wiring CHEVROLET SILVERADO 2010 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: SILVERADO, Model: CHEVROLET SILVERADO 2010 2.GPages: 626, PDF Size: 4.8 MB

Page 134 of 626

Servicing Your Airbag-Equipped

Vehicle

Airbags affect how the vehicle should be serviced.

There are parts of the airbag system in several places

around the vehicle. Your dealer and the service manual

have information about servicing the vehicle and the

airbag system. To purchase a service manual, see

Service Publications Ordering Information

on

page 8‑16.

{WARNING:

For up to 10 seconds after the ignition is turned off

and the battery is disconnected, an airbag can still

inflate during improper service. You can be injured

if you are close to an airbag when it inflates. Avoid

yellow connectors. They are probably part of the

airbag system. Be sure to follow proper service

procedures, and make sure the person performing

work for you is qualified to do so.

Adding Equipment to Your

Airbag-Equipped Vehicle

Q: Is there anything I might add to or change about the vehicle that could keep the airbags from

working properly?

A: Yes. If you add things that change your vehicle's

frame, bumper system, height, front end or side

sheet metal, they may keep the airbag system from

working properly. Changing or moving any parts of

the front seats, safety belts, the airbag sensing and

diagnostic module, steering wheel, instrument panel,

roof-rail airbag modules, ceiling headliner or pillar

garnish trim, overhead console, front sensors, side

impact sensors, rollover sensor module, or airbag

wiring can affect the operation of the airbag system.

In addition, the vehicle may have a passenger

sensing system for the right front passenger's

position, which includes sensors that are part of the

passenger's seat. The passenger sensing system

may not operate properly if the original seat trim is

replaced with non-GM covers, upholstery or trim,

or with GM covers, upholstery or trim designed for a

different vehicle. Any object, such as an aftermarket

seat heater or a comfort enhancing pad or device,

installed under or on top of the seat fabric, could

also interfere with the operation of the passenger

sensing system. This could either prevent proper

2-92

Page 135 of 626

deployment of the passenger airbag(s) or prevent

the passenger sensing system from properly turning

off the passenger airbag(s). SeePassenger Sensing

System on page 2‑86.

If you have any questions about this, you should

contact Customer Assistance before you modify

your vehicle. The phone numbers and addresses for

Customer Assistance are in Step Two of the

Customer Satisfaction Procedure in this manual.

See Customer Satisfaction Procedure on page 8‑2.

If the vehicle has rollover roof-rail airbags, see

Different Size Tires and Wheels

on page 6‑85for

additional important information.

Q: What if I added a snow plow? Will it keep the airbags from working properly?

A: We have designed our airbag systems to work

properly under a wide range of conditions, including

snow plowing with vehicles that have the optional

Snow Plow Prep Package (RPO VYU). But do not

change or defeat the snow plow's “tripping

mechanism.” If you do, it can damage your snow

plow and your vehicle, and it may cause an airbag

inflation. Q: Because I have a disability, I have to get my

vehicle modified. How can I find out whether this

will affect my airbag system?

A: If you have questions, call Customer Assistance.

The phone numbers and addresses for Customer

Assistance are in Step Two of the Customer

Satisfaction Procedure in this manual. See

Customer Satisfaction Procedure on page 8‑2.

In addition, your dealer and the service manual have

information about the location of the airbag sensors,

sensing and diagnostic module and airbag wiring.

