wheel CHEVROLET SILVERADO 1500 2018 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2018, Model line: SILVERADO 1500, Model: CHEVROLET SILVERADO 1500 2018Pages: 501, PDF Size: 6.69 MB

Page 317 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

316 Driving and Operating

Ask your dealer for trailering

information or advice.

Weight of the Trailer Tongue

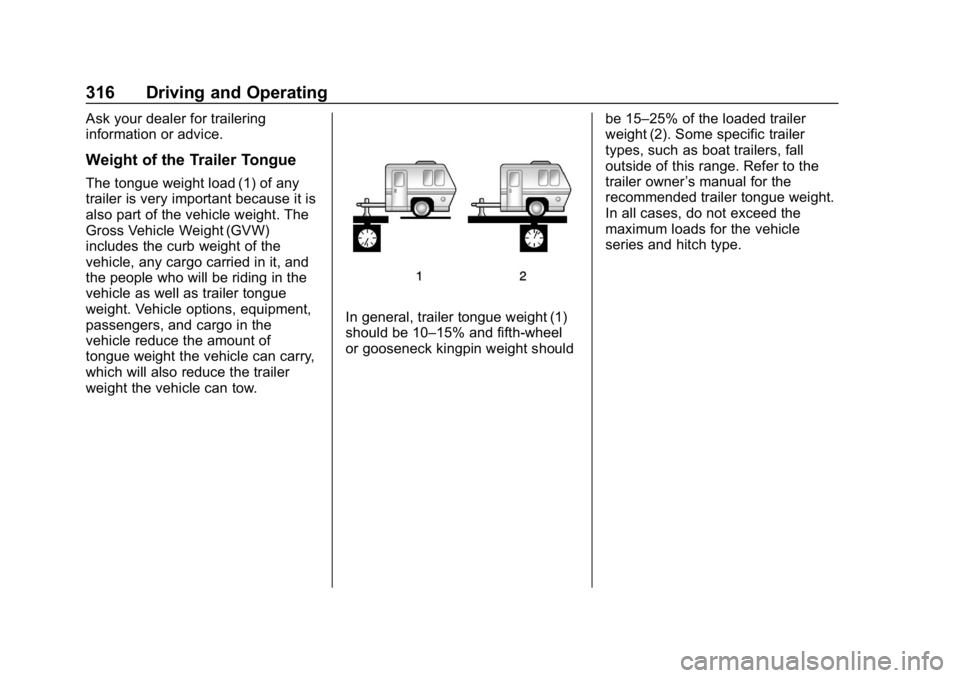

The tongue weight load (1) of any

trailer is very important because it is

also part of the vehicle weight. The

Gross Vehicle Weight (GVW)

includes the curb weight of the

vehicle, any cargo carried in it, and

the people who will be riding in the

vehicle as well as trailer tongue

weight. Vehicle options, equipment,

passengers, and cargo in the

vehicle reduce the amount of

tongue weight the vehicle can carry,

which will also reduce the trailer

weight the vehicle can tow.

In general, trailer tongue weight (1)

should be 10–15% and fifth-wheel

or gooseneck kingpin weight shouldbe 15–25% of the loaded trailer

weight (2). Some specific trailer

types, such as boat trailers, fall

outside of this range. Refer to the

trailer owner

’s manual for the

recommended trailer tongue weight.

In all cases, do not exceed the

maximum loads for the vehicle

series and hitch type.

