engine CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 16 of 2438

CHRYSLER

CORPORATION

ENGINEÐCHASSISÐBODY

SERVICE MANUAL

1993 FRONT WHEEL DRIVE

PASSENGER VEHICLES

To order the special service tools used and

illustrated, please refer to the instructions on

inside back cover.

NO PART OF THIS PUBLICATION MAY BE

REPRODUCED, STORED IN A RETRIEVAL

SYSTEM, OR TRANSMITTED, IN ANY FORM

OR BY ANY MEANS, ELECTRONIC, ME-

CHANICAL, PHOTOCOPYING, RECORDING,

OR OTHERWISE, WITHOUT THE PRIOR

WRITTEN PERMISSION OF CHRYSLER

CORPORATION.

Chrysler Corporation reserves the right to make changes in design or to make

additions to or improvements in its products without imposing any obligations

upon itself to install them on its products previously manufactured.

Litho in U.S.A. Copyright 1992 Chrysler Corporation 30M0792

NEXT PAGE©

Page 17 of 2438

FOREWORD

The information contained in this service manual has been prepared for the professional automotive

technician involved in daily repair operations. This manual does not cover theory of operation, which is addressed

in service training material. Information describing the operation and use of standard and optional equipment is

included in the Owner's Manual provided with the vehicle.

Information in this manual is divided into groups. These groups contain general information, diagnosis,

testing, adjustments, removal, installation, disassembly, and assembly procedures for the components.

The Component and System Index of this manual identifies the correct group for the component or system to

be serviced. To assist in locating a group title page, use the Group Tab Locator on the following page. The solid bar

after the group title is aligned to a solid tab on the first page of each group. The first page of the group has a

contents section that lists major topics within the group.

A Service Manual Comment form is included at the rear of this manual. Use the form to provide Chrysler

Corporation with your comments and suggestions.

Tightening torques are provided as a specific value throughout this manual. This value represents the

midpoint of the acceptable engineering torque range for a given fastener application. These torque values are

intended for use in service assembly and installation procedures using the correct OEM fasteners. When replacing

fasteners, always use the same type (part number) fastener as removed.

Chrysler Corporation reserves the right to change testing procedures, specifications, diagnosis, repair

methods, or vehicle wiring at any time without prior notice or incurring obligation.

NOTE: The acronyms, terminology and nomenclature used to identify emissions related components in this

manual may have changed from prior publications. These new terms are in compliance with S.A.E.

recommended practice J1930. This terminology standard (J1930) is required to comply with the 1993

California Air Research Board (CARB) requirements.

FOR INFORMATION NOT CONTAINED IN THIS MANUAL, REFER TO FRONT WHEEL DRIVE

PASSENGER VEHICLES ELECTRICALÐFUELÐEMISSIONS OR WIRING DIAGRAMS SERVICE

MANUALS.

