check engine CHEVROLET SILVERADO 2010 2.G Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: SILVERADO, Model: CHEVROLET SILVERADO 2010 2.GPages: 626, PDF Size: 4.8 MB

Page 492 of 626

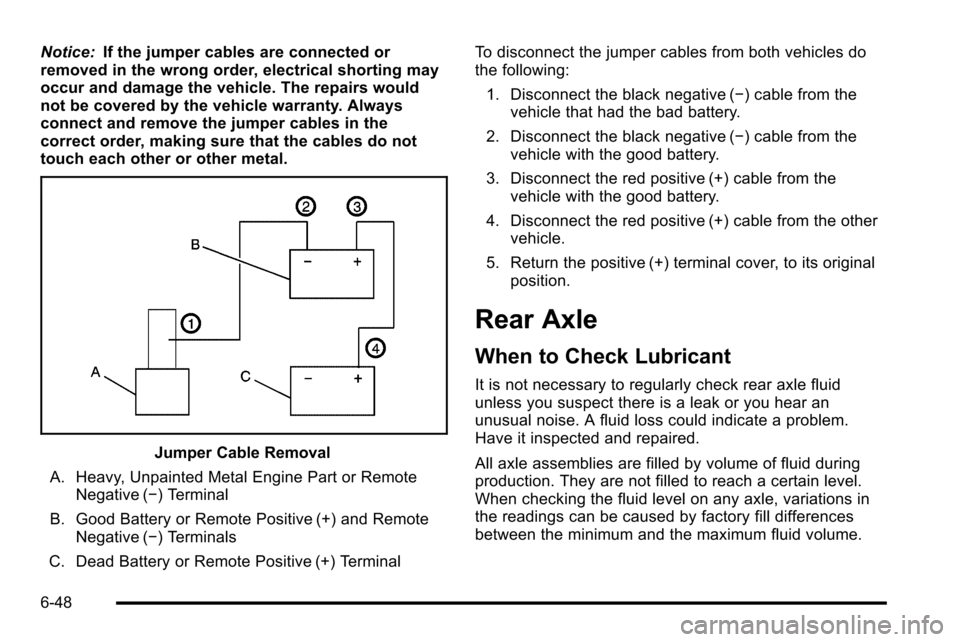

Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by the vehicle warranty. Always

connect and remove the jumper cables in the

correct order, making sure that the cables do not

touch each other or other metal.

Jumper Cable Removal

A. Heavy, Unpainted Metal Engine Part or Remote Negative (−) Terminal

B. Good Battery or Remote Positive (+) and Remote Negative (−) Terminals

C. Dead Battery or Remote Positive (+) Terminal To disconnect the jumper cables from both vehicles do

the following:

1. Disconnect the black negative (−) cable from the vehicle that had the bad battery.

2. Disconnect the black negative (−) cable from the vehicle with the good battery.

3. Disconnect the red positive (+) cable from the vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other vehicle.

5. Return the positive (+) terminal cover, to its original position.

Rear Axle

When to Check Lubricant

It is not necessary to regularly check rear axle fluid

unless you suspect there is a leak or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

All axle assemblies are filled by volume of fluid during

production. They are not filled to reach a certain level.

When checking the fluid level on any axle, variations in

the readings can be caused by factory fill differences

between the minimum and the maximum fluid volume.

6-48

Page 493 of 626

Also, if a vehicle has just been driven before checking

the fluid level, it may appear lower than normal because

fluid has traveled out along the axle tubes and has not

drained back to the sump area. Therefore, a reading

taken five minutes after the vehicle has been driven will

appear to have a lower fluid level than a vehicle that

has been stationary for an hour or two. Remember that

the rear axle assembly must be supported to get a true

reading.