Page 318 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

Driving and Operating 317

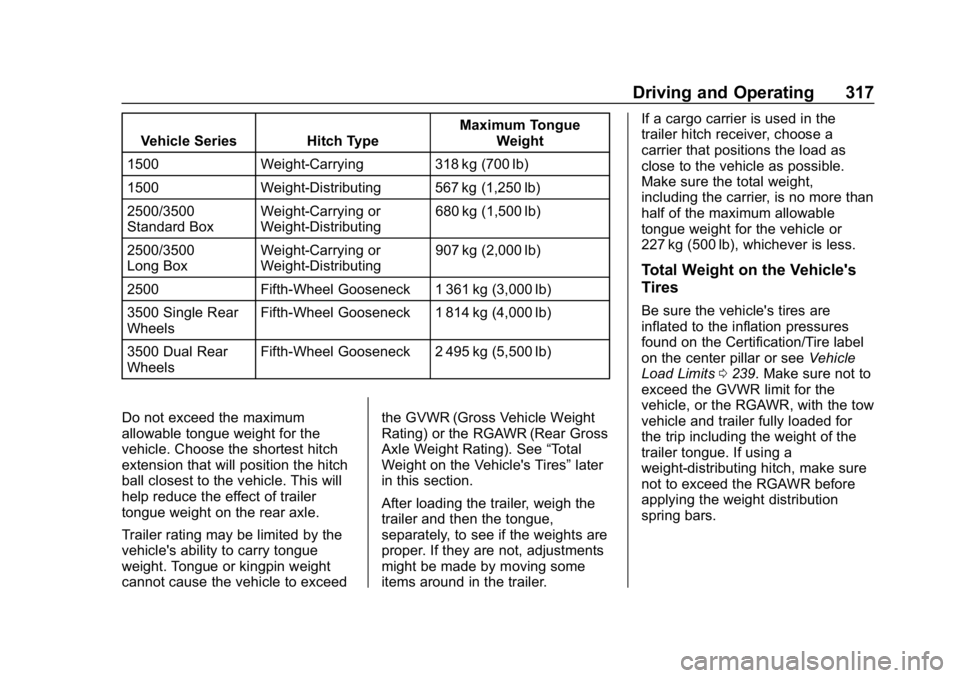

Vehicle Series Hitch TypeMaximum Tongue

Weight

1500 Weight-Carrying 318 kg (700 lb)

1500 Weight-Distributing 567 kg (1,250 lb)

2500/3500

Standard Box Weight-Carrying or

Weight-Distributing 680 kg (1,500 lb)

2500/3500

Long Box Weight-Carrying or

Weight-Distributing 907 kg (2,000 lb)

2500 Fifth-Wheel Gooseneck 1 361 kg (3,000 lb)

3500 Single Rear

Wheels Fifth-Wheel Gooseneck 1 814 kg (4,000 lb)

3500 Dual Rear

Wheels Fifth-Wheel Gooseneck 2 495 kg (5,500 lb)

Do not exceed the maximum

allowable tongue weight for the

vehicle. Choose the shortest hitch

extension that will position the hitch

ball closest to the vehicle. This will

help reduce the effect of trailer

tongue weight on the rear axle.

Trailer rating may be limited by the

vehicle's ability to carry tongue

weight. Tongue or kingpin weight

cannot cause the vehicle to exceed the GVWR (Gross Vehicle Weight

Rating) or the RGAWR (Rear Gross

Axle Weight Rating). See

“Total

Weight on the Vehicle's Tires” later

in this section.

After loading the trailer, weigh the

trailer and then the tongue,

separately, to see if the weights are

proper. If they are not, adjustments

might be made by moving some

items around in the trailer. If a cargo carrier is used in the

trailer hitch receiver, choose a

carrier that positions the load as

close to the vehicle as possible.

Make sure the total weight,

including the carrier, is no more than

half of the maximum allowable

tongue weight for the vehicle or

227 kg (500 lb), whichever is less.

Total Weight on the Vehicle's

Tires

Be sure the vehicle's tires are

inflated to the inflation pressures

found on the Certification/Tire label

on the center pillar or see

Vehicle

Load Limits 0239. Make sure not to

exceed the GVWR limit for the

vehicle, or the RGAWR, with the tow

vehicle and trailer fully loaded for

the trip including the weight of the

trailer tongue. If using a

weight-distributing hitch, make sure

not to exceed the RGAWR before

applying the weight distribution

spring bars.

Page 319 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

318 Driving and Operating

Weight of the Trailering

Combination

It is important that the combination

of the tow vehicle and trailer

does not exceed any of its weight

ratings—GCWR, GVWR, RGAWR,

Trailer Weight Rating, or Tongue

Weight. The only way to be sure it is

not exceeding any of these ratings

is to weigh the tow vehicle and

trailer combination, fully loaded for

the trip, getting individual weights

for each of these items.

Towing Equipment

Hitches

The correct hitch equipment helps

maintain combination control. Many

trailers can be towed with a

weight-carrying hitch which simply

features a coupler latched to the

hitch ball, or a tow eye latched to a

pintle hook. Other trailers may

require a weight-distributing hitch

that uses spring bars to distribute

the trailer tongue weight among the

tow vehicle and trailer axles.

