service CHEVROLET SILVERADO 2010 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: SILVERADO, Model: CHEVROLET SILVERADO 2010 2.GPages: 626, PDF Size: 4.8 MB

Page 522 of 626

.One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your dealer

for service.

.Replacement tires or wheels do not match your

vehicle's original equipment tires or wheels. Tires

and wheels other than those recommended for

your vehicle could prevent the TPMS from

functioning properly. SeeBuying New Tires

on

page 6‑83.

.Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or signal

a low tire condition. See your dealer for service if the

TPMS malfunction light and DIC message comes on

and stays on.

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.

Any time you rotate your vehicle's tires or replace one

or more of the TPMS sensors, the identification codes

will need to be matched to the new tire/wheel position.

The sensors are matched to the tire/wheel positions in

the following order: driver side front tire, passenger side

front tire, passenger side rear tire, and driver side rear

tire using a TPMS diagnostic tool. See your dealer for

service.

The TPMS sensors can also be matched to each tire/

wheel position by increasing or decreasing the tire's air

pressure. If increasing the tire's air pressure, do not

exceed the maximum inflation pressure indicated on the

tire's sidewall.

To decrease air-pressure out of a tire you can use the

pointed end of the valve cap, a pencil-style air pressure

gauge, or a key.

You have two minutes to match the first tire/wheel

position, and five minutes overall to match all four tire/

wheel positions. If it takes longer than two minutes, to

match the first tire and wheel, or more than five minutes

to match all four tire and wheel positions the matching

process stops and you need to start over.

6-78

Page 530 of 626

While the tires available on General Motors

passenger cars and light trucks may vary with

respect to these grades, they must also conform

to federal safety requirements and additional

General Motors Tire Performance Criteria (TPC)

standards.

All Passenger Car Tires Must Conform to Federal

Safety Requirements In Addition To These

Grades.

Treadwear

The treadwear grade is a comparative rating

based on the wear rate of the tire when tested

under controlled conditions on a specified

government test course. For example, a tire

graded 150 would wear one and a half (1½) times

as well on the government course as a tire graded

100. The relative performance of tires depends

upon the actual conditions of their use, however,

and may depart significantly from the norm due to

variations in driving habits, service practices and

differences in road characteristics and climate.

Traction–AA, A, B, C

The traction grades, from highest to lowest, are

AA, A, B, and C. Those grades represent the tire's

ability to stop on wet pavement as measured

under controlled conditions on specified

government test surfaces of asphalt and concrete.

A tire marked C may have poor traction

performance. Warning: The traction grade

assigned to this tire is based on straight-ahead

braking traction tests, and does not include

acceleration, cornering, hydroplaning, or peak

traction characteristics.

Temperature –A, B, C

The temperature grades are A (the highest), B,

and C, representing the tire's resistance to the

generation of heat and its ability to dissipate heat

when tested under controlled conditions on a

specified indoor laboratory test wheel. Sustained

high temperature can cause the material of the

tire to degenerate and reduce tire life, and

excessive temperature can lead to sudden tire

failure. The grade C corresponds to a level of

performance which all passenger car tires must

meet under the Federal Motor Safety Standard

No. 109. Grades B and A represent higher levels

of performance on the laboratory test wheel than

6-86

Page 546 of 626

{WARNING:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose

or come off. The wheel nuts should be tightened

with a torque wrench to the proper torque

specification after replacing. Follow the torque

specification supplied by the aftermarket

manufacturer when using accessory locking wheel

nuts. SeeCapacities and Specifications

on

page 6‑126

for original equipment wheel nut

torque specifications.

Notice: Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification. See Capacities and

Specifications

on page 6‑126for the wheel nut torque

specification.

