maintenance CHEVROLET S10 1994 2.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1994, Model line: S10, Model: CHEVROLET S10 1994 2.GPages: 340, PDF Size: 18.45 MB

Page 236 of 340

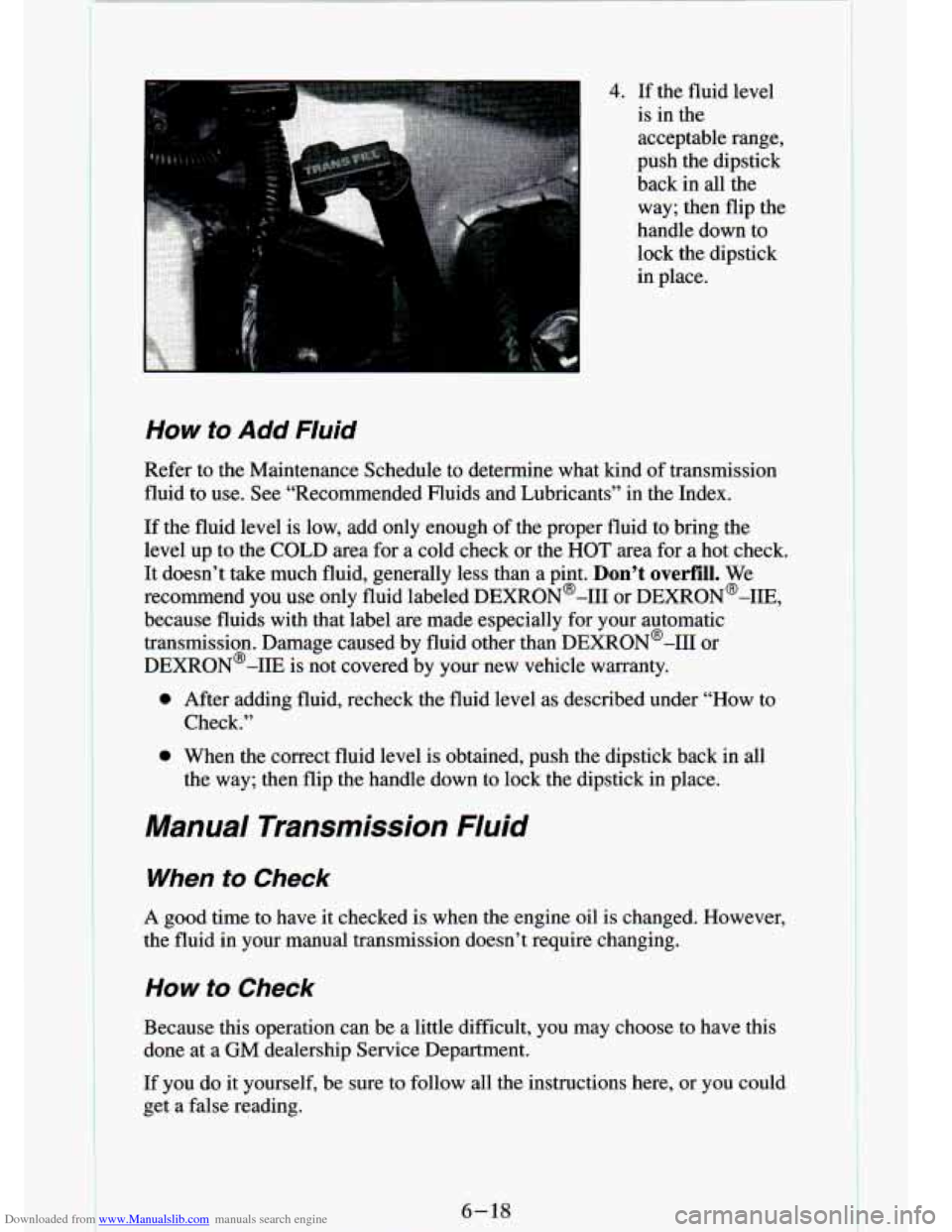

Downloaded from www.Manualslib.com manuals search engine 4. If the fluid level

is in the

acceptable range,

push the dipstick

back in all the

way; then flip the

handle down to

lock the dipstick

in place.

How to Add Fluid

Refer to the Maintenance Schedule to determine what kind of transmission

fluid to use. See “Recommended Fluids and Lubricants”

in the Index.