Fifth-wheel and gooseneck hitches

may also be used. See “Weight of

the Trailer Tongue” underTrailer

Towing 0300 for rating limits with

various hitch types. If a step-bumper hitch will be used,

the bumper could be damaged in

sharp turns. Make sure there

is ample room when turning to avoid

contact between the trailer and the

bumper.

Consider using sway controls with

any trailer. Ask a trailering

professional about sway controls or

refer to the trailer manufacturer's

recommendations and instructions.

Weight-Distributing Hitch and

Adjustment

A weight-distributing hitch may be

useful with some trailers. Use the

following guidelines to determine if a

weight-distributing hitch should

be used.

Page 320 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

Driving and Operating 319

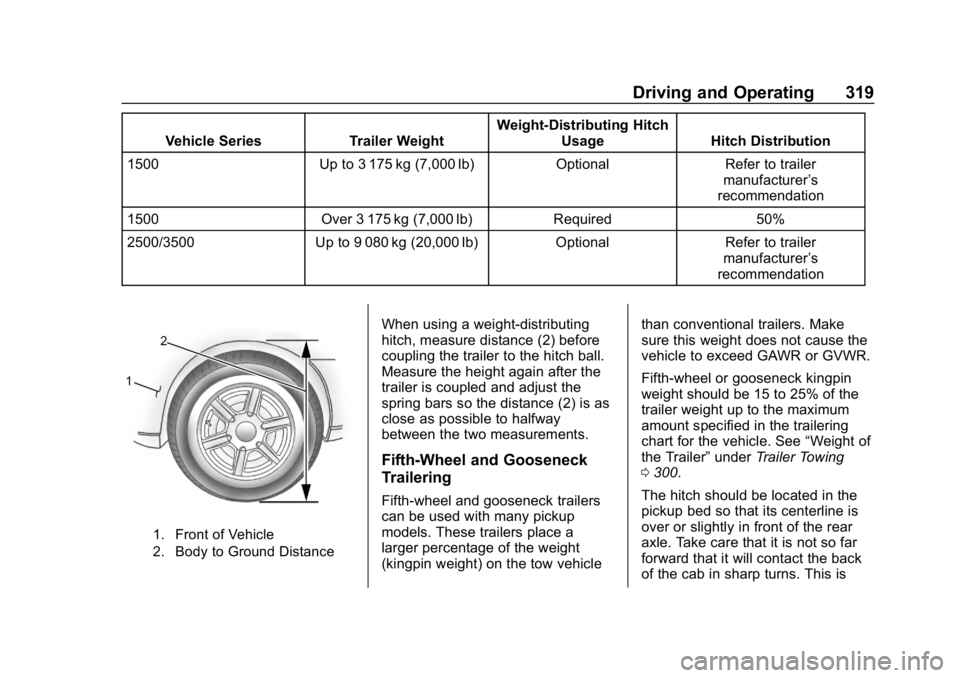

Vehicle SeriesTrailer WeightWeight-Distributing Hitch

Usage Hitch Distribution

1500 Up to 3 175 kg (7,000 lb) OptionalRefer to trailer

manufacturer ’s

recommendation

1500 Over 3 175 kg (7,000 lb) Required50%

2500/3500 Up to 9 080 kg (20,000 lb) OptionalRefer to trailer

manufacturer ’s

recommendation

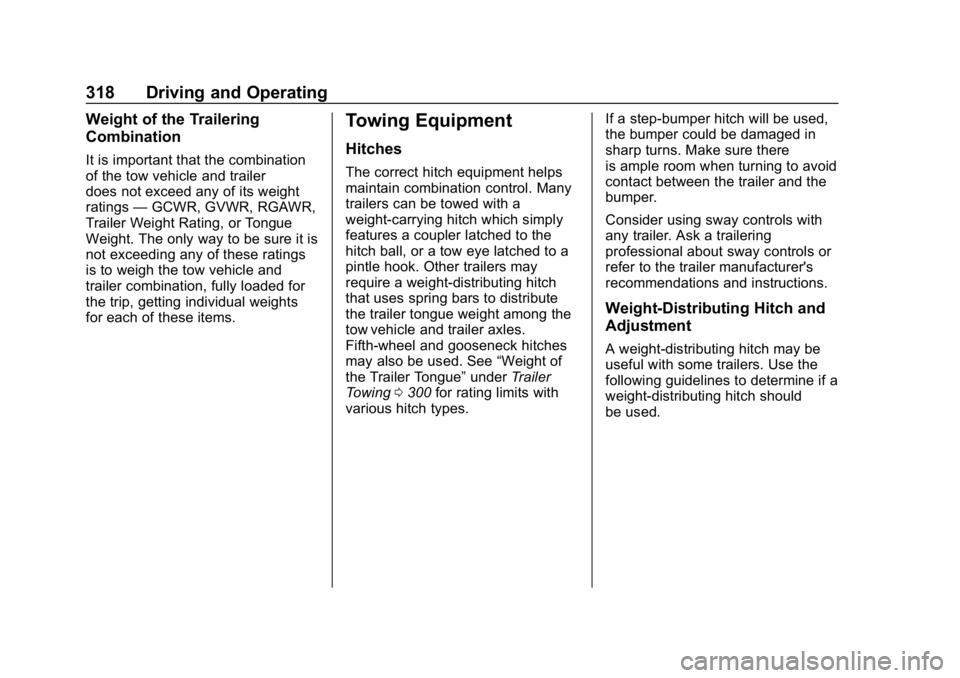

1. Front of Vehicle

2. Body to Ground Distance

When using a weight-distributing

hitch, measure distance (2) before

coupling the trailer to the hitch ball.

Measure the height again after the

trailer is coupled and adjust the

spring bars so the distance (2) is as

close as possible to halfway

between the two measurements.

Fifth-Wheel and Gooseneck

Trailering

Fifth-wheel and gooseneck trailers

can be used with many pickup

models. These trailers place a

larger percentage of the weight

(kingpin weight) on the tow vehicle than conventional trailers. Make

sure this weight does not cause the

vehicle to exceed GAWR or GVWR.

Fifth-wheel or gooseneck kingpin

weight should be 15 to 25% of the

trailer weight up to the maximum

amount specified in the trailering

chart for the vehicle. See

“Weight of

the Trailer” underTrailer Towing

0 300.

The hitch should be located in the

pickup bed so that its centerline is

over or slightly in front of the rear

axle. Take care that it is not so far

forward that it will contact the back

of the cab in sharp turns. This is

Page 321 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

