transmission CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 2106 of 2438

² Park

² Neutral

² Reverse

² Second Gear

No upshifts or downshifts are allowed while in the

Limp-in mode. The position of the manual valve

alone allows the three ranges that are available. Although engine performance will be reduced while

in this mode, the vehicle can be driven in for service.

DRB II SCAN TOOL

The DRB II scan tool is a diagnostic read-out box

designed by Chrysler to gain access to the on-board

diagnostics. These on-board diagnostics are found on

all Chrysler-built cars and trucks. The DRB II scan tool has a few diagnostic capabil-

ities by itself. To perform most diagnostic tests, a

program cartridge must be inserted. It contains the

diagnostic test programs. There are scan tools available from other manufac-

tures that can be used on Chrysler vehicles. How-

ever, the diagnostic test procedures in this manual

have been designed for use with the Chrysler's DRB

II scan tool. The DRB II scan tool operates by communicating

with the module of the vehicle system being tested.

To communicate with the transmission control mod-

ule, the DRB II scan tool must be connected to the blue CCD bus connector located under the instru-

ment panel. Refer to the ``Using the DRB II Scan

Tool'' manual or the Diagnostic Procedures Manual

for information on how to use the DRB II scan tool.

DIAGNOSTIC TROUBLE CODE CHARTS

Below is a brief description of what each section of

the diagnostic trouble code charts are addressing.

² DIAGNOSTIC TROUBLE CODE- Tells the code

number and name (as shown on the DRB II scan

tool).

² BACKGROUND- A brief description of the circuit

that the transmission control module is monitoring.

² WHEN CHECKED- The point of time or condition

when the transmission control module makes it's sys-

tem check.

² ARMING CONDITIONS- The parameters that

must be met before a code can be set.

² FAULT CONDITION- What the transmission con-

trol module saw that is determined to be a problem.

(ie. voltage to high or low, switch/solenoid problems)

² FAULT SET TIME- Refers to the amount of time

(in seconds) a failure must occur before a diagnostic

trouble code is set in memory.

² EFFECT- Refers to how the fault effects transaxle

operations.

² POSSIBLE CAUSE- Refers to the systems or cir-

cuits which could cause the fault to be recorded.

21 - 146 TRANSAXLE Ä

Page 2251 of 2438

HYDRAULIC SYSTEMS

The power convertible top hydraulic system con-

sists of;

² Two hydraulic cylinders

² Hydraulic lines

² Electric hydraulic pump and reservoir

² Dual relays

HYDRAULIC SYSTEM TESTS

The convertible top will raise slowly or make ab-

normal noise if the hydraulic fluid level is low. (1) Remove sling well and floor cover.

(2) With the top up and latched, remove the reser-

voir fill plug. (3) Visually inspect fluid level. If low, inspect for

leak in hydraulic system. (4) Repair or replace components, as necessary.

(5) Fill reservoir with Dexron tII, Type A, auto-

matic transmission fluid to the bottom of the fill

hole. (6) Replace fill plug and lower top.

(7) Raise top and verify fluid level.

(8) Install sling well and floor cover.

HYDRAULIC PUMP ASSEMBLY

HYDRAULIC PUMP REMOVAL (FIG. 13)

(1) Disconnect battery negative cable.

(2) Remove sling well and floor cover from behind

rear seat. (3) Disconnect pump wire connector and ground

connection. (4) Disconnect hydraulic lines from pump.

(5) Remove motor pump assembly from vehicle.

The rubber mounts are pressed and locked into the

mounting bracket. Pull up motor assembly to re-

move.

HYDRAULIC PUMP INSTALLATION

Reverse the preceding operation

HYDRAULIC CYLINDER

HYDRAULIC CYLINDER REMOVAL

(1) Disconnect battery negative cable.

(2) Remove interior trim as necessary to gain ac-

cess to hydraulic cylinders. (3) Remove cylinder mounting bracket and nut.

