CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 2411 of 2438

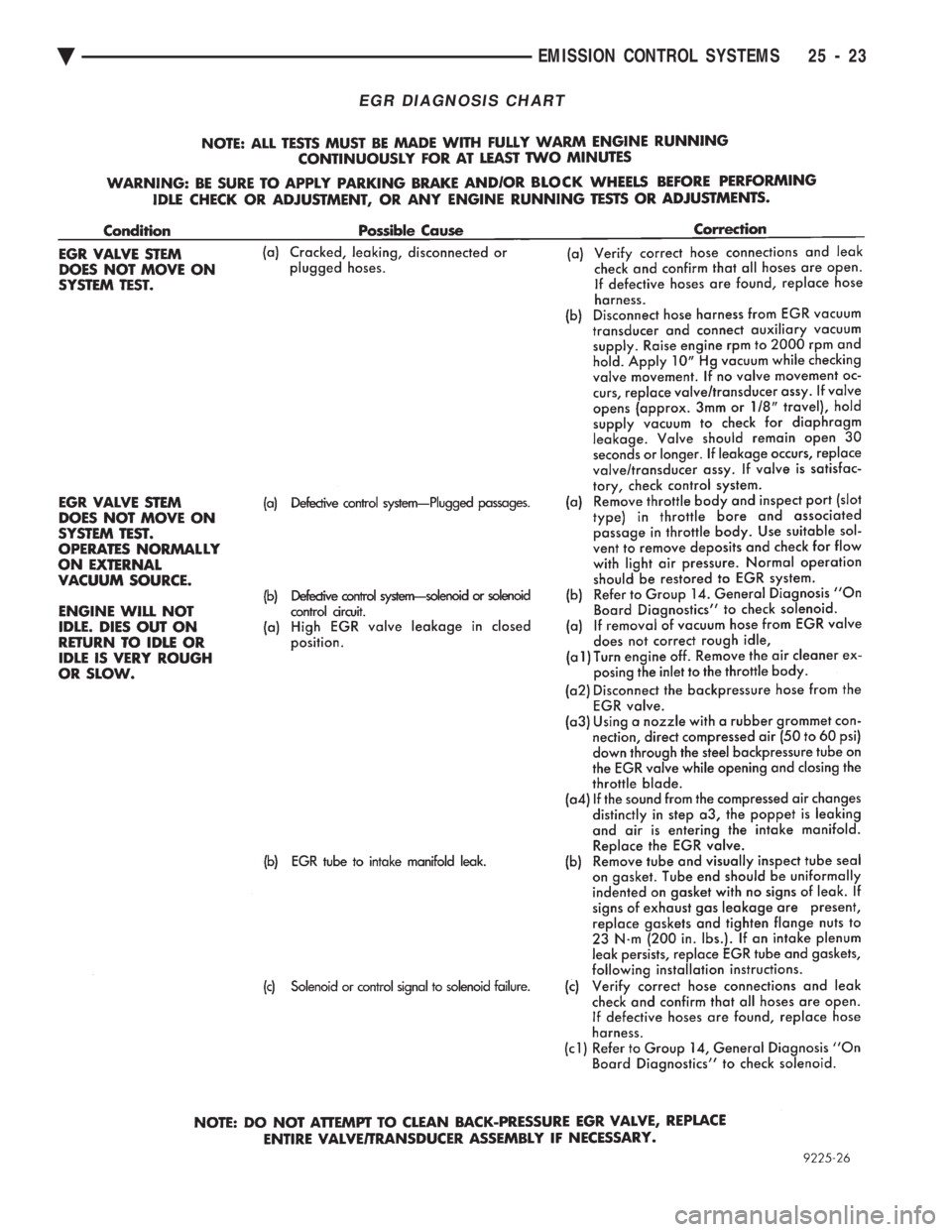

EGR DIAGNOSIS CHART

Ä EMISSION CONTROL SYSTEMS 25 - 23

Page 2412 of 2438

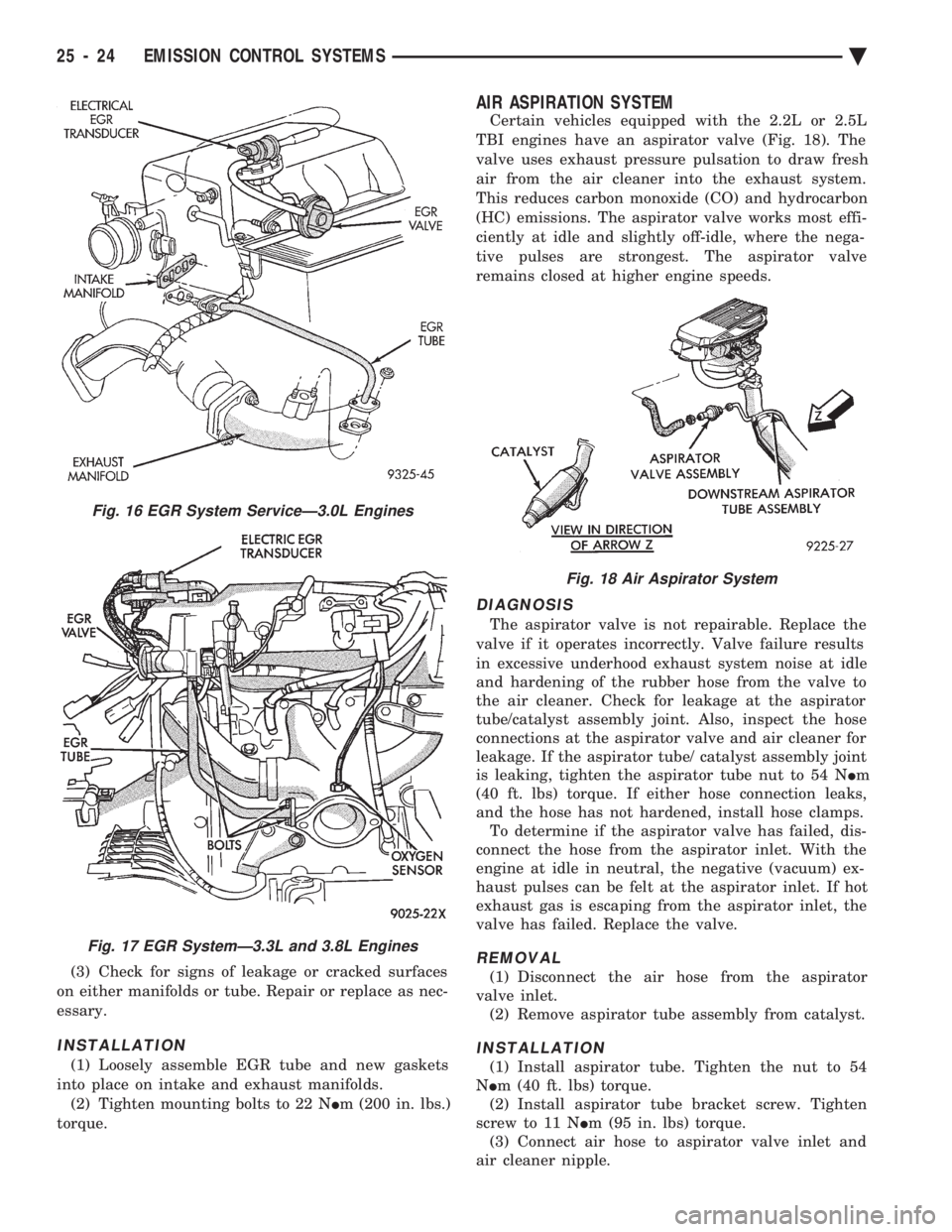

(3) Check for signs of leakage or cracked surfaces

on either manifolds or tube. Repair or replace as nec-

essary.

INSTALLATION

(1) Loosely assemble EGR tube and new gaskets

into place on intake and exhaust manifolds. (2) Tighten mounting bolts to 22 N Im (200 in. lbs.)

torque.

AIR ASPIRATION SYSTEM

Certain vehicles equipped with the 2.2L or 2.5L

TBI engines have an aspirator valve (Fig. 18). The

valve uses exhaust pressure pulsation to draw fresh

air from the air cleaner into the exhaust system.

This reduces carbon monoxide (CO) and hydrocarbon

(HC) emissions. The aspirator valve works most effi-

ciently at idle and slightly off-idle, where the nega-

tive pulses are strongest. The aspirator valve

remains closed at higher engine speeds.

DIAGNOSIS

The aspirator valve is not repairable. Replace the

valve if it operates incorrectly. Valve failure results

in excessive underhood exhaust system noise at idle

and hardening of the rubber hose from the valve to

the air cleaner. Check for leakage at the aspirator

tube/catalyst assembly joint. Also, inspect the hose

connections at the aspirator valve and air cleaner for

leakage. If the aspirator tube/ catalyst assembly joint

is leaking, tighten the aspirator tube nut to 54 N Im

(40 ft. lbs) torque. If either hose connection leaks,

and the hose has not hardened, install hose clamps. To determine if the aspirator valve has failed, dis-

connect the hose from the aspirator inlet. With the

engine at idle in neutral, the negative (vacuum) ex-

haust pulses can be felt at the aspirator inlet. If hot

exhaust gas is escaping from the aspirator inlet, the

valve has failed. Replace the valve.

REMOVAL

(1) Disconnect the air hose from the aspirator

valve inlet. (2) Remove aspirator tube assembly from catalyst.

