tires CHEVROLET S10 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2004, Model line: S10, Model: CHEVROLET S10 2004Pages: 422, PDF Size: 4.16 MB

Page 239 of 422

Do not exceed the maximum allowable tongue weight

for your vehicle. Choose the shortest hitch extension

that will position the hitch ball closest to the vehicle. This

will help reduce the effect of trailer tongue weight on

the rear axle.

After you’ve loaded your trailer, weigh the trailer and then

the tongue, separately, to see if the weights are proper. If

they aren’t, you may be able to get them right simply by

moving some items around in the trailer.

Total Weight on Your Vehicle’s Tires

Be sure your vehicle’s tires are inflated to the upper limit

for cold tires. You’ll find these numbers on the

Certification label at the rear edge of the driver’s door

above the door latch, or seeLoading Your Vehicle

on page 4-42. Then be sure you don’t go over the GVW

limit for your vehicle, including the weight of the trailer

tongue. If you use a weight distributing hitch, make sure

you don’t go over the rear axle limit before you apply

the weight distribution spring bars.

Hitches

It’s important to have the correct hitch equipment.

Crosswinds, large trucks going by and rough roads are

a few reasons why you’ll need the right hitch. Here

are some rules to follow:

•If you use a step-bumper hitch, your bumper could

be damaged in sharp turns. Make sure you have

ample room when turning to avoid contact between

the trailer and the bumper.

•If you’ll be pulling a trailer that, when loaded, will

weigh more than 3,500 lbs. (1 589 kg) be sure to

use a properly mounted, weight-distributing

hitch and sway control of the proper size. This

equipment is very important for proper vehicle

loading and good handling when you’re driving.

•If your vehicle has the bumper delete option, do not

bolt any type of hitch to the close-out panel. The

close-out panel will not support a hitch.

4-55

Page 241 of 422

Trailer Brakes

If your trailer weighs more than 1,000 lbs. (450 kg)

loaded, then it needs its own brake–and they must be

adequate. Be sure to read and follow the instructions for

the trailer brakes so you’ll be able to install, adjust

and maintain them properly.

Your trailer’s brake system can tap into the vehicle’s

hydraulic brake system only if:

•The trailer parts can withstand 3,000 psi (20

650 kPa) of pressure.

•The trailer’s brake system will use less than

0.02 cubic inch (0.3 cc) of fluid from your vehicle’s

master cylinder. Otherwise, both braking systems

won’t work well. You could even lose your brakes.

If everything checks out this far, then make the brake

fluid tap at the port on the master cylinder that

sends fluid to the rear brakes. But don’t use copper

tubing for this. If you do, it will bend and finally break off.

Use steel brake tubing.

Driving with a Trailer

Towing a trailer requires a certain amount of experience.

Before setting out for the open road, you’ll want to get

to know your rig. Acquaint yourself with the feel of

handling and braking with the added weight of the trailer.

And always keep in mind that the vehicle you are

driving is now a good deal longer and not nearly as

responsive as your vehicle is by itself.

Before you start, check all trailer hitch, all parts and

attachments, safety chains, electrical connector, lamps,

tires and mirror adjustment. If the trailer has electric

brakes, start your vehicle and trailer moving and then

apply the trailer brake controller by hand to be sure

the brakes are working. This lets you check your

electrical connection at the same time.

During your trip, check occasionally to be sure that the

load is secure, and that the lamps and any trailer

brakes are still working.

Following Distance

Stay at least twice as far behind the vehicle ahead as

you would when driving your vehicle without a trailer.

This can help you avoid situations that require

heavy braking and sudden turns.

