ignition CHEVROLET SILVERADO 2500 2023 Manual PDF

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2023, Model line: SILVERADO 2500, Model: CHEVROLET SILVERADO 2500 2023Pages: 441, PDF Size: 14.4 MB

Page 324 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Vehicle Care 323

Brake pads should always be replaced as

complete axle sets.

How to Reset the Brake Pad Life System

The system will automatically detect when

significantly worn brake pads are replaced.

When the ignition is turned on after new

pads and wear sensors are installed, a

message will display. Follow the prompts to

reset the system.

The brake pad life system can also be

manually reset:1. Display Brake Pad Life on the DIC. See Driver Information Center (DIC) (Base

Level) 0124 or

Driver Information Center (DIC) (Midlevel

and Uplevel) 0125.

2. Select the Brake Pad Life menu.

3. Select front or rear pads as appropriate.

4. Select YES on the confirmation message. Repeat for pads on the other axle if they

were also replaced.

How to Disable the Brake Pad Life

System

The brake pad life system can be turned off.

This may be necessary if aftermarket brake

pads without wear sensors are installed. When the system is turned off, the front

and rear brake pad life percentages will not

display. However, the built-in wear

indicators that make a high-pitched warning

sound when the brake pads are worn can

still determine when the pads should be

replaced. See

Brakes0322.

To turn off the brake pad life system: 1. Display Brake Pad Life on the DIC. See Driver Information Center (DIC) (Base

Level) 0124 or

Driver Information Center (DIC) (Midlevel

and Uplevel) 0125.

2. Select the Brake Pad Life menu.

3. Select DISABLE.

To turn the brake pad life system back on,

follow the above steps but select ENABLE in

Step 2.

Brake Fluid

The brake master cylinder reservoir is filled

with GM approved DOT 4 brake fluid as

indicated on the reservoir cap. See Engine

Compartment Overview 0310 for the

location of the reservoir.

Checking Brake Fluid

With the vehicle in P (Park) on a level

surface, the brake fluid level should be

between the minimum and maximum marks

on the brake fluid reservoir.

There are only two reasons why the brake

fluid level in the reservoir may go down:

.Normal brake lining wear. When new

linings are installed, the fluid level goes

back up.

.A fluid leak in the brake hydraulic system.

Have the brake hydraulic system fixed.

With a leak, the brakes will not

work well.

Always clean the brake fluid reservoir cap

and the area around the cap before

removing it.

Do not top off the brake fluid. Adding fluid

does not correct a leak. If fluid is added

when the linings are worn, there will be too

much fluid when new brake linings are

Page 326 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Vehicle Care 325

Extended Storage: Remove the black,

negative (−) cable from the battery or use a

battery trickle charger.

Negative Battery Cable Disconnection

{Warning

Before disconnecting the negative battery

cable, turn off all features, turn the

ignition off, and remove the key,

if equipped, from the vehicle. If this is

not done, you or others could be injured,

and the vehicle could be damaged.

Caution

If the battery is disconnected with the

ignition on or the vehicle in Retained

Accessory Power (RAP), the OnStar

back-up battery will be permanently

discharged and will need to be replaced.