NEXT PAGE©

Page 18 of 2438

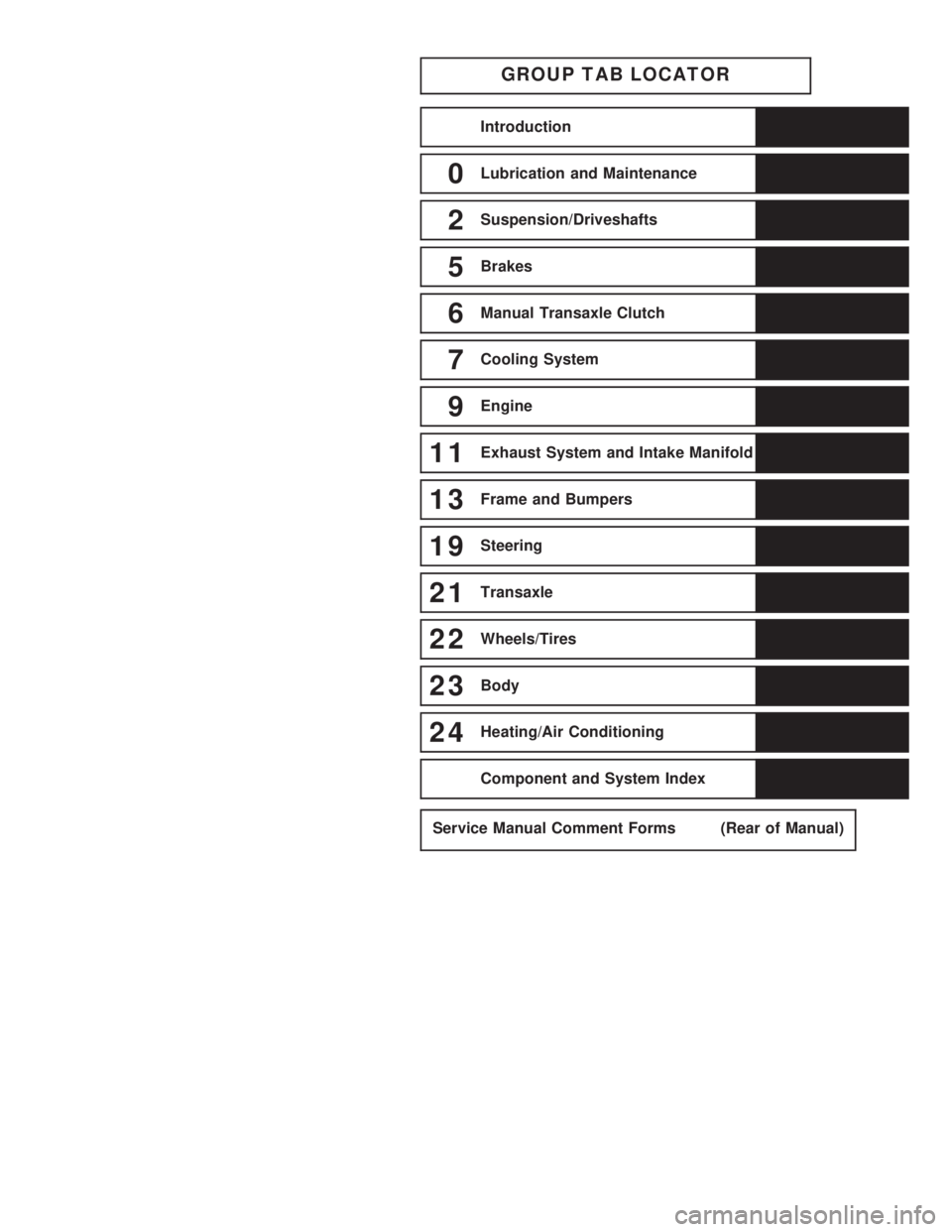

GROUP TAB LOCATOR

Introduction

0Lubrication and Maintenance

2Suspension/Driveshafts

5Brakes

6Manual Transaxle Clutch

7Cooling System

9Engine

11Exhaust System and Intake Manifold

13Frame and Bumpers

19Steering

21Transaxle

22Wheels/Tires

23Body

24Heating/Air Conditioning

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 21 of 2438

FOREWORD

The information contained in this service manual has been prepared for the professional automotive

technician involved in daily repair operations. This manual does not cover theory of operation, which is addressed

in service training material. Information describing the operation and use of standard and optional equipment is

included in the Owner's Manual provided with the vehicle.

Information in this manual is divided into groups. These groups contain general information, diagnosis,

testing, adjustments, removal, installation, disassembly, and assembly procedures for the components.

The Component and System Index of this manual identifies the correct group for the component or system to

be serviced. To assist in locating a group title page, use the Group Tab Locator on the following page. The solid bar

after the group title is aligned to a solid tab on the first page of each group. The first page of the group has a

contents section that lists major topics within the group.

A Service Manual Comment form is included at the rear of this manual. Use the form to provide Chrysler

Corporation with your comments and suggestions.

Tightening torques are provided as a specific value throughout this manual. This value represents the

midpoint of the acceptable engineering torque range for a given fastener application. These torque values are

intended for use in service assembly and installation procedures using the correct OEM fasteners. When replacing

fasteners, always use the same type (part number) fastener as removed.

Chrysler Corporation reserves the right to change testing procedures, specifications, diagnosis, repair

methods, or vehicle wiring at any time without prior notice or incurring obligation.

NOTE: The acronyms, terminology and nomenclature used to identify emissions related components in this

manual may have changed from prior publications. These new terms are in compliance with S.A.E.

recommended practice J1930. This terminology standard (J1930) is required to comply with the 1993

California Air Research Board (CARB) requirements.

FOR INFORMATION NOT CONTAINED IN THIS MANUAL, REFER TO FRONT WHEEL DRIVE

PASSENGER VEHICLES ENGINEÐCHASSISÐBODY OR WIRING DIAGRAMS SERVICE MANUALS.

