brake fluid CHEVROLET LOW CAB FORWARD 2019 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2019, Model line: LOW CAB FORWARD, Model: CHEVROLET LOW CAB FORWARD 2019Pages: 382, PDF Size: 5.95 MB

Page 214 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

Driving and Operating 213

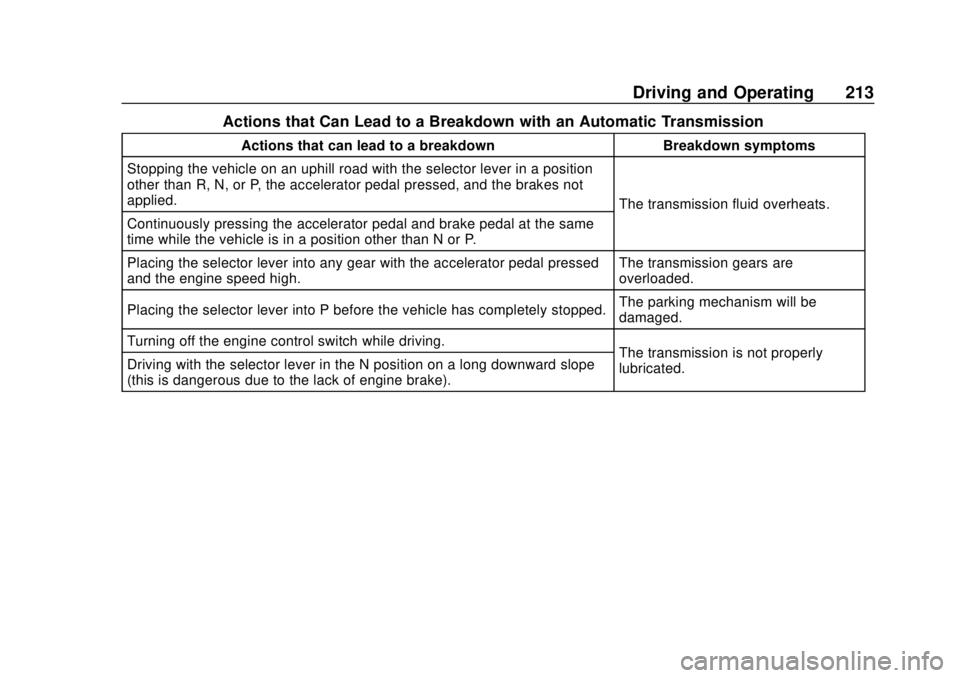

Actions that Can Lead to a Breakdown with an Automatic Transmission

Actions that can lead to a breakdownBreakdown symptoms

Stopping the vehicle on an uphill road with the selector lever in a position

other than R, N, or P, the accelerator pedal pressed, and the brakes not

applied. The transmission fluid overheats.

Continuously pressing the accelerator pedal and brake pedal at the same

time while the vehicle is in a position other than N or P.

Placing the selector lever into any gear with the accelerator pedal pressed

and the engine speed high. The transmission gears are

overloaded.

Placing the selector lever into P before the vehicle has completely stopped. The parking mechanism will be

damaged.

Turning off the engine control switch while driving. The transmission is not properly

lubricated.

Driving with the selector lever in the N position on a long downward slope

(this is dangerous due to the lack of engine brake).

Page 240 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

Vehicle Care 239

Vehicle Care

General Information

General Information . . . . . . . . . . 240

California Proposition65 Warning . . . . . . . . . . . . . . . . . 240

California Perchlorate Materials Requirements . . . . . 240

Accessories and Modifications . . . . . . . . . . . . . . . . 240

Vehicle Checks

Doing Your OwnService Work . . . . . . . . . . . . . . . 241

Cab Tilting . . . . . . . . . . . . . . . . . . . . 243

Engine Compartment Overview . . . . . . . . . . . . . . . . . . . . 244

Engine Cover . . . . . . . . . . . . . . . . . 245

Engine Oil . . . . . . . . . . . . . . . . . . . . 245

Automatic Transmission Fluid . . . . . . . . . . . . . . . . . . . . . . . . 251

Engine Air Cleaner/Filter . . . . . . 253

Engine Coolant . . . . . . . . . . . . . . . 253

Engine Overheating . . . . . . . . . . 259

Power Steering Fluid . . . . . . . . . 262

Washer Fluid . . . . . . . . . . . . . . . . . 262

Brakes . . . . . . . . . . . . . . . . . . . . . . . 263

Brake Fluid . . . . . . . . . . . . . . . . . . . 268

Battery - North America . . . . . . 269 Fuel Filter . . . . . . . . . . . . . . . . . . . . 270