INSTALLATION

(1) Install aspirator tube. Tighten the nut to 54

N Im (40 ft. lbs) torque.

(2) Install aspirator tube bracket screw. Tighten

screw to 11 N Im (95 in. lbs) torque.

(3) Connect air hose to aspirator valve inlet and

air cleaner nipple.

Fig. 16 EGR System ServiceÐ3.0L Engines

Fig. 17 EGR SystemÐ3.3L and 3.8L Engines

Fig. 18 Air Aspirator System

25 - 24 EMISSION CONTROL SYSTEMS Ä

Page 2413 of 2438

CHRYSLER

CORPORATION

SERVICE MANUAL and SUPPLEMENTS

1993 FRONT WHEEL DRIVE PASSENGER VEHICLES

To order the special service tools used and

illustrated, please refer to the instructions on

inside back cover.

NO PART OF THIS PUBLICATION MAY BE

REPRODUCED, STORED IN A RETRIEVAL

SYSTEM, OR TRANSMITTED, IN ANY FORM

OR BY ANY MEANS, ELECTRONIC, ME-

CHANICAL, PHOTOCOPYING, RECORDING,

OR OTHERWISE, WITHOUT THE PRIOR

WRITTEN PERMISSION OF CHRYSLER

CORPORATION.

Chrysler Corporation reserves the right to make changes in design or to make

additions to or improvements in its products without imposing any obligations

upon itself to install them on its products previously manufactured.

Litho in U.S.A. Copyright 1992 Chrysler Corporation 30M0792

NEXT PAGE ©

Page 2414 of 2438

FOREWORD

The information contained in this Service Manual has been prepared for the professional automotive

technician involved in daily repair operations. Information describing the operation and use of standard and

optional equipment is included in the Owner's Manual provided with the vehicle.

These diagrams contain the latest information at the time of publication and incorporate the wiring schematic

for the basic vehicle and available optional equipment.

The diagrams are grouped by body type and sales division. The body codes are explained in the General

Information section. (ExampleÐAP-D, P=Shadow, Sundance). To locate a system or component refer to the black

index tabs on the next page. The tab will assist you in locating the desired area of the manual.

An alphabetical index is provided at the beginning of each section to help you in locating a system or

component. All diagrams are identified by SHEET NUMBER which is found in the lower right- or left-hand corner

of the page.

A Service Manual Comment form is included at the rear of this manual. Use the form to provide Chrysler

Corporation with your comments and suggestions.

Chrysler Corporation reserves the right to change testing procedures, specifications, diagnosis, repair

methods, or vehicle wiring at any time without prior notice or incurring obligation.

NOTE: The acronyms, terminology and nomenclature used to identify emissions related components in this

manual may have changed from prior publications. These new terms are in compliance with S.A.E.

recommended practice J1930. This terminology standard (J1930) is required to comply with the 1993

California Air Research Board (CARB) requirements.

NEXT PAGE ©

Page 2415 of 2438

GROUP TAB LOCATOR

ENGINE, CHASSIS BODY

ELECTRICAL, FUEL EMISSION SYSTEMS

WIRING DIAGRAMS

SUPPLEMENTS

Service Manual Comment Forms (Rear of Manual)