If the fluid level is low, add only enough of the proper fluid to bring the

level up to the COLD area for a cold check or the

HOT area for a hot check.

It doesn’t take much fluid, generally less than a pint.

Don’t overfill. We

recommend you use only fluid labeled DEXRON@-I11 or DEXRON@-IIE,

because fluids with that label are made especially for your automatic

transmission. Damage caused by fluid other than DEXRON@-I11 or

DEXR0N’-IIE is not covered by your new vehicle warranty.

0 After adding fluid, recheck the fluid level as described under “How to

Check.”

0 When the correct fluid level is obtained, push the dipstick ba\

ck in all

the way; then flip the handle down to lock the dipstick in place.

Manual Transmission Fluid

When to Check

A good time to have it checked is when the engine oil is changed. However,

the fluid in your manual transmission

doesn’t require changing.

How to Check

Because this operation can be a little difficult, you may choose to have this

done at a

GM dealership Service Department.

If you do it yourself, be sure to follow all the instructions\

here, or you could get a false reading.

6-18

Page 237 of 340

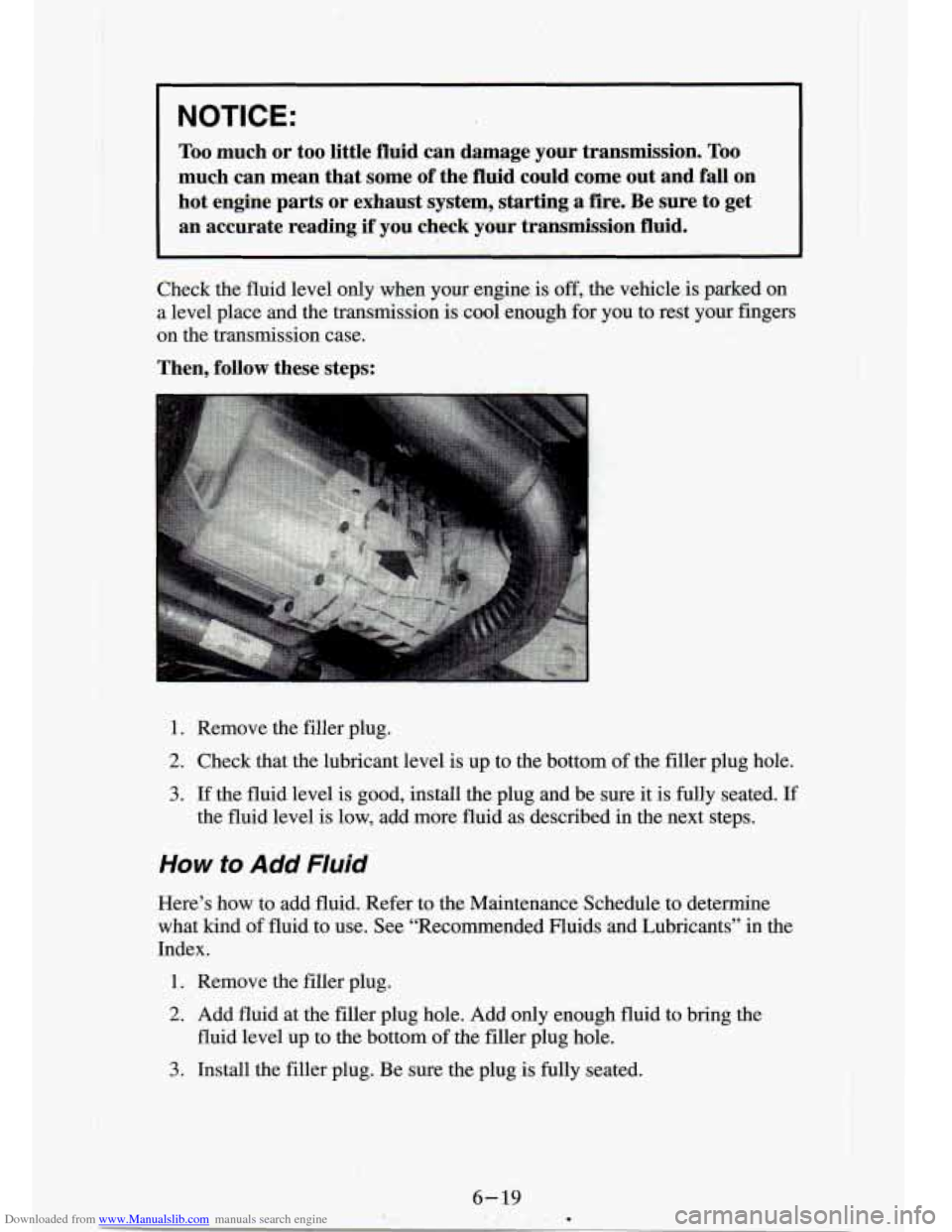

Downloaded from www.Manualslib.com manuals search engine NOTICE:

Too much or too little fluid cm damage your transmission. Too

much can mean that some of the’fluid could come out and fall on

hot engine parts or exhaust systm, starting a fire. Be sure to get

an accurate reading

if you check your transmission fluid.

Check the fluid level only ‘when your engine is off, the vehicle is parked on

a level place and the transmission is cool enough for you to rest your fingers

on the transmission case.

Then, follow these steps:

1. Remove the filler plug.

2. Check that the lubricant level is up to the bottom of the filler plug hole.

3. If the fluid level is good, install the plug and be sure it is fully seated. If

the fluid level is low, add more fluid as described in the next steps.

How to Add Fluid

Here’s how to add fluid. Refer to the Maintenance Schedule \

to determine

what

kind of fluid to use. See “Recommended Fluids and Lubricants” in the

Index.

1. Remove the filler plug.

2. Add fluid’at the filler plug hole. Add only enough fluid to bring the

fluid level up to the bottom

of the filler plug hole.

3. Install the filler plug. Be sure the plug is fully seated.

Page 238 of 340

Downloaded from www.Manualslib.com manuals search engine Hydraulic Clutch

The hydraulic clutch in your vehicle is self-adjusting. A slight amount of

play

(1/4 inch to 1/2 inch) in the pedal is normal.

When to Check and What to Use

Refer to the Maintenance Schedule to determine how often you should

check the fluid level in your clutch master cylinder reservoir and what to

add. See “Owner Checks and Services” and “Recommended F\

luids and

Lubricants” in the Index.

How to check

The proper fluid should be added if the level does not reach the bottom of

the diaphragm when it’s in place in the reservoir. See the \

instructions on the

reservoir cap.

Rear Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how often to ch\

eck the

lubricant and when to change it. See “Scheduled Maintenance Services” in

the Index.