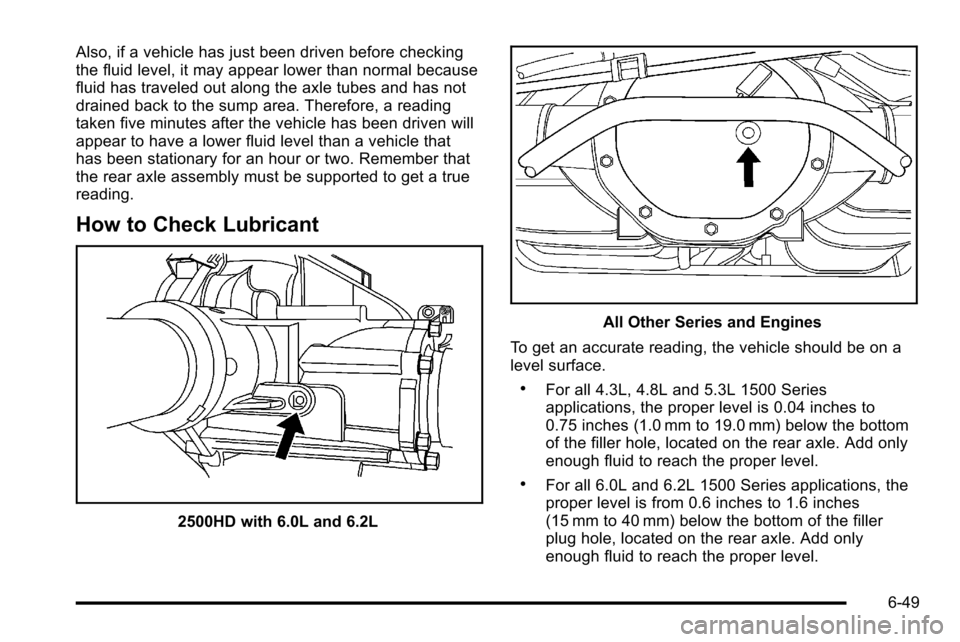

How to Check Lubricant

2500HD with 6.0L and 6.2L

All Other Series and Engines

To get an accurate reading, the vehicle should be on a

level surface.

.For all 4.3L, 4.8L and 5.3L 1500 Series

applications, the proper level is 0.04 inches to

0.75 inches (1.0 mm to 19.0 mm) below the bottom

of the filler hole, located on the rear axle. Add only

enough fluid to reach the proper level.

.For all 6.0L and 6.2L 1500 Series applications, the

proper level is from 0.6 inches to 1.6 inches

(15 mm to 40 mm) below the bottom of the filler

plug hole, located on the rear axle. Add only

enough fluid to reach the proper level.

6-49

Page 561 of 626

Vehicle Identification

Vehicle Identification Number (VIN)

This legal identifier is in the front corner of the

instrument panel, on the driver side. It can be seen

through the windshield from outside. The VIN also

appears on the Certification/Tire and Service Parts

labels and certificates of title and registration.

Engine Identification

The eighth character in the VIN is the engine code. This

code identifies the vehicle's engine, specifications, and

replacement parts. See“Engine Specifications”under

Capacities and Specifications

on page 6‑126for the

vehicle's engine code.

Service Parts Identification Label

This label, on the inside of the glove box, has the

following information:

.Vehicle Identification Number (VIN)

.Model designation

.Paint information

.Production options and special equipment

Do not remove this label from the vehicle.

Electrical System

Add-On Electrical Equipment

Notice: Do not add anything electrical to the vehicle

unless you check with your dealer first. Some

electrical equipment can damage the vehicle and

the damage would not be covered by the vehicle's

warranty. Some add-on electrical equipment can

keep other components from working as they

should.

Add-on equipment can drain the vehicle battery, even if

the vehicle is not operating.

6-117

Page 573 of 626

Section 7 Maintenance Schedule

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Owner Checks and Services . . . . . . . . . . . . . . . . . . . 7-11 Recommended Fluids and Lubricants . . . . . . . . . . 7-13

Maintenance Replacement Parts . . . . . . . . . . . . . . 7-15

Engine Drive Belt Routing . . . . . . . . . . . . . . . . . . . . . 7-16

Maintenance Record . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7-1

Page 574 of 626

Maintenance Schedule

Introduction

This maintenance section applies to vehicles with a

gasoline engine. For diesel engine vehicles, see the

maintenance schedule section in the DURAMAX Diesel

manual.

Notice:Maintenance intervals, checks, inspections,

recommended fluids, and lubricants are necessary

to keep this vehicle in good working condition.

Damage caused by failure to follow scheduled

maintenance might not be covered by the vehicle

warranty.

As the vehicle owner, you are responsible for the

scheduled maintenance in this section. We recommend

having your dealer perform these services. Proper

vehicle maintenance helps to keep the vehicle in good

working condition, improves fuel economy, and reduces

vehicle emissions for better air quality.

Because of all the different ways people use vehicles,

maintenance needs vary. The vehicle might need more

frequent checks and services. Please read the

information under Scheduled Maintenance. To keep the

vehicle in good condition, see your dealer. The maintenance schedule is for vehicles that:

.carry passengers and cargo within recommended

limits on the Tire and Loading Information label.

See

Loading the Vehicle on page 5‑29.