NEXT PAGE ©

Page 25 of 2438

FOREWORD

The information contained in this service manual has been prepared for the professional automotive

technician involved in daily repair operations. This manual does not cover theory of operation, which is addressed

in service training material. Information describing the operation and use of standard and optional equipment is

included in the Owner's Manual provided with the vehicle.

Information in this manual is divided into groups. These groups contain general information, diagnosis,

testing, adjustments, removal, installation, disassembly, and assembly procedures for the components.

The Component and System Index of this manual identifies the correct group for the component or system to

be serviced. To assist in locating a group title page, use the Group Tab Locator on the following page. The solid bar

after the group title is aligned to a solid tab on the first page of each group. The first page of the group has a

contents section that lists major topics within the group.

A Service Manual Comment form is included at the rear of this manual. Use the form to provide Chrysler

Corporation with your comments and suggestions.

Tightening torques are provided as a specific value throughout this manual. This value represents the

midpoint of the acceptable engineering torque range for a given fastener application. These torque values are

intended for use in service assembly and installation procedures using the correct OEM fasteners. When replacing

fasteners, always use the same type (part number) fastener as removed.

Chrysler Corporation reserves the right to change testing procedures, specifications, diagnosis, repair

methods, or vehicle wiring at any time without prior notice or incurring obligation.

NOTE: The acronyms, terminology and nomenclature used to identify emissions related components in this

manual may have changed from prior publications. These new terms are in compliance with S.A.E.

recommended practice J1930. This terminology standard (J1930) is required to comply with the

California Air Research Board (CARB) requirements.

NEXT PAGE ©

Page 29 of 2438

FOREWORD

The information contained in this Service Manual has been prepared for the professional automotive

technician involved in daily repair operations. Information describing the operation and use of standard and

optional equipment is included in the Owner's Manual provided with the vehicle.

These diagrams contain the latest information at the time of publication and incorporate the wiring schematic

for the basic vehicle and available optional equipment.

The diagrams are grouped by body type and sales division. The body codes are explained in the General

Information section. (ExampleÐAP-D, P=Shadow, Sundance). To locate a system or component refer to the black

index tabs on the next page. The tab will assist you in locating the desired area of the manual.

An alphabetical index is provided at the beginning of each section to help you in locating a system or

component. All diagrams are identified by SHEET NUMBER which is found in the lower right- or left-hand corner

of the page.

A Service Manual Comment form is included at the rear of this manual. Use the form to provide Chrysler

Corporation with your comments and suggestions.

Chrysler Corporation reserves the right to change testing procedures, specifications, diagnosis, repair

methods, or vehicle wiring at any time without prior notice or incurring obligation.

NOTE: The acronyms, terminology and nomenclature used to identify emissions related components in this

manual may have changed from prior publications. These new terms are in compliance with S.A.E.

recommended practice J1930. This terminology standard (J1930) is required to comply with the 1993

California Air Research Board (CARB) requirements.

FOR INFORMATION NOT CONTAINED IN THIS MANUAL, REFER TO THE FRONT WHEEL

DRIVE PASSENGER VEHICLES ENGINEÐCHASSISÐBODY OR ELECTRICALÐFUELÐEMISSIONS

SERVICE MANUALS.