1. Make sure the lamps, features, and accessories are turned off.

2. Turn the ignition off and remove the key, if equipped.

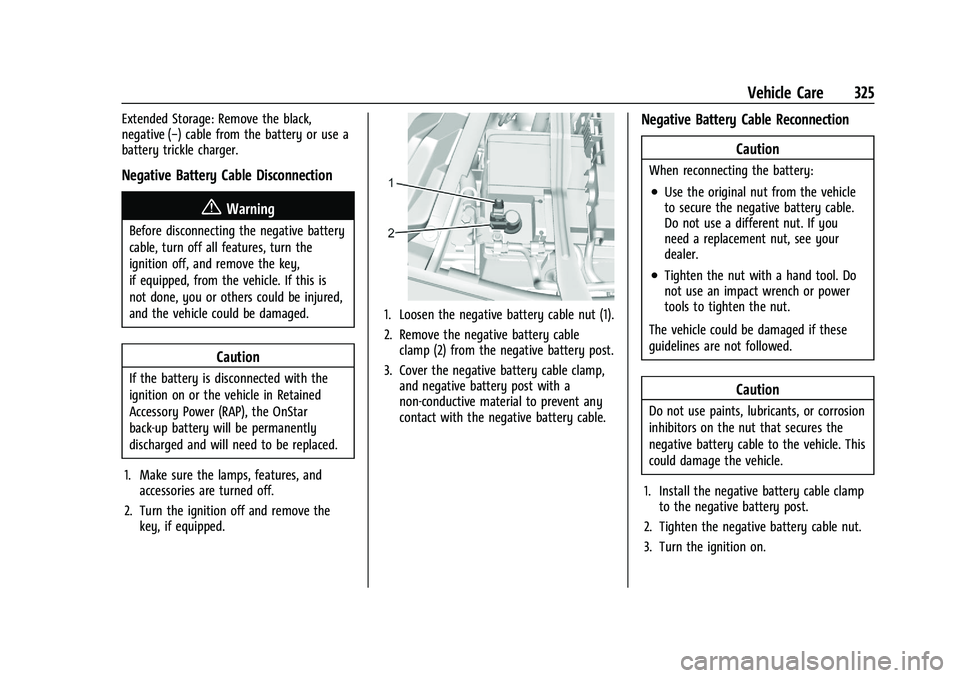

1. Loosen the negative battery cable nut (1).

2. Remove the negative battery cableclamp (2) from the negative battery post.

3. Cover the negative battery cable clamp, and negative battery post with a

non-conductive material to prevent any

contact with the negative battery cable.

Negative Battery Cable Reconnection

Caution

When reconnecting the battery:

.Use the original nut from the vehicle

to secure the negative battery cable.

Do not use a different nut. If you

need a replacement nut, see your

dealer.

.Tighten the nut with a hand tool. Do

not use an impact wrench or power

tools to tighten the nut.

The vehicle could be damaged if these

guidelines are not followed.

Caution

Do not use paints, lubricants, or corrosion

inhibitors on the nut that secures the

negative battery cable to the vehicle. This

could damage the vehicle.

1. Install the negative battery cable clamp to the negative battery post.

2. Tighten the negative battery cable nut.

3. Turn the ignition on.

Page 329 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

328 Vehicle Care

Automatic Transmission Shift Lock

Control Function Check

{Warning

When you are doing this inspection, the

vehicle could move suddenly. If the

vehicle moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room around the vehicle.

It should be parked on a level surface.

2. Apply the parking brake. Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the ignition on, but do not start the engine. Without

applying the regular brake, try to move

the shift lever out of P (Park) with

normal effort. If the shift lever moves

out of P (Park), contact your dealer for

service.

Ignition Transmission Lock Check

If equipped with Key Access ignition, while

parked, and with the parking brake set, try

to turn the ignition off in each shift lever

position. The ignition should turn to off only

when the shift lever is in P (Park).

The ignition key should come out only when

the ignition is off. Contact your dealer if

service is required.

Park Brake and P (Park)

Mechanism Check

{Warning

When you are doing this check, the

vehicle could begin to move. You or

others could be injured and property

could be damaged. Make sure there is

room in front of the vehicle in case it

begins to roll. Be ready to apply the

regular brake at once should the vehicle

begin to move.

Park on a fairly steep hill, with the vehicle

facing downhill. Keeping your foot on the

regular brake, set the parking brake.

.To check the parking brake's holding

ability: With the engine running and the

transmission in N (Neutral), slowly remove

foot pressure from the regular brake

pedal. Do this until the vehicle is held by

the parking brake only.

.To check the P (Park) mechanism's holding

ability: With the engine running, shift to

P (Park). Then release the parking brake

followed by the regular brake.

Contact your dealer if service is required.

Wiper Blade Replacement

Windshield wiper blades should be replaced

periodically. See Maintenance Schedule

0 392.