6-20 I i

Page 239 of 340

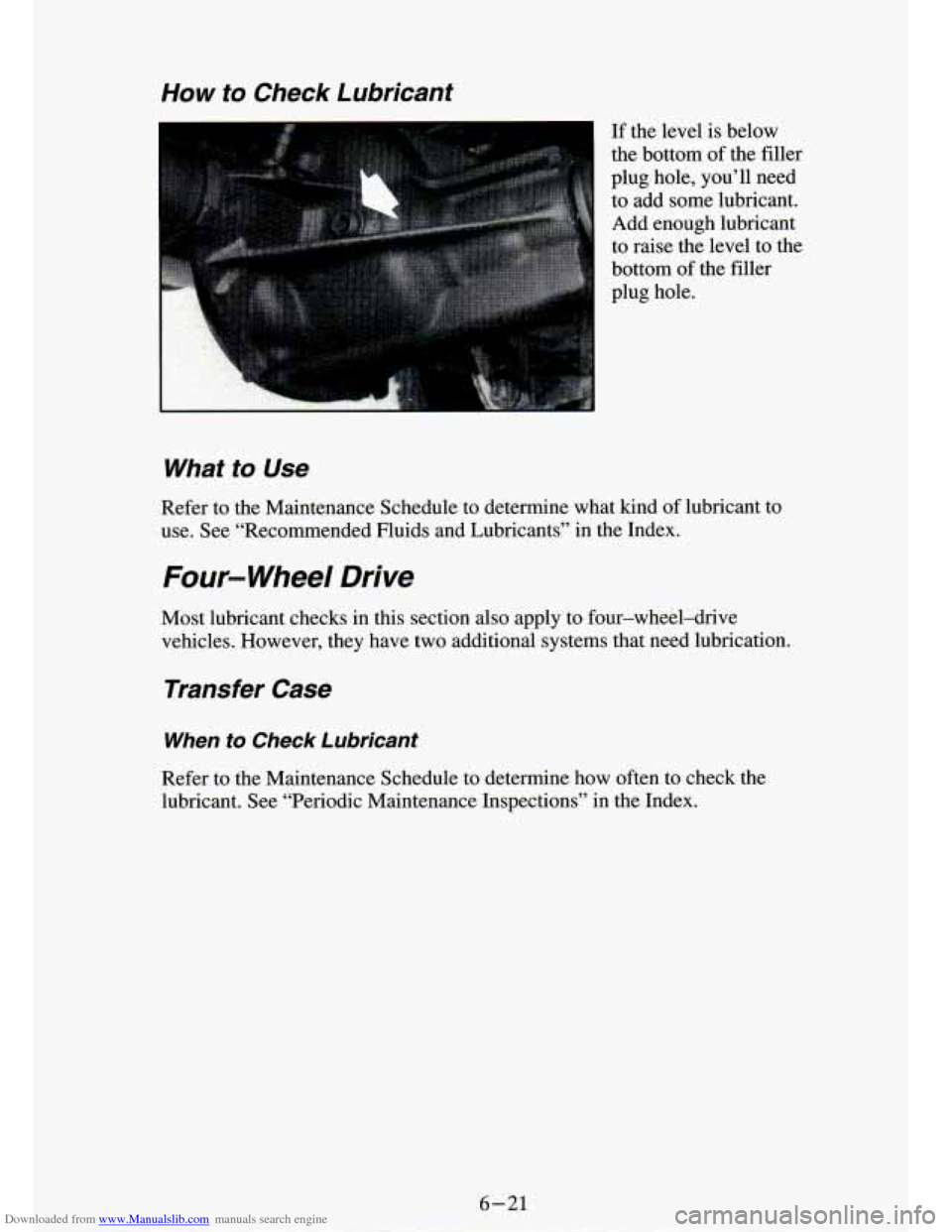

Downloaded from www.Manualslib.com manuals search engine How to Check Lubricant

If the level is below

the bottom of the filler

plug hole, you’ll need to add some lubricant.

Add enough lubricant

to raise the level to the

bottom of the filler

plug hole.

What to Use

Refer to the Maintenance Schedule to determine what kind of lubricant to

use. See “Recommended Fluids and Lubricants” in the Index.

Four- Wheel Drive

Most lubricant checks in this section also apply to four-wheel-drive

vehicles. However, they have two additional systems that need l\

ubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine how often to ch\

eck the lubricant. See “Periodic Maintenance Inspections” in the Index.