NEXT PAGE ©

Page 31 of 2438

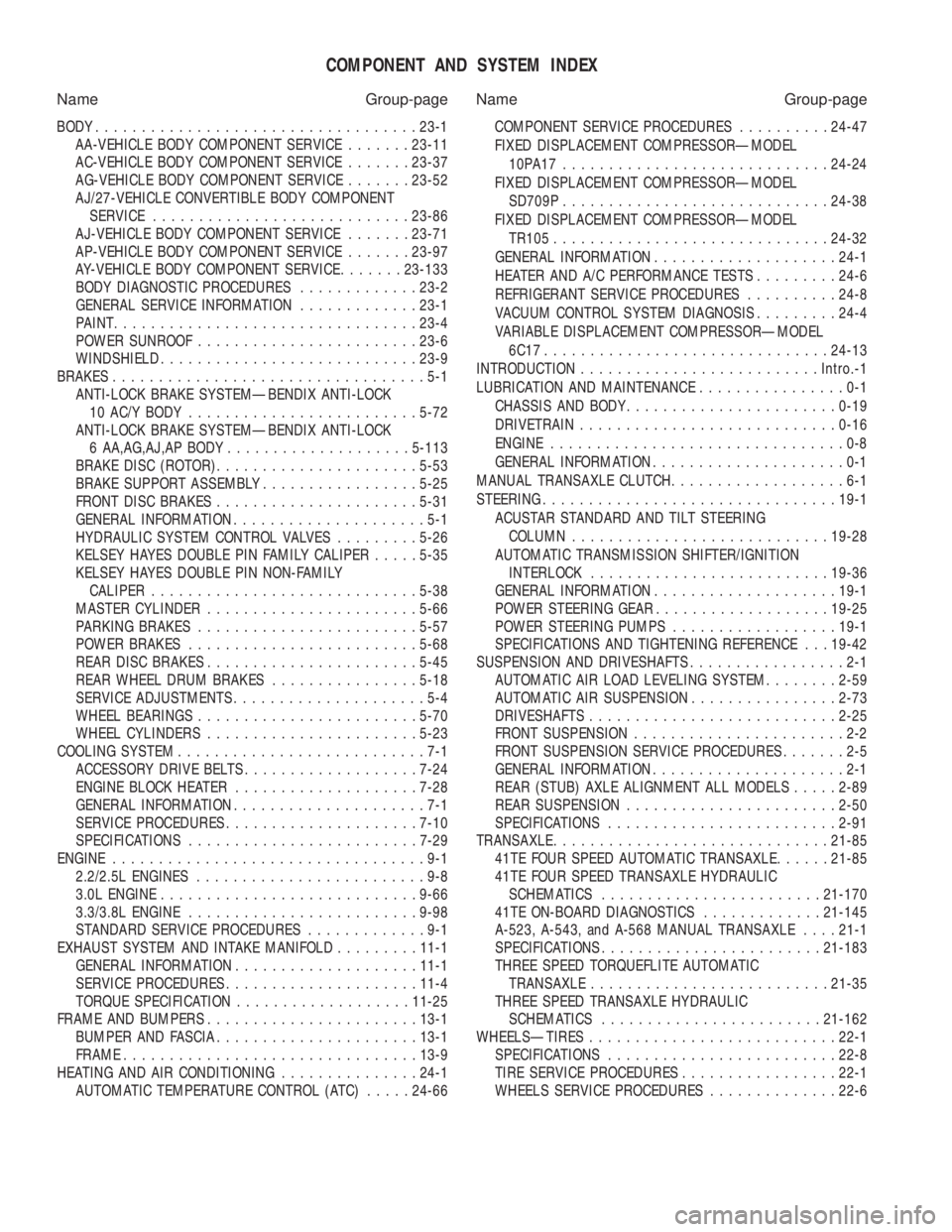

COMPONENT AND SYSTEM INDEX

Name Group-page Name Group-page

BODY ................................... 23-1

AA-VEHICLE BODY COMPONENT SERVICE .......23-11

AC-VEHICLE BODY COMPONENT SERVICE .......23-37

AG-VEHICLE BODY COMPONENT SERVICE .......23-52

AJ/27-VEHICLE CONVERTIBLE BODY COMPONENT SERVICE ............................ 23-86

AJ-VEHICLE BODY COMPONENT SERVICE .......23-71

AP-VEHICLE BODY COMPONENT SERVICE .......23-97

AY-VEHICLE BODY COMPONENT SERVICE .......23-133

BODY DIAGNOSTIC PROCEDURES .............23-2

GENERAL SERVICE INFORMATION .............23-1

PAINT ................................. 23-4

POWER SUNROOF ........................ 23-6

WINDSHIELD ............................ 23-9

BRAKES ..................................5-1

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ......................... 5-72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY .................... 5-113

BRAKE DISC (ROTOR) ...................... 5-53

BRAKE SUPPORT ASSEMBLY .................5-25

FRONT DISC BRAKES ...................... 5-31

GENERAL INFORMATION .....................5-1

HYDRAULIC SYSTEM CONTROL VALVES .........5-26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER .....5-35