Page 2416 of 2438

INTRODUCTION

CONTENTS

page page

BODY CODE PLATE LOCATION AND DECODING INFORMATION ........................ 2

INTERNATIONAL SYMBOLS ................ 9

METRIC SYSTEM ........................ 6

METRIC THREAD AND GRADE IDENTIFICATION ....................... 6 TORQUE REFERENCES

.................... 6

VEHICLE FAMILY IDENTIFICATION ........... 1

VEHICLE IDENTIFICATION NUMBER ......... 1

VEHICLE SAFETY CERTIFICATION LABEL ..... 1

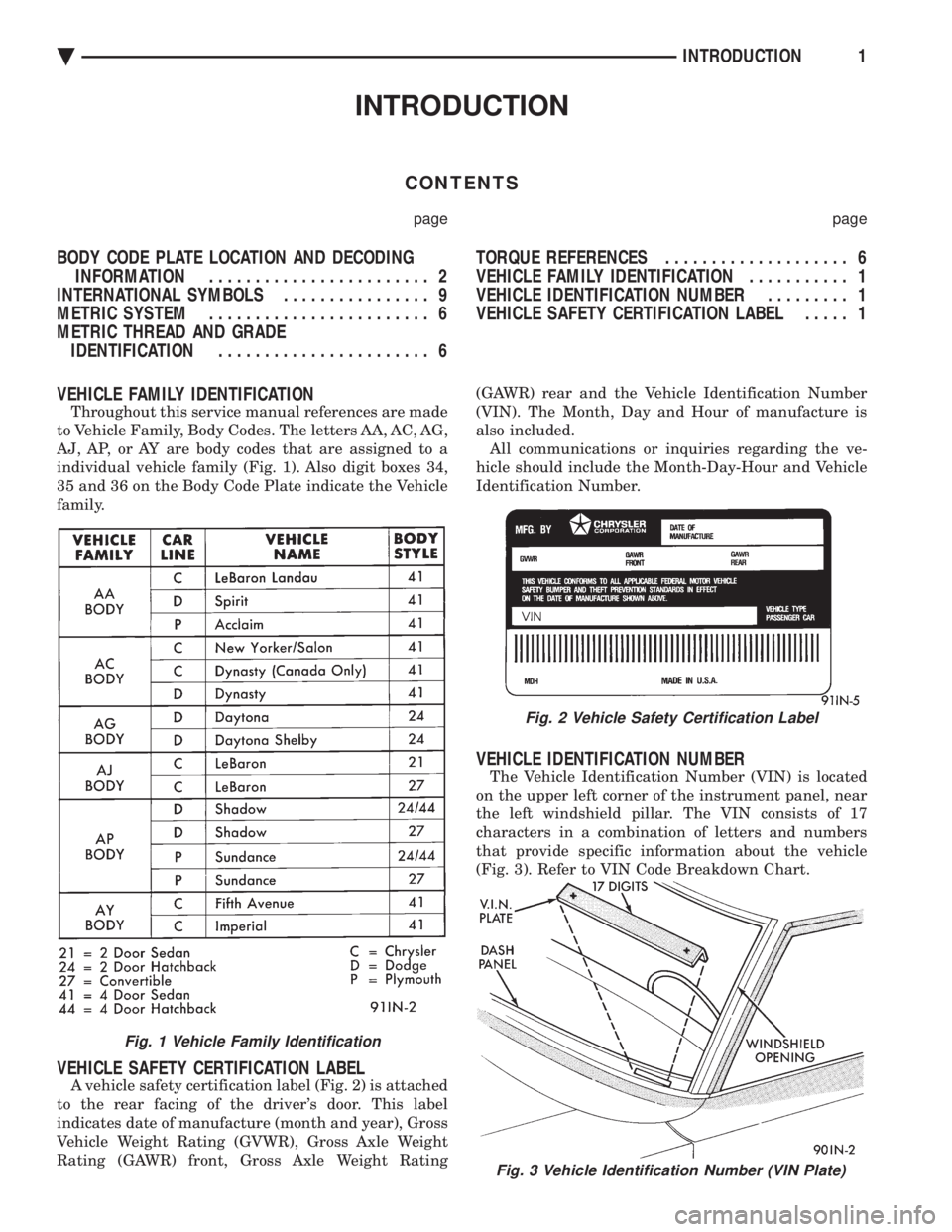

VEHICLE FAMILY IDENTIFICATION

Throughout this service manual references are made

to Vehicle Family, Body Codes. The letters AA, AC, AG,

AJ, AP, or AY are body codes that are assigned to a

individual vehicle family (Fig. 1). Also digit boxes 34,

35 and 36 on the Body Code Plate indicate the Vehicle

family.

VEHICLE SAFETY CERTIFICATION LABEL

A vehicle safety certification label (Fig. 2) is attached

to the rear facing of the driver's door. This label

indicates date of manufacture (month and year), Gross

Vehicle Weight Rating (GVWR), Gross Axle Weight

Rating (GAWR) front, Gross Axle Weight Rating (GAWR) rear and the Vehicle Identification Number

(VIN). The Month, Day and Hour of manufacture is

also included. All communications or inquiries regarding the ve-

hicle should include the Month-Day-Hour and Vehicle

Identification Number.

VEHICLE IDENTIFICATION NUMBER

The Vehicle Identification Number (VIN) is located

on the upper left corner of the instrument panel, near

the left windshield pillar. The VIN consists of 17

characters in a combination of letters and numbers

that provide specific information about the vehicle

(Fig. 3). Refer to VIN Code Breakdown Chart.

