key CHEVROLET PLYMOUTH ACCLAIM 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 533 of 2438

(4) Remove panel top cover by pushing forward

and prying up, using a straight edge to assist in the

removal. (5) Disconnect bulkhead connector at brace under

instrument panel at left side. (6) Remove glovebox/ash receiver module and right

instrument panel silencer. (7) Remove center panel support brace and air bag

diagnostic module assembly. (8) Disconnect wiring to airbag module.

(9) Remove upper and lower cluster bezels.

(10) Remove steering column cover.

(11) Remove steering column mounting nuts and

lower steering column. (12) Unhook shift indicator cable eyelet from steer-

ing column actuator. (13) Unlatch lock tab in shift indicator column in-

sert and squeeze legs together to remove from steer-

ing column. (14) Remove cluster assembly while guiding trans-

mission range indicator guide tube through access

hole in the base panel. (15) Remove instrument panel steering column

opening support/hood release handle assembly. (16) Remove two steering column upper studs and

loosen side cowl tie-down bolts. (17) Remove steering column tilt lever.

(18) Remove upper and lower lock housing shroud.

(19) Remove lower fixed shroud.

(20) Remove upper fixed shroud (snaps in place).

(21) Disconnect airbag pigtail, ignition switch and

halo light/key buzzer switch wiring. (22) Disconnect Multi-function switch by loosening

connector jack screw and pulling connector from

switch. (23) Disconnect airbag pigtail from wiring trough

housing by pulling two push fasteners. (24) Remove wiring trough from steering column.

(25) Remove defroster ducts.

(26) Remove five screws along fence line and roll

panel down, attach a hook to hold in position. (27) Open hood and remove plenum grill.

(28) Disconnect washer bottle, resistor block and

under hood lamp wiring. Washer bottle must be re-

moved to gain access. (29) Remove grommet and pull plenum wiring into

vehicle through plenum panel. (30) Disconnect right demister hose from instru-

ment panel. (31) Disconnect antenna cable.

(32) Disconnect right and left 25 way body wiring

connectors. (33) Disconnect A/C heater control cables, wiring

connectors and vacuum harness. (34) Remove right side panel ground wire.

(35) Disconnect body controller wiring.

(36) Remove instrument panel assembly from vehi-

cle. (37) For installation reverse above procedures.

INTERIOR LAMP REPLACEMENT

The reading, overhead console and door lamps op-

erate when the doors are open or headlamp switch is

placed in courtesy position. Front overhead lamps re-

fer to Group 8C, Overhead Console.

TRUNK LAMP

The lamp has easily accessible without removing

components.

DOOR LAMP

Pry along the forward edge of the lens and pivot

lens out of the door trim panel. Remove lamp. To re-

move lamp housing, remove door trim panel. Refer to

Group 23, Body. Disconnect all wiring. Remove

screws, if so equipped securing lamp housing to trim

panel, and replace housing.

CÐPILLAR READING/COURTESY LAMP

Pry along the rearward edge of the lamp and pivot

lamp out from quarter trim panel. Disconnect wiring

and remove lamp cover. Replace lamp. The lamp operates when the doors are open or the

headlamp switch is turned to the courtesy mode. The

lamp will function as a reading lamp when the doors

are closed and the button switch on the lamp is de-

pressed.

ROOF RAIL READING

Pry along the bottom edge of the lens and pivot

lens out. Replace lamp. To remove the lamp, remove

the screw which retains the coat hook. Remove the

garnish molding. Disconnect the wiring harness. Re-

move the two clips which retain the lamp to the

molding. Replace lamp. The lamp operates like the

C-pillar reading/courtesy lamp.