320 Driving and Operating

especially important for short box

pickups. Trailer pin box extensions

and sliding fifth-wheel hitch

assemblies can help this condition.

There should be at least 15 cm (6 in)

of clearance between the top of the

pickup box and the bottom of the

trailer shelf that extends over

the box.

Safety Chains

Always attach chains between the

vehicle and the trailer. Cross the

safety chains under the tongue of

the trailer to help prevent the tongue

from contacting the road if it

becomes separated from the hitch.

Instructions about safety chains

may be provided by the hitch

manufacturer or by the trailer

manufacturer. If the trailer is being

towed with a factory-installed step

bumper, safety chains may be

attached to the attaching points on

the bumper; otherwise, safety

chains should be attached to holes

on the trailer hitch platform. Always

leave just enough slack so thecombination can turn. Never allow

safety chains to drag on the ground.

Trailer Brakes

A loaded trailer that weighs more

than 900 kg (2,000 lb) must be

equipped with its own brake system,

with brakes working on all axles.

Trailer braking equipment

conforming to Canadian Standards

Association (CSA) requirement

CAN3-D313, or its equivalent, is

recommended.

State and local regulations may also

require the trailer to have its own

braking system if loaded above a

certain threshold. These

requirements vary from state to

state.

Read and follow the instructions for

the trailer brakes so they are

installed, adjusted, and maintained

properly.

Do not tap into the vehicle's

hydraulic brake system.

Auxiliary Battery

The auxiliary battery provision can

be used to supply electrical power

to additional equipment that may be

added, such as a slide-in camper.

If equipped, this relay will be on the

driver side of the vehicle, next to the

underhood electrical center.

Be sure to follow the proper

installation instructions included with

any electrical equipment that is

installed.

Caution

Leaving electrical equipment on

for extended periods will drain the

battery. Always turn off electrical

equipment when not in use and

do not use equipment that

exceeds the maximum amperage

rating of 30 amps for the auxiliary

battery provision.