Fig. 3 Vehicle Identification Number (VIN Plate)

Fig. 1 Vehicle Family Identification

Fig. 2 Vehicle Safety Certification Label

Ä INTRODUCTION1

Page 2417 of 2438

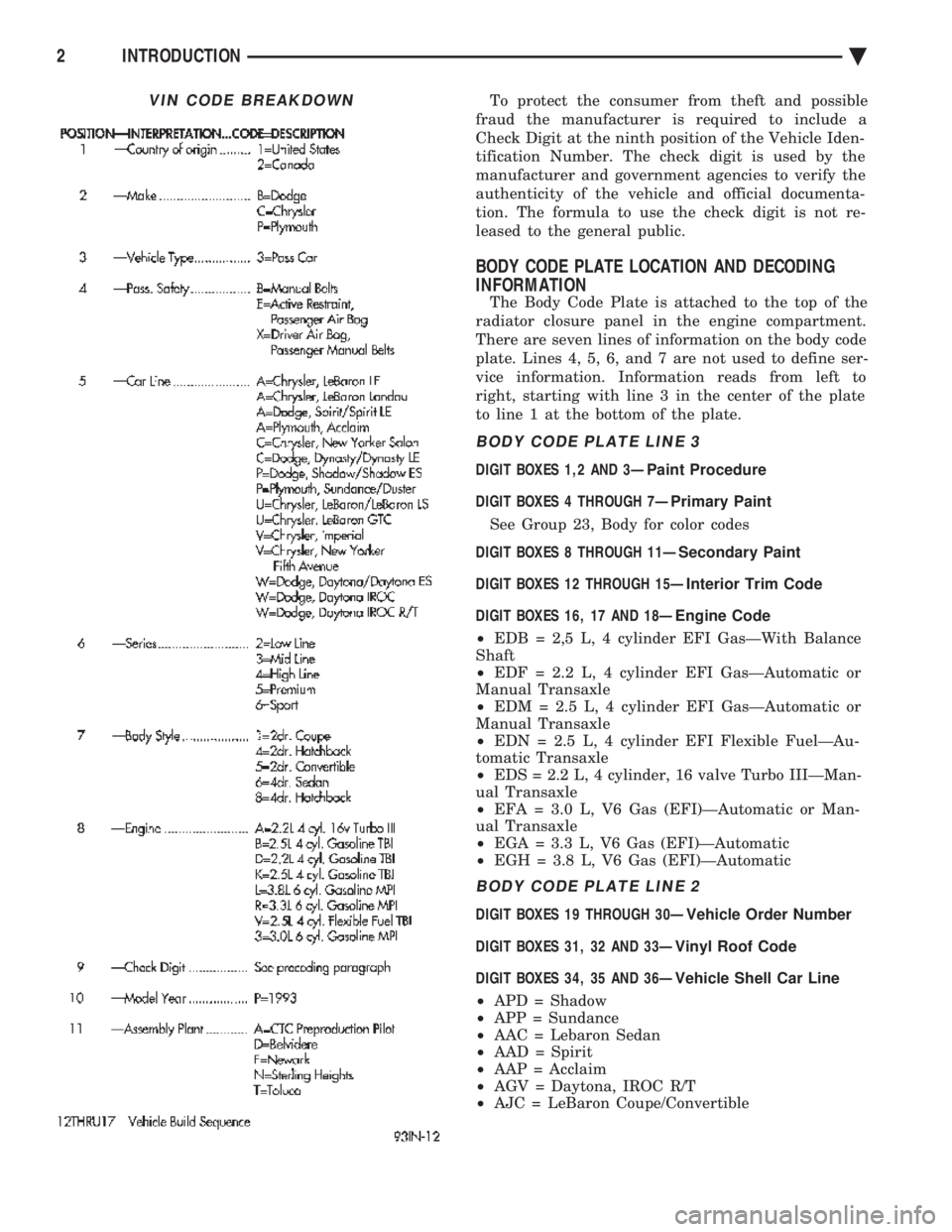

To protect the consumer from theft and possible

fraud the manufacturer is required to include a

Check Digit at the ninth position of the Vehicle Iden-

tification Number. The check digit is used by the

manufacturer and government agencies to verify the

authenticity of the vehicle and official documenta-

tion. The formula to use the check digit is not re-

leased to the general public.