(4) Remove pivot bolt holding cylinder shaft to top

linkage. (5) Disconnect hydraulic lines from the cylinder.

(6) Remove cylinder from vehicle.

HYDRAULIC CYLINDER INSTALLATION

Reverse the preceding operation, and verify each

hydraulic seal is in place when connecting the line to

the cylinder. Replace seal if damaged.

HYDRAULIC PUMP LINE SEALS

HYDRAULIC PUMP LINE SEALS REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect hydraulic lines from pump and re-

move seals.

HYDRAULIC PUMP LINE SEALS INSTALLATION

Reverse the preceding operation.

HYDRAULIC CYLINDER LINE SEALS

REMOVAL

(1) Remove hydraulic cylinder to gain access to hy-

draulic line connections. (2) Disconnect hydraulic lines from cylinder and

remove seals.

INSTALLATION

Reverse the preceding operation.

Ä AJ/27-BODY 23 - 95

Page 2409 of 2438

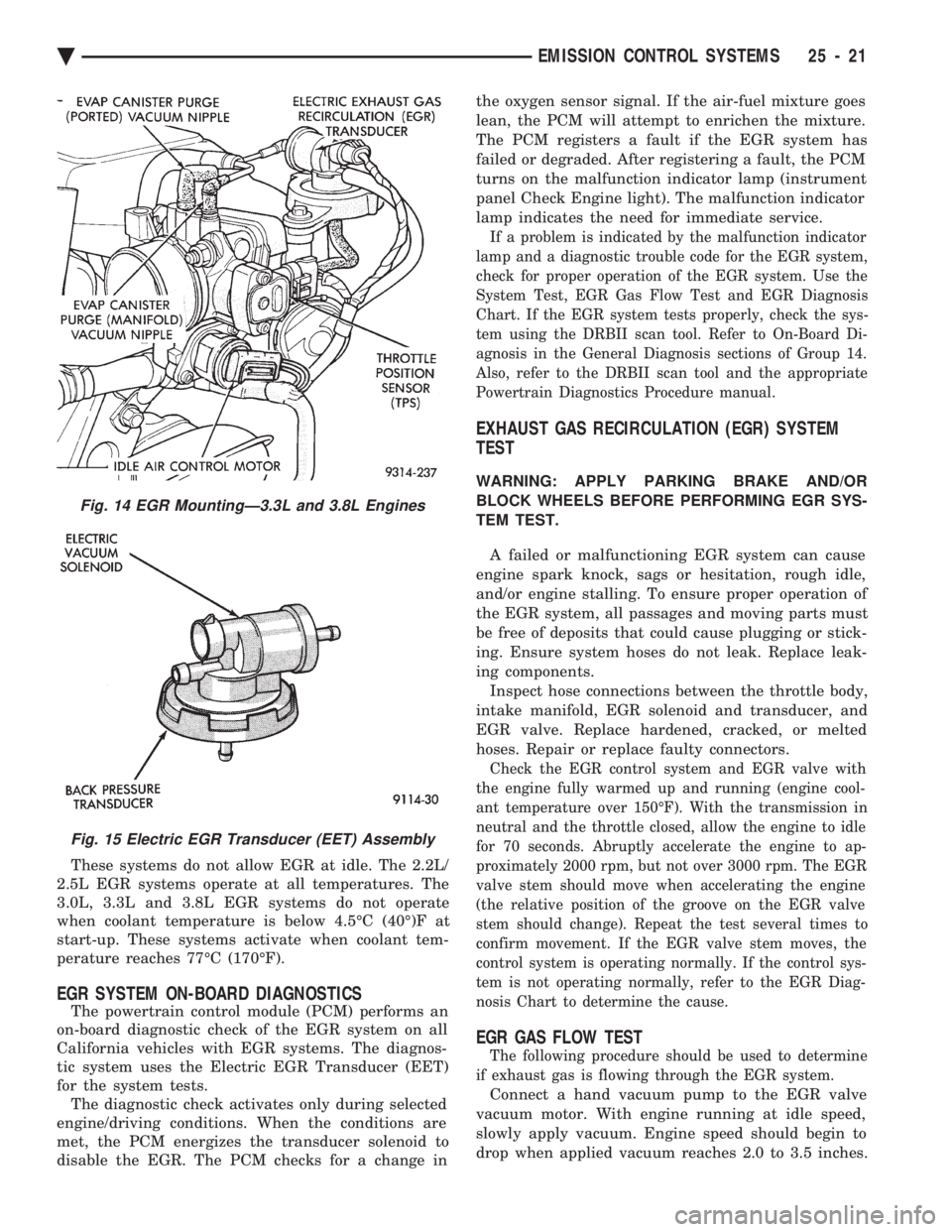

These systems do not allow EGR at idle. The 2.2L/

2.5L EGR systems operate at all temperatures. The

3.0L, 3.3L and 3.8L EGR systems do not operate

when coolant temperature is below 4.5ÉC (40É)F at

start-up. These systems activate when coolant tem-

perature reaches 77ÉC (170ÉF).

EGR SYSTEM ON-BOARD DIAGNOSTICS

The powertrain control module (PCM) performs an

on-board diagnostic check of the EGR system on all

California vehicles with EGR systems. The diagnos-

tic system uses the Electric EGR Transducer (EET)

for the system tests. The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in the oxygen sensor signal. If the air-fuel mixture goes

lean, the PCM will attempt to enrichen the mixture.

The PCM registers a fault if the EGR system has

failed or degraded. After registering a fault, the PCM

turns on the malfunction indicator lamp (instrument

panel Check Engine light). The malfunction indicator

lamp indicates the need for immediate service.

If a problem is indicated by the malfunction indicator

lamp and a diagnostic trouble code for the EGR system,

check for proper operation of the EGR system. Use the