KELSEY HAYES DOUBLE PIN NON-FAMILY CALIPER ............................. 5-38

MASTER CYLINDER ....................... 5-66

PARKING BRAKES ........................ 5-57

POWER BRAKES ......................... 5-68

REAR DISC BRAKES ....................... 5-45

REAR WHEEL DRUM BRAKES ................5-18

SERVICE ADJUSTMENTS .....................5-4

WHEEL BEARINGS ........................ 5-70

WHEEL CYLINDERS ....................... 5-23

COOLING SYSTEM ...........................7-1

ACCESSORY DRIVE BELTS ................... 7-24

ENGINE BLOCK HEATER .................... 7-28

GENERAL INFORMATION .....................7-1

SERVICE PROCEDURES ..................... 7-10

SPECIFICATIONS ......................... 7-29

ENGINE ..................................9-1

2.2/2.5L ENGINES .........................9-8

3.0L ENGINE ............................ 9-66

3.3/3.8L ENGINE ......................... 9-98

STANDARD SERVICE PROCEDURES .............9-1

EXHAUST SYSTEM AND INTAKE MANIFOLD .........11-1

GENERAL INFORMATION .................... 11-1

SERVICE PROCEDURES ..................... 11-4

TORQUE SPECIFICATION ................... 11-25

FRAME AND BUMPERS ....................... 13-1

BUMPER AND FASCIA ...................... 13-1

FRAME ................................ 13-9

HEATING AND AIR CONDITIONING ...............24-1

AUTOMATIC TEMPERATURE CONTROL (ATC) .....24-66 COMPONENT SERVICE PROCEDURES

..........24-47

FIXED DISPLACEMENT COMPRESSORÐMODEL 10PA17............................. 24-24

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P ............................. 24-38

FIXED DISPLACEMENT COMPRESSORÐMODEL TR105 .............................. 24-32

GENERAL INFORMATION .................... 24-1

HEATER AND A/C PERFORMANCE TESTS .........24-6

REFRIGERANT SERVICE PROCEDURES ..........24-8

VACUUM CONTROL SYSTEM DIAGNOSIS .........24-4

VARIABLE DISPLACEMENT COMPRESSORÐMODEL 6C17 ............................... 24-13

INTRODUCTION .......................... Intro.-1

LUBRICATION AND MAINTENANCE ................0-1

CHASSIS AND BODY ....................... 0-19

DRIVETRAIN ............................ 0-16

ENGINE ................................0-8

GENERAL INFORMATION .....................0-1

MANUAL TRANSAXLE CLUTCH ...................6-1

STEERING ................................ 19-1

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 19-28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 19-36

GENERAL INFORMATION .................... 19-1

POWER STEERING GEAR ................... 19-25

POWER STEERING PUMPS ..................19-1

SPECIFICATIONS AND TIGHTENING REFERENCE . . . 19-42

SUSPENSION AND DRIVESHAFTS .................2-1

AUTOMATIC AIR LOAD LEVELING SYSTEM ........2-59

AUTOMATIC AIR SUSPENSION ................2-73

DRIVESHAFTS ........................... 2-25

FRONT SUSPENSION .......................2-2

FRONT SUSPENSION SERVICE PROCEDURES .......2-5

GENERAL INFORMATION .....................2-1

REAR (STUB) AXLE ALIGNMENT ALL MODELS .....2-89

REAR SUSPENSION ....................... 2-50

SPECIFICATIONS ......................... 2-91

TRANSAXLE .............................. 21-85

41TE FOUR SPEED AUTOMATIC TRANSAXLE ......21-85

41TE FOUR SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 21-170

41TE ON-BOARD DIAGNOSTICS .............21-145

A-523, A-543, and A-568 MANUAL TRANSAXLE ....21-1

SPECIFICATIONS ........................ 21-183

THREE SPEED TORQUEFLITE AUTOMATIC TRANSAXLE .......................... 21-35

THREE SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 21-162

WHEELSÐTIRES ........................... 22-1

SPECIFICATIONS ......................... 22-8

TIRE SERVICE PROCEDURES .................22-1

WHEELS SERVICE PROCEDURES ..............22-6

Page 37 of 2438

LUBRICATION AND MAINTENANCE

CONTENTS

page page

CHASSIS AND BODY .................... 19

DRIVETRAIN ........................... 16 ENGINE

................................ 8

GENERAL INFORMATION .................. 1

GENERAL INFORMATION INDEX

page page

Classification of Lubricants .................. 1

Fluid Capacities .......................... 4

Fuel Usage .............................. 1

Hoisting Recommendations .................. 5

Introduction .............................. 1 Jump Starting Procedure

.................... 4

Parts and Lubricant Recommendations ......... 1

Parts Requiring No Lubrication ............... 4

Severe Service ........................... 1

Towing Recommendations ................... 7

INTRODUCTION

Chrysler Corporation has compiled recommended

lubrication and maintenance schedules and proce-

dures to help reduce premature wear or failure over

a broad range of operating conditions. When select-

ing the proper maintenance schedule, the climate

and operating conditions must be considered. A vehi-

cle subjected to severe usage requires service more

frequently than a vehicle used for general transpor-

tation.