Replacement blades come in different types

and are removed in different ways. For

proper type and length, see Maintenance

Replacement Parts 0402.

Caution

Allowing the wiper arm to touch the

windshield when no wiper blade is

installed could damage the windshield.

Any damage that occurs would not be

(Continued)

Page 339 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

338 Vehicle Care

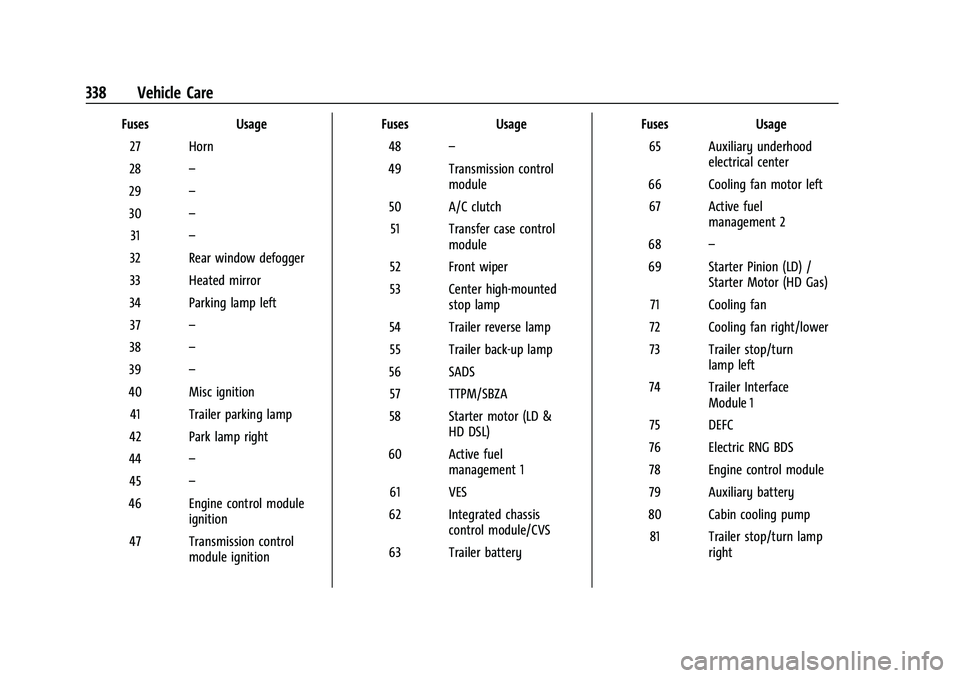

FusesUsage

27 Horn

28 –

29 –

30 –

31 –

32 Rear window defogger

33 Heated mirror

34 Parking lamp left 37 –

38 –

39 –

40 Misc ignition 41 Trailer parking lamp

42 Park lamp right

44 –

45 –

46 Engine control module ignition

47 Transmission control module ignition Fuses

Usage

48 –

49 Transmission control module

50 A/C clutch 51 Transfer case control module

52 Front wiper

53 Center high-mounted stop lamp

54 Trailer reverse lamp 55 Trailer back-up lamp

56 SADS 57 TTPM/SBZA

58 Starter motor (LD & HD DSL)

60 Active fuel management 1

61 VES

62 Integrated chassis control module/CVS

63 Trailer battery Fuses

Usage

65 Auxiliary underhood electrical center

66 Cooling fan motor left 67 Active fuel management 2

68 –

69 Starter Pinion (LD) / Starter Motor (HD Gas)

71 Cooling fan

72 Cooling fan right/lower

73 Trailer stop/turn lamp left

74 Trailer Interface Module 1

75 DEFC

76 Electric RNG BDS

78 Engine control module

79 Auxiliary battery

80 Cabin cooling pump 81 Trailer stop/turn lamp right

Page 343 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

342 Vehicle Care

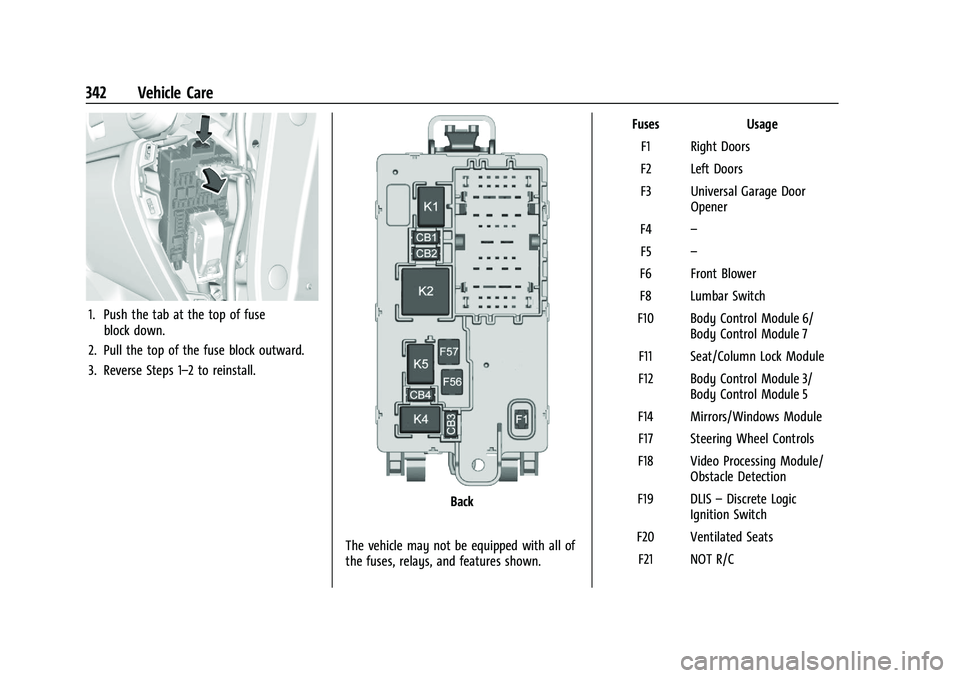

1. Push the tab at the top of fuseblock down.

2. Pull the top of the fuse block outward.

3. Reverse Steps 1–2 to reinstall.

Back

The vehicle may not be equipped with all of

the fuses, relays, and features shown. Fuses Usage

F1 Right Doors

F2 Left Doors

F3 Universal Garage Door Opener

F4 –

F5 –

F6 Front Blower

F8 Lumbar Switch

F10 Body Control Module 6/ Body Control Module 7

F11 Seat/Column Lock Module

F12 Body Control Module 3/ Body Control Module 5

F14 Mirrors/Windows Module F17 Steering Wheel Controls

F18 Video Processing Module/ Obstacle Detection

F19 DLIS –Discrete Logic

Ignition Switch

F20 Ventilated Seats F21 NOT R/C

Page 344 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Vehicle Care 343

FusesUsage

F22 Heated Steering Wheel

F23 MISC R/C

F24 Power Take Off/Reflective Light Auxiliary Display/

Instrument Panel Cluster/

Central Gateway Module/

Inside Rear View Mirror/

Overhead Console Module

Ignition