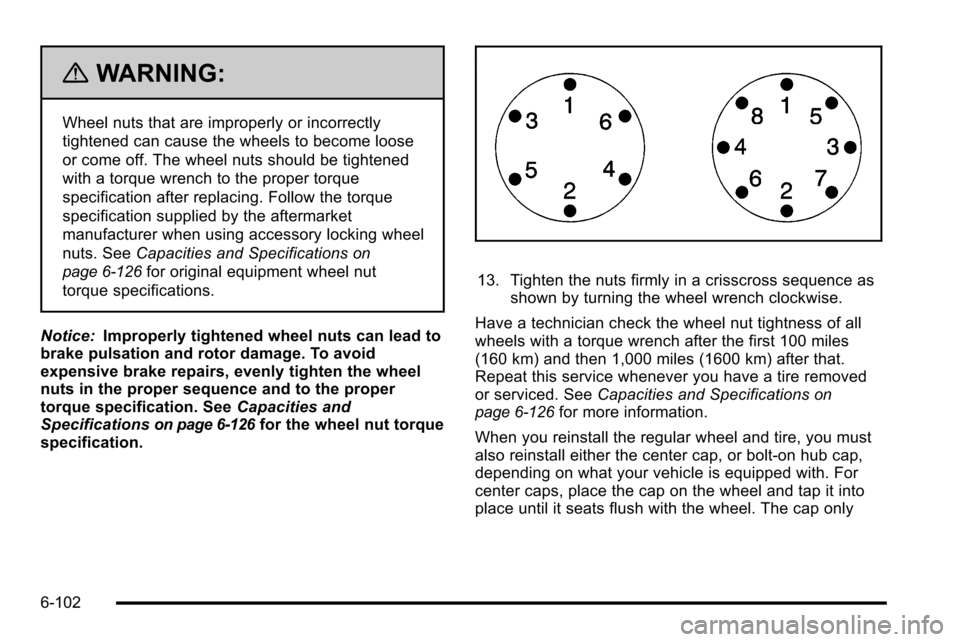

13. Tighten the nuts firmly in a crisscross sequence as

shown by turning the wheel wrench clockwise.

Have a technician check the wheel nut tightness of all

wheels with a torque wrench after the first 100 miles

(160 km) and then 1,000 miles (1600 km) after that.

Repeat this service whenever you have a tire removed

or serviced. See Capacities and Specifications

on

page 6‑126for more information.

When you reinstall the regular wheel and tire, you must

also reinstall either the center cap, or bolt-on hub cap,

depending on what your vehicle is equipped with. For

center caps, place the cap on the wheel and tap it into

place until it seats flush with the wheel. The cap only

6-102

Page 561 of 626

Vehicle Identification

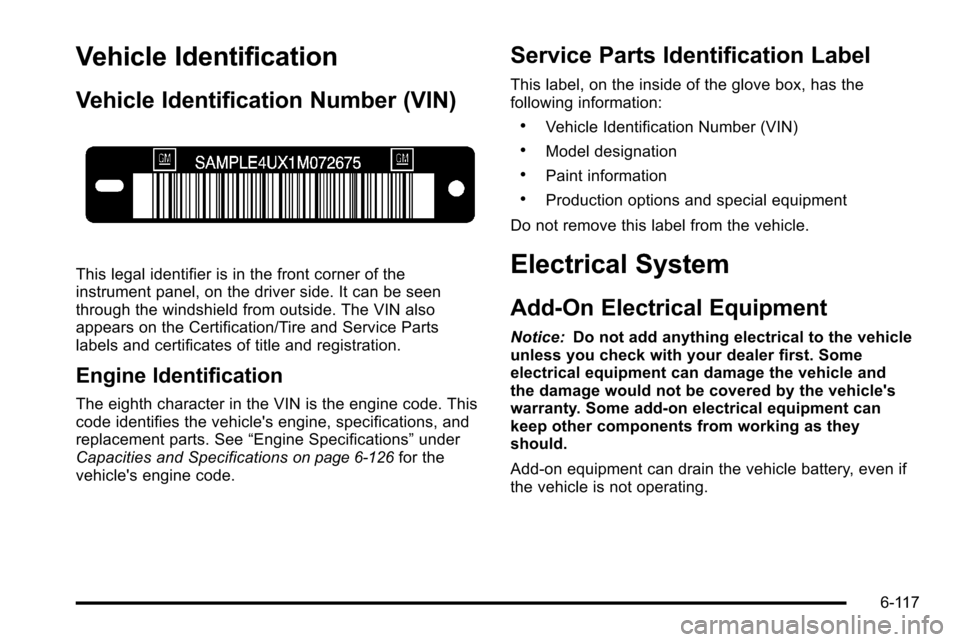

Vehicle Identification Number (VIN)

This legal identifier is in the front corner of the

instrument panel, on the driver side. It can be seen

through the windshield from outside. The VIN also

appears on the Certification/Tire and Service Parts

labels and certificates of title and registration.

Engine Identification

The eighth character in the VIN is the engine code. This

code identifies the vehicle's engine, specifications, and

replacement parts. See“Engine Specifications”under

Capacities and Specifications

on page 6‑126for the

vehicle's engine code.

Service Parts Identification Label

This label, on the inside of the glove box, has the

following information:

.Vehicle Identification Number (VIN)

.Model designation

.Paint information

.Production options and special equipment

Do not remove this label from the vehicle.