4-57

Page 246 of 422

Windshield Wiper Blade Replacement..............5-59

Tires..............................................................5-61

Inflation - Tire Pressure.................................5-72

Tire Inspection and Rotation...........................5-74

When It Is Time for New Tires.......................5-75

Buying New Tires.........................................5-76

Uniform Tire Quality Grading..........................5-77

Wheel Alignment and Tire Balance..................5-78

Wheel Replacement......................................5-78

Tire Chains..................................................5-80

If a Tire Goes Flat........................................5-81

Changing a Flat Tire.....................................5-82

Compact Spare Tire......................................5-94

Appearance Care............................................5-94

Cleaning the Inside of Your Vehicle.................5-95

Care of Safety Belts......................................5-97

Weatherstrips...............................................5-98Cleaning the Outside of Your Vehicle..............5-98

Sheet Metal Damage...................................5-101

Finish Damage...........................................5-101

Underbody Maintenance...............................5-101

Chemical Paint Spotting...............................5-101

Vehicle Care/Appearance Materials................5-102

Vehicle Identi�cation.....................................5-103

Vehicle Identification Number (VIN)................5-103

Service Parts Identification Label...................5-104

Electrical System..........................................5-104

Add-On Electrical Equipment.........................5-104

Headlamps.................................................5-104

Windshield Wiper Fuses...............................5-105

Power Windows and Other Power Options......5-105

Fuses and Circuit Breakers..........................5-105

Capacities and Speci�cations........................5-111

Section 5 Service and Appearance Care

5-2

Page 286 of 422

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to GM torque specifications.

Brake linings should always be replaced as complete

axle sets.

SeeBrake System Inspection on page 6-31.Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in

pedal travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you make a brake stop, your disc brakes

adjust for wear.

If you do not have four-wheel drive and your brake

pedal goes down farther than normal, your rear drum

brakes may need adjustment. Adjust them by backing up

and firmly applying the brakes a few times.

5-42

Page 305 of 422

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service,

see your GM Warranty booklet for details. For additional

information refer to the tire manufacturer’s booklet

included with your vehicle’s Owner’s Manual.

{CAUTION:

Poorly maintained and improperly used tires

are dangerous.

Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. See “Loading Your

Vehicle” in the Index.

CAUTION: (Continued)

CAUTION: (Continued)

Underin�ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

Overin�ated tires are more likely to be

cut, punctured or broken by a sudden

impact — such as when you hit a pothole.

Keep tires at the recommended pressure.

Worn, old tires can cause accidents. If

your tread is badly worn, or if your tires

have been damaged, replace them.

5-61

Page 307 of 422

(A) Tire Size Code:The tire size code is a combination

of letters and numbers used to define a particular

tire’s width, height, aspect ratio, construction type and

service description. See the “Tire Size Code” illustration

later in this section for more detail.

(B) Tire Performance Criteria Speci�cation (TPC

Spec):Original equipment tires designed to GM’s

specific tire performance criteria have a TPC

specification code molded onto the sidewall. GM’s

TPC specifications meet or exceed all federal

safety guidelines.

(C) Department of Transportation (DOT):The

Department of Transportation (DOT) code indicates that

the tire is in compliance with the U.S. Department of

Transportation Motor Vehicle Safety Standards.

(D) Tire Identi�cation Number (TIN):The letters and

numbers following DOT code are the Tire Identification

Number (TIN). The TIN shows the manufacturer and

plant code, tire size, and date the tire was manufactured.

The TIN is molded onto both sides of the tire, although

only one side may have the date of manufacture.(E) Tire Ply Material:The type of cord and number of

plies in the sidewall and under the tread.

(F) Uniform Tire Quality Grading (UTQG):Tire

manufacturers are required to grade tires based on three

performance factors: treadwear, traction and

temperature resistance. For more information, see

Uniform Tire Quality Grading on page 5-77.

(G) Maximum Cold In�ation Load Limit:Maximum

load that can be carried and the maximum pressure

needed to support that load. For information on

recommended tire pressure seeIn�ation - Tire Pressure

on page 5-72andLoading Your Vehicle on page 4-42.

