oil-filled

hubs, use lubricant identical to that used in the

axle. Lubricant change intervals are the same for

front and rear axles. However, you must maintain

the proper oil level between change intervals.

SeeFront Wheel Bearings with Oil-Filled Hubs on

page 5-81andPart C: Recommended Fluids

and Lubricants on page 6-31.

(23)= Check the air intake system installation to see

that gaskets are seated properly and all hose

connections, fasteners, and other components are tight.

Tighten connections and fasteners or replace parts as

required.

(24)= Evaporative Control System Service, if equipped:

Check all fuel and vapor lines and hoses for proper

connections and correct routing (or every 24 months,

whichever occurs first). Replace parts as needed.(25)= Replace spark plugs. Inspect wires for damage.

Check the wire boot and boot heat shield fit at spark

plugs and coil. Replace parts as needed.

(26)= Check the fuel tank, fuel cap and fuel lines for

damage which could cause leakage. Inspect fuel cap for

correct sealing ability and any indications of damage.

Check fuel cap gasket for even filler neck imprint.

Replace parts as needed.

(27)= Check Exhaust Gas Recirculation (EGR) system

as described in the service manual. SeeService

Publications Ordering Information on page 7-10.

(28)= Inspect Electronic Vacuum Regulator Valve

(EVRV) filter for excessive contamination or plugging.

If needed, clean filter with solution of soap and water, let

dry and install.

(29)= Drain, flush, and refill cooling system. This

service can be complex; you should have your

dealer/retailer perform this service. SeePart C:

Recommended Fluids and Lubricants on page 6-31for

what to use. Inspect hoses. Clean radiator, condenser,

pressure cap, and neck. Pressure test cooling system

and pressure cap. For Caterpillar

®diesel engines,

always refer to the Caterpillar®Diesel Engine

Operation & Maintenance Manual for coolant

recommendations and change intervals.

6-23

Page 374 of 384

Audio System(s).............................................3-48

Automatic Transmission

Fluid..........................................................5-43

Operation...................................................2-29

B

Battery..........................................................5-66

Bench Seat, Split............................................. 1-6

Brake

Diesel Engine Exhaust.................................2-26

Emergencies................................................ 4-5

Exhaust Indicator Light.................................3-40

Trailer Hand Control Valve.............................. 4-6

Brakes..........................................................5-57

Hydraulic Systems......................................... 4-4

Parking Brake Burnish Procedure...................2-43

System Warning Light..................................3-32

Braking........................................................... 4-4

Braking in Emergencies..................................... 4-5

Break-In, New Vehicle.....................................2-10

Bucket Seats................................................... 1-2

Bulb Replacement...........................................5-76

Buying New Tires...........................................5-85

C

California Perchlorate Materials Requirements....... 5-5

California Proposition 65 Warning....................... 5-5Capacities and Specifications..........................5-109

Carbon Monoxide...................................2-45, 4-16

Care of

Safety Belts................................................5-96

Center Console Storage Area...........................2-53

Change Fuel Filter Warning Light......................3-44

Charging System Light....................................3-30

Check

Engine Light...............................................3-36

Gages Warning Light...................................3-42

Checking Things Under the Hood......................5-22

Chemical Paint Spotting.................................5-100

Child Restraints

Child Restraint Systems...............................1-35

Infants and Young Children...........................1-31

Lower Anchors and Tethers for Children..........1-40

Older Children.............................................1-28

Securing a Child Restraint in a Rear Outside

Seat Position...........................................1-40

Securing a Child Restraint in the Center Front

Seat Position...........................................1-44

Securing a Child Restraint in the Center Rear

Seat Position...........................................1-42

Securing a Child Restraint in the Right Front

Seat Position...........................................1-44

Where to Put the Restraint...........................1-38

Chime Level Adjustment..................................3-58

Cigarette Lighter.............................................3-20

2

Page 375 of 384

Cleaning

Aluminum or Chrome-Plated Wheels..............5-98

Exterior Lamps/Lenses.................................5-97

Fabric/Carpet..............................................5-95

Finish Care.................................................5-97

Instrument Panel, Vinyl, and Other Plastic

Surfaces.................................................5-96

Interior.......................................................5-94

Tires..........................................................5-99

Underbody Maintenance.............................5-100

Washing Your Vehicle...................................5-97

Weatherstrips..............................................5-96

Windshield and Wiper Blades........................5-98

Climate Control System...................................3-20

Outlet Adjustment........................................3-23

Rear Heating System...................................3-24

Clock, Setting.................................................3-48

Collision Damage Repair................................... 7-6

Control of a Vehicle.......................................... 4-3

Coolant

Engine Temperature Gage............................3-35

Heater, Engine............................................2-25

Low Warning Light.......................................3-35

Surge Tank Pressure Cap.............................5-47

Cooling System..............................................5-50

Cruise Control................................................3-10

Customer Assistance Information

Customer Assistance for Text

Telephone (TTY) Users............................... 7-3

Customer Assistance Offices........................... 7-4Customer Assistance Information (cont.)

Customer Satisfaction Procedure..................... 7-2

GM Mobility Reimbursement Program............... 7-5

Reporting Safety Defects to General Motors...... 7-9

Reporting Safety Defects to the Canadian

Government.............................................. 7-9

Reporting Safety Defects to the United

States Government.................................... 7-9

Roadside Assistance Program......................... 7-5

Service Publications Ordering Information........7-10

D

Daytime Running Lamps..................................3-15

Daytime Running Lamps Indicator Light.............3-41

Defensive Driving............................................. 4-2

Diesel

Running Out of Fuel....................................2-50

Diesel Engine.................................................2-26

Engine Alarm and Automatic Shutdown...........2-18

Exhaust Restrictor.......................................2-22

Fuel............................................................ 5-9

High Idle System.........................................2-20

Starting......................................................2-14

Diesel Particulate Filter....................................2-46

Diesel Particulate Filter Warning Light................3-45

Differential Lock Control, Rear Axle..................... 4-7

Differential Lock Indicator Light.........................3-40

Doing Your Own Service Work........................... 5-6

3