Page 323 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

322 Driving and Operating

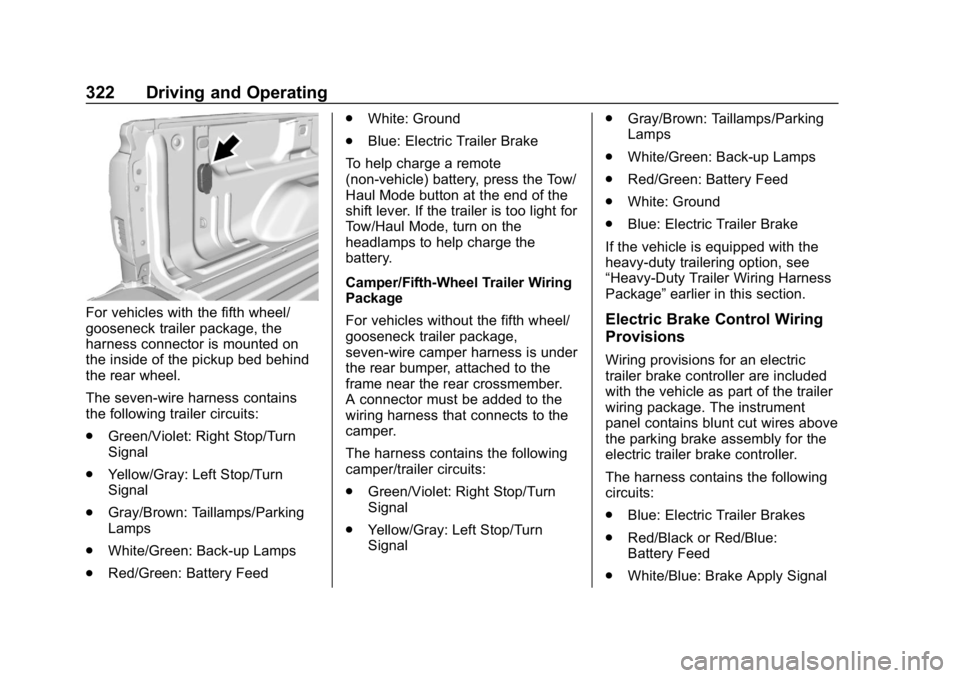

For vehicles with the fifth wheel/

gooseneck trailer package, the

harness connector is mounted on

the inside of the pickup bed behind

the rear wheel.

The seven-wire harness contains

the following trailer circuits:

.Green/Violet: Right Stop/Turn

Signal

. Yellow/Gray: Left Stop/Turn

Signal

. Gray/Brown: Taillamps/Parking

Lamps

. White/Green: Back-up Lamps

. Red/Green: Battery Feed .

White: Ground

. Blue: Electric Trailer Brake

To help charge a remote

(non-vehicle) battery, press the Tow/

Haul Mode button at the end of the

shift lever. If the trailer is too light for

Tow/Haul Mode, turn on the

headlamps to help charge the

battery.

Camper/Fifth-Wheel Trailer Wiring

Package

For vehicles without the fifth wheel/

gooseneck trailer package,

seven-wire camper harness is under

the rear bumper, attached to the

frame near the rear crossmember.

A connector must be added to the

wiring harness that connects to the

camper.

The harness contains the following

camper/trailer circuits:

. Green/Violet: Right Stop/Turn

Signal

. Yellow/Gray: Left Stop/Turn

Signal .

Gray/Brown: Taillamps/Parking

Lamps

. White/Green: Back-up Lamps

. Red/Green: Battery Feed

. White: Ground

. Blue: Electric Trailer Brake

If the vehicle is equipped with the

heavy-duty trailering option, see

“Heavy-Duty Trailer Wiring Harness

Package” earlier in this section.Electric Brake Control Wiring

Provisions

Wiring provisions for an electric

trailer brake controller are included

with the vehicle as part of the trailer

wiring package. The instrument

panel contains blunt cut wires above

the parking brake assembly for the

electric trailer brake controller.

The harness contains the following

circuits:

.