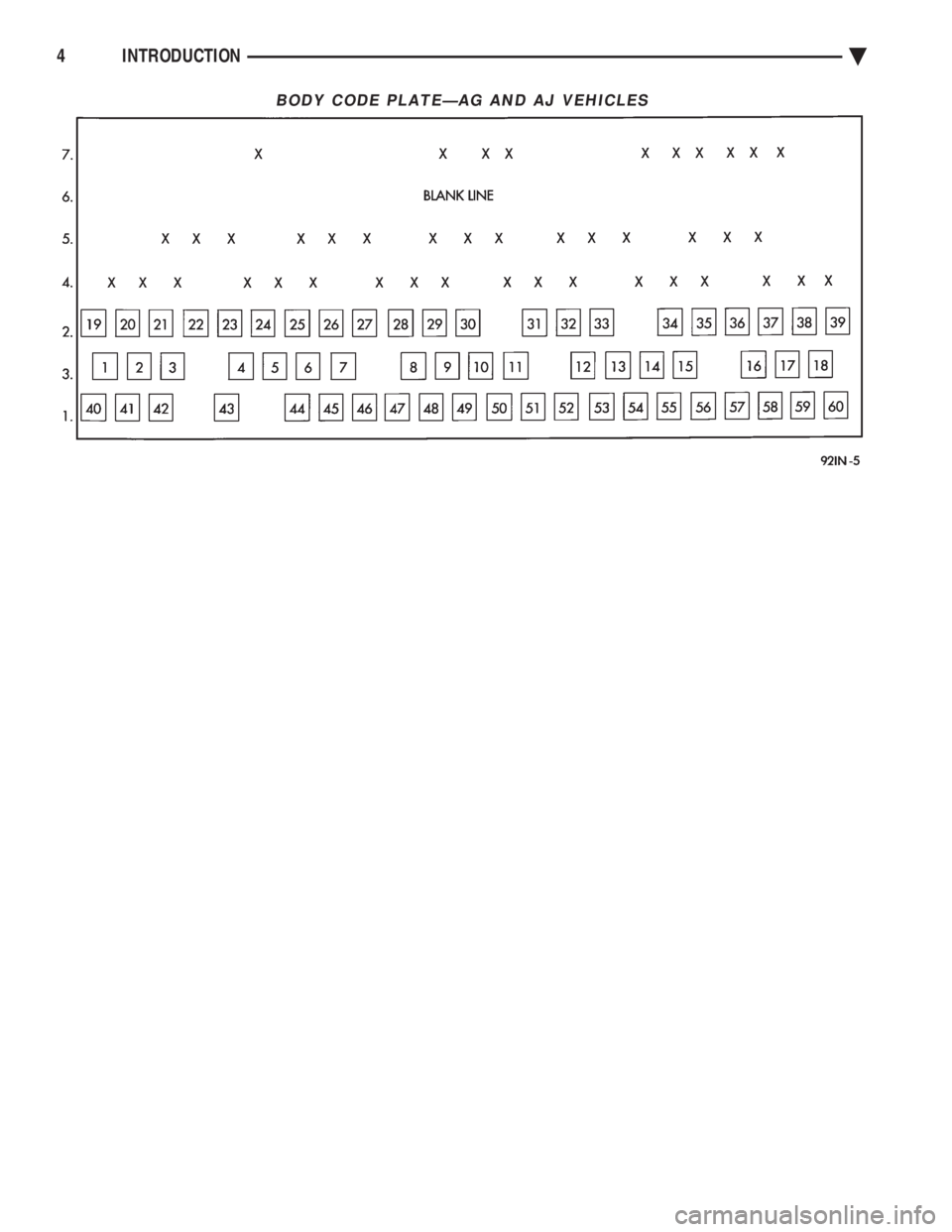

BODY CODE PLATE LOCATION AND DECODING

INFORMATION

The Body Code Plate is attached to the top of the

radiator closure panel in the engine compartment.

There are seven lines of information on the body code

plate. Lines 4, 5, 6, and 7 are not used to define ser-

vice information. Information reads from left to

right, starting with line 3 in the center of the plate

to line 1 at the bottom of the plate.