System Test, EGR Gas Flow Test and EGR Diagnosis

Chart. If the EGR system tests properly, check the sys-

tem using the DRBII scan tool. Refer to On-Board Di-

agnosis in the General Diagnosis sections of Group 14.

Also, refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedure manual.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING EGR SYS-

TEM TEST.

A failed or malfunctioning EGR system can cause

engine spark knock, sags or hesitation, rough idle,

and/or engine stalling. To ensure proper operation of

the EGR system, all passages and moving parts must

be free of deposits that could cause plugging or stick-

ing. Ensure system hoses do not leak. Replace leak-

ing components. Inspect hose connections between the throttle body,

intake manifold, EGR solenoid and transducer, and

EGR valve. Replace hardened, cracked, or melted

hoses. Repair or replace faulty connectors.

Check the EGR control system and EGR valve with

the engine fully warmed up and running (engine cool-

ant temperature over 150ÉF). With the transmission in

neutral and the throttle closed, allow the engine to idle

for 70 seconds. Abruptly accelerate the engine to ap-

proximately 2000 rpm, but not over 3000 rpm. The EGR

valve stem should move when accelerating the engine

(the relative position of the groove on the EGR valve

stem should change). Repeat the test several times to

confirm movement. If the EGR valve stem moves, the

control system is operating normally. If the control sys-

tem is not operating normally, refer to the EGR Diag-

nosis Chart to determine the cause.

EGR GAS FLOW TEST

The following procedure should be used to determine

if exhaust gas is flowing through the EGR system.

Connect a hand vacuum pump to the EGR valve

vacuum motor. With engine running at idle speed,

slowly apply vacuum. Engine speed should begin to

drop when applied vacuum reaches 2.0 to 3.5 inches.

Fig. 14 EGR MountingÐ3.3L and 3.8L Engines

Fig. 15 Electric EGR Transducer (EET) Assembly

Ä EMISSION CONTROL SYSTEMS 25 - 21