Ä INSTRUMENT PANEL AND GAUGES 8E - 41

Page 536 of 2438

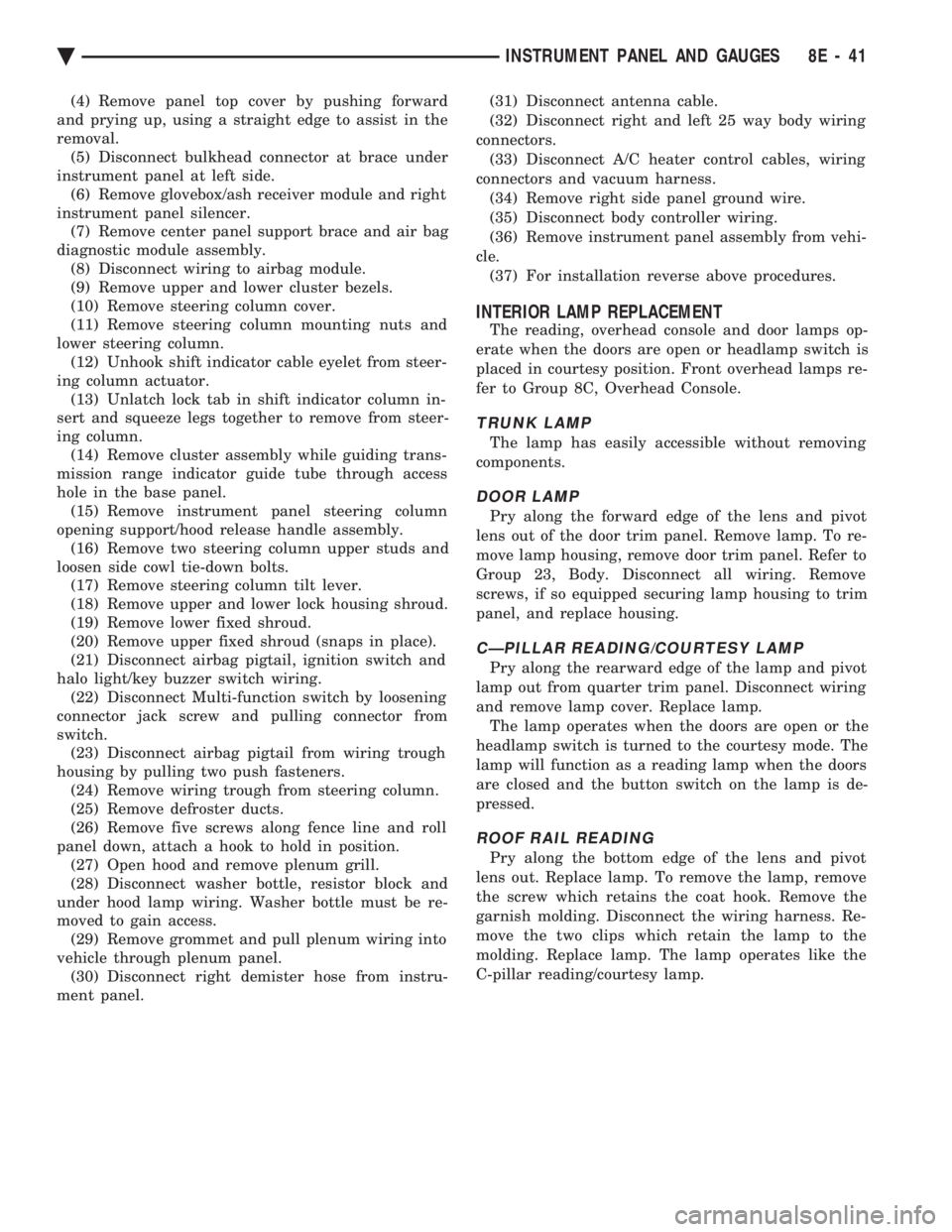

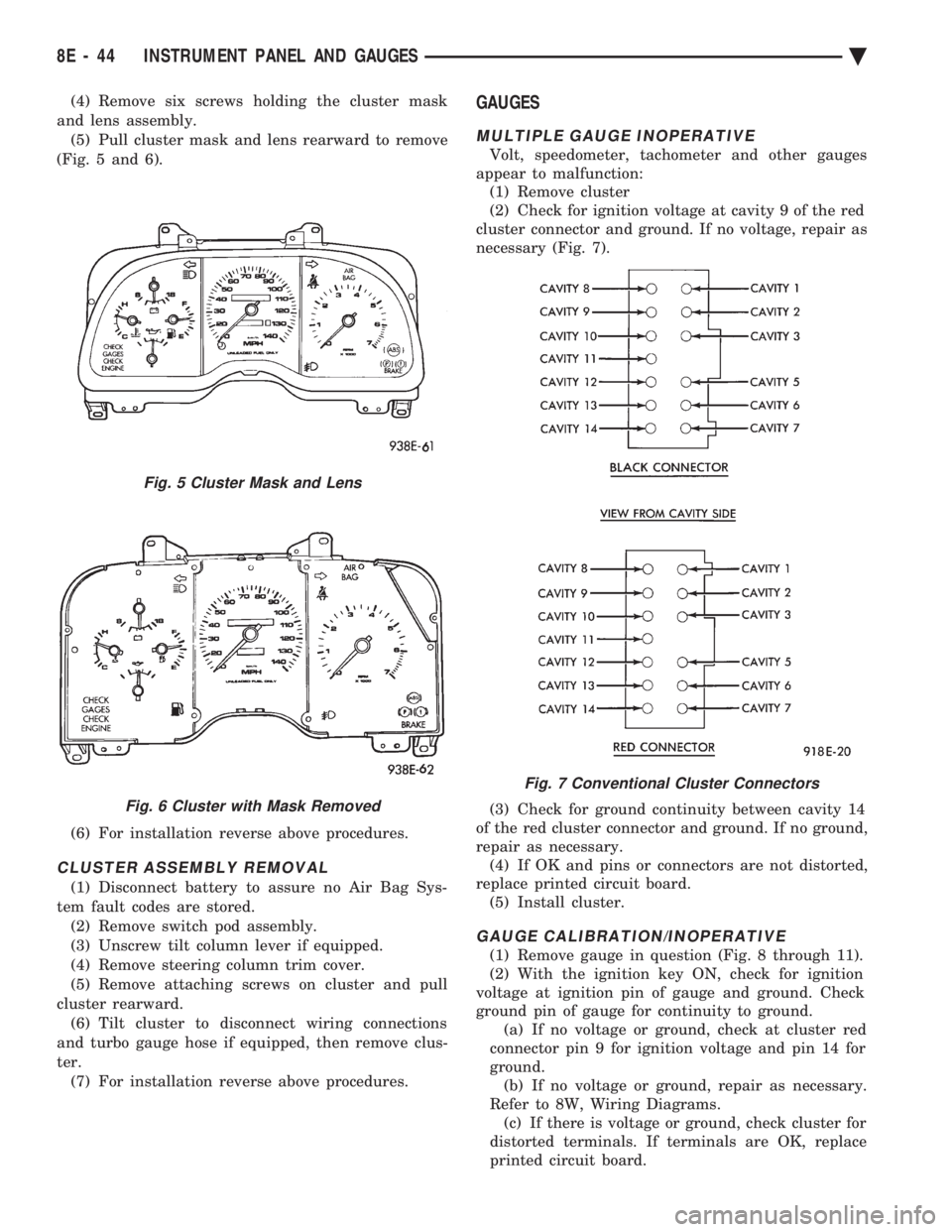

(4) Remove six screws holding the cluster mask

and lens assembly. (5) Pull cluster mask and lens rearward to remove

(Fig. 5 and 6).

(6) For installation reverse above procedures.

CLUSTER ASSEMBLY REMOVAL

(1) Disconnect battery to assure no Air Bag Sys-

tem fault codes are stored. (2) Remove switch pod assembly.

(3) Unscrew tilt column lever if equipped.

(4) Remove steering column trim cover.

(5) Remove attaching screws on cluster and pull

cluster rearward. (6) Tilt cluster to disconnect wiring connections

and turbo gauge hose if equipped, then remove clus-

ter. (7) For installation reverse above procedures.

GAUGES

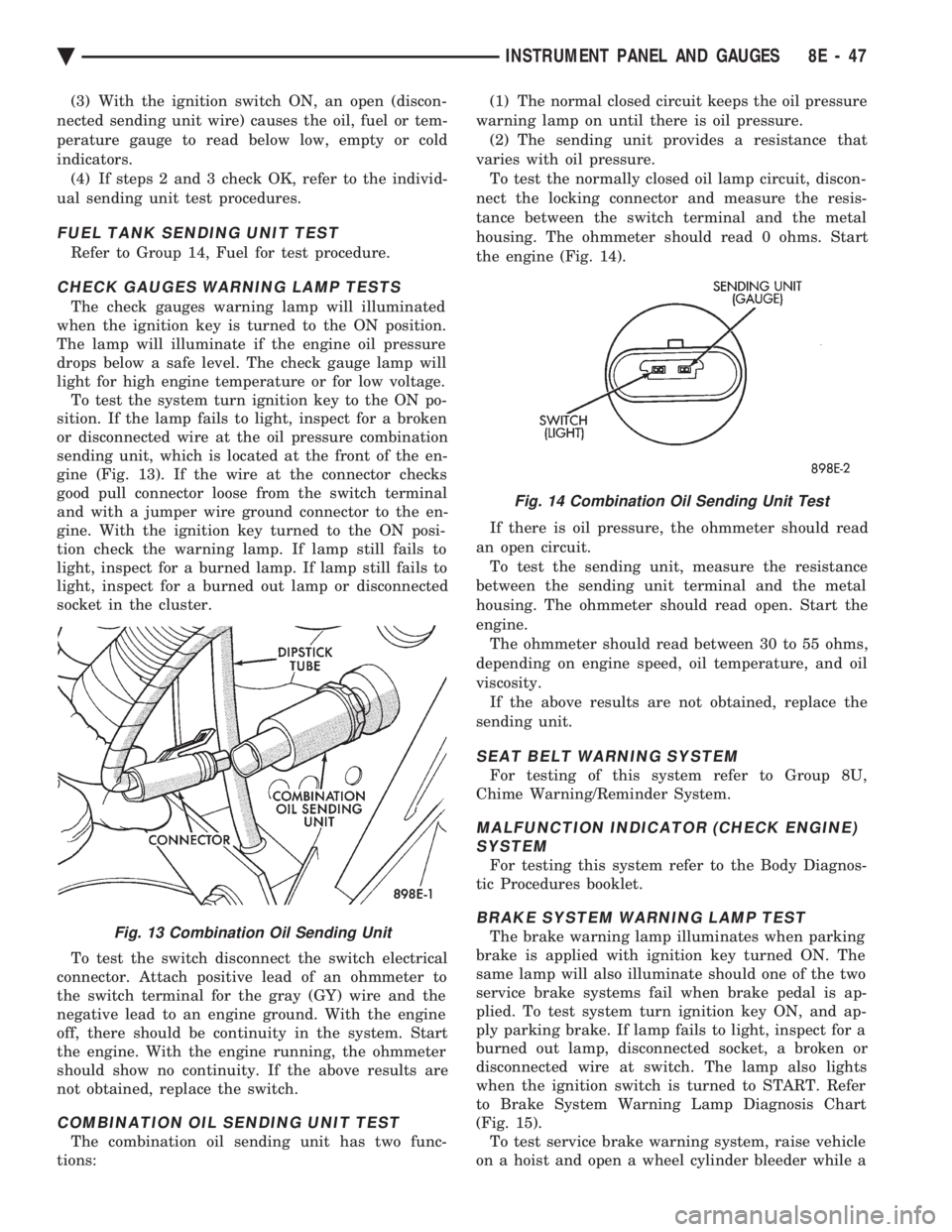

MULTIPLE GAUGE INOPERATIVE

Volt, speedometer, tachometer and other gauges

appear to malfunction: (1) Remove cluster

(2) Check for ignition voltage at cavity 9 of the red

cluster connector and ground. If no voltage, repair as

necessary (Fig. 7).