5-63

Page 308 of 422

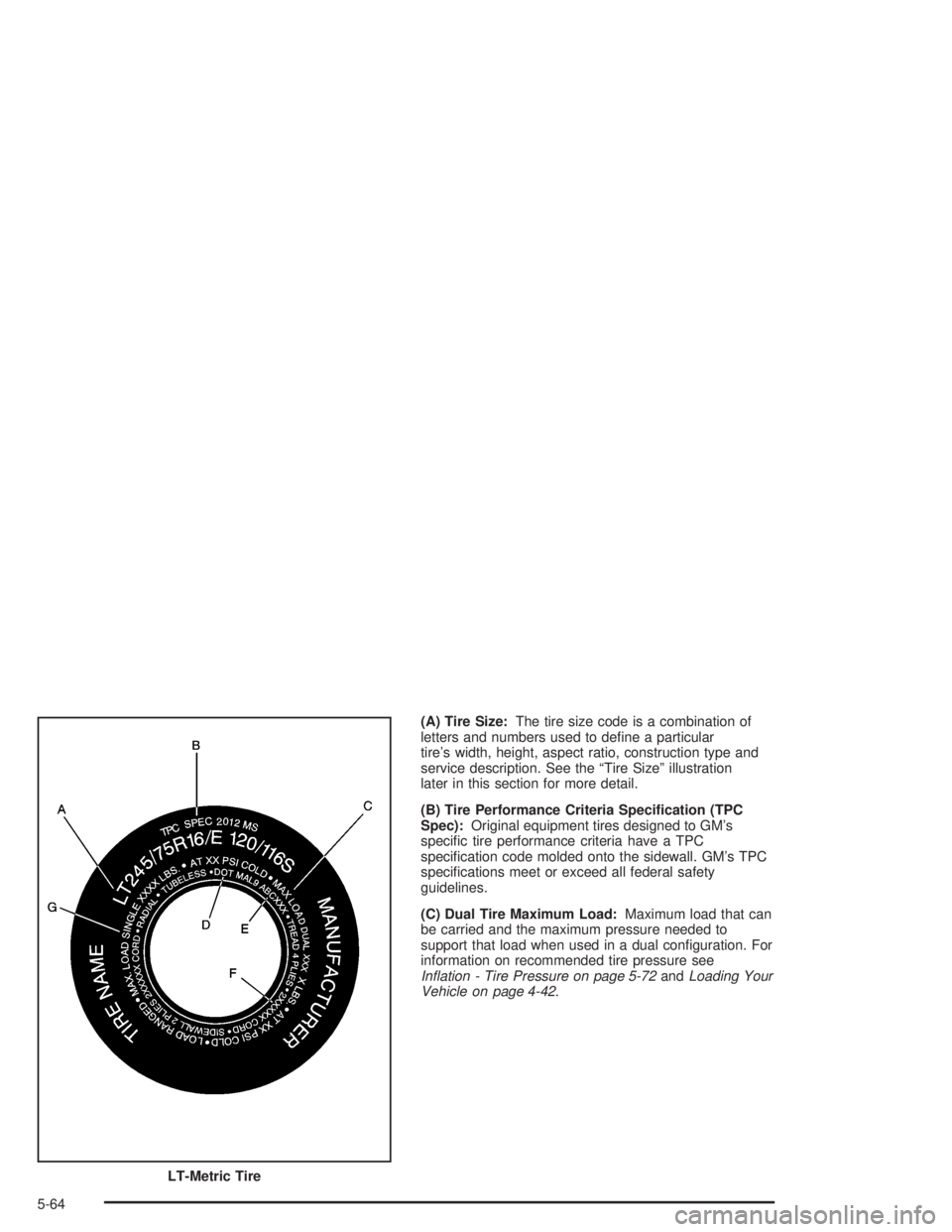

(A) Tire Size:The tire size code is a combination of

letters and numbers used to define a particular

tire’s width, height, aspect ratio, construction type and

service description. See the “Tire Size” illustration

later in this section for more detail.

(B) Tire Performance Criteria Speci�cation (TPC

Spec):Original equipment tires designed to GM’s

specific tire performance criteria have a TPC

specification code molded onto the sidewall. GM’s TPC

specifications meet or exceed all federal safety

guidelines.

(C) Dual Tire Maximum Load:Maximum load that can

be carried and the maximum pressure needed to

support that load when used in a dual configuration. For

information on recommended tire pressure see

In�ation - Tire Pressure on page 5-72andLoading Your

Vehicle on page 4-42.

LT-Metric Tire

5-64

Page 311 of 422

(D) Maximum Cold In�ation Load Limit:Maximum

load that can be carried and the maximum pressure

needed to support that load. SeeCompact Spare Tire

on page 5-94andLoading Your Vehicle on page 4-42.

(E) Tire In�ation:The temporary use tire or compact

spare tire should be inflated to 60 psi (420 kPa).