PARTS AND LUBRICANT RECOMMENDATIONS

When service is required, Chrysler Corporation rec-

ommends that only Mopar tbrand parts, lubricants

and chemicals be used. Mopar tprovides the best en-

gineered products for servicing Chrysler Corporation

vehicles.

SEVERE SERVICE

If a vehicle is operated under any of the following

conditions, it is considered severe service.

² Extremely dusty areas.

² 50% or more of vehicle operation in 32ÉC (90ÉF) or

higher temperatures.

² Prolonged idling ( such as, vehicle operation in

stop and go traffic).

² Frequent short running periods. Not allowing en-

gine to warm to operating temperatures.

² Police or taxi usage.

FUEL USAGE

All Chrysler Corporation engines require the use of

unleaded fuel to reduce exhaust emissions. Use fuel

with a minimum octane rating of 87,(R + M)/2. See

Engine section of this group for Fuel Recommenda-

tions.

CLASSIFICATION OF LUBRICANTS

Only lubricants that are endorsed by the following

organizations standards should be used to service a

Chrysler Corporation vehicle.

² Society of Automotive Engineers (SAE)

² American Petroleum Institute (API)

² National Lubricating Grease Institute (NLGI)

ENGINE OIL

SAE GRADE RATING INDICATES ENGINE OIL VISCOSITY

² SAE 30 = single grade engine oil.

² SAE 5W-30 = multiple grade engine oil.

API QUALITY CLASSIFICATION.

² SG service engine oil is a high quality crankcase

lubricant designed for use in all naturally aspirated

engines.

² SG/CD service engine oil is a high quality crank-

case lubricant designed for use in most naturally as-

pirated and turbocharged gasoline or diesel engines.

GEAR LUBRICANTS

SAE ratings also apply to multiple grade gear lu-

bricants. In addition, API classification defines the

lubricants usage.

Ä LUBRICATION AND MAINTENANCE 0 - 1

Page 40 of 2438

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol on the label. At the bottom NLGI symbol is the usage and qual-

ity identification letters. Wheel bearing lubricant is

identified by the letter ``G''. Chassis lubricant is iden-

tified by the letter ``L''. The letter following the us-

age letter indicates the quality of the lubricant. The

following symbols indicate the highest quality.

FLUID CAPACITIES

Fuel Tank

AP,AG and AJ ......................................53 L (14 gal.)

AA,AC and AY .....................................60 L (16 gal.)

AA-Flexible Fuel ..................................68 L (18 gal.)

Engine Oil

All.........................................................3.8 L (4.5 qts.)

Cooling System

2.2L ......................................................8.5 L (9.0 qts.)

2.5L ......................................................8.5 L (9.0 qts.)

3.0L ......................................................9.0 L (9.5 qts.)

3.3L ......................................................9.0 L (9.5 qts.)

3.8L ......................................................9.0 L (9.5 qts.)

Includes heater and coolant recovery bottle

Automatic Transaxle

Estimated Service Fill

ALL ......................................................3.8 L (4.0 qts.)

Overhaul Fill Capacity with Torque Converter

Empty

3-speed Fleet .......................................8.7 L (9.2 qts.)

3-speed .................................................8.2 L (8.8 qts.)

4-speed Electronic ................................9.4L (9.9 qts.)

Manual Transaxle

All ..........................................................9.4L (9.9 qts.)

Fill to bottom of fill hole.

Power Steering

All ...........................................................75L (1.5 pts.)

PARTS REQUIRING NO LUBRICATION

Many components on a Chrysler Corporation vehi-

cle require no periodic maintenance. Some compo-

nents are sealed and permanently lubricated. Rubber

bushings can deteriorate or limit damping ability if

lubricated. The following list of components require

no lubrication: ²

Air Pump

² Generator Bushings

² Drive Belts

² Drive Belt Idler/Tensioner Pulley

² Front Wheel Bearings

² Rubber Bushings

² Starter Bearings/Bushings

² Suspension Strut Bearings

² Throttle Control Cable

² Throttle Linkage

² Water Pump Bearings

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT JUMP START A FROZEN BATTERY, PER-

SONAL INJURY CAN RESULT. DO NOT JUMP START WHEN BATTERY INDICA-

TOR DOT IS YELLOW OR BRIGHT COLOR. DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE. DO NOT USE OPEN FLAME NEAR BATTERY.