Rear Axle (Gear Oil Viscosity

Chart) . . . . . . . . . . . . . . . . . . . . . . . 271

Rear Axle (Oil Level Check) . . . . . . . . . . . . . . . . . . . . . . 272

Noise Control System . . . . . . . . 272

Automatic Transmission Shift Lock Control Function

Check . . . . . . . . . . . . . . . . . . . . . . . 274

Wiper Blade Replacement . . . . 275

Headlamp Aiming

Headlamp Aiming . . . . . . . . . . . . 277

Bulb Replacement

Bulb Replacement . . . . . . . . . . . . 277

Headlamps and Front Turn Signal . . . . . . . . . . . . . . . . . . . . . . . 280

Roofmarker Lamps . . . . . . . . . . . 284

Sidemarker Lamps (Including Turn Signal and Cornering

Lamps) . . . . . . . . . . . . . . . . . . . . . . 284

Taillamps, Turn Signal, Stoplamps, and Back-Up

Lamps . . . . . . . . . . . . . . . . . . . . . . 286

License Plate Lamp . . . . . . . . . . 286

Interior Lamps . . . . . . . . . . . . . . . . 287

Electrical System

Electrical System Overload . . . 287

Wheels and Tires

Wheels and Tires . . . . . . . . . . . . . 295

Tire Pressure . . . . . . . . . . . . . . . . . 307

Tire Rotation . . . . . . . . . . . . . . . . . 307

If a Tire Goes Flat . . . . . . . . . . . . 310

Jump Starting

Jump Starting - North America . . . . . . . . . . . . . . . . . . . . . 311

Towing the Vehicle

Towing the Vehicle . . . . . . . . . . . 315

Appearance Care

Exterior Care . . . . . . . . . . . . . . . . . 317

Interior Care . . . . . . . . . . . . . . . . . . 323

Page 243 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

242 Vehicle Care

chock the wheels. It would be very

dangerous if the vehicle started

to move.

When performing work on the

electrical system, begin by turning

the engine control switch to the

"LOCK" position, wait at least

3 minutes, and then disconnect the

negative cable from the negative

terminal on battery. If the negative

cable is disconnected within

3 minutes, the engine control

module may malfunction.

When working on the fuel line or

fuel filter, remove the fuel tank filler

cap. The fuel system is under

pressure and the fuel will overspill

unless the pressure is relieved,

possibly leading to combustion or

a fire.

Do not make engine adjustments

yourself. Be sure to consult your

dealer.

Use only appropriate tools.Oils, brake fluid and engine coolant

have lubrication, cooling and rust

prevention functions. If these liquids

deteriorate through loss or

contamination, it will cause a

decline in the performance of the

parts and such problems as seizure

or malfunctioning. Replenish or

change these liquids when

performing the checks (daily and

periodic checks) as required by the

relevant regulations or in

accordance with the Maintenance

Schedule (when either the specified

driving distance or period of time,

whichever comes first, has expired).

Confirm that all systems and

components are normal after

performing the work.

Do not leave the removed parts or

tools in the engine compartment.

They could damage the equipment if

caught in the belts or other moving

components.

Dirty water, dirt and other impurities

seriously impair the effectiveness of

the oil, grease and fluids, and

damage the parts. Exercise all due

caution to prevent waste or otherrefuse from coming in contact with

parts or materials that have been

removed when changing or

replenishing them.

Do not step on the engine or climb

onto it. You could cause an engine

failure by, for example, damaging

the cylinder head cover or various

connectors.