BODY CODE PLATE LINE 3

DIGIT BOXES 1,2 AND 3Ð Paint Procedure

DIGIT BOXES 4 THROUGH 7Ð Primary Paint

See Group 23, Body for color codes

DIGIT BOXES 8 THROUGH 11Ð Secondary Paint

DIGIT BOXES 12 THROUGH 15Ð Interior Trim Code

DIGIT BOXES 16, 17 AND 18Ð Engine Code

² EDB = 2,5 L, 4 cylinder EFI GasÐWith Balance

Shaft

² EDF = 2.2 L, 4 cylinder EFI GasÐAutomatic or

Manual Transaxle

² EDM = 2.5 L, 4 cylinder EFI GasÐAutomatic or

Manual Transaxle

² EDN = 2.5 L, 4 cylinder EFI Flexible FuelÐAu-

tomatic Transaxle

² EDS = 2.2 L, 4 cylinder, 16 valve Turbo IIIÐMan-

ual Transaxle

² EFA = 3.0 L, V6 Gas (EFI)ÐAutomatic or Man-

ual Transaxle

² EGA = 3.3 L, V6 Gas (EFI)ÐAutomatic

² EGH = 3.8 L, V6 Gas (EFI)ÐAutomatic

BODY CODE PLATE LINE 2

DIGIT BOXES 19 THROUGH 30Ð Vehicle Order Number

DIGIT BOXES 31, 32 AND 33Ð Vinyl Roof Code

DIGIT BOXES 34, 35 AND 36Ð Vehicle Shell Car Line

² APD = Shadow

² APP = Sundance

² AAC = Lebaron Sedan

² AAD = Spirit

² AAP = Acclaim

² AGV = Daytona, IROC R/T

² AJC = LeBaron Coupe/Convertible

VIN CODE BREAKDOWN

2 INTRODUCTION Ä

Page 2418 of 2438

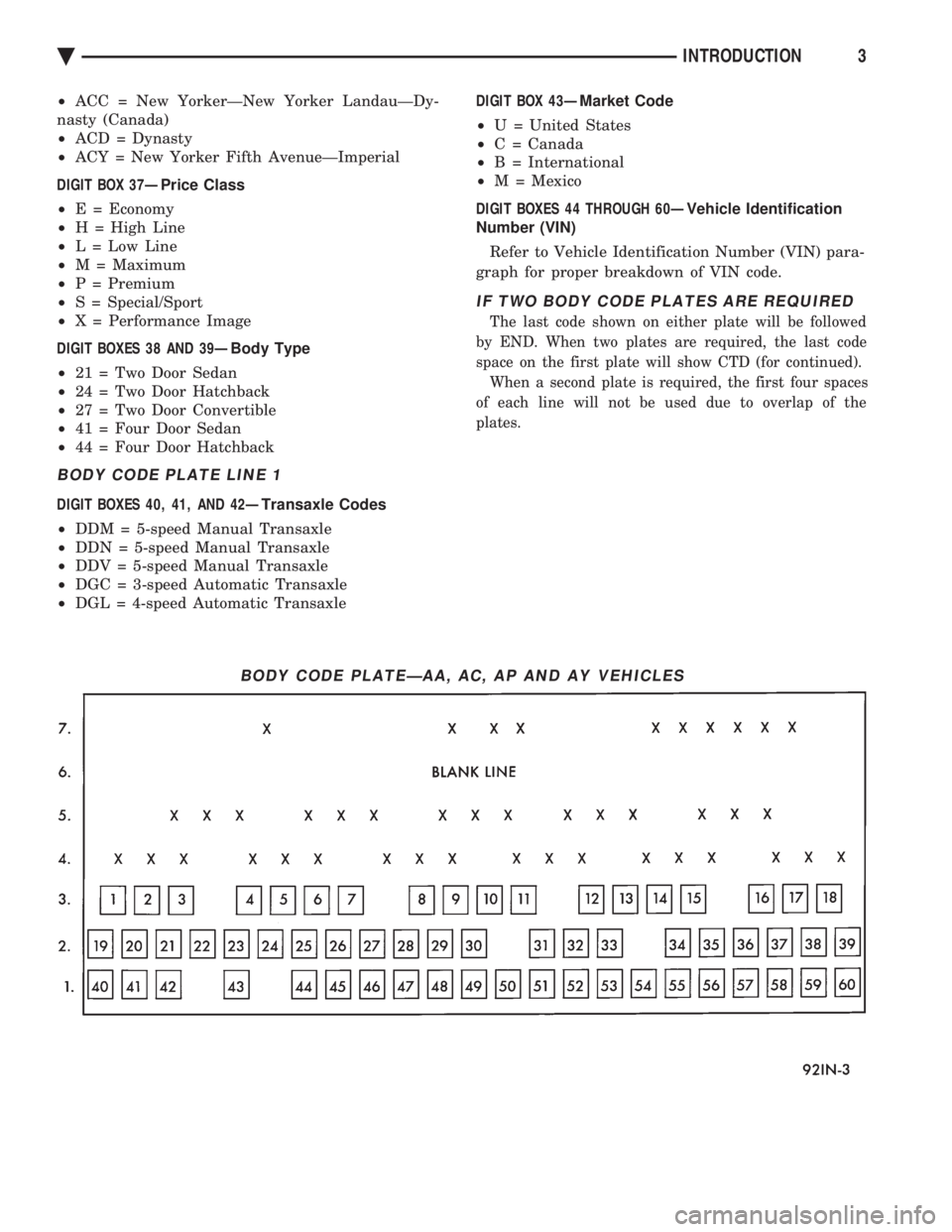

² ACC = New YorkerÐNew Yorker LandauÐDy-

nasty (Canada)

² ACD = Dynasty

² ACY = New Yorker Fifth AvenueÐImperial

DIGIT BOX 37Ð Price Class

² E = Economy

² H = High Line

² L = Low Line

² M = Maximum

² P = Premium

² S = Special/Sport

² X = Performance Image

DIGIT BOXES 38 AND 39Ð Body Type

² 21 = Two Door Sedan

² 24 = Two Door Hatchback

² 27 = Two Door Convertible

² 41 = Four Door Sedan

² 44 = Four Door Hatchback

BODY CODE PLATE LINE 1

DIGIT BOXES 40, 41, AND 42Ð Transaxle Codes

² DDM = 5-speed Manual Transaxle

² DDN = 5-speed Manual Transaxle

² DDV = 5-speed Manual Transaxle

² DGC = 3-speed Automatic Transaxle

² DGL = 4-speed Automatic Transaxle DIGIT BOX 43Ð

Market Code

² U = United States

² C = Canada

² B = International

² M = Mexico

DIGIT BOXES 44 THROUGH 60Ð Vehicle Identification

Number (VIN)

Refer to Vehicle Identification Number (VIN) para-

graph for proper breakdown of VIN code.