(3) Check for ground continuity between cavity 14

of the red cluster connector and ground. If no ground,

repair as necessary. (4) If OK and pins or connectors are not distorted,

replace printed circuit board. (5) Install cluster.

GAUGE CALIBRATION/INOPERATIVE

(1) Remove gauge in question (Fig. 8 through 11).

(2) With the ignition key ON, check for ignition

voltage at ignition pin of gauge and ground. Check

ground pin of gauge for continuity to ground. (a) If no voltage or ground, check at cluster red

connector pin 9 for ignition voltage and pin 14 for

ground. (b) If no voltage or ground, repair as necessary.

Refer to 8W, Wiring Diagrams. (c) If there is voltage or ground, check cluster for

distorted terminals. If terminals are OK, replace

printed circuit board.

Fig. 5 Cluster Mask and Lens

Fig. 6 Cluster with Mask Removed

Fig. 7 Conventional Cluster Connectors

8E - 44 INSTRUMENT PANEL AND GAUGES Ä

Page 539 of 2438

(3) With the ignition switch ON, an open (discon-

nected sending unit wire) causes the oil, fuel or tem-

perature gauge to read below low, empty or cold

indicators. (4) If steps 2 and 3 check OK, refer to the individ-

ual sending unit test procedures.

FUEL TANK SENDING UNIT TEST

Refer to Group 14, Fuel for test procedure.

CHECK GAUGES WARNING LAMP TESTS

The check gauges warning lamp will illuminated

when the ignition key is turned to the ON position.

The lamp will illuminate if the engine oil pressure

drops below a safe level. The check gauge lamp will

light for high engine temperature or for low voltage. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

sending unit, which is located at the front of the en-

gine (Fig. 13). If the wire at the connector checks

good pull connector loose from the switch terminal

and with a jumper wire ground connector to the en-

gine. With the ignition key turned to the ON posi-

tion check the warning lamp. If lamp still fails to

light, inspect for a burned lamp. If lamp still fails to

light, inspect for a burned out lamp or disconnected

socket in the cluster.

To test the switch disconnect the switch electrical

connector. Attach positive lead of an ohmmeter to

the switch terminal for the gray (GY) wire and the

negative lead to an engine ground. With the engine

off, there should be continuity in the system. Start

the engine. With the engine running, the ohmmeter

should show no continuity. If the above results are

not obtained, replace the switch.

COMBINATION OIL SENDING UNIT TEST

The combination oil sending unit has two func-

tions: (1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure. (2) The sending unit provides a resistance that

varies with oil pressure. To test the normally closed oil lamp circuit, discon-

nect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine (Fig. 14).

If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should read open. Start the

engine. The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature, and oil

viscosity. If the above results are not obtained, replace the

sending unit.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8U,

Chime Warning/Reminder System.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing this system refer to the Body Diagnos-

tic Procedures booklet.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START. Refer

to Brake System Warning Lamp Diagnosis Chart

(Fig. 15). To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while aFig. 13 Combination Oil Sending Unit

Fig. 14 Combination Oil Sending Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 47

Page 551 of 2438

FUEL TANK SENDING UNIT TEST

Refer to Group 14, Fuel for test procedures.

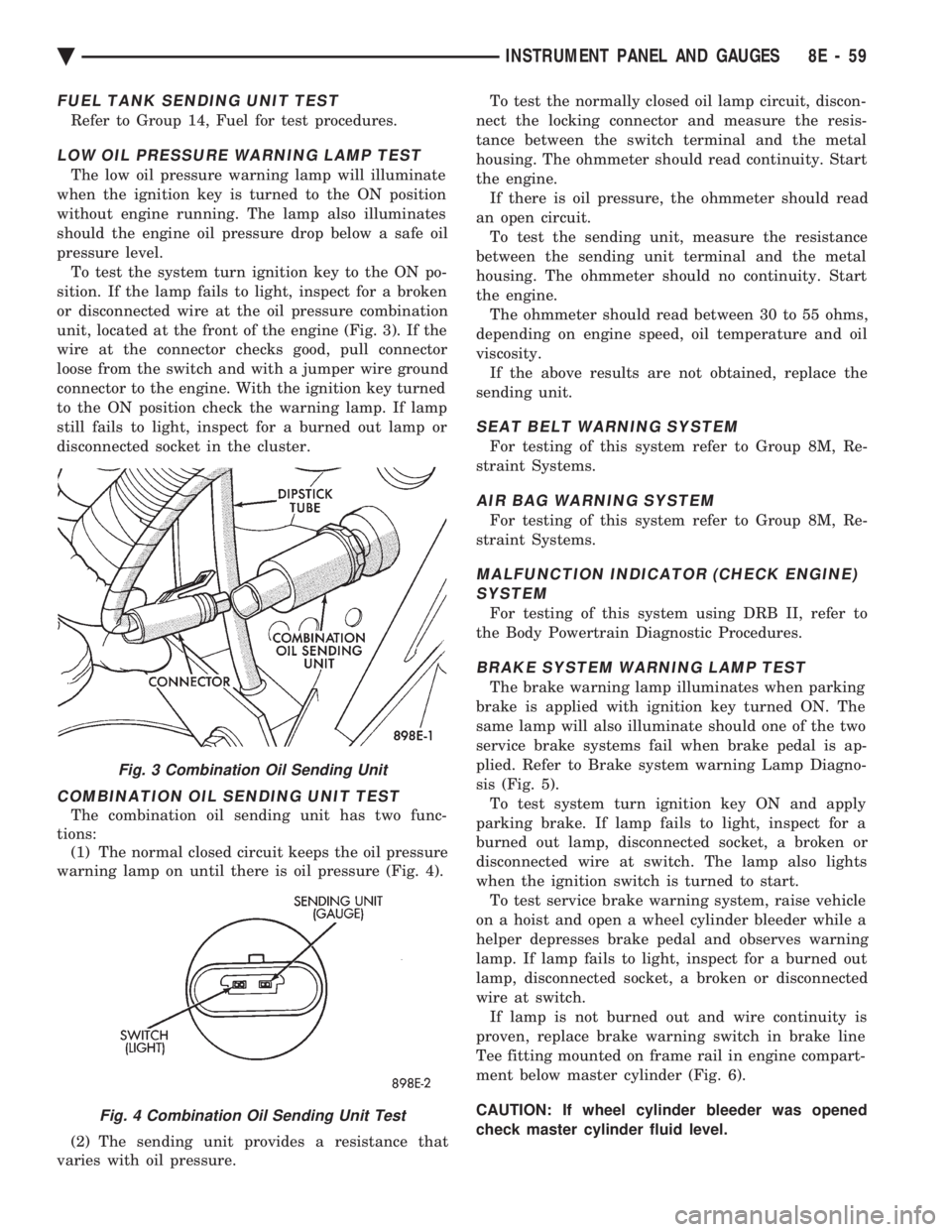

LOW OIL PRESSURE WARNING LAMP TEST

The low oil pressure warning lamp will illuminate

when the ignition key is turned to the ON position

without engine running. The lamp also illuminates

should the engine oil pressure drop below a safe oil

pressure level. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

unit, located at the front of the engine (Fig. 3). If the

wire at the connector checks good, pull connector

loose from the switch and with a jumper wire ground

connector to the engine. With the ignition key turned

to the ON position check the warning lamp. If lamp

still fails to light, inspect for a burned out lamp or

disconnected socket in the cluster.