REMOVE METALLIC JEWELRY WORN ON HANDS

OR WRISTS TO AVOID INJURY BY ACCIDENTAL

ARCHING OF BATTERY CURRENT. WHEN USING A HIGH OUTPUT BOOSTING DE-

VICE, DO NOT ALLOW BATTERY VOLTAGE TO EX-

CEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually in-

spect engine compartment for:

² Battery cable clamp condition, clean if necessary.

² Frozen battery.

² Yellow or bright color test indicator, if equipped.

² Low battery fluid level.

² Generator drive belt condition and tension.

² Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, turn off all accessories, place gear selector in

park or neutral, set park brake and operate engine

at 1200 rpm.

NLGI SYMBOL

0 - 4 LUBRICATION AND MAINTENANCE Ä

Page 41 of 2438

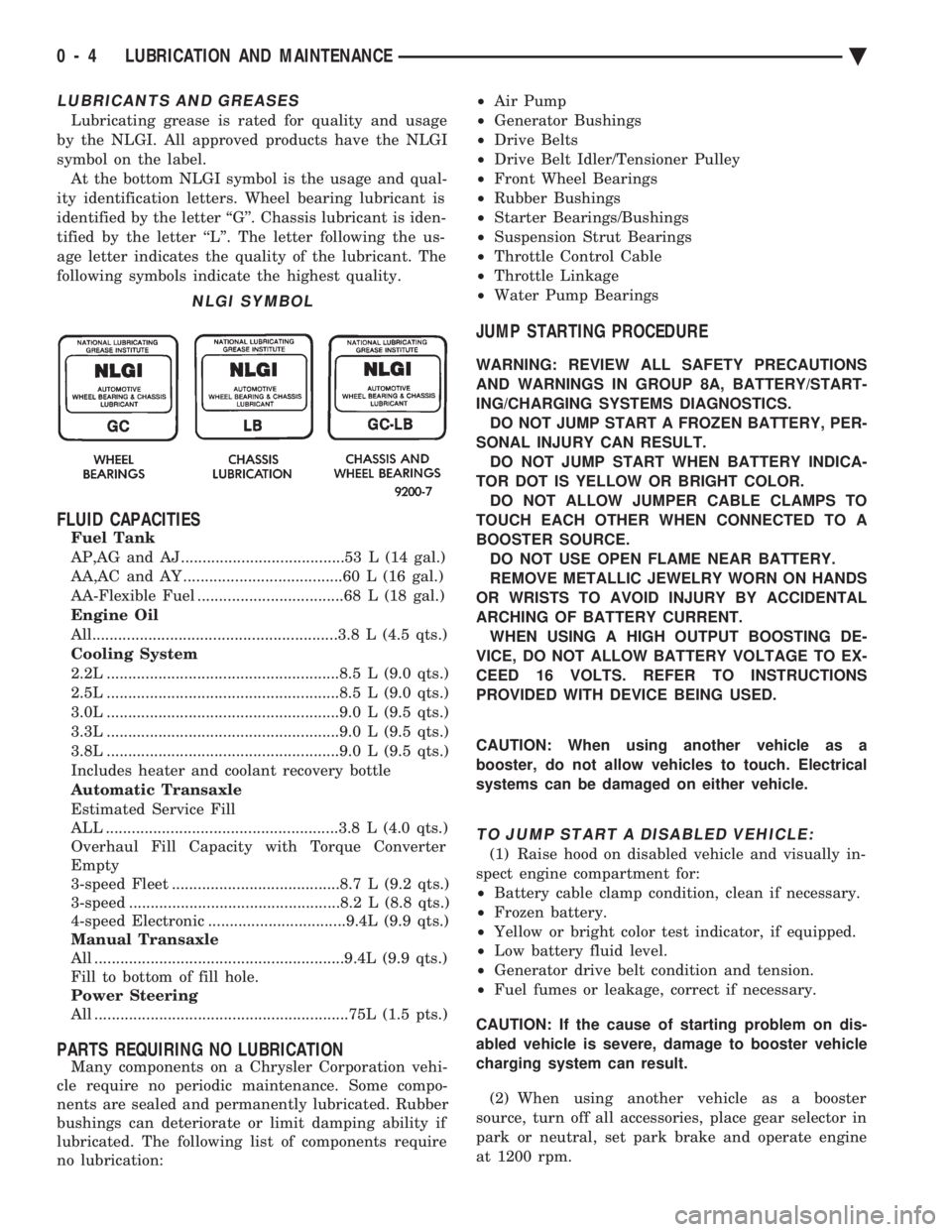

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries. (4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to

negative terminal (-). DO NOT allow clamps at oppo-

site end of cables to touch, electrical arc will result

(Fig. 1). Review all warnings in this procedure. (5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(6) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

² Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

² When using a Booster vehicle, disconnect BLACK

cable clamp from battery negative terminal. Discon-

nect RED cable clamp from battery positive terminal.