F25 Heating, Ventilation, and Air Conditioning Ignition/

Heating, Ventilation, and

Air Conditioning Auxiliary

F26 USB Ports/Special Equipment Option Retained

Accessory Power

F27 Accessory Power Outlet/ Retained Accessory Power

F28 Accessory Power Outlet/ Battery

F30 Sensing and Diagnostic Module/Parking Brake

F31 Body Control Module 4 Fuses

Usage

F32 Special Equipment Option/ Data Link Connection

F33 Body Control Module 8

F34 Cargo Lamp

F40 CGM –Central Gateway

Module

F41 Infotainment 1

F42 TCP –Telematics

Connectivity Platform

F43 –

F44 –

F45 Body Control Module 2

F46 Heating, Ventilation, and Air Conditioning/Battery 1

F47 Instrument Panel Cluster/ Battery

F48 Transmission Control Module

F49 Body Control Module 1 F50 –

F51 Battery 1

F52 Battery 2 Fuses

Usage

F53 –

F54 Sunroof F55 Driver Power Seat

F56 DC DC TRANS 1 F57 DC DC TRANS 2

F58 Infotainment 2

Circuit

Breakers Usage

1 Accessory Power Outlet 2

2 Accessory Power Outlet 1/ Cigarette Lighter

3 –

4 –

Relays Usage

K1 Run/Crank

K2 Retained Accessory Power/ Accessory 1

K4 –

K5 –

Page 352 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Vehicle Care 351

sequence will continue upon subsequent

vehicle start-ups as long as the malfunction

exists.

When the malfunction indicator is

illuminated, the system may not be able to

detect or signal low tire pressure as

intended. TPMS malfunctions may occur for

a variety of reasons, including the

installation of replacement or alternate tires

or wheels on the vehicle that prevent the

TPMS from functioning properly. Always

check the TPMS malfunction telltale after

replacing one or more tires or wheels on

your vehicle to ensure that the replacement

or alternate tires and wheels allow the

TPMS to continue to function properly.

SeeTire Pressure Monitor Operation 0351.

See Radio Frequency Statement 0417.

Tire Pressure Monitor Operation

This vehicle may have a Tire Pressure

Monitor System (TPMS). The TPMS is

designed to warn the driver when a low tire

pressure condition exists. TPMS sensors are

mounted onto each tire and wheel

assembly, excluding the spare tire and

wheel assembly. The TPMS sensors monitor the air pressure in the tires and transmit the

tire pressure readings to a receiver located

in the vehicle.

When a low tire pressure condition is

detected, the TPMS illuminates the low tire

pressure warning light located on the

instrument cluster. If the warning light

comes on, stop as soon as possible and

inflate the tires to the recommended

pressure shown on the Tire and Loading

Information label. See