COMBINATION OIL SENDING UNIT TEST

The combination oil sending unit has two func-

tions: (1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure (Fig. 4).

(2) The sending unit provides a resistance that

varies with oil pressure. To test the normally closed oil lamp circuit, discon-

nect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read continuity. Start

the engine. If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should no continuity. Start

the engine. The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature and oil

viscosity. If the above results are not obtained, replace the

sending unit.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

AIR BAG WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing of this system using DRB II, refer to

the Body Powertrain Diagnostic Procedures.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. Refer to Brake system warning Lamp Diagno-

sis (Fig. 5). To test system turn ignition key ON and apply

parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to start. To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a

helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig. 6).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

Fig. 3 Combination Oil Sending Unit

Fig. 4 Combination Oil Sending Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 59

Page 553 of 2438

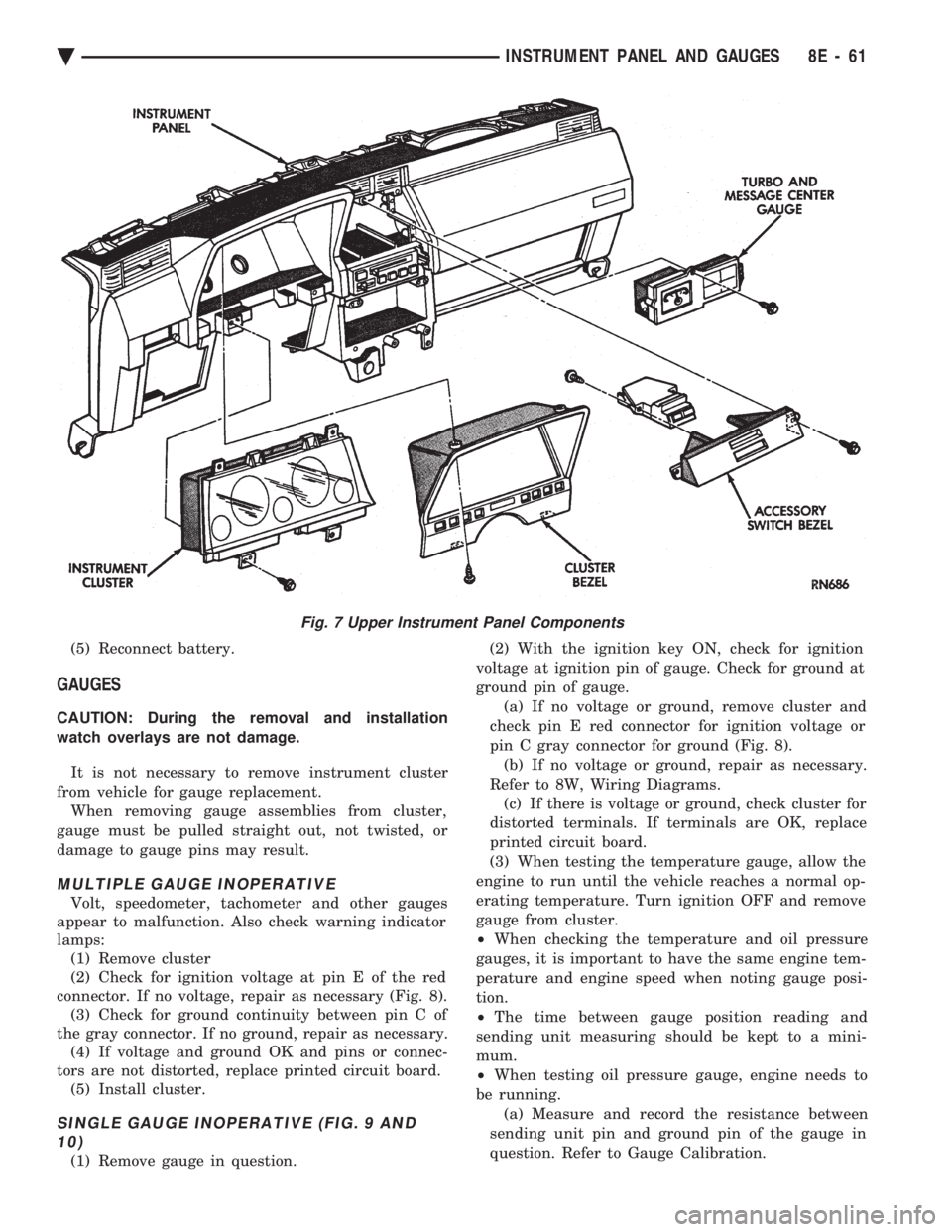

(5) Reconnect battery.

GAUGES

CAUTION: During the removal and installation

watch overlays are not damage.

It is not necessary to remove instrument cluster

from vehicle for gauge replacement. When removing gauge assemblies from cluster,

gauge must be pulled straight out, not twisted, or

damage to gauge pins may result.

MULTIPLE GAUGE INOPERATIVE

Volt, speedometer, tachometer and other gauges

appear to malfunction. Also check warning indicator

lamps: (1) Remove cluster

(2) Check for ignition voltage at pin E of the red

connector. If no voltage, repair as necessary (Fig. 8). (3) Check for ground continuity between pin C of

the gray connector. If no ground, repair as necessary. (4) If voltage and ground OK and pins or connec-

tors are not distorted, replace printed circuit board. (5) Install cluster.

SINGLE GAUGE INOPERATIVE (FIG. 9 AND10)

(1) Remove gauge in question. (2) With the ignition key ON, check for ignition

voltage at ignition pin of gauge. Check for ground at

ground pin of gauge. (a) If no voltage or ground, remove cluster and

check pin E red connector for ignition voltage or

pin C gray connector for ground (Fig. 8). (b) If no voltage or ground, repair as necessary.

Refer to 8W, Wiring Diagrams. (c) If there is voltage or ground, check cluster for

distorted terminals. If terminals are OK, replace

printed circuit board.

(3) When testing the temperature gauge, allow the

engine to run until the vehicle reaches a normal op-

erating temperature. Turn ignition OFF and remove

gauge from cluster.

² When checking the temperature and oil pressure

gauges, it is important to have the same engine tem-

perature and engine speed when noting gauge posi-

tion.

² The time between gauge position reading and

sending unit measuring should be kept to a mini-

mum.

² When testing oil pressure gauge, engine needs to

be running. (a) Measure and record the resistance between

sending unit pin and ground pin of the gauge in

question. Refer to Gauge Calibration.

Fig. 7 Upper Instrument Panel Components

Ä INSTRUMENT PANEL AND GAUGES 8E - 61

Page 555 of 2438

(f) If everything checks out OK, refer to Sending

Unit Test.

(4) With the ignition switch in the ON position,

check for battery voltage across the ignition pin and

the ground pin. (5) If fuel gauge meets specifications check fuel

tank and original fuel tank sending unit as follows: (a) Carefully remove fuel tank sending unit from

tank. (b) Refer to sending unit removal Group 14,

Fuel. (c) Connect sending unit wire and jumper wire

as described in the test procedure.