2-93

Page 205 of 626

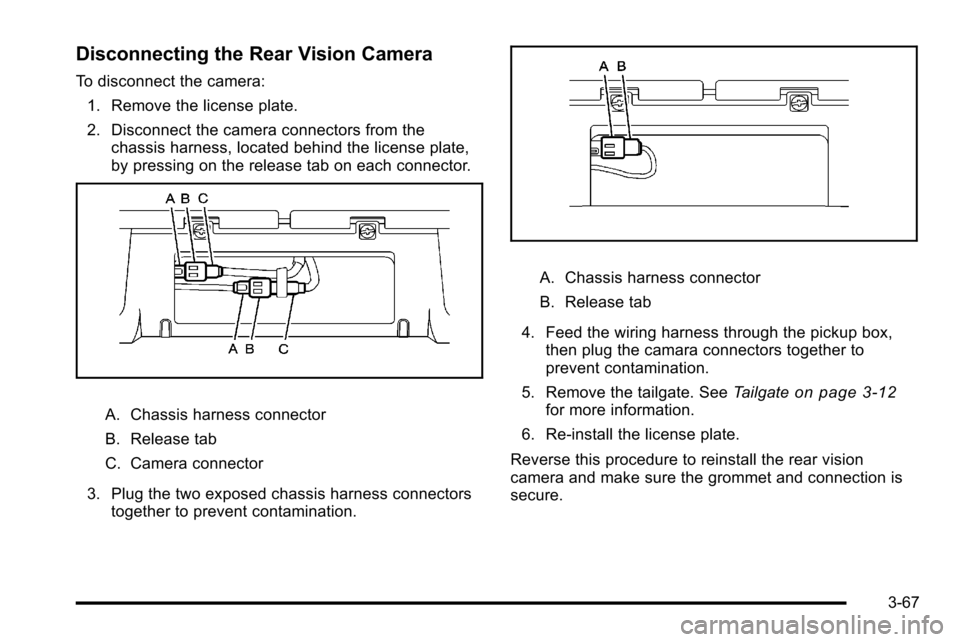

Disconnecting the Rear Vision Camera

To disconnect the camera:1. Remove the license plate.

2. Disconnect the camera connectors from the chassis harness, located behind the license plate,

by pressing on the release tab on each connector.

A. Chassis harness connector

B. Release tab

C. Camera connector

3. Plug the two exposed chassis harness connectors together to prevent contamination.

A. Chassis harness connector

B. Release tab

4. Feed the wiring harness through the pickup box, then plug the camara connectors together to

prevent contamination.

5. Remove the tailgate. See Tailgate

on page 3‑12for more information.

6. Re‐install the license plate.

Reverse this procedure to reinstall the rear vision

camera and make sure the grommet and connection is

secure.

3-67

Page 232 of 626

Auxiliary Roof-Mounted Lamp

If the vehicle has this feature, this button includes wiring

provisions for a dealer or a qualified service center to

install an auxiliary roof lamp.

This button is located on

the overhead console.

When the wiring is connected to an auxiliary roof

mounted lamp, pressing the bottom of the button will

activate the lamp and illuminate an indicator light at the

bottom of this button. Pressing the top of the button will

turn off the roof mounted lamp and indicator.

The emergency roof lamp circuit is fused at 30 amps,

so the total current draw of the attached lamps should

be less than this value. The attachment points for the

roof lamp circuits are two blunt cut wires located above

the overhead console, a dark green switched power

wire and a black ground wire.

For further information on roof mount emergency lamp

installation, please visit the GM Upfitter website at

www.gmupfitters.com or contact your dealer. If the vehicle has this button, the vehicle may have the

snow plow prep package. For further information see

Adding a Snow Plow or Similar Equipment

on

page 5‑37.

Instrument Panel Brightness

D (Instrument Panel Brightness): This feature

controls the brightness of the instrument panel lights

and is located next to the exterior lamp control.

Push the knob to extend out and then it can be turned.

Turn the knob clockwise or counterclockwise to brighten

or dim the instrument panel lights. Turning the knob to

the farthest clockwise position turns on the dome lamps.

Dome Lamps

The dome lamps come on when any door is opened.

They turn off after all the doors are closed.

The dome lamps can also be turned on by turning the

instrument panel brightness knob, located on the

instrument panel to the left of the steering column,

clockwise to the farthest position. In this position, the

dome lamps remain on whether a door is opened or

closed.