² Disconnect RED cable clamp from battery positive

terminal on disabled vehicle.

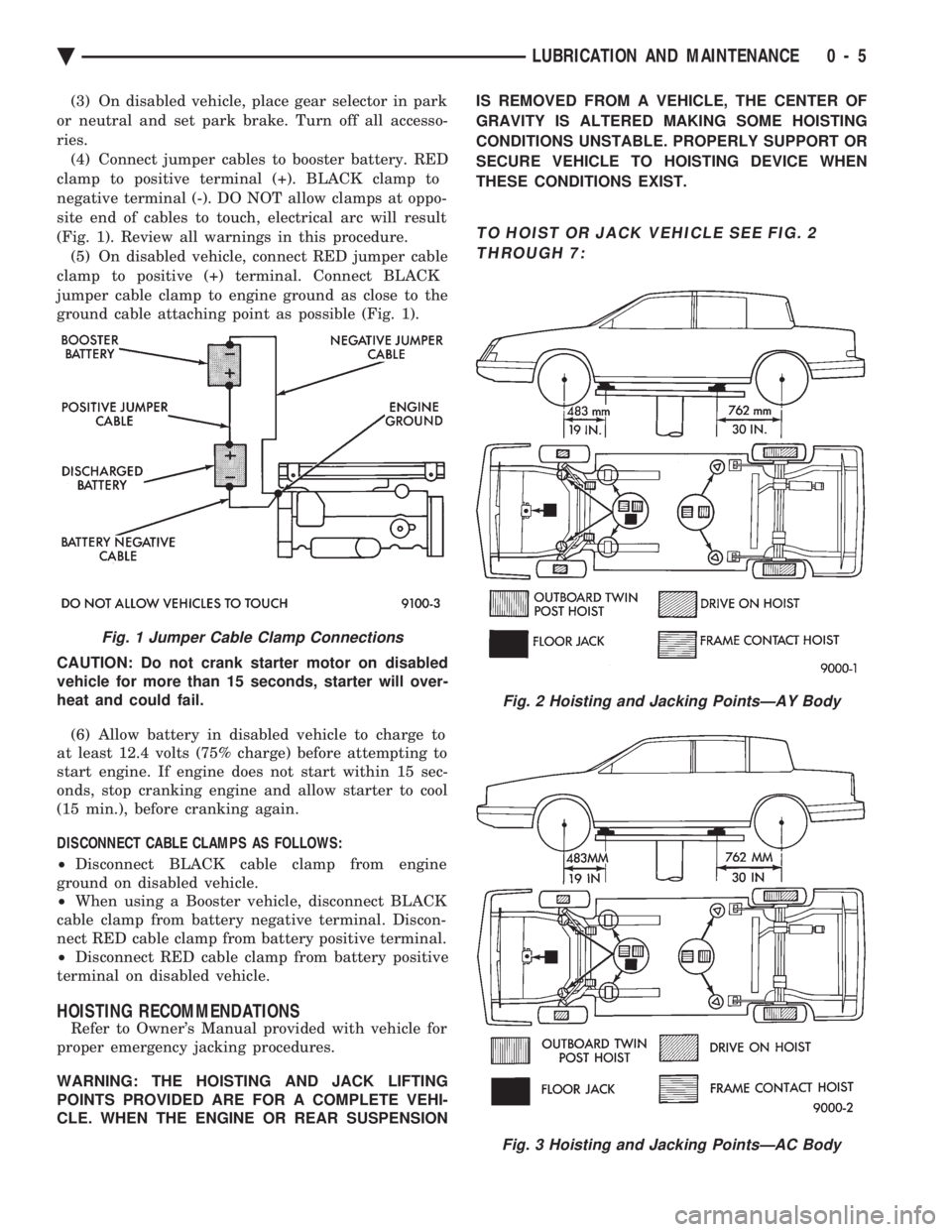

HOISTING RECOMMENDATIONS

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

TO HOIST OR JACK VEHICLE SEE FIG. 2 THROUGH 7:

Fig. 1 Jumper Cable Clamp Connections

Fig. 2 Hoisting and Jacking PointsÐAY Body

Fig. 3 Hoisting and Jacking PointsÐAC Body

Ä LUBRICATION AND MAINTENANCE 0 - 5