IF TWO BODY CODE PLATES ARE REQUIRED

The last code shown on either plate will be followed

by END. When two plates are required, the last code

space on the first plate will show CTD (for continued). When a second plate is required, the first four spaces

of each line will not be used due to overlap of the

plates.

BODY CODE PLATEÐAA, AC, AP AND AY VEHICLES

Ä INTRODUCTION3

Page 2419 of 2438

BODY CODE PLATEÐAG AND AJ VEHICLES

4 INTRODUCTION Ä

Page 2420 of 2438

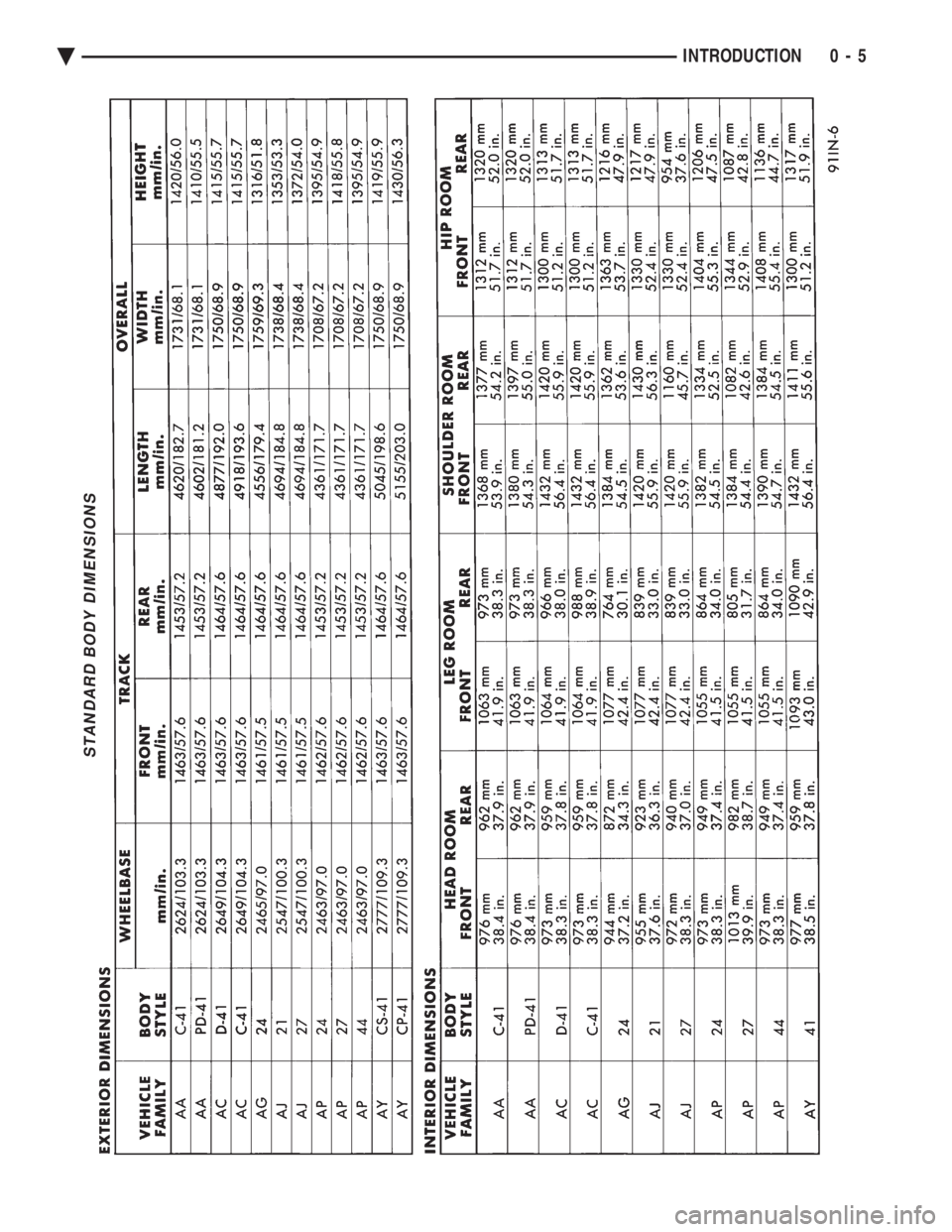

STANDARD BODY DIMENSIONS

Ä INTRODUCTION 0 - 5