4-14

Page 250 of 626

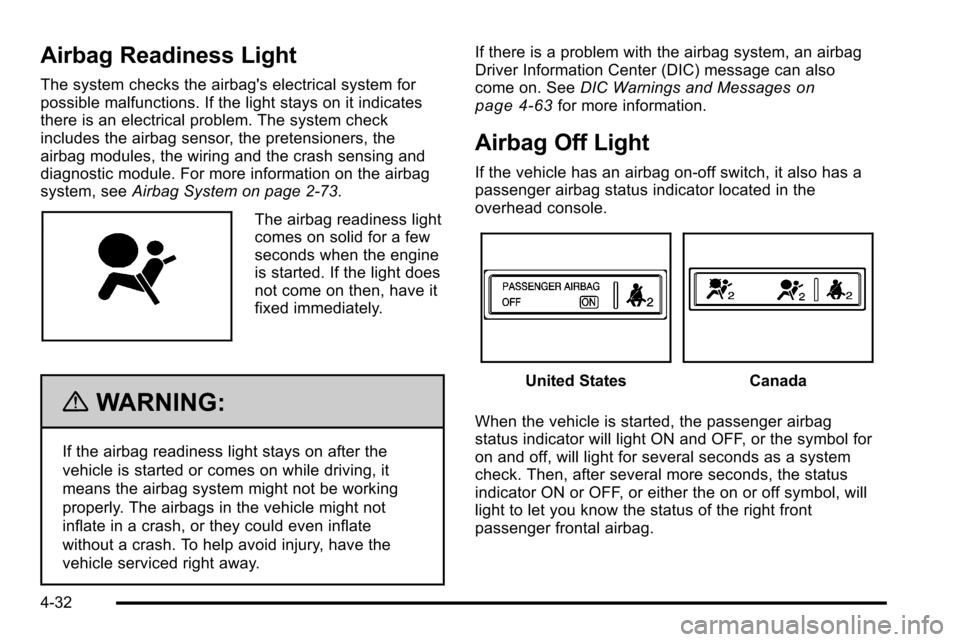

Airbag Readiness Light

The system checks the airbag's electrical system for

possible malfunctions. If the light stays on it indicates

there is an electrical problem. The system check

includes the airbag sensor, the pretensioners, the

airbag modules, the wiring and the crash sensing and

diagnostic module. For more information on the airbag

system, seeAirbag System on page 2‑73.

The airbag readiness light

comes on solid for a few

seconds when the engine

is started. If the light does

not come on then, have it

fixed immediately.

{WARNING:

If the airbag readiness light stays on after the

vehicle is started or comes on while driving, it

means the airbag system might not be working

properly. The airbags in the vehicle might not

inflate in a crash, or they could even inflate

without a crash. To help avoid injury, have the

vehicle serviced right away. If there is a problem with the airbag system, an airbag

Driver Information Center (DIC) message can also

come on. See

DIC Warnings and Messages

on

page 4‑63for more information.

Airbag Off Light

If the vehicle has an airbag on-off switch, it also has a

passenger airbag status indicator located in the

overhead console.

United StatesCanada

When the vehicle is started, the passenger airbag

status indicator will light ON and OFF, or the symbol for

on and off, will light for several seconds as a system

check. Then, after several more seconds, the status

indicator ON or OFF, or either the on or off symbol, will

light to let you know the status of the right front

passenger frontal airbag.

4-32

Page 282 of 626

CHECK TRAILER WIRING

On vehicles with the Integrated Trailer Brake Control

(ITBC) system, this message may display and a chime

may sound when one of the following conditions exists:

.A trailer with electric brakes becomes

disconnected from the vehicle.

‐If the disconnect occurs while the vehicle is

stopped, this message clears itself after a

short time.

‐ If the disconnect occurs while the vehicle is

moving, this message stays on until the ignition

is turned off.

.There is a short in the wiring to the electric trailer

brakes.

When this message displays, power is no longer

available to the trailer brakes.

As soon as it is safe to do so, carefully pull your vehicle

over to the side of the road and turn the ignition off.

Check the wiring connection to the trailer and turn the

ignition back on. This message clears if the trailer is

reconnected. This message also clears if you

acknowledge it. If this message still displays, either your

vehicle or the trailer needs service. See your dealer.

See “Integrated Trailer Brake Control System” under

Towing a Trailer

on page 5‑51for more information.

DRIVER DOOR OPEN

This message displays and a chime may sound if the

driver door is not fully closed and the vehicle is shifted

out of P (Park). Stop and turn off the vehicle, check the

door for obstructions, and close the door again. Check

to see if the message still appears on the DIC.

ENGINE HOT A/C (Air Conditioning)

TURNED OFF

This message displays when the engine coolant

becomes hotter than the normal operating temperature.