Blue: Electric Trailer Brakes

. Red/Black or Red/Blue:

Battery Feed

. White/Blue: Brake Apply Signal

Page 325 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

324 Driving and Operating

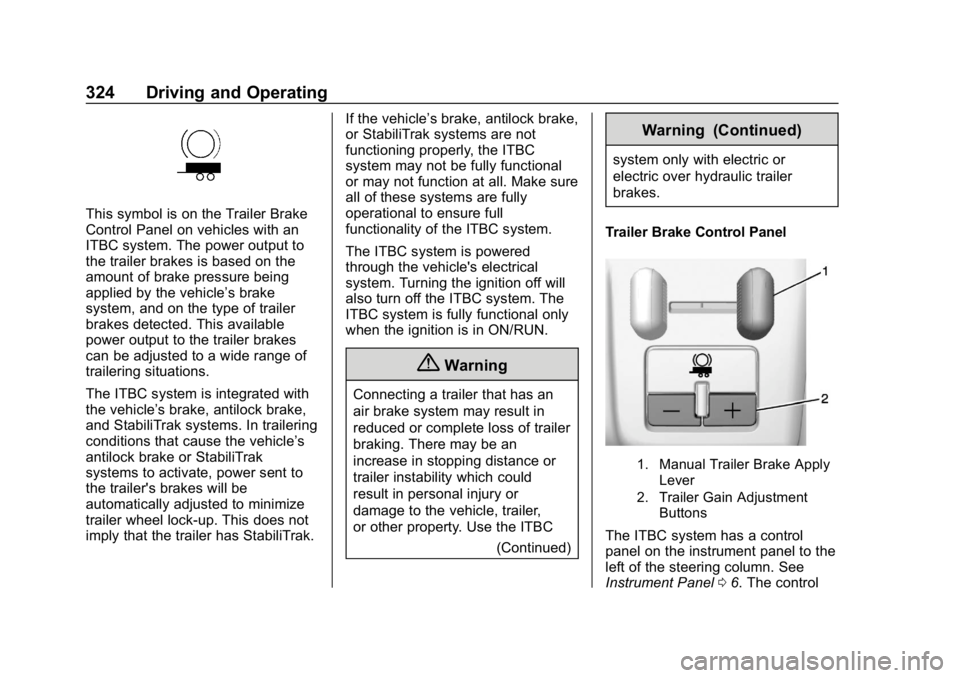

This symbol is on the Trailer Brake

Control Panel on vehicles with an

ITBC system. The power output to

the trailer brakes is based on the

amount of brake pressure being

applied by the vehicle’s brake

system, and on the type of trailer

brakes detected. This available

power output to the trailer brakes

can be adjusted to a wide range of

trailering situations.

The ITBC system is integrated with

the vehicle’s brake, antilock brake,

and StabiliTrak systems. In trailering

conditions that cause the vehicle’s

antilock brake or StabiliTrak

systems to activate, power sent to

the trailer's brakes will be

automatically adjusted to minimize

trailer wheel lock-up. This does not

imply that the trailer has StabiliTrak. If the vehicle’s brake, antilock brake,

or StabiliTrak systems are not

functioning properly, the ITBC

system may not be fully functional

or may not function at all. Make sure

all of these systems are fully

operational to ensure full

functionality of the ITBC system.

The ITBC system is powered

through the vehicle's electrical

system. Turning the ignition off will

also turn off the ITBC system. The

ITBC system is fully functional only

when the ignition is in ON/RUN.

{Warning

Connecting a trailer that has an

air brake system may result in

reduced or complete loss of trailer

braking. There may be an

increase in stopping distance or

trailer instability which could

result in personal injury or

damage to the vehicle, trailer,

or other property. Use the ITBC

(Continued)

Warning (Continued)

system only with electric or

electric over hydraulic trailer

brakes.

Trailer Brake Control Panel

1. Manual Trailer Brake Apply Lever

2. Trailer Gain Adjustment Buttons

The ITBC system has a control

panel on the instrument panel to the

left of the steering column. See

Instrument Panel 06. The control

Page 327 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

326 Driving and Operating

The trailer's and the vehicle's brake

lamps will come on when either

vehicle brakes or manual trailer

brakes are applied.

Trailer Gain Adjustment Procedure

Trailer Gain should be set for a

specific trailering condition and must

be adjusted anytime vehicle loading,

trailer loading, or road surface

conditions change.

{Warning

Trailer brakes that are

over-gained or under-gained may

not stop the vehicle and the trailer

as intended and can result in a

crash. Always follow the

instructions to set the Trailer Gain

for the proper trailer stopping

performance.