6-21

Page 240 of 340

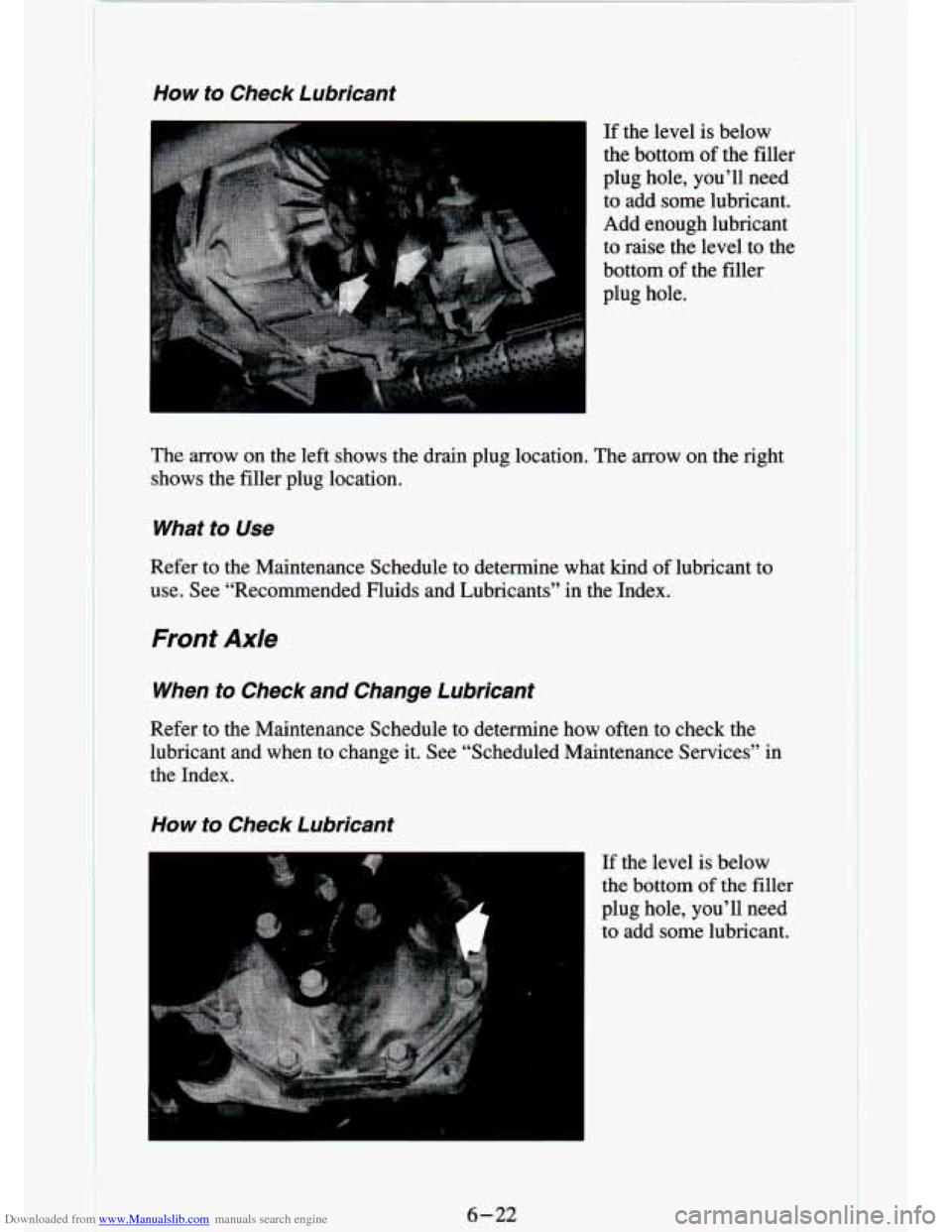

Downloaded from www.Manualslib.com manuals search engine How to Check Lubricant

6-22

I

Refer to the Maintenance Schedule to determine how often to check the

lubricant and when to change

it. See “Scheduled Maintenance Services” in

the Index.

How to Check Lubricant

If the level is below

the bottom of the filler

plug hole, you’ll need

to add some lubricant.

Add enough lubricant

to raise the level to the

bottom

of the filler

plug hole.

The arrow on the left shows the drain plug location. The arrow

on the right

shows the filler plug location.

What to Use

Refer to the Maintenance Schedule to determine what kind of lubricant to

use. See “Recommended Fluids and Lubricants” in the Index.

Front Axle

When to Check and Change Lubricant

If the level is below

the bottom of the filler

plug hole, you’ll need to add some lubricant.

Page 241 of 340

Downloaded from www.Manualslib.com manuals search engine If the differential is at operating temperature (w,arm), add enou\

gh lubricant

to raise the level to the bottom of the filler plug hole.

If the differential is cold, add enough lubricant to raise the level to 1/2 inch

(12

mm) below the filler plug hole.

What to use

Refer to the Maintenance Schedule to determine what kind of lubricant to

use. See “Recommended Fluids and Lubricants” in the Index.

Engine Coolant

The following explains your cooling system and how to add coolant \

when it

is low.

If you have a problem with engine overheating, see “Engine

Overheating” in the Index.

The proper coolant for your vehicle will:

Give freezing protection down to -20 “F (-29” C), or -34°F (-37 “C) in

Canada and for vehicles with the cold climate option.

e Give boiling protection up to 258°F (125°C).

Protect against rust and corrosion.

Help keep the proper engine temperature.

Let the warning lights and gages work as they should.

What to Use

Use a mi,xture of one-half clean water (preferably distilled) and one-half

antifreeze that meets “GM Specification 603%” or “GM Specification

6043-M ”for the 2.2L (LN2) Code 4 engine, which won’t damage

aluminum parts. You can also use

a recycled coolant conforming to “GM

Specification 603%” or “GM Specification 6043-M ”for the 2.2L (LN2)

Code 4 engine with a complete coolant flush and refill.

If you use this

mixture, you don’t need to add anything else.

6-23

Page 245 of 340

Downloaded from www.Manualslib.com manuals search engine A Then remove the again and look at

fluid level on the

dipstick. cap

the

0 When the engine compartment is hot, the level should be at the “HOT”

mark.