See Engine Coolant Temperature Gauge

on

page 4‑40. To avoid added strain on a hot engine, the

air conditioning compressor automatically turns off.

When the coolant temperature returns to normal, the air

conditioning compressor turns back on. You can

continue to drive your vehicle.

If this message continues to appear, have the system

repaired by your dealer as soon as possible to avoid

damage to the engine.

ENGINE OIL HOT IDLE ENGINE

This message displays when the engine oil becomes

hotter than the normal operating temperature. Stop and

allow the vehicle to idle until it cools down. See Engine

Coolant Temperature Gauge

on page 4‑40.

4-64

Page 287 of 626

SERVICE THEFT DETERRENT SYSTEM

This message displays when there is a problem

with the theft-deterrent system. The vehicle may

or may not restart so you may want to take the vehicle

to your dealer before turning off the engine. See

PASS-Key

®III+ Electronic Immobilizer Operationon

page 3‑19for more information.

SERVICE TIRE MONITOR SYSTEM

If your vehicle has the Tire Pressure Monitor System

(TPMS), this message displays if a part on the system

is not working properly. The tire pressure light also

flashes and then remains on during the same ignition

cycle. See Tire Pressure Light

on page 4‑40. Several

conditions may cause this message to appear. See Tire

Pressure Monitor Operation

on page 6‑76for more

information. If the warning comes on and stays on,

there may be a problem with the TPMS. See your

dealer.

SERVICE TRACTION CONTROL

If your vehicle has StabiliTrak, this message displays

when there is a problem with the Traction Control

System (TCS). When this message displays, the

system will not limit wheel spin. Adjust your driving

accordingly. See your dealer for service. See

StabiliTrak

®Systemon page 5‑6for more

information.

SERVICE TRAILER BRAKE SYSTEM

On vehicles with the Integrated Trailer Brake Control

(ITBC) system, this message displays and a chime may

sound when there is a problem with the ITBC system.

When this message displays, power is no longer

available to the trailer brakes.

As soon as it is safe to do so, carefully pull your vehicle

over to the side of the road and turn the ignition off.

Check the wiring connection to the trailer and turn the

ignition back on. If this message still displays, either

your vehicle or the trailer needs service. See your

dealer.

See “Integrated Trailer Brake Control System” under

Towing a Trailer

on page 5‑51for more information.

4-69

Page 406 of 626

You can add heavier equipment on the front of the

vehicle if you compensate for it by carrying fewer

passengers, less cargo, or by positioning cargo toward

the rear. This has the effect of reducing the load on the

front. However, the front GAWR, rear GAWR, and the

Gross Vehicle Weight Rating (GVWR) must never be

exceeded.

{WARNING:

On some vehicles that have certain front mounted

equipment, such as a snow plow, it may be

possible to load the front axle to the front gross

axle weight rating (GAWR) but not have enough

weight on the rear axle to have proper braking

performance. If your brakes can not work properly,

you could have a crash. To help your brakes work

properly when a snow plow is installed, always

follow the snow plow manufacturer or installer's

recommendation for rear ballast to ensure a

proper front and rear weight distribution ratio,

even though the actual front weight may be less

than the front GAWR, and the total vehicle weight

is less than the gross vehicle weight rating

(GVWR). Maintaining a proper front and rear

weight distribution ratio is necessary to provide

proper braking performance.Total vehicle reserve capacity is the difference between

the GVWR and the weight of the truck with full fuel and

passengers. It is the amount of weight that can be

added to the vehicle before reaching the GVWR. Keep

in mind that reserve capacity numbers are intended as

a guide when selecting the amount of equipment or

cargo the truck can carry. If unsure of the vehicle's front,

rear, or total weight, go to a weigh station and weigh the

vehicle. Your dealer can also help with this.

The total vehicle reserve capacity for the vehicle can be

found in the lower right corner of the Certification/Tire

label as shown previously.

See your dealer for additional advice and information

about using a snow plow on the vehicle. Also, see

Loading the Vehicle on page 5‑29.

Emergency Roof Lamp Provisions

Vehicles with the RPO VYU snow plow prep package

also have an emergency roof lamp provision package,

RPO TRW. Wiring for the emergency roof lamp is

provided above the overhead console. See

Auxiliary

Roof-Mounted Lamp

on page 4‑14for switch location.