Use the following to adjust Trailer

Gain for each towing condition: 1. Drive the vehicle with the trailer attached on a level road

surface representative of the

towing condition and free of traffic at about 32 to 40 km/h

(20 to 25 mph) and fully apply

the Manual Trailer Brake Apply

Lever.

Adjusting Trailer Gain at

speeds lower than 32 to

40 km/h (20 to 25 mph) may

result in an incorrect gain

setting.

2. Adjust the Trailer Gain, using the Trailer Gain Adjustment

Buttons, to just below the point

of trailer wheel lock-up,

indicated by trailer wheel

squeal or tire smoke when a

trailer wheel locks.

Trailer wheel lock-up may not

occur if towing a heavily loaded

trailer. In this case, adjust the

Trailer Gain to the highest

allowable setting for the towing

condition.

3. Readjust Trailer Gain anytime vehicle loading, trailer loading,

or road surface conditions

change or if trailer wheel

lock-up is noticed at any time

while towing. Other ITBC-Related DIC Messages

In addition to displaying TRAILER

GAIN and OUTPUT through the

DIC, trailer connection and ITBC

system status are displayed on

the DIC.

TRAILER CONNECTED: This

message will briefly display when a

trailer with electric brakes is first

connected to the vehicle. This

message will automatically turn off

in about 10 seconds. This message

can be acknowledged before it

automatically turns off.

CHECK TRAILER WIRING: This

message will display if:

.

The ITBC system first

determines connection to a

trailer with electric brakes and

then the trailer harness becomes

disconnected from the vehicle.

If the disconnect occurs while

the vehicle is stationary, this

message will automatically turn

off in about 30 seconds. This

message will also turn off if it is

acknowledged or if the trailer

harness is reconnected.

Page 328 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

Driving and Operating 327

If the disconnect occurs while

the vehicle is moving, this

message will continue until the

ignition is turned off. This

message will also turn off if it is

acknowledged or if the trailer

harness is reconnected.

. There is an electrical fault in the

wiring to the trailer brakes. This

message will continue as long

as there is an electrical fault in

the trailer wiring. This message

will also turn off if it is

acknowledged.

To determine if the electrical fault is

on the vehicle side or trailer side of

the trailer wiring harness

connection: 1. Disconnect the trailer wiring harness from the vehicle.

2. Turn the ignition off.

3. Wait 10 seconds, then turn the ignition back to RUN.

4. If the CHECK TRAILER WIRING message reappears,

the electrical fault is on the

vehicle side. If the CHECK TRAILER

WIRING message only

reappears when connecting the

trailer wiring harness to the

vehicle, the electrical fault is on

the trailer side.

SERVICE TRAILER BRAKE

SYSTEM: This message will display

when there is a problem with the

ITBC system. If this message

continues over multiple ignition

cycles, there is a problem with the

ITBC system. Have the vehicle

serviced.

If either the CHECK TRAILER

WIRING or SERVICE TRAILER

BRAKE SYSTEM message displays

while driving, the ITBC system may

not be fully functional or may not

function at all. When traffic

conditions allow, carefully pull the

vehicle over to the side of the road

and turn the ignition off. Check the

wiring connection to the trailer and

turn the ignition back on. If either of

these messages continues, either

the vehicle or trailer needs service. A GM dealer may be able to

diagnose and repair problems with

the trailer. However, any diagnosis

and repair of the trailer is not

covered under the vehicle warranty.

Contact your trailer dealer for

assistance with trailer repairs and

trailer warranty information.

Trailer Sway

Control (TSC)

Vehicles with StabiliTrak have a

Trailer Sway Control (TSC) feature.

Trailer sway is unintended

side-to-side motion of a trailer while

being towed. If the vehicle is towing

a trailer and the TSC detects that

sway is increasing, the vehicle

brakes are selectively applied at

each wheel, to help reduce

excessive trailer sway. If the vehicle

is equipped with the Integrated

Trailer Brake Control (ITBC) system,

and the trailer has the electric

actuated brake system, StabiliTrak

may also apply the trailer brakes.