Vehicle Load Limits

0 220.

A message to check the pressure in a

specific tire displays in the Driver

Information Center (DIC). The low tire

pressure warning light and the

DIC warning message come on at each

ignition cycle until the tires are inflated to

the correct inflation pressure. If the vehicle

has DIC buttons, tire pressure levels can be

viewed. For additional information and

details about the DIC operation and displays, see

Driver Information Center (DIC) (Base

Level) 0124 or

Driver Information Center (DIC) (Midlevel and

Uplevel) 0125.

The low tire pressure warning light may

come on in cool weather when the vehicle is

first started, and then turn off as the vehicle

is driven. This could be an early indicator

that the air pressure is getting low and

needs to be inflated to the proper pressure.

A Tire and Loading Information label shows

the size of the original equipment tires and

the correct inflation pressure for the tires

when they are cold. See Vehicle Load Limits

0 220, for an example of the Tire and

Loading Information label and its location.

Also see Tire Pressure 0349.

The TPMS can warn about a low tire

pressure condition but it does not replace

normal tire maintenance. See Tire Inspection

0 355, Tire Rotation 0356 and

Tires 0344.

Caution

Tire sealant materials are not all the

same. A non-approved tire sealant could

damage the TPMS sensors. TPMS sensor

(Continued)

Page 353 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

352 Vehicle Care

Caution (Continued)

damage caused by using an incorrect tire

sealant is not covered by the vehicle

warranty. Always use only the GM

approved tire sealant available through

your dealer or included in the vehicle.

TPMS Malfunction Light and Message

The TPMS will not function properly if one

or more of the TPMS sensors are missing or

inoperable. When the system detects a

malfunction, the low tire pressure warning

light flashes for about one minute and then

stays on for the remainder of the ignition

cycle. A DIC warning message also displays.

The malfunction light and DIC warning

message come on at each ignition cycle

until the problem is corrected. Some of the

conditions that can cause these to come

on are:

.One of the road tires has been replaced

with the spare tire. The spare tire does

not have a TPMS sensor. The malfunction

light and the DIC message should go off

after the road tire is replaced and the

sensor matching process is performed

successfully. See "TPMS Sensor Matching

Process" later in this section.

