clock CHEVROLET SUBURBAN 2010 10.G Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: SUBURBAN, Model: CHEVROLET SUBURBAN 2010 10.GPages: 608, PDF Size: 6.53 MB

Page 485 of 608

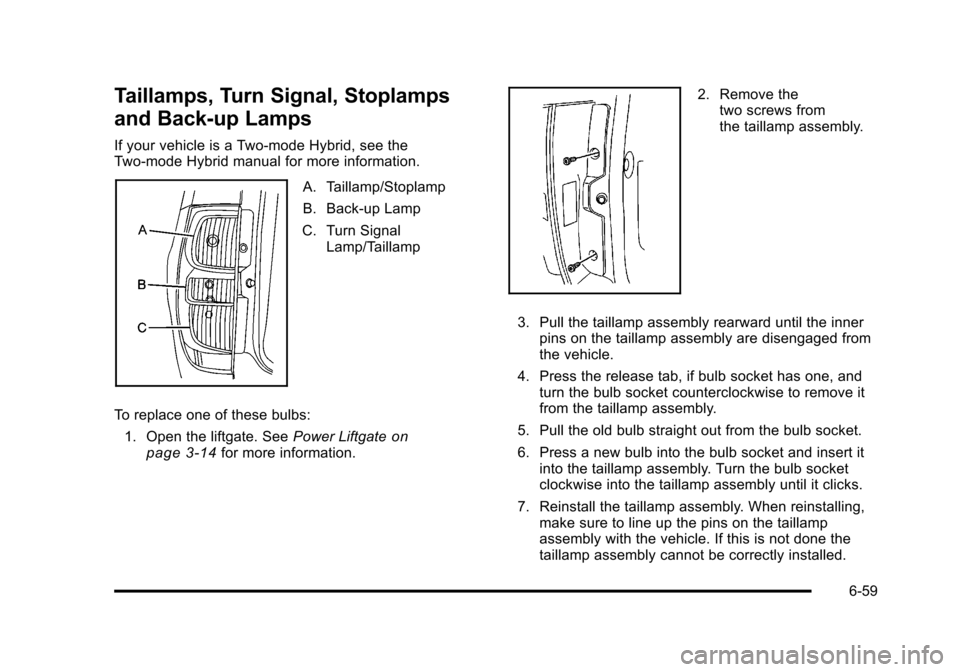

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps

If your vehicle is a Two-mode Hybrid, see the

Two-mode Hybrid manual for more information.

A. Taillamp/Stoplamp

B. Back-up Lamp

C. Turn Signal Lamp/Taillamp

To replace one of these bulbs: 1. Open the liftgate. See Power Liftgate

on

page 3‑14for more information.

2. Remove the two screws from

the taillamp assembly.

3. Pull the taillamp assembly rearward until the inner pins on the taillamp assembly are disengaged from

the vehicle.

4. Press the release tab, if bulb socket has one, and turn the bulb socket counterclockwise to remove it

from the taillamp assembly.

5. Pull the old bulb straight out from the bulb socket.

6. Press a new bulb into the bulb socket and insert it into the taillamp assembly. Turn the bulb socket

clockwise into the taillamp assembly until it clicks.

7. Reinstall the taillamp assembly. When reinstalling, make sure to line up the pins on the taillamp

assembly with the vehicle. If this is not done the

taillamp assembly cannot be correctly installed.