(6) If fuel gauge now checks within specifications,

original sending unit is electrically okay, check fol-

lowing as a possible cause: (a) Ground wire from sending unit to left side

cowl for continuity. (b) Sending unit deformed. Make sure sending

unit float arm moves freely and pick up tube is not

bent upwards creating an interference with bottom

of tank and inspect float. (c) Sending unit improperly installed. Install

properly. (d) Mounting flange on fuel tank for sending

unit deformed. Feel for interference fit of sending

unit to bottom of tank. It is permissible to bend

pick up tube down a little near mounting flange to

gain interference fit. (e) Fuel tank bottom deformed, causing improper

positioning of sending unit pick up tube. Replace or

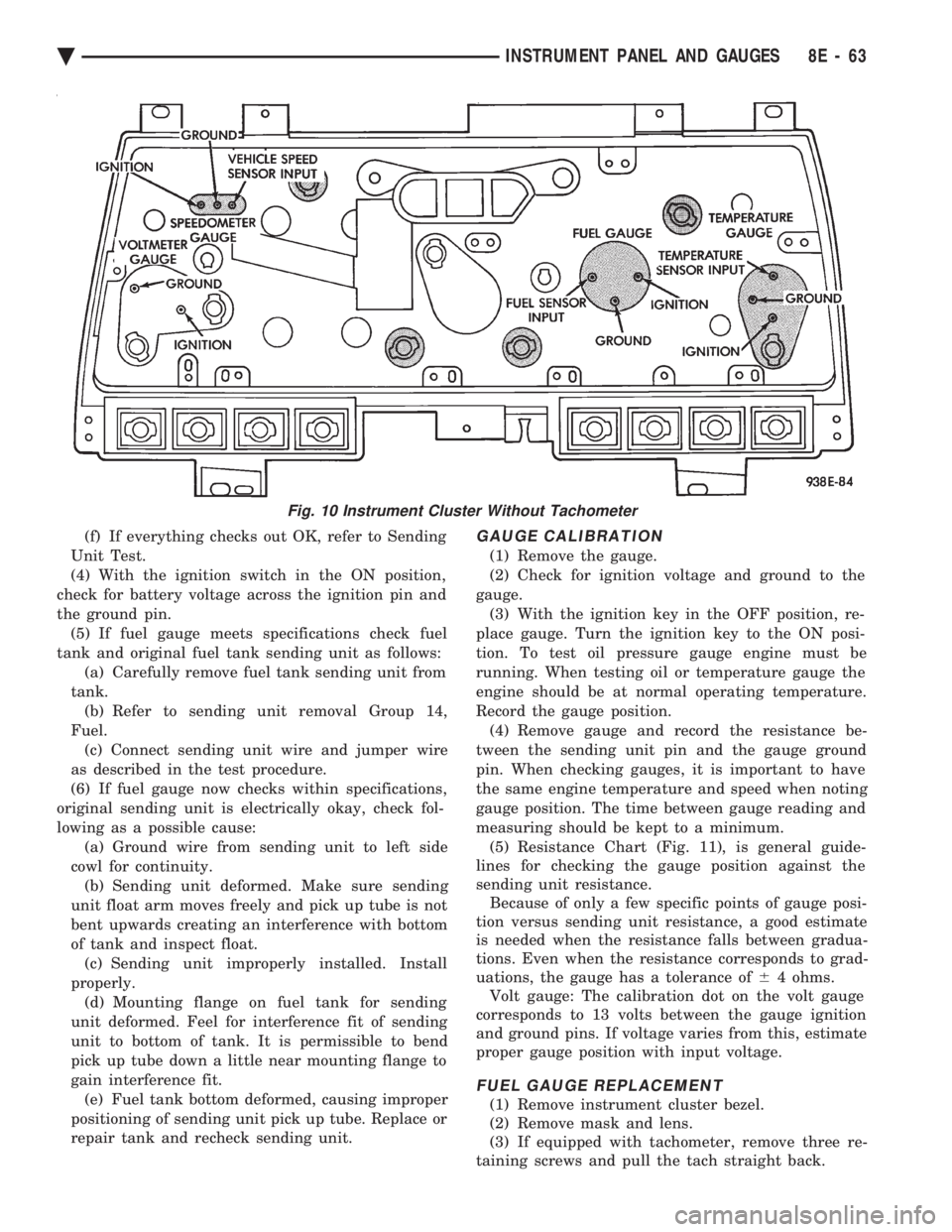

repair tank and recheck sending unit.GAUGE CALIBRATION

(1) Remove the gauge.

(2) Check for ignition voltage and ground to the

gauge. (3) With the ignition key in the OFF position, re-

place gauge. Turn the ignition key to the ON posi-

tion. To test oil pressure gauge engine must be

running. When testing oil or temperature gauge the

engine should be at normal operating temperature.

Record the gauge position. (4) Remove gauge and record the resistance be-

tween the sending unit pin and the gauge ground

pin. When checking gauges, it is important to have

the same engine temperature and speed when noting

gauge position. The time between gauge reading and

measuring should be kept to a minimum. (5) Resistance Chart (Fig. 11), is general guide-

lines for checking the gauge position against the

sending unit resistance. Because of only a few specific points of gauge posi-

tion versus sending unit resistance, a good estimate

is needed when the resistance falls between gradua-

tions. Even when the resistance corresponds to grad-

uations, the gauge has a tolerance of 64 ohms.

Volt gauge: The calibration dot on the volt gauge

corresponds to 13 volts between the gauge ignition

and ground pins. If voltage varies from this, estimate

proper gauge position with input voltage.

FUEL GAUGE REPLACEMENT

(1) Remove instrument cluster bezel.

(2) Remove mask and lens.

(3) If equipped with tachometer, remove three re-

taining screws and pull the tach straight back.