.The TPMS sensor matching process was

not done or not completed successfully

after rotating the tires. The malfunction

light and the DIC message should go off

after successfully completing the sensor

matching process. See "TPMS Sensor

Matching Process" later in this section.

.One or more TPMS sensors are missing or

damaged. The malfunction light and the

DIC message should go off when the

TPMS sensors are installed and the sensor

matching process is performed

successfully. See your dealer for service.

.Replacement tires or wheels do not match

the original equipment tires or wheels.

Tires and wheels other than those

recommended could prevent the TPMS

from functioning properly. SeeBuying

New Tires 0359.

.Operating electronic devices or being near

facilities using radio wave frequencies

similar to the TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning properly, it

cannot detect or signal a low tire pressure

condition. See your dealer for service if the

TPMS malfunction light and DIC message

come on and stay on.

Tire Fill Alert (If Equipped)

This feature provides visual and audible

alerts outside the vehicle to help when

inflating an underinflated tire to the

recommended cold tire pressure.

When the low tire pressure warning light

comes on: 1. Park the vehicle in a safe, level place.

2. Set the parking brake firmly.

3. Place the vehicle in P (Park).

4. Add air to the tire that is underinflated. The turn signal lamp will flash.

When the recommended pressure is

reached, the horn sounds once and the

turn signal lamp will stop flashing and

briefly turn solid.

Repeat these steps for all underinflated tires

that have illuminated the low tire pressure

warning light.

{Warning

Overinflating a tire could cause the tire

to rupture and you or others could be

injured. Do not exceed the maximum (Continued)

Page 354 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Vehicle Care 353

Warning (Continued)

pressure listed on the tire sidewall. See

Tire Sidewall Labeling0345 and

Vehicle Load Limits 0220.

If the tire is overinflated by more than

35 kPa (5 psi), the horn will sound multiple

times and the turn signal lamp will continue

to flash for several seconds after filling

stops. To release and correct the pressure,

while the turn signal lamp is still flashing,

briefly press the center of the valve stem.

When the recommended pressure is reached,

the horn sounds once.

If the turn signal lamp does not flash within

15 seconds after starting to inflate the tire,

the tire fill alert has not been activated or is

not working.

If the hazard warning flashers are on, the

tire fill alert visual feedback will not work

properly.

The TPMS will not activate the tire fill alert

properly under the following conditions:

.There is interference from an external

device or transmitter.

.The air pressure from the inflation device

is not sufficient to inflate the tire.

.There is a malfunction in the TPMS.

.There is a malfunction in the horn or turn

signal lamps.

.The identification code of the TPMS

sensor is not registered to the system.

.The battery of the TPMS sensor is low.

If the tire fill alert does not operate due to

TPMS interference, move the vehicle about

1 m (3 ft) back or forward and try again.

If the tire fill alert feature is not working,

use a tire pressure gauge.

TPMS Sensor Matching Process

Each TPMS sensor has a unique

identification code. The identification code

needs to be matched to a new tire/wheel

position after rotating the vehicle’s tires or

replacing one or more of the TPMS sensors.

Also, the TPMS sensor matching process

should be performed after replacing a spare

tire with a road tire containing the TPMS

sensor. The malfunction light and the DIC

message should go off at the next ignition

cycle. The sensors are matched to the tire/

wheel positions, using a TPMS relearn tool,

in the following order: driver side front tire,

passenger side front tire, passenger side rear

tire, and driver side rear. See your dealer for

service or to purchase a relearn tool. A TPMS relearn tool can also be purchased.

See Tire Pressure Monitor Sensor Activation

Tool at www.gmtoolsandequipment.com or

call 1-800-GM TOOLS (1-800-468-6657).

There are two minutes to match the first

tire/wheel position, and five minutes overall

to match all four tire/wheel positions. If it

takes longer, the matching process stops

and must be restarted.

The TPMS sensor matching process is:

1. Set the parking brake.

2. Turn the ignition on without starting the vehicle.

3. Uplevel DIC Only: Make sure the Tire Pressure info page option is turned on.

The info pages on the DIC can be turned

on and off through the Options menu.