If TSC is enabled, the Traction

Control System (TCS)/StabiliTrak

warning light will flash on the

Page 333 of 501

Chevrolet Silverado Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

11349200) - 2018 - CRC - 2/27/18

332 Driving and Operating

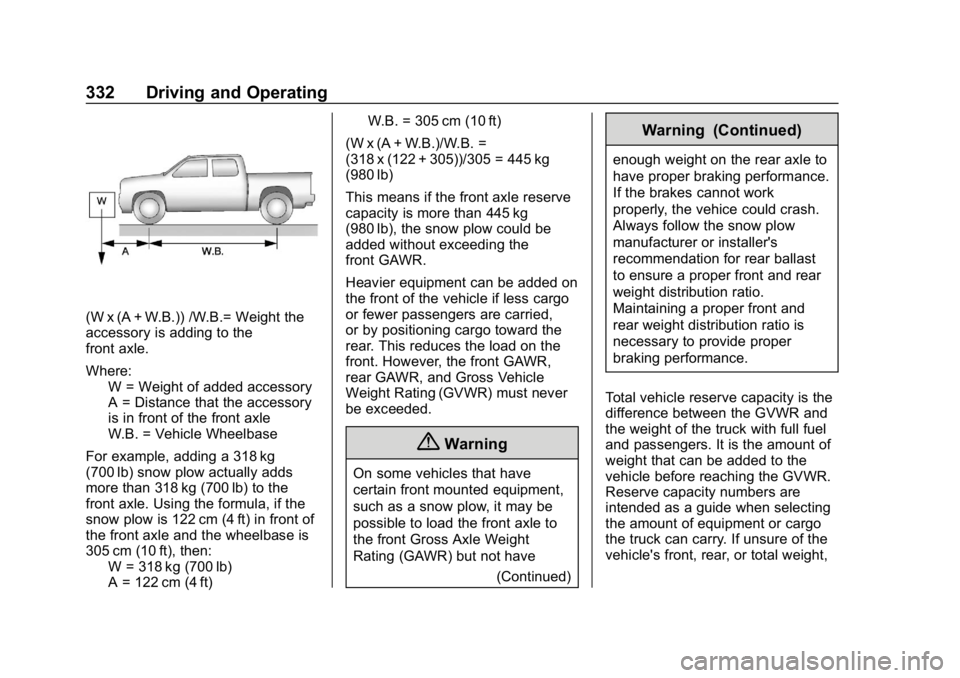

(W x (A + W.B.)) /W.B.= Weight the

accessory is adding to the

front axle.

Where:W = Weight of added accessory

A = Distance that the accessory

is in front of the front axle

W.B. = Vehicle Wheelbase

For example, adding a 318 kg

(700 lb) snow plow actually adds

more than 318 kg (700 lb) to the

front axle. Using the formula, if the

snow plow is 122 cm (4 ft) in front of

the front axle and the wheelbase is

305 cm (10 ft), then: W = 318 kg (700 lb)

A = 122 cm (4 ft) W.B. = 305 cm (10 ft)

(W x (A + W.B.)/W.B. =

(318 x (122 + 305))/305 = 445 kg

(980 lb)

This means if the front axle reserve

capacity is more than 445 kg

(980 lb), the snow plow could be

added without exceeding the

front GAWR.

Heavier equipment can be added on

the front of the vehicle if less cargo

or fewer passengers are carried,

or by positioning cargo toward the

rear. This reduces the load on the

front. However, the front GAWR,

rear GAWR, and Gross Vehicle

Weight Rating (GVWR) must never

be exceeded.

{Warning

On some vehicles that have

certain front mounted equipment,

such as a snow plow, it may be

possible to load the front axle to

the front Gross Axle Weight

Rating (GAWR) but not have (Continued)

Warning (Continued)

enough weight on the rear axle to

have proper braking performance.

If the brakes cannot work

properly, the vehice could crash.

Always follow the snow plow

manufacturer or installer's

recommendation for rear ballast

to ensure a proper front and rear

weight distribution ratio.

Maintaining a proper front and

rear weight distribution ratio is

necessary to provide proper

braking performance.

Total vehicle reserve capacity is the

difference between the GVWR and

the weight of the truck with full fuel

and passengers. It is the amount of

weight that can be added to the

vehicle before reaching the GVWR.

Reserve capacity numbers are

intended as a guide when selecting

the amount of equipment or cargo

the truck can carry. If unsure of the

vehicle's front, rear, or total weight,