Electric Welding

Careless electric welding of vehicle

parts can cause welding current to

flow back through the vehicle’s

ground circuit and damage electrical

and electronic parts so that they do

not function normally. Whenever

electric welding is necessary,

consult your dealer.

Page 253 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

252 Vehicle Care

For the crew cab vehicle, the

dipstick is located beneath the

rear-of-engine inspection panel.

After unlatching the A/T fluid

inspection cover, the dipstick will be

visible.

Inspection

Wait at least 30 minutes before

checking the transmission fluid if

you have been driving at high speed

for a long period of time, in city/

heavy traffic or while pulling a trailer.1. Start the engine, and drive the vehicle for approximately

10 minutes to warm up the

engine. During 10 minutes, the automatic transmission fluid

should reach a temperature of

approximately 70 - 80 °C (158 -

176 °F). During the winter

when temperatures are low,

adjust the amount of driving

time according to the actual

conditions.

2. Park the vehicle on level ground, and firmly apply the

parking brake.

3. With the engine idling, move the selector lever from the “P”

position to the “1”position

while pressing the brake pedal,

and then return the lever from

the “1”position to the “P”

position.

4. With the engine still idling, pull out the dipstick and wipe it with

a clean cloth.Transmission Dipstick

5. Reinsert the dipstick into position, pull out the dipstick

slowly, and check whether the

fluid level is within the “H”

marked range. Always check

the fluid level at least twice.

Consistently is important in

maintaining accuracy.

If inconsistent readings persist,

check the transmission

breather to ensure that it is

clean and free of debris.

. Dipstick C (COLD) —

Transmission fluid

temperature Approx. 20 -

30 °C (68 - 86 °F).

Page 264 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

Vehicle Care 263

properly wiped. At this time, also

check the spraying condition of the

windshield washer.

Inspect the washer fluid level

regularly, especially during bad

weather conditions.

Use a high quality premixed solvent

available at most dealers or service

stations.

Avoid hard water when mixing

windshield washer solvents. Hard

water contaminants may plug

orifices in the washer system and

reduce performance.

Do not use radiator antifreeze in the

windshield washer; it could cause

cab paint damage.

In cold weather, warm the

windshield with the defrosters

before using the washer, to help

prevent icing that may block the

driver's vision.Refilling Windshield Washer

Fluid

1. The windshield washer fluidtank (1) is located under the

instrument panel on the

passenger side.

2. Open the cap (2) and fill the tank with windshield washer

fluid.

Upon factory shipment, new

vehicles contain only tap water in

the washer fluid tank. Adjust the

concentration of the fluid to suit your

own usage. Follow the instructions provided with

the windshield washer fluid

regarding the ratio for mixing with

tap water.

Poor quality products, engine

coolant, and soapy water must not

be used. Failure to observe this

precaution can result in nozzle

blockage or damage to painted

surfaces.

The washer should never be used

while the tank is empty. Operating

the washer with the tank empty can

result in motor damage.Brakes

For the most effective braking and

for maximum life from brake system

components, follow these

suggestions:

.

Keep any obstructions from

interfering with brake pedal

travel.

. Keep tires properly inflated.

Improperly inflated tires can

reduce the efficiency of the

brakes.

Page 266 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

Vehicle Care 265

Another characteristic of the HBB

system is that the brake pedal may

be pressed easily to the floor with

the vehicle at a stop. This is not a

sign of malfunction.

When the engine is running, the

system automatically charges the

accumulator whenever pressure has

been reduced after braking. Auto

charge may be activated without

braking, depending on temperature

changes in the accumulator. During

auto charge, a hissing and clicking

sound can be heard. This is not a

malfunction.

With the engine running, a booming

sound can be heard during hard

braking. This comes from the

brake-fluid pump. It is not a

malfunction.