Fig. 10 Instrument Cluster Without Tachometer

Ä INSTRUMENT PANEL AND GAUGES 8E - 63

Page 589 of 2438

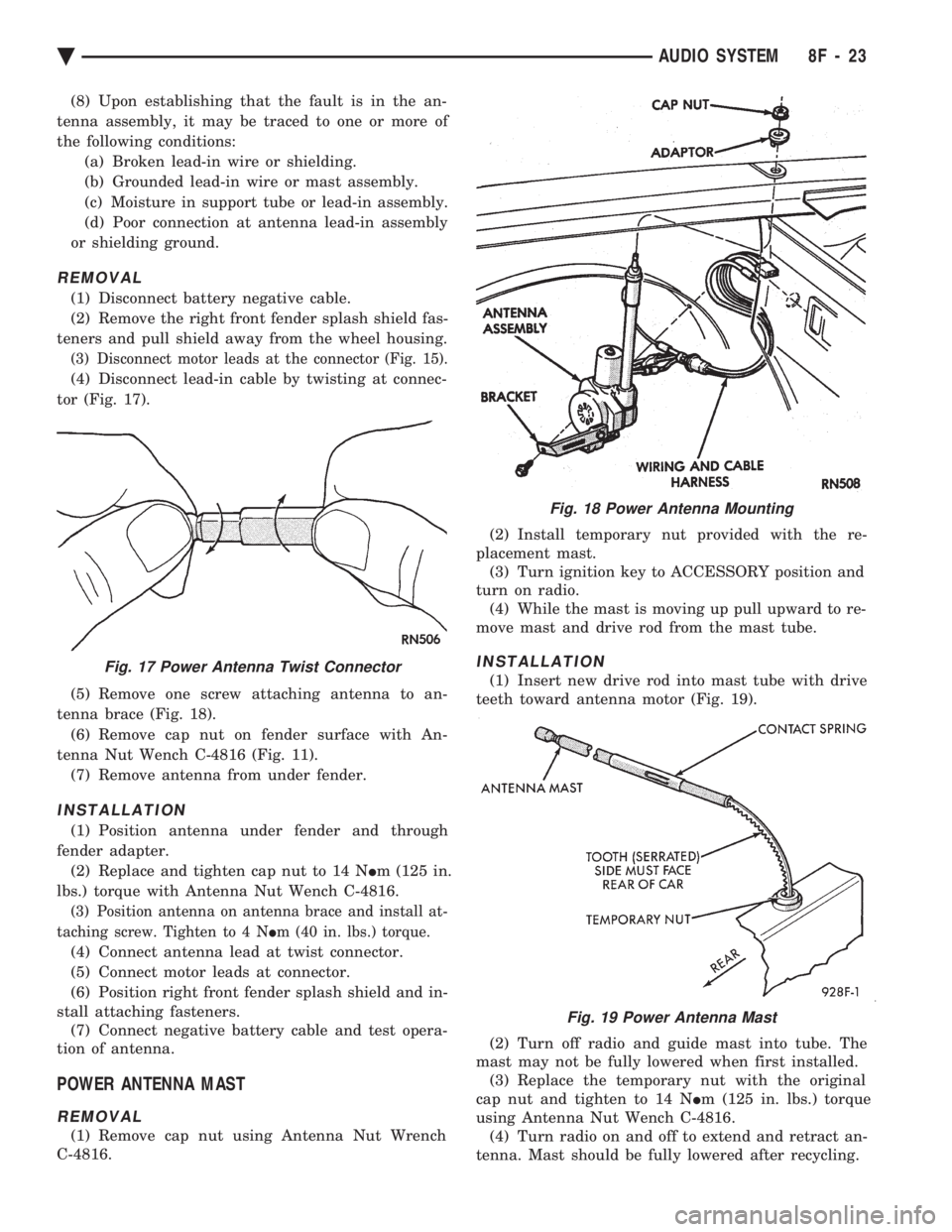

(8) Upon establishing that the fault is in the an-

tenna assembly, it may be traced to one or more of

the following conditions: (a) Broken lead-in wire or shielding.

(b) Grounded lead-in wire or mast assembly.

(c) Moisture in support tube or lead-in assembly.

(d) Poor connection at antenna lead-in assembly

or shielding ground.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the right front fender splash shield fas-

teners and pull shield away from the wheel housing.

(3) Disconnect motor leads at the connector (Fig. 15).

(4) Disconnect lead-in cable by twisting at connec-

tor (Fig. 17).

(5) Remove one screw attaching antenna to an-

tenna brace (Fig. 18). (6) Remove cap nut on fender surface with An-

tenna Nut Wench C-4816 (Fig. 11). (7) Remove antenna from under fender.

INSTALLATION

(1) Position antenna under fender and through

fender adapter. (2) Replace and tighten cap nut to 14 N Im (125 in.

lbs.) torque with Antenna Nut Wench C-4816.

(3) Position antenna on antenna brace and install at-

taching screw. Tighten to 4 N Im (40 in. lbs.) torque.

(4) Connect antenna lead at twist connector.

(5) Connect motor leads at connector.

(6) Position right front fender splash shield and in-

stall attaching fasteners. (7) Connect negative battery cable and test opera-

tion of antenna.

POWER ANTENNA MAST

REMOVAL

(1) Remove cap nut using Antenna Nut Wrench

C-4816. (2) Install temporary nut provided with the re-

placement mast. (3) Turn ignition key to ACCESSORY position and

turn on radio. (4) While the mast is moving up pull upward to re-

move mast and drive rod from the mast tube.

INSTALLATION

(1) Insert new drive rod into mast tube with drive

teeth toward antenna motor (Fig. 19).

(2) Turn off radio and guide mast into tube. The

mast may not be fully lowered when first installed. (3) Replace the temporary nut with the original

cap nut and tighten to 14 N Im (125 in. lbs.) torque

using Antenna Nut Wench C-4816. (4) Turn radio on and off to extend and retract an-

tenna. Mast should be fully lowered after recycling.

Fig. 18 Power Antenna Mounting

Fig. 17 Power Antenna Twist Connector

Fig. 19 Power Antenna Mast

Ä AUDIO SYSTEM 8F - 23

Page 605 of 2438

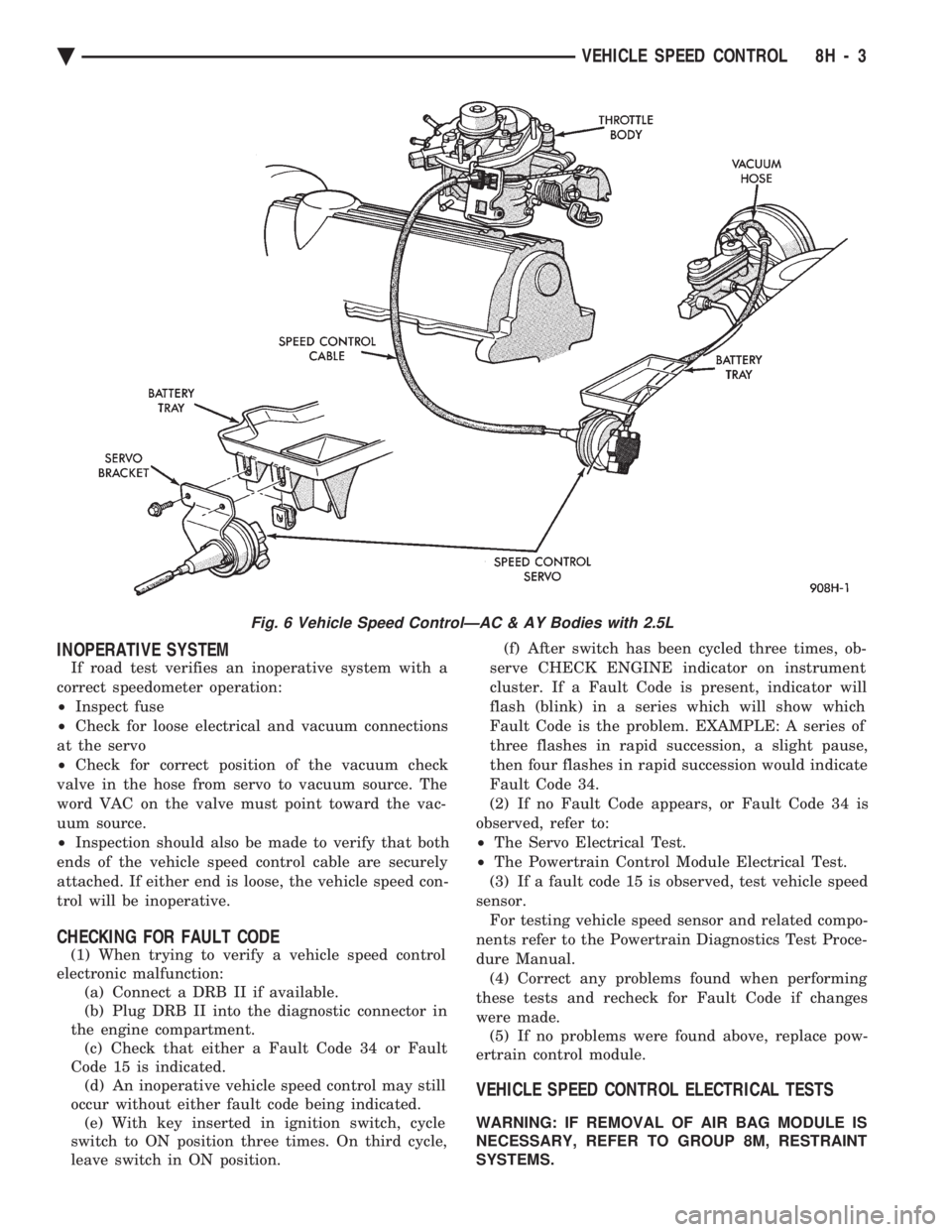

INOPERATIVE SYSTEM

If road test verifies an inoperative system with a

correct speedometer operation:

² Inspect fuse

² Check for loose electrical and vacuum connections

at the servo

² Check for correct position of the vacuum check

valve in the hose from servo to vacuum source. The

word VAC on the valve must point toward the vac-

uum source.