When the engine compartment is cool, the level should be at the

“FULL COLD” mark.

What to Add

Refer to the Maintenance Schedule to determine what kind of fluid to use.

See “Recommended Fluids and Lubricants”

in the Index.

NOTICE:

When adding power steering fluid or making a complete fluid

change, always use the proper fluid. Failure to use the proper\

fluid can cause leaks and damage hoses and seals.

6-27

Page 247 of 340

Downloaded from www.Manualslib.com manuals search engine Brakes

Brake Master Cylnder

Your brake master

cylinder is here. It is

filled with

DOT-3

brake fluid.

There are only two reasons why the brake fluid level

in your master cylinder

might go down, The first is that the brake fluid goes down to an acceptable

level during normal brake lining wear. When new linings are pu\

t in, the

fluid level goes back up. The other reason is that fluid is leaking out of the

brake system.

If it is, you should have your brake system fixed, since a leak

means that sooner or later your brakes won’t work well, or \

won’t work at all.

So, it isn’t a good idea to “top off’ your brake fluid. Adding brake fluid

won’t correct a leak.

If you add fluid when your linings are worn, then

you’ll have too much fluid when you get new brake linings.

You should add

(or remove) brake fluid, as necessary, only when work is done on the brake

hydraulic system.

Refer to the Maintenance Schedule to determine when to check y\

our brake fluid. See “Periodic Maintenance Inspections” in the Index.

6-29

Page 257 of 340

Downloaded from www.Manualslib.com manuals search engine Other Maintenance Items

Front Suspension and Steering Linkage

Refer to the Maintenance Schedule to determine how often to lubricate the

fittings and what type

of lubricant to use.

Front Wheel Bearings (Two-Wheel Drive)

If your vehicle is two-wheel drive, it has wheel bearings that must be

cleaned and repacked.

Refer to the Maintenance Schedule to determine how often this must be

done.

Single Belt Accessory Drive

Your new vehicle uses a serpentine belt that is lighter, and more durable

than systc

.s with several belts.

The belt runs over or around the pulleys on the engine. A tensioner is used

to keep the belt tight at all times. The tensioner also makes replacing the

belt easier if you need to replace the belt, be sure

to get the correct

replacement belt. Your dealership or parts supplier can help you with this.

The Accessory Drive Belt Routing label on your vehicle will show y\

ou how

to route the belt your vehicle uses.

Windshield Wiper Blade Replacement

NOTICE:

Use care when removing or installing a blade assembly.

Accidental bumping can cause the arm to fall back and strike

the windshield.

6-39

Page 261 of 340

Downloaded from www.Manualslib.com manuals search engine Lubrication

Accelerator Control System

Refer to the Maintenance Schedule to determine how often the a\

ccelerator linkage pivot points must be lubricated and what type

of lubricant to use.

Accelerator cables and cruise control cables should not be lubr\

icated. Any

cables that are worn or are hard

to pull should be replaced.

When cleaning the engine compartment with water or steam, avoid\

directing the flow onto the throttle linkage

in a manner that would cause moisture to

enter the cables.

Hood Latches and Hood Hinge

Refer to the Maintenance Schedule to determine how to lubricate\

the hood

latch and hood hinge assembly.

Propeller Shaft Slip Splines/Universal Joints

Refer to the Maintenance Schedule to determine how often the slip and

universal joints must be lubricated and what type

of lubricant to use.

Body

Normal use of your vehicle will cause metal to metal wear at some points on

the cab and body if they are not lubricated.

For exposed surfaces, such as door checks, door lock bolts, lock s\

triker

plates, dovetail bumper wedges, etc., a thin film

of engine oil should be

applied.

Where oil holes are provided in the body or cab, a dripless oil can be used.

The seat adjusters and seat track should be lubricated with chassis\

grease.

Door weatherstrips and rubber hood bumpers should be wiped clea\

n with a wet cloth and lightly coated with a rubber lubricant.

Never use too much

of any lubricant and be sure to wipe up any extra

lubricant when you are finished.

Window regulators and controls are inside the doors. They are lubricated

with a long lasting grease.

If lubrication is required your dealer should

perform this service.

Refer to the Maintenance Schedule to determine how often to lubricate

these items and what type of lubricant to use.