5-40

Page 435 of 626

The Trailer Output will indicate“- - - - - -“on the Trailer

Brake Display Page whenever the following occur:

.No trailer is connected.

.A trailer without electric brakes is connected (no

DIC message is displayed).

.A trailer with electric brakes has become

disconnected (a CHECK TRAILER WIRING

message will also be displayed on the DIC).

.There is a fault present in the wiring to the electric

trailer brakes (a CHECK TRAILER WIRING

message will also be displayed on the DIC).

.There is a fault in the ITBC system (a SERVICE

TRAILER BRAKE SYSTEM message will also be

displayed in the DIC).

Manual Trailer Brake Apply

The Manual Trailer Brake Apply Lever is located on the

Trailer Brake Control Panel and is used to apply the

trailer ’s electric brakes independent of the vehicle’ s

brakes. This lever is used in the Trailer Gain Adjustment

Procedure to properly adjust the power output to the

trailer brakes. Sliding the lever to the left will apply only

the trailer brakes. The power output to the trailer is

indicated in the Trailer Brake Display Page in the DIC.

If the vehicle’s service brakes are applied while using

the Manual Trailer Brake Apply Lever, the trailer output

power will be the greater of the two. The trailer and the vehicle's brake lamps will come on

when either vehicle braking or manual trailer brakes are

applied.

Trailer Gain Adjustment Procedure

Trailer Gain should be set for a specific trailering

condition and must be adjusted any time vehicle

loading, trailer loading or road surface conditions

change.

Setting the Trailer Gain properly is needed for the best

trailer stopping performance. A trailer that is

over-gained may result in locked trailer brakes. A trailer

that is under-gained may result in not enough trailer

braking. Both of these conditions may result in poorer

stopping and stability of the vehicle and trailer.

Use the following procedure to correctly adjust Trailer

Gain for each towing condition:

1. Make sure the trailer brakes are in proper working condition.

2. Connect a properly loaded trailer to the vehicle and make all necessary mechanical and electrical

connections. See Loading the Vehicle

on

page 5‑29for more information.

5-69

Page 437 of 626

CHECK TRAILER WIRING–This message will be

displayed if:

1. The ITBC system first determines connection to a trailer with electric brakes and then the trailer

harness becomes disconnected from the vehicle.

If the disconnect occurs while the vehicle is

stationary, this message will automatically turn off

in about thirty seconds. This message will also turn

off if the driver acknowledges this message off or if

the trailer harness is re-connected.

If the disconnect occurs while the vehicle is

moving, this message will continue until the ignition

is turned off. This message will also turn off if the

driver acknowledges this message off or if the

trailer harness is re-connected.

2. There is an electrical fault in the wiring to the electric trailer brakes. This message will continue

as long as there is an electrical fault in the trailer

wiring. This message will also turn off if the driver

acknowledges this message off.

To determine if the electrical fault is on the vehicle side

or trailer side of the trailer wiring harness connection,

do the following: 1. Disconnect the trailer wiring harness from the vehicle.

2. Turn the ignition OFF. 3. Wait ten seconds, then turn the ignition back

to RUN.

4. If the CHECK TRAILER WIRING message re-appears, the electrical fault is on the

vehicle side.

If the CHECK TRAILER WIRING message only

re-appears when connecting the trailer wiring

harness to the vehicle, the electrical fault is on the

trailer side.

SERVICE TRAILER BRAKE SYSTEM –This message

will be displayed when there is a problem with the ITBC

system. If this message persists over multiple ignition

cycles there is a problem with the ITBC system. Take

the vehicle to an authorized GM dealer to have the

ITBC system diagnosed and repaired.

If either the CHECK TRAILER WIRING or SERVICE

TRAILER BRAKE SYSTEM message is displayed while

driving the vehicle, power is no longer available to the

trailer brakes. When traffic conditions allow, carefully

pull the vehicle over to the side of the road and turn the

ignition off. Check the wiring connection to the trailer

and turn the ignition back on. If either of these

messages continues, either the vehicle or trailer needs

service.

5-71