For more information on tire pressure and inflation see

In�ation - Tire Pressure on page 5-72.(F) Tire Size:A combination of letters and numbers

define a tire’s width, height, aspect ratio, construction

type and service description. The letter “T” as the

first character in the tire size means the tire is for

temporary use only.

(G) Tire Performance Criteria Speci�cation (TPC

Spec):Original equipment tires designed to GM’s

specific tire performance criteria have a TPC

specification code molded onto the sidewall. GM’s

TPC specifications meet or exceed all federal

safety guidelines.

5-67

Page 315 of 422

Load Index:An assigned number ranging from 1 to

279 that corresponds to the load carrying capacity

of a tire.

Maximum In�ation Pressure:The maximum air

pressure to which a cold tire may be inflated. The

maximum air pressure is molded onto the sidewall.

Maximum Load Rating:The load rating for a tire at the

maximum permissible inflation pressure for that tire.

Maximum Loaded Vehicle Weight:The sum of curb

weight; accessory weight; vehicle capacity weight;

and production options weight.

Normal Occupant Weight:The number of occupants a

vehicle is designed to seat multiplied by 150 pounds

(68 kg). SeeLoading Your Vehicle on page 4-42.

Occupant Distribution:Designated seating positions.

Outward Facing Sidewall:The side of a asymmetrical

tire that has a particular side that faces outward

when mounted on a vehicle. The side of the tire that

contains a whitewall, bears white lettering or bears

manufacturer, brand and or model name molding that is

higher or deeper than the same moldings on the

other sidewall of the tire.

Passenger (P-Metric) Tire:A tire used on passenger

cars and some light duty trucks and multipurpose

vehicles.Recommended In�ation Pressure:Vehicle

manufacturer’s recommended tire inflation pressure and

shown on the tire placard. SeeIn�ation - Tire Pressure

on page 5-72andLoading Your Vehicle on page 4-42.

Radial Ply tire:A pneumatic tire in which the ply cords

that extend to the beads are laid at 90 degrees to the

centerline of the tread.

Rim:A metal support for a tire and upon which the tire

beads are seated.

Sidewall:The portion of a tire between the tread and

the bead.

Speed Rating:An alphanumeric code assigned to a

tire indicating the maximum speed at which a tire

can operate.

Traction:The friction between the tire and the road

surface. The amount of grip provided.

Tread:The portion of a tire that comes into contact

with the road.

Treadwear Indicators:Narrow bands, sometimes

called “wear bars,” that show across the tread of a tire

when only 2/32 inch of tread remains. SeeWhen It

Is Time for New Tires on page 5-75.

5-71

Page 316 of 422

UTQGS:Uniform Tire Quality Grading Standards, a tire

information system that provides consumers with

ratings for a tire’s traction, temperature and treadwear.

Ratings are determined by tire manufacturers using

government testing procedures. The ratings are molded

into the sidewall of the tire. SeeUniform Tire Quality

Grading on page 5-77.

Vehicle Capacity Weight:The number of designated

seating positions multiplied by 150 lbs. (68 kg) plus

the rated cargo load. SeeLoading Your Vehicle

on page 4-42.

Vehicle Maximum Load on the Tire:Load on an

individual tire due to curb weight, accessory weight,

occupant weight and cargo weight.

Vehicle Placard:A label permanently attached to a

vehicle showing the original equipment tire size

and recommended inflation pressure. SeeLoading Your

Vehicle on page 4-42.In�ation - Tire Pressure

The tire and loading information label, shows the correct

inflation pressures for your tires when they’re cold.

“Cold” means your vehicle has been sitting for at least

three hours or driven no more than 1 mile (1.6 km). See

Loading Your Vehicle on page 4-42, for the location

of your vehicle’s tire and loading information label.

Notice:Don’t let anyone tell you that underin�ation

or overin�ation is all right. It’s not. If your tires

don’t have enough air (underin�ation), you can get

the following:

Too much �exing

Too much heat

Tire overloading

Bad wear

Bad handling

Bad fuel economy

If your tires have too much air (overin�ation), you

can get the following:

Unusual wear

Bad handling

Rough ride

Needless damage from road hazards

5-72