Electrical System

Add-On Electrical Equipment

Notice: Do not add anything electrical to the vehicle

unless you check with your dealer first. Some

electrical equipment can damage the vehicle and

the damage would not be covered by the vehicle's

warranty. Some add-on electrical equipment can

keep other components from working as they

should.

Add-on equipment can drain the vehicle battery, even if

the vehicle is not operating.

6-117

Page 573 of 626

Section 7 Maintenance Schedule

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Owner Checks and Services . . . . . . . . . . . . . . . . . . . 7-11 Recommended Fluids and Lubricants . . . . . . . . . . 7-13

Maintenance Replacement Parts . . . . . . . . . . . . . . 7-15

Engine Drive Belt Routing . . . . . . . . . . . . . . . . . . . . . 7-16

Maintenance Record . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7-1

Page 574 of 626

Maintenance Schedule

Introduction

This maintenance section applies to vehicles with a

gasoline engine. For diesel engine vehicles, see the

maintenance schedule section in the DURAMAX Diesel

manual.

Notice:Maintenance intervals, checks, inspections,

recommended fluids, and lubricants are necessary

to keep this vehicle in good working condition.

Damage caused by failure to follow scheduled

maintenance might not be covered by the vehicle

warranty.

As the vehicle owner, you are responsible for the

scheduled maintenance in this section. We recommend

having your dealer perform these services. Proper

vehicle maintenance helps to keep the vehicle in good

working condition, improves fuel economy, and reduces

vehicle emissions for better air quality.

Because of all the different ways people use vehicles,

maintenance needs vary. The vehicle might need more

frequent checks and services. Please read the

information under Scheduled Maintenance. To keep the

vehicle in good condition, see your dealer. The maintenance schedule is for vehicles that:

.carry passengers and cargo within recommended

limits on the Tire and Loading Information label.

See

Loading the Vehicle on page 5‑29.

.are driven on reasonable road surfaces within legal

driving limits.

.are driven off‐road in the recommended manner.

SeeOff-Road Driving on page 5‑11.

.use the recommended fuel. See Gasoline Octaneon page 6‑7.

{WARNING:

Performing maintenance work on a vehicle can be

dangerous. In trying to do some jobs, you can be

seriously injured. Do your own maintenance work

only if you have the required know-how and the

proper tools and equipment for the job. If you

have any doubt, see your dealer to have a

qualified technician do the work. See Doing Your

Own Service Work on page 6‑5.

7-2

Page 575 of 626

At your dealer, you can be certain that you will receive

the highest level of service available. Your dealer has

specially trained service technicians, uses genuine

replacement parts, as well as, up to date tools and

equipment to ensure fast and accurate diagnostics.

The proper replacement parts, fluids, and lubricants to

use are listed inRecommended Fluids and Lubricants

on page 7‑13andMaintenance Replacement Partson

page 7‑15. We recommend the use of genuine parts

from your dealer.

Rotation of New Tires

To maintain ride, handling, and performance of the

vehicle, it is important that the first rotation service for

new tires be performed when they have 8 000 to

13 000 km (5,000 to 8,000 miles). See Tire Inspection

and Rotation on page 6‑80.

Scheduled Maintenance

When the Change Engine Oil Soon

Message Displays

Change engine oil and filter. See Engine Oilon

page 6‑18. An Emission Control Service.

When the Change Engine Oil Soon message displays,

service is required for the vehicle as soon as possible,

within the next 1 000 km/600 miles. If driving under the

best conditions, the engine oil life system might not indicate the need for vehicle service for more than a

year. The engine oil and filter must be changed at least

once a year and the oil life system must be reset. Your

dealer has trained service technicians who will perform

this work and reset the system. If the engine oil life

system is reset accidentally, service the vehicle within

5 000 km/3,000 miles since the last service. Reset the

oil life system whenever the oil is changed. See

Engine

Oil Life System on page 6‑20.

When the Change Engine Oil Soon message displays,

certain services, checks, and inspections are required.

The services described for Maintenance Ishould be

performed at every engine oil change. The services

described for Maintenance IIshould be

performed when:

.Maintenance Iwas performed the last time the

engine oil was changed.

.It has been 10 months or more since the Change

Engine Oil Soon message has displayed or since

the last service.

7-3

Page 576 of 626

MaintenanceI

.Change engine oil and filter. See Engine Oilon

page 6‑18. An Emission Control Service.

.Engine coolant level check. See Engine Coolanton page 6‑31.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑38.

.Tire inflation check. SeeInflation - Tire Pressureon page 6‑73.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑80.