Applying continuous hard braking

for a long time will lead to

considerable temperature rise in the

HBB pump. Such overworking of the

brakes is best avoided.Vacuum or hydraulic power

assisted brakes

If the engine stops, do not pump the

brakes. The system is designed to

stop the vehicle with reserve power

assist if the brake pedal is held

down. This reserve is greatly

reduced each time you apply and

release the brakes. If, when you

turn the steering wheel during

braking, the vehicle does not turn,

release some pressure from the

brake pedal.

In a Vehicle Equipped with an

HBB, Do Not Keep the Brake

Pedal Pressed for an Extended

Period

Caution

Failure to follow the above

instruction will cause the oil inside

the HBB oil pump to get very hot.

This could damage the HBB tank

and deteriorate seals and also

could cause damage to the HBB

oil pump, HBB unit and/or HBB

(Continued)

Caution (Continued)

hosing. Eventual leakage of HBB

oil, sudden increase in brake

pedal resistance and fire could

unexpectedly result in a crash.

Hydraulic Brake Booster (HBB)

Fluid (5500HD/5500XD Series)

The HBB system has been

designed to use Dexron VI ATF

fluid. If any other fluid is used with

this system, rubber components

may be damaged, oil may leak and

the system may malfunction. It is

important to remember that the fluid

used in the hydro-booster is

completely different in

characteristics from the brake fluid

used in the master and wheel

cylinders.

If hydro-booster fluid and brake fluid

from the master cylinder are

mistakenly mixed together and

used, rubber components will

deteriorate as a result of insufficient

lubrication. Any resultant oil leakage

or system malfunction can in turn

Page 267 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

266 Vehicle Care

lead to dragging brakes or other

major brake problems. As such,

mixing of these two fluids can

ultimately lead to vehicle fire or

other serious crashes.

When the pump operates while the

engine is running, the fluid in the

hydro-booster will become hot.

During normal braking, the

temperature in piping and within the

hydro-booster can rise above 100 °

C (212 °F). For this reason, special

care will be required when working

with hydro-booster components.

If the hydro-booster is to be

removed from the vehicle, shut off

the engine and then allow at least

30 minutes for it to cool down before

beginning this operation.

Even when the engine is stopped,

the hydro-booster's accumulator will

remain in a highly-pressurized

condition for a significant period of

time. Before removing the

hydro-booster or piping from the

vehicle, stop the engine and press

the brake pedal at least 10 times in

order to lower the accumulator

pressure to atmospheric pressure.This is of particular importance

when removing components such

as the accumulator or pressure

switch from the hydro-booster.

If these operations are attempted

while the accumulator is still at a

high pressure, hydro-booster fluid

may spray out.

Checking the Hydro-booster Fluid

Level

Check the hydro-booster fluid level

and change the fluid according to

the Maintenance Schedule.

The hydro-booster fluid level is

correct if it is between the "MAX"

and "MIN" lines. If the level is too

low, add fluid up to the "MAX" line.

Be sure to use Dexron VI ATF fluid

when adding fluid. The brake

booster reservoir is located behind

the cab on the left side.

Brake Pedal

Stroke

Shut off the engine and press the

brake pedal about 10 times strongly,

then check the brake pedal for free

play by lightly pushing it by hand

until you feel resistance.

Page 269 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

268 Vehicle Care

free of any type of damage. Check

the right front brake hose and pipe

in the same way. The rear left and

right brake hoses and pipes should

also be checked in the same

manner.

Disc Brakes and Drum Brakes

If the brake pads and shoe linings

wear out beyond their usable limit,

not only will the brake performance

be impaired, but brake components

could also fail.

{Warning

Do not drive with brake pads and

shoe linings worn out beyond the

limit. Excessively worn brake

pads and shoe linings may cause

breakdown of brake components

and poor braking performance.

You and others could be seriously

injured.

Caution

The pad has an embedded wear

indicator. A squeaking noise from

the indicator means that the pad

is approaching the usable limit.

If the squeaking noise from the

indicator can be heard, contact

the nearest dealer for inspection

or replacement.