.are driven on reasonable road surfaces within legal

driving limits.

.are driven off‐road in the recommended manner.

SeeOff-Road Driving on page 5‑11.

.use the recommended fuel. See Gasoline Octaneon page 6‑7.

{WARNING:

Performing maintenance work on a vehicle can be

dangerous. In trying to do some jobs, you can be

seriously injured. Do your own maintenance work

only if you have the required know-how and the

proper tools and equipment for the job. If you

have any doubt, see your dealer to have a

qualified technician do the work. See Doing Your

Own Service Work on page 6‑5.

7-2

Page 575 of 626

At your dealer, you can be certain that you will receive

the highest level of service available. Your dealer has

specially trained service technicians, uses genuine

replacement parts, as well as, up to date tools and

equipment to ensure fast and accurate diagnostics.

The proper replacement parts, fluids, and lubricants to

use are listed inRecommended Fluids and Lubricants

on page 7‑13andMaintenance Replacement Partson

page 7‑15. We recommend the use of genuine parts

from your dealer.

Rotation of New Tires

To maintain ride, handling, and performance of the

vehicle, it is important that the first rotation service for

new tires be performed when they have 8 000 to

13 000 km (5,000 to 8,000 miles). See Tire Inspection

and Rotation on page 6‑80.

Scheduled Maintenance

When the Change Engine Oil Soon

Message Displays

Change engine oil and filter. See Engine Oilon

page 6‑18. An Emission Control Service.

When the Change Engine Oil Soon message displays,

service is required for the vehicle as soon as possible,

within the next 1 000 km/600 miles. If driving under the

best conditions, the engine oil life system might not indicate the need for vehicle service for more than a

year. The engine oil and filter must be changed at least

once a year and the oil life system must be reset. Your

dealer has trained service technicians who will perform

this work and reset the system. If the engine oil life

system is reset accidentally, service the vehicle within

5 000 km/3,000 miles since the last service. Reset the

oil life system whenever the oil is changed. See

Engine

Oil Life System on page 6‑20.

When the Change Engine Oil Soon message displays,

certain services, checks, and inspections are required.

The services described for Maintenance Ishould be

performed at every engine oil change. The services

described for Maintenance IIshould be

performed when:

.Maintenance Iwas performed the last time the

engine oil was changed.

.It has been 10 months or more since the Change

Engine Oil Soon message has displayed or since

the last service.

7-3

Page 576 of 626

MaintenanceI

.Change engine oil and filter. See Engine Oilon

page 6‑18. An Emission Control Service.

.Engine coolant level check. See Engine Coolanton page 6‑31.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑38.

.Tire inflation check. SeeInflation - Tire Pressureon page 6‑73.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑80.

.Rotate tires. See Tire Inspection and Rotationon

page 6‑80.

.Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system must

be repaired and the fluid level checked.

.Engine air cleaner filter inspection (vehicles driven

in dusty conditions only). See Engine Air Cleaner/

Filter on page 6‑21.

.Brake system inspection (or every 12 months,

whichever occurs first).

.For vehicles with Allison Transmission®only: At

the first engine oil change only, replace external

transmission filter.

Maintenance II

.Perform all services described in Maintenance I.

.Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts or

signs of wear.

.Lubricate the front suspension, steering linkage,

and parking brake cable guides. Control arm ball

joints on 2500/3500 series vehicles require

lubrication but should not be lubricated unless their

temperature is−12°C (10°F) or higher, or they

could be damaged. Control arm ball joints on

1500 series vehicles are maintenance‐free.

Vehicles used under severe commercial operating

conditions require lubrication on a regular basis

every 5 000 km/3,000 miles.

.Engine cooling system inspection. Visual

inspection of hoses, pipes, fittings, and clamps and

replacement, if needed.

.Windshield wiper blade inspection for wear,

cracking, or contamination and windshield and

wiper blade cleaning, if contaminated. See

Windshield and Wiper Blades

on page 6‑114. Worn

or damaged wiper blade replacement. See

Windshield Wiper Blade Replacement

on

page 6‑63.

7-4

Page 577 of 626

.Body hinges and latches, key lock cylinders,

folding seat hardware, and tailgate hinges, linkage,

and handle pivot points lubrication. See

Recommended Fluids and Lubricants

on

page 7‑13. More frequent lubrication may be

required when vehicle is exposed to a corrosive

environment. Applying silicone grease on

weatherstrips with a clean cloth makes them last

longer, seal better, and not stick or squeak.