.Rotate tires. See Tire Inspection and Rotationon

page 6‑80.

.Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system must

be repaired and the fluid level checked.

.Engine air cleaner filter inspection (vehicles driven

in dusty conditions only). See Engine Air Cleaner/

Filter on page 6‑21.

.Brake system inspection (or every 12 months,

whichever occurs first).

.For vehicles with Allison Transmission®only: At

the first engine oil change only, replace external

transmission filter.

Maintenance II

.Perform all services described in Maintenance I.

.Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts or

signs of wear.

.Lubricate the front suspension, steering linkage,

and parking brake cable guides. Control arm ball

joints on 2500/3500 series vehicles require

lubrication but should not be lubricated unless their

temperature is−12°C (10°F) or higher, or they

could be damaged. Control arm ball joints on

1500 series vehicles are maintenance‐free.

Vehicles used under severe commercial operating

conditions require lubrication on a regular basis

every 5 000 km/3,000 miles.

.Engine cooling system inspection. Visual

inspection of hoses, pipes, fittings, and clamps and

replacement, if needed.

.Windshield wiper blade inspection for wear,

cracking, or contamination and windshield and

wiper blade cleaning, if contaminated. See

Windshield and Wiper Blades

on page 6‑114. Worn

or damaged wiper blade replacement. See

Windshield Wiper Blade Replacement

on

page 6‑63.

7-4

Page 577 of 626

.Body hinges and latches, key lock cylinders,

folding seat hardware, and tailgate hinges, linkage,

and handle pivot points lubrication. See

Recommended Fluids and Lubricants

on

page 7‑13. More frequent lubrication may be

required when vehicle is exposed to a corrosive

environment. Applying silicone grease on

weatherstrips with a clean cloth makes them last

longer, seal better, and not stick or squeak.

.Restraint system component check. See Checking

the Restraint Systems on page 2‑94.

.Automatic transmission fluid level check and

adding fluid, if needed. See Automatic

Transmission Fluid (4-Speed Transmission)

on

page 6‑23or Automatic Transmission Fluid

(6-Speed Transmission) on page 6‑26.

.Four‐wheel drive vehicles: Transfer case fluid level

check and adding fluid, if needed.

.Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6‑21.

.Vehicles with diesel engine or GVWR above

4 536 kg (10,000 lbs) only: Shields inspection for

damage or looseness. Adjust or replace as

required. This is a Noise Emission Control Service.

Applicable to vehicles sold in the United States

and recommended for vehicles sold in Canada.

Additional Required Services

At the First 160 km/100 Miles,

1 600 km/1,000 Miles, and

10 000 km/6,000 Miles

.For vehicles with dual wheels: Check dual wheel

nut torque. For proper torque, see Capacities and

Specifications on page 6‑126.

At Each Fuel Stop

.Engine oil level check. See Engine Oilon

page 6‑18.

.Engine coolant level check. See Engine Coolanton page 6‑31.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑38.

Once a Month

.Tire inflation check. SeeInflation - Tire Pressureon page 6‑73.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑80.

7-5

Page 578 of 626

Once a Year

.Starter switch check. SeeOwner Checks and

Services on page 7‑11.

.Parking brake and automatic transmission P (Park)

mechanism check. See Owner Checks and

Services on page 7‑11.

.Automatic transmission shiftlock control system

check. See Owner Checks and Serviceson

page 7‑11.

.Ignition transmission lock check. See Owner

Checks and Services on page 7‑11.

.Engine cooling system and pressure cap pressure

check. Radiator and air conditioning condenser

outside cleaning. See Cooling System

on

page 6‑29.

.Exhaust system and nearby heat shields

inspection for loose or damaged components.

.Accelerator pedal check for damage, high effort,

or binding. Replace if needed.

First Engine Oil Change After Every

40 000 km/25,000 Miles

.Fuel system inspection for damage or leaks.

.Four‐wheel drive only: Transfer case fluid change

(extreme duty service) for vehicles mainly driven

off‐road in four‐wheel drive. Vehicles used for

farming, mining, forestry, Department of Natural

Resources (DNR), and snow plowing occupations

meet this definition. Check vent hose at transfer

case for kinks and proper installation. Check to be

sure vent hose is unobstructed, clear, and free of

debris. During any maintenance, if a power washer

is used to clean mud and dirt from the underbody,

care should be taken to not directly spray the

transfer case output seals. High pressure water

can overcome the seals and contaminate the

transfer case fluid. Contaminated fluid will

decrease the life of the transfer case and should

be replaced.

7-6