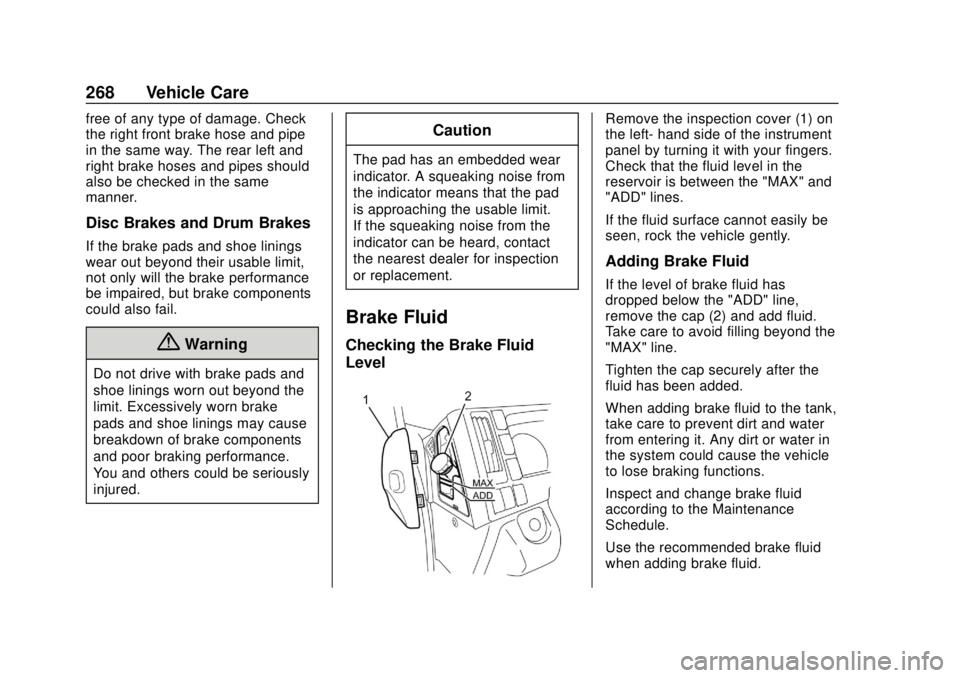

Brake Fluid

Checking the Brake Fluid

Level

Remove the inspection cover (1) on

the left- hand side of the instrument

panel by turning it with your fingers.

Check that the fluid level in the

reservoir is between the "MAX" and

"ADD" lines.

If the fluid surface cannot easily be

seen, rock the vehicle gently.

Adding Brake Fluid

If the level of brake fluid has

dropped below the "ADD" line,

remove the cap (2) and add fluid.

Take care to avoid filling beyond the

"MAX" line.

Tighten the cap securely after the

fluid has been added.

When adding brake fluid to the tank,

take care to prevent dirt and water

from entering it. Any dirt or water in

the system could cause the vehicle

to lose braking functions.

Inspect and change brake fluid

according to the Maintenance

Schedule.

Use the recommended brake fluid

when adding brake fluid.

Page 270 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

Vehicle Care 269

Never mix the specified brake fluid

with fluids of another brand.

Be careful not to spill brake fluid

onto painted surfaces or to let it

come in contact with skin. If fluid is

spilled onto a painted surface or

comes in contact with skin, wash

away the fluid with water and

immediately wipe the area clean.

Brake fluid readily absorbs moisture.

Therefore, it is necessary to close

the brake fluid container tightly for

storage.

If the brake fluid level decreases

rapidly, there may be a problem in

the brake system or brake pads or

shoe linings may have worn out.

Have your vehicle inspected by the

nearest dealer immediately.Battery - North America

Working Near Battery

The batteries are located on the

outboard side of the left frame rail,

behind the cab. The batteries are in

a carrier with the cover (2) retained

by spring clips (1).

{Danger

Follow the precautions listed in

the jump starting Danger (see

"When the Battery is Discharged")(Continued)

Danger (Continued)

when working on or near the

battery. Personal injury

(particularly to eyes) or property

damage may result from battery

explosion, battery fluid or

electrical (short circuit) burns. You

and others could be seriously

injured or killed.