See Driver Information Center (DIC) (Base

Level) 0124 or

Driver Information Center (DIC) (Midlevel

and Uplevel) 0125.

4. If the vehicle has an uplevel DIC, use the DIC controls on the right side of the

steering wheel to scroll to the Tire

Pressure screen under the DIC info page.

If the vehicle has a base level DIC, use

the trip odometer reset stem to scroll to

the Tire Pressure screen.

Page 366 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Vehicle Care 365

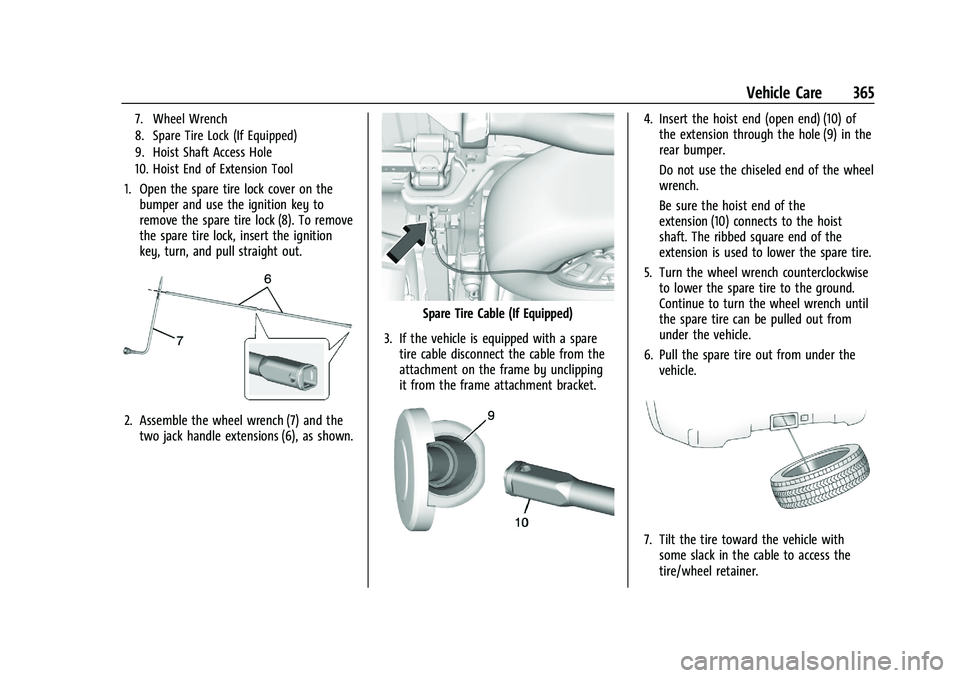

7. Wheel Wrench

8. Spare Tire Lock (If Equipped)

9. Hoist Shaft Access Hole

10. Hoist End of Extension Tool

1. Open the spare tire lock cover on thebumper and use the ignition key to

remove the spare tire lock (8). To remove

the spare tire lock, insert the ignition

key, turn, and pull straight out.

2. Assemble the wheel wrench (7) and thetwo jack handle extensions (6), as shown.

Spare Tire Cable (If Equipped)

3. If the vehicle is equipped with a spare tire cable disconnect the cable from the

attachment on the frame by unclipping

it from the frame attachment bracket.

4. Insert the hoist end (open end) (10) ofthe extension through the hole (9) in the

rear bumper.

Do not use the chiseled end of the wheel

wrench.

Be sure the hoist end of the

extension (10) connects to the hoist

shaft. The ribbed square end of the

extension is used to lower the spare tire.

5. Turn the wheel wrench counterclockwise to lower the spare tire to the ground.

Continue to turn the wheel wrench until

the spare tire can be pulled out from

under the vehicle.

6. Pull the spare tire out from under the vehicle.

7. Tilt the tire toward the vehicle withsome slack in the cable to access the

tire/wheel retainer.