.Restraint system component check. See Checking

the Restraint Systems on page 2‑94.

.Automatic transmission fluid level check and

adding fluid, if needed. See Automatic

Transmission Fluid (4-Speed Transmission)

on

page 6‑23or Automatic Transmission Fluid

(6-Speed Transmission) on page 6‑26.

.Four‐wheel drive vehicles: Transfer case fluid level

check and adding fluid, if needed.

.Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6‑21.

.Vehicles with diesel engine or GVWR above

4 536 kg (10,000 lbs) only: Shields inspection for

damage or looseness. Adjust or replace as

required. This is a Noise Emission Control Service.

Applicable to vehicles sold in the United States

and recommended for vehicles sold in Canada.

Additional Required Services

At the First 160 km/100 Miles,

1 600 km/1,000 Miles, and

10 000 km/6,000 Miles

.For vehicles with dual wheels: Check dual wheel

nut torque. For proper torque, see Capacities and

Specifications on page 6‑126.

At Each Fuel Stop

.Engine oil level check. See Engine Oilon

page 6‑18.

.Engine coolant level check. See Engine Coolanton page 6‑31.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑38.

Once a Month

.Tire inflation check. SeeInflation - Tire Pressureon page 6‑73.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑80.

7-5

Page 578 of 626

Once a Year

.Starter switch check. SeeOwner Checks and

Services on page 7‑11.

.Parking brake and automatic transmission P (Park)

mechanism check. See Owner Checks and

Services on page 7‑11.

.Automatic transmission shiftlock control system

check. See Owner Checks and Serviceson

page 7‑11.

.Ignition transmission lock check. See Owner

Checks and Services on page 7‑11.

.Engine cooling system and pressure cap pressure

check. Radiator and air conditioning condenser

outside cleaning. See Cooling System

on

page 6‑29.

.Exhaust system and nearby heat shields

inspection for loose or damaged components.

.Accelerator pedal check for damage, high effort,

or binding. Replace if needed.

First Engine Oil Change After Every

40 000 km/25,000 Miles

.Fuel system inspection for damage or leaks.

.Four‐wheel drive only: Transfer case fluid change

(extreme duty service) for vehicles mainly driven

off‐road in four‐wheel drive. Vehicles used for

farming, mining, forestry, Department of Natural

Resources (DNR), and snow plowing occupations

meet this definition. Check vent hose at transfer

case for kinks and proper installation. Check to be

sure vent hose is unobstructed, clear, and free of

debris. During any maintenance, if a power washer

is used to clean mud and dirt from the underbody,

care should be taken to not directly spray the

transfer case output seals. High pressure water

can overcome the seals and contaminate the

transfer case fluid. Contaminated fluid will

decrease the life of the transfer case and should

be replaced.

7-6

Page 579 of 626

First Engine Oil Change After Every

80 000 km/50,000 Miles

.Engine air cleaner filter replacement. SeeEngine

Air Cleaner/Filter on page 6‑21.

.Automatic transmission fluid change (severe

service) for vehicles with Gross Vehicle Weight

Rating (GVWR) over 3 901 kg (8,600 lbs) or mainly

driven in heavy city traffic in hot weather, in hilly or

mountainous terrain, when frequently towing a

trailer, or used for taxi, police, or delivery service.

See Automatic Transmission Fluid (4-Speed

Transmission)

on page 6‑23or Automatic

Transmission Fluid (6-Speed Transmission)on

page 6‑26.

.Four‐wheel drive only: Transfer case fluid change

(severe service) for vehicles mainly driven when

frequently towing a trailer, or used for taxi, police,

or delivery service. Check vent hose at transfer

case for kinks and proper installation. Check to be

sure vent hose is unobstructed, clear, and free of

debris. During any maintenance, if a power washer is used to clean mud and dirt from the underbody,

care should be taken to not directly spray the

transfer case output seals. High pressure water

can overcome the seals and contaminate the

transfer case fluid. Contaminated fluid will

decrease the life of the transfer case and should

be replaced.

.Evaporative control system inspection. Check all

fuel and vapor lines and hoses for proper hook‐up,

routing, and condition. Check that the purge valve,

if the vehicle has one, works properly. Replace as

needed.

An Emission Control Service. The U.S.

Environmental Protection Agency or the California

Air Resources Board has determined that the

failure to perform this maintenance item will not

nullify the emission warranty or limit recall liability

prior to the completion of the vehicle's useful life.

We, however, urge that all recommended

maintenance services be performed at the

indicated intervals and the maintenance be

recorded.

7-7