If the negative cable is disconnected

from the negative terminal on the

battery within 3 minutes after turning

the engine control switch to the

"LOCK" position, the engine control

module may malfunction.

Checking the Battery

Your new vehicle is equipped with

DELKOR batteries. They need no

periodic electrolyte level

maintenance. Its top is permanently

sealed (except for two small vent

holes) and has no filler caps. You

will never have to add water.

Page 333 of 382

Chevrolet Low Cab Forward 5.2L Diesel Engine 4500/5500 Series (GMNA-

Localizing-U.S.-12407814) - 2019 - crc - 12/13/17

332 Service and Maintenance

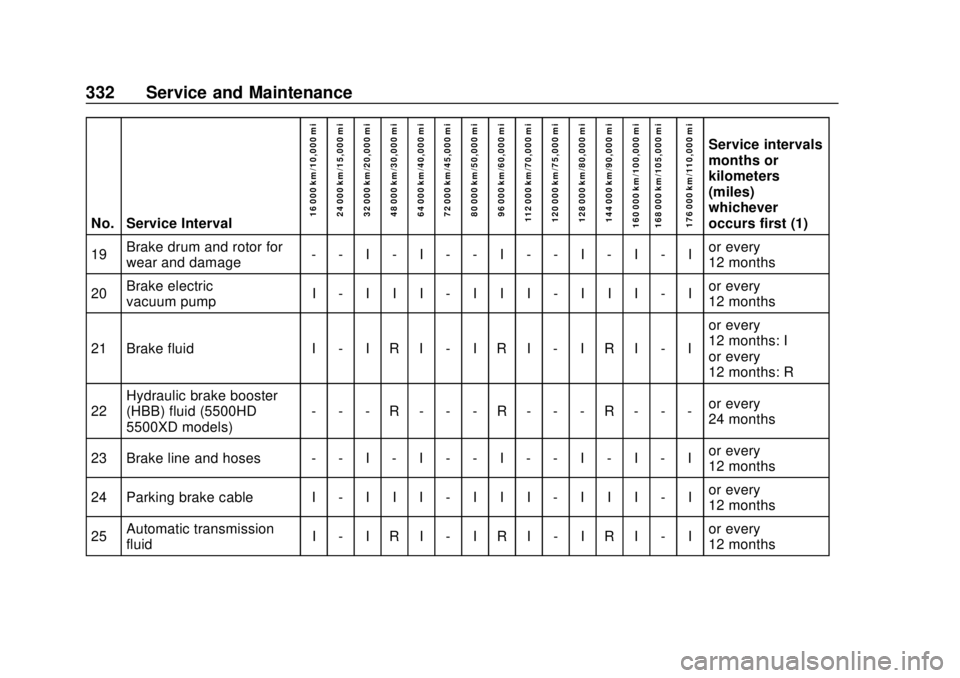

No. Service Interval16 000 km/10,000 mi

24 000 km/15,000 mi

32 000 km/20,000 mi

48 000 km/30,000 mi

64 000 km/40,000 mi

72 000 km/45,000 mi

80 000 km/50,000 mi

96 000 km/60,000 mi

112 000 km/70,000 mi

120 000 km/75,000 mi

128 000 km/80,000 mi

144 000 km/90,000 mi

160 000 km/100,000 mi

168 000 km/105,000 mi

176 000 km/110,000 mi

Service intervals

months or

kilometers

(miles)

whichever

occurs first (1)

19 Brake drum and rotor for

wear and damage

- - I - I - - I - - I - I - I or every

12 months

20 Brake electric

vacuum pump I - I I I - I I I - I I I - I or every

12 months

21 Brake fluid I - I R I - I R I - I R I - I or every

12 months: I

or every

12 months: R

22 Hydraulic brake booster

(HBB) fluid (5500HD

5500XD models) - - - R - - - R - - - R - - -

or every

24 months

23 Brake line and hoses - - I - I - - I - - I - I - I or every

12 months

24 Parking brake cable I - I I I - I I I - I I I - I or every

12 months

25 Automatic transmission

fluid I - I R I - I R I - I R I - I

or every

12 months