² Inspection should also be made to verify that both

ends of the vehicle speed control cable are securely

attached. If either end is loose, the vehicle speed con-

trol will be inoperative.

CHECKING FOR FAULT CODE

(1) When trying to verify a vehicle speed control

electronic malfunction: (a) Connect a DRB II if available.

(b) Plug DRB II into the diagnostic connector in

the engine compartment. (c) Check that either a Fault Code 34 or Fault

Code 15 is indicated. (d) An inoperative vehicle speed control may still

occur without either fault code being indicated. (e) With key inserted in ignition switch, cycle

switch to ON position three times. On third cycle,

leave switch in ON position. (f) After switch has been cycled three times, ob-

serve CHECK ENGINE indicator on instrument

cluster. If a Fault Code is present, indicator will

flash (blink) in a series which will show which

Fault Code is the problem. EXAMPLE: A series of

three flashes in rapid succession, a slight pause,

then four flashes in rapid succession would indicate

Fault Code 34.

(2) If no Fault Code appears, or Fault Code 34 is

observed, refer to:

² The Servo Electrical Test.

² The Powertrain Control Module Electrical Test.

(3) If a fault code 15 is observed, test vehicle speed

sensor. For testing vehicle speed sensor and related compo-

nents refer to the Powertrain Diagnostics Test Proce-

dure Manual. (4) Correct any problems found when performing

these tests and recheck for Fault Code if changes

were made. (5) If no problems were found above, replace pow-

ertrain control module.

VEHICLE SPEED CONTROL ELECTRICAL TESTS

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

Fig. 6 Vehicle Speed ControlÐAC & AY Bodies with 2.5L

Ä VEHICLE SPEED CONTROL 8H - 3

Page 675 of 2438

ILLUMINATED ENTRY SYSTEM INDEX

page page

Body Controller ComputerÐAC, AG, AJ and AY-Body ............................. 34

Diagnostic ProceduresÐAA-Body ............ 33 Diagnostic ProceduresÐAC, AG, AJ and AY-Body . 33

General Information ....................... 33

Illuminated Entry ModuleÐAA-Body ........... 34

GENERAL INFORMATION

AA-BODY

The Illuminated Entry System (on AA Body) actu-

ates the interior courtesy and/or dome lamps (except

for the illuminated ignition switch) by lifting either

front door exterior handle. Lamp illumination is terminated 35 seconds ( 68

seconds later when battery voltage is normal), or by

turning the ignition switch to the run position,

whichever occurs first. When testing the system, all

vehicle doors must be closed to prevent the door jam

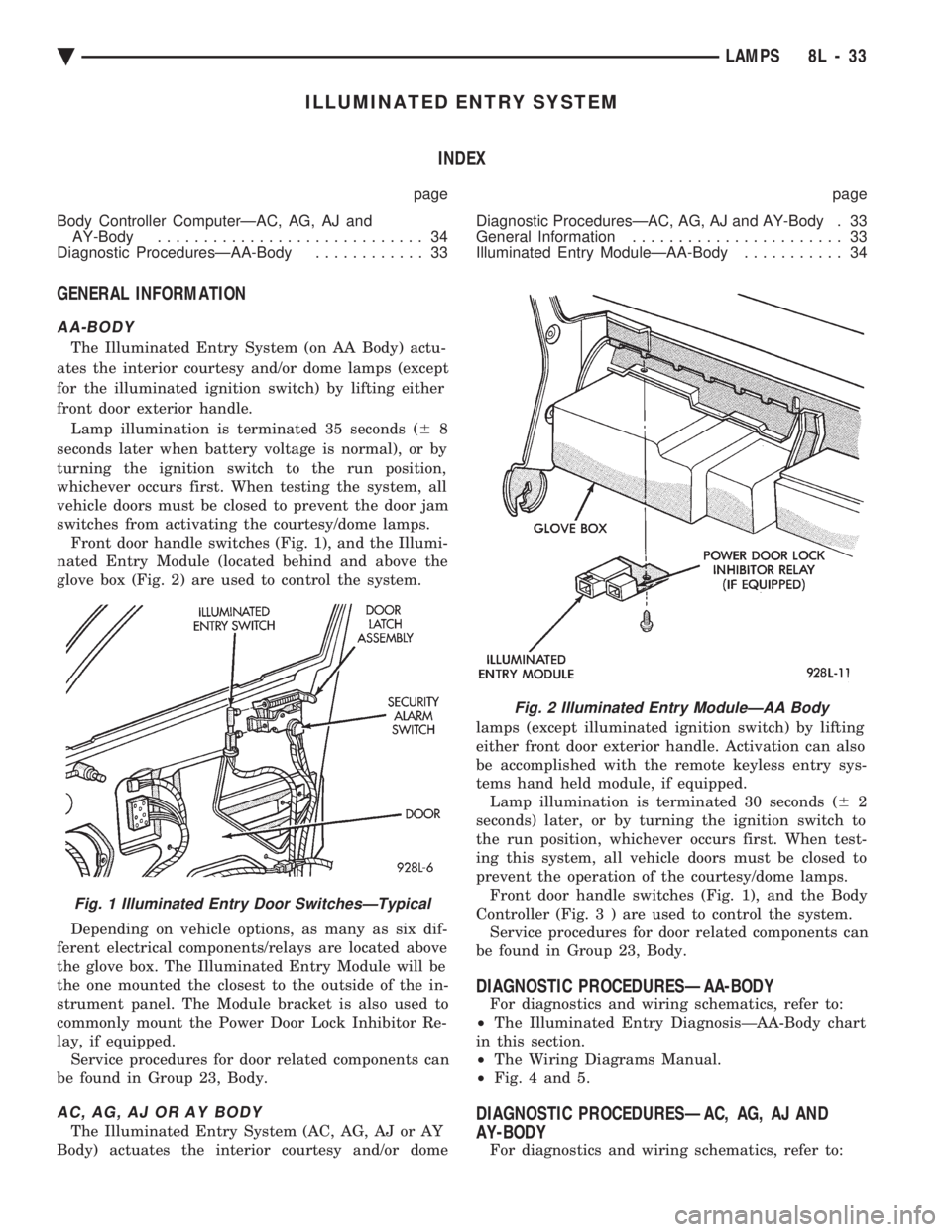

switches from activating the courtesy/dome lamps. Front door handle switches (Fig. 1), and the Illumi-

nated Entry Module (located behind and above the

glove box (Fig. 2) are used to control the system.

Depending on vehicle options, as many as six dif-

ferent electrical components/relays are located above

the glove box. The Illuminated Entry Module will be

the one mounted the closest to the outside of the in-

strument panel. The Module bracket is also used to

commonly mount the Power Door Lock Inhibitor Re-

lay, if equipped. Service procedures for door related components can

be found in Group 23, Body.

AC, AG, AJ OR AY BODY

The Illuminated Entry System (AC, AG, AJ or AY

Body) actuates the interior courtesy and/or dome lamps (except illuminated ignition switch) by lifting

either front door exterior handle. Activation can also

be accomplished with the remote keyless entry sys-

tems hand held module, if equipped. Lamp illumination is terminated 30 seconds ( 62

seconds) later, or by turning the ignition switch to

the run position, whichever occurs first. When test-

ing this system, all vehicle doors must be closed to

prevent the operation of the courtesy/dome lamps. Front door handle switches (Fig. 1), and the Body

Controller (Fig . 3 ) are used to control the system.

