TPMS CHEVROLET SILVERADO 2012 2.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2012, Model line: SILVERADO, Model: CHEVROLET SILVERADO 2012 2.GPages: 584, PDF Size: 8.03 MB

Page 474 of 584

Black plate (68,1)Chevrolet Silverado Owner Manual - 2012

10-68 Vehicle Care

If the vehicle does not have RKE

or DIC buttons, press the trip

odometer reset stem located on

the instrument panel cluster until

the PRESS

VTO RELEARN

TIRE POSITIONS message

displays. The horn sounds twice

to signal the receiver is in

relearn mode and TIRE

LEARNING ACTIVE message

displays on the DIC screen.

4. Start with the driver side front tire.

5. Place the relearn tool against the tire sidewall, near the valve

stem. Then press the button to

activate the TPMS sensor.

A horn chirp confirms that the

sensor identification code has

been matched to this tire and

wheel position. 6. Proceed to the passenger side

front tire, and repeat the

procedure in Step 5.

7. Proceed to the passenger side rear tire, and repeat the

procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the procedure

in Step 5. The horn sounds

two times to indicate the sensor

identification code has been

matched to the driver side rear

tire, and the TPMS sensor

matching process is no longer

active. The TIRE LEARNING

ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Tire

and Loading Information label.

Tire Inspection

We recommend that the tires,

including the spare tire, if the

vehicle has one, be inspected

for signs of wear or damage at

least once a month.

Replace the tire if:

.The indicators at three or

more places around the tire

can be seen.

.There is cord or fabric

showing through the tire's

rubber.

.The tread or sidewall is

cracked, cut, or snagged

deep enough to show cord or

fabric.

.The tire has a bump, bulge,

or split.

.The tire has a puncture, cut,

or other damage that cannot

be repaired well because of

the size or location of the

damage.

Page 476 of 584

Black plate (70,1)Chevrolet Silverado Owner Manual - 2012

10-70 Vehicle Care

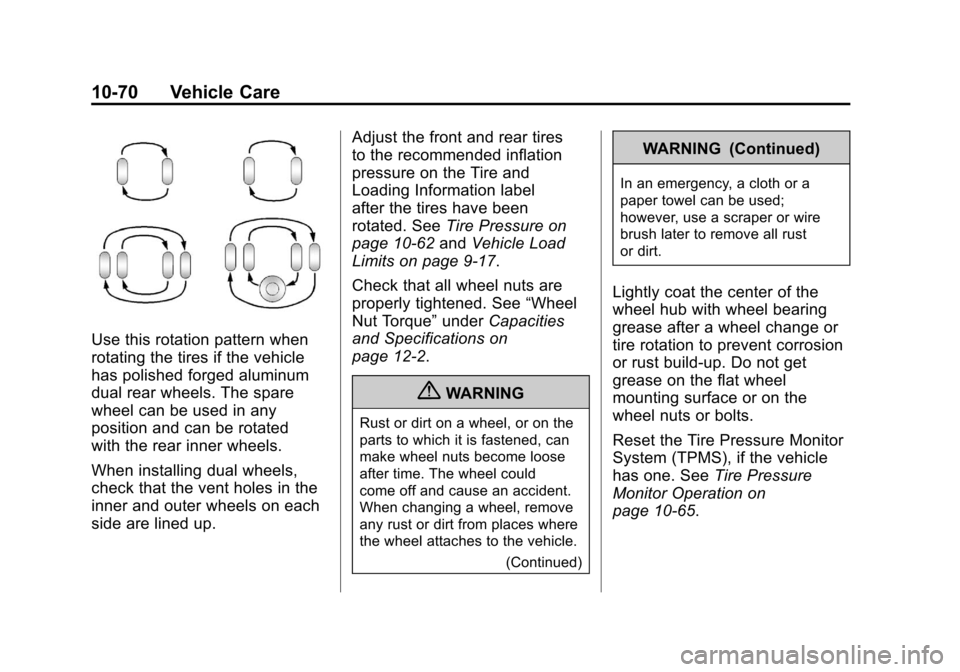

Use this rotation pattern when

rotating the tires if the vehicle

has polished forged aluminum

dual rear wheels. The spare

wheel can be used in any

position and can be rotated

with the rear inner wheels.

When installing dual wheels,

check that the vent holes in the

inner and outer wheels on each

side are lined up.Adjust the front and rear tires

to the recommended inflation

pressure on the Tire and

Loading Information label

after the tires have been

rotated. See

Tire Pressure on

page 10‑62 andVehicle Load

Limits on page 9‑17.

Check that all wheel nuts are

properly tightened. See “Wheel

Nut Torque” underCapacities

and Specifications on

page 12‑2.

{WARNING

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose

after time. The wheel could

come off and cause an accident.

When changing a wheel, remove

any rust or dirt from places where

the wheel attaches to the vehicle.

(Continued)

WARNING (Continued)

In an emergency, a cloth or a

paper towel can be used;

however, use a scraper or wire

brush later to remove all rust

or dirt.

Lightly coat the center of the

wheel hub with wheel bearing

grease after a wheel change or

tire rotation to prevent corrosion

or rust build-up. Do not get

grease on the flat wheel

mounting surface or on the

wheel nuts or bolts.

Reset the Tire Pressure Monitor

System (TPMS), if the vehicle

has one. SeeTire Pressure

Monitor Operation on

page 10‑65.

Page 483 of 584

Black plate (77,1)Chevrolet Silverado Owner Manual - 2012

Vehicle Care 10-77

Wheel Replacement

Replace any wheel that is bent,

cracked, or badly rusted or

corroded. If wheel nuts keep coming

loose, the wheel, wheel bolts and

wheel nuts should be replaced.

If the wheel leaks air, replace it.

Some aluminum wheels can be

repaired. See your dealer if any of

these conditions exist.

Your dealer will know the kind of

wheel that is needed.

Each new wheel should have the

same load-carrying capacity,

diameter, width, offset and be

mounted the same way as the

one it replaces.

Replace wheels, wheel bolts, wheel

nuts, or Tire Pressure Monitor

System (TPMS) sensors with new

GM original equipment parts.{WARNING

Using the wrong replacement

wheels, wheel bolts, or wheel

nuts can be dangerous. It could

affect the braking and handling of

the vehicle. Tires can lose air,

and cause loss of control, causing

a crash. Always use the correct

wheel, wheel bolts, and wheel

nuts for replacement.

Notice: The wrong wheel can

also cause problems with bearing

life, brake cooling, speedometer

or odometer calibration,

headlamp aim, bumper height,

vehicle ground clearance, and tire

or tire chain clearance to the

body and chassis. Whenever a wheel, wheel bolt,

or wheel nut is replaced on a dual

wheel setup, check the wheel nut

torque after 160, 1 600 and

10 000 km (100, 1,000 and 6,000 mi)

of driving. For proper torque,

see

“Wheel Nut Torque” under

Capacities and Specifications on

page 12‑2.

See If a Tire Goes Flat on

page 10‑79 for more information.

Used Replacement Wheels

{WARNING

Replacing a wheel with a used

one is dangerous. How it has

been used or how far it has been

driven may be unknown. It could

fail suddenly and cause a crash.

When replacing wheels, use a

new GM original equipment

wheel.