Service procedures for door related components can

be found in Group 23, Body.

DIAGNOSTIC PROCEDURESÐAA-BODY

For diagnostics and wiring schematics, refer to:

² The Illuminated Entry DiagnosisÐAA-Body chart

in this section.

² The Wiring Diagrams Manual.

² Fig. 4 and 5.

DIAGNOSTIC PROCEDURESÐAC, AG, AJ AND

AY-BODY

For diagnostics and wiring schematics, refer to:

Fig. 1 Illuminated Entry Door SwitchesÐTypical

Fig. 2 Illuminated Entry ModuleÐAA Body

Ä LAMPS 8L - 33

Page 685 of 2438

SERVICE OF DEPLOYED AIR BAG MODULE

After an air bag has been deployed, the air bag

module and clockspring must be replaced because

they cannot be reused. Other air bag system compo-

nents are replaced if damaged.

SCHEDULED MAINTENANCE INSPECTION

Vehicles equipped with a Air Bag System must be

inspected every three years or 30,000 miles / 48,000

Km. The following items should be inspected. (1) Inspect components for damage or deteriora-

tion. (a) If the air bag module housing shows signs of

physical damage or abuse, replace the module. (b) Check that both front impact sensors are

properly installed to the upper crossmember of the

radiator closure panel. Repair as required.

(2) Check the air bag warning lamp for proper op-

eration as follows: (a) Turn ignition switch to the ON position, the

air bag warning lamp should light. If not, test the system using the DRB II and Passive Restraint

System Diagnostic Procedures Manual. Repair as

required.

(b) The air bag warning lamp lights, but fails to go

out after ten seconds. Test the system using the DRB

II and Passive Restraint System Diagnostic Proce-

dures Manual. Repair as required. (c) Erasing of fault codes is not required.

AIR BAG SYSTEM CHECK

WARNING: BEFORE BEGINNING ANY AIR BAG SYS-

TEM CHECK PROCEDURES, REMOVE AND ISOLATE

THE BATTERY NEGATIVE (-) CABLE (GROUND)

FROM THE VEHICLE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIR BAG SYSTEM.

FAILURE TO DO THIS COULD RESULT IN ACCIDEN-

TAL AIR BAG DEPLOYMENT AND POSSIBLE PER-

SONAL INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY IS

TO BE REMOVED FROM THE STEERING WHEEL,

DISCONNECT BATTERY GROUND CABLE AND

ISOLATE. ALLOW SYSTEM CAPACITOR TO DIS-

CHARGE FOR TWO MINUTES, THEN BEGIN AIR

BAG REMOVAL. (1) Disconnect the battery negative cable and iso-

late. (2) Remove forward console or cover as necessary.

(3) Connect DRB II to ASDM diagnostic 6-way con-

nector, located at right side of module. (4) Turn the ignition key to ON position. Exit vehicle

with DRB II. Use the latest version of the proper

cartridge. (5) After checking that no one is inside the vehicle,

connect the negative battery cable. (6) Using the DRB II, read and record active fault

data. (7) Read and record any stored faults.

(8) Refer to the Passive Restraint Diagnostic Test

Manual if any faults are found in steps 6 and 7. (9) Erase stored faults if there are no active fault

codes. If problems remain, fault codes will not erase. (10) With the ignition key in the ON position, make

sure no one is in the vehicle. (11) From the passenger side of vehicle, turn the

ignition key to OFF then ON and observe the instru-

ment cluster air bag lamp. It should go on for 6 to 8

seconds, then go out; indicating system is functioning

normally. If air bag warning lamp either fails to light,

blinks on and off or goes on and stays on, there is

a system malfunction. Refer to the Passive Re-

straint Diagnostic Test Manual to diagnose the

problem.

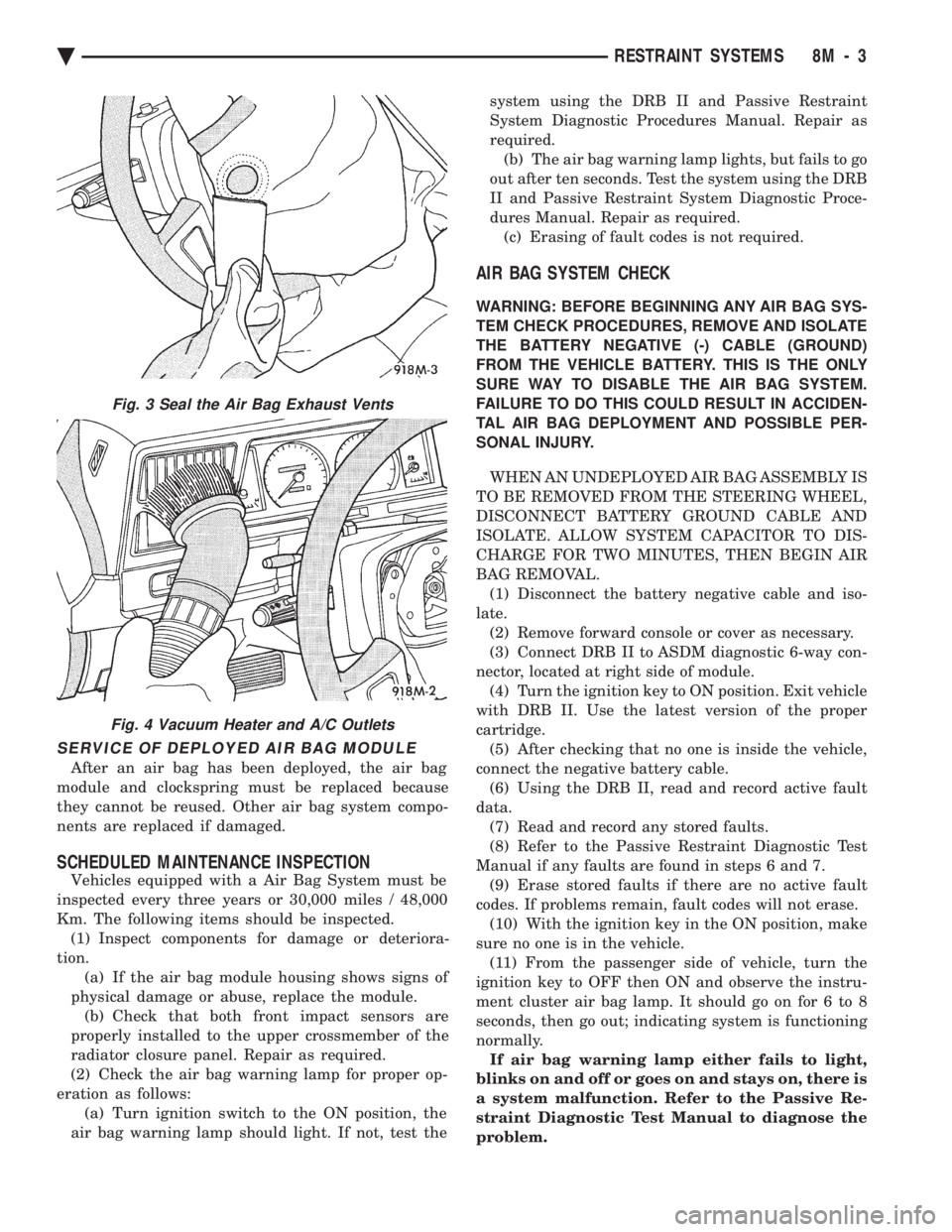

Fig. 3 Seal the Air Bag Exhaust Vents

Fig. 4 Vacuum Heater and A/C Outlets

Ä RESTRAINT SYSTEMS 8M - 3