6-59

Page 486 of 608

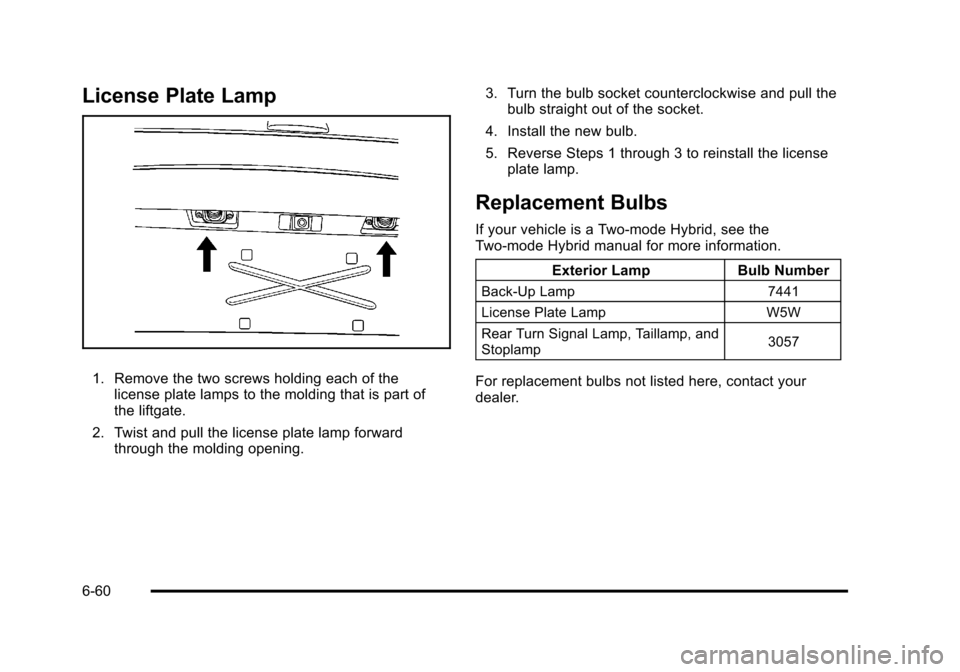

License Plate Lamp

1. Remove the two screws holding each of thelicense plate lamps to the molding that is part of

the liftgate.

2. Twist and pull the license plate lamp forward through the molding opening. 3. Turn the bulb socket counterclockwise and pull the

bulb straight out of the socket.

4. Install the new bulb.

5. Reverse Steps 1 through 3 to reinstall the license plate lamp.

Replacement Bulbs

If your vehicle is a Two-mode Hybrid, see the

Two-mode Hybrid manual for more information.

Exterior Lamp Bulb Number

Back-Up Lamp 7441

License Plate Lamp W5W

Rear Turn Signal Lamp, Taillamp, and

Stoplamp 3057

For replacement bulbs not listed here, contact your

dealer.

6-60

Page 516 of 608

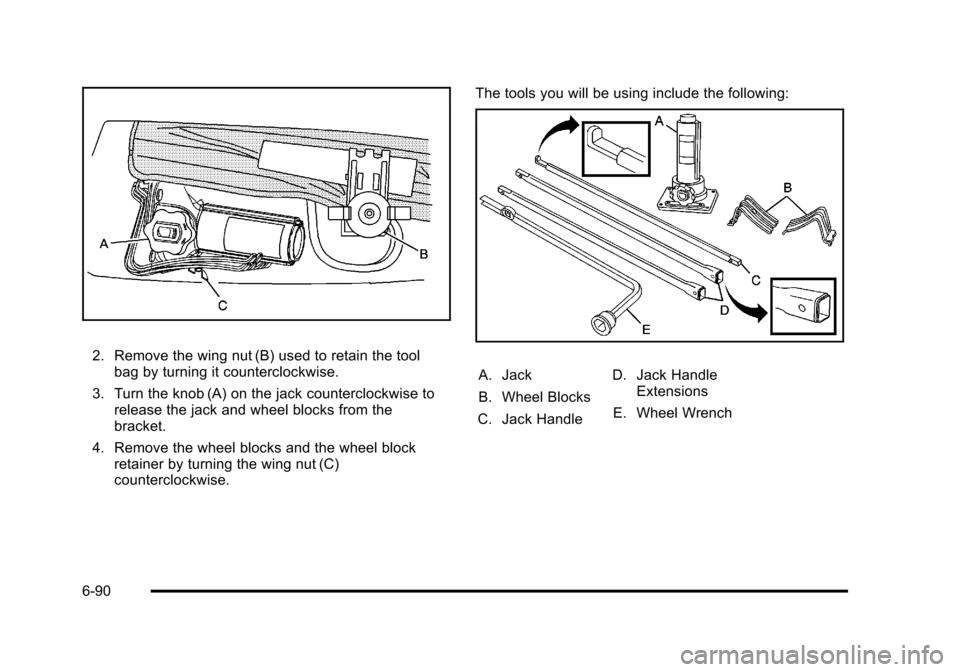

2. Remove the wing nut (B) used to retain the toolbag by turning it counterclockwise.

3. Turn the knob (A) on the jack counterclockwise to release the jack and wheel blocks from the

bracket.

4. Remove the wheel blocks and the wheel block retainer by turning the wing nut (C)

counterclockwise. The tools you will be using include the following:

A. Jack

B. Wheel Blocks

C. Jack Handle D. Jack Handle

Extensions

E. Wheel Wrench

6-90

Page 517 of 608

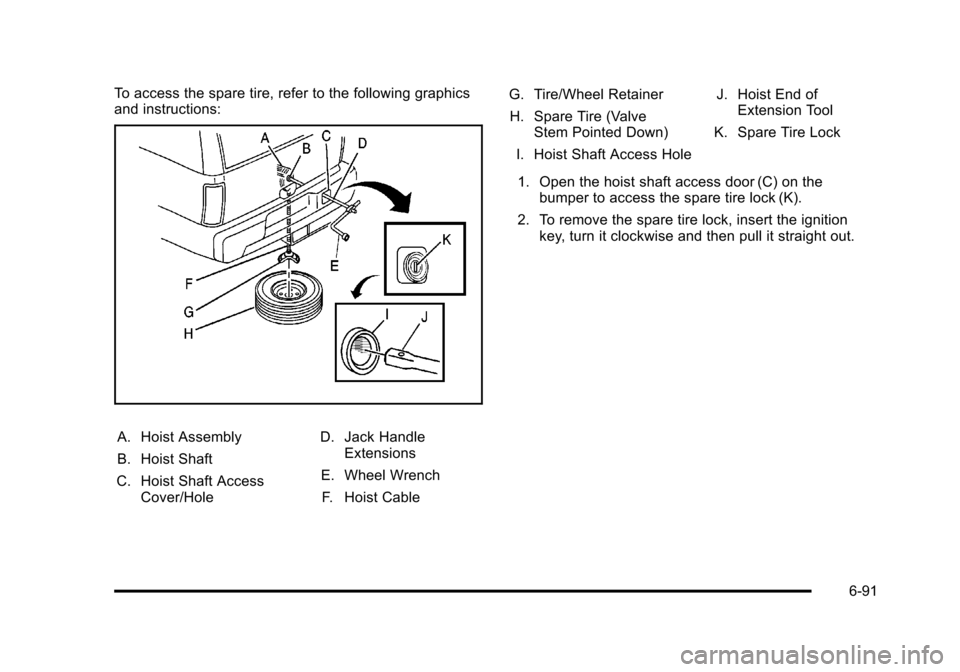

To access the spare tire, refer to the following graphics

and instructions:

A. Hoist Assembly

B. Hoist Shaft

C. Hoist Shaft Access Cover/Hole D. Jack Handle

Extensions

E. Wheel Wrench F. Hoist Cable G. Tire/Wheel Retainer

H. Spare Tire (Valve Stem Pointed Down)

I. Hoist Shaft Access Hole J. Hoist End of

Extension Tool

K. Spare Tire Lock

1. Open the hoist shaft access door (C) on the bumper to access the spare tire lock (K).

2. To remove the spare tire lock, insert the ignition key, turn it clockwise and then pull it straight out.

6-91

Page 518 of 608

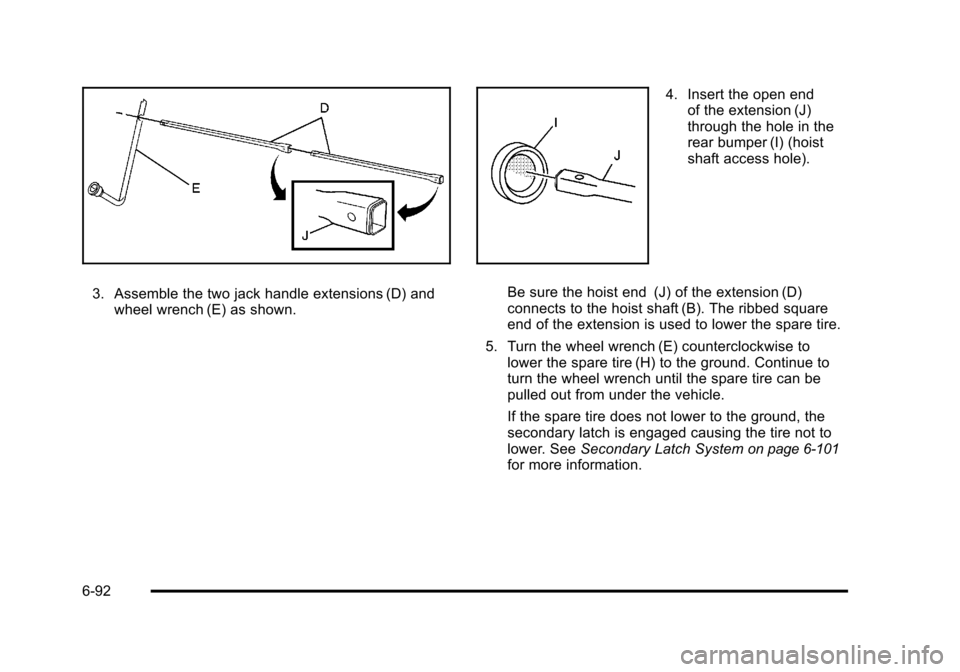

3. Assemble the two jack handle extensions (D) andwheel wrench (E) as shown.

4. Insert the open endof the extension (J)

through the hole in the

rear bumper (I) (hoist

shaft access hole).

Be sure the hoist end (J) of the extension (D)

connects to the hoist shaft (B). The ribbed square

end of the extension is used to lower the spare tire.

5. Turn the wheel wrench (E) counterclockwise to lower the spare tire (H) to the ground. Continue to

turn the wheel wrench until the spare tire can be

pulled out from under the vehicle.

If the spare tire does not lower to the ground, the

secondary latch is engaged causing the tire not to

lower. See Secondary Latch System

on page 6‑101for more information.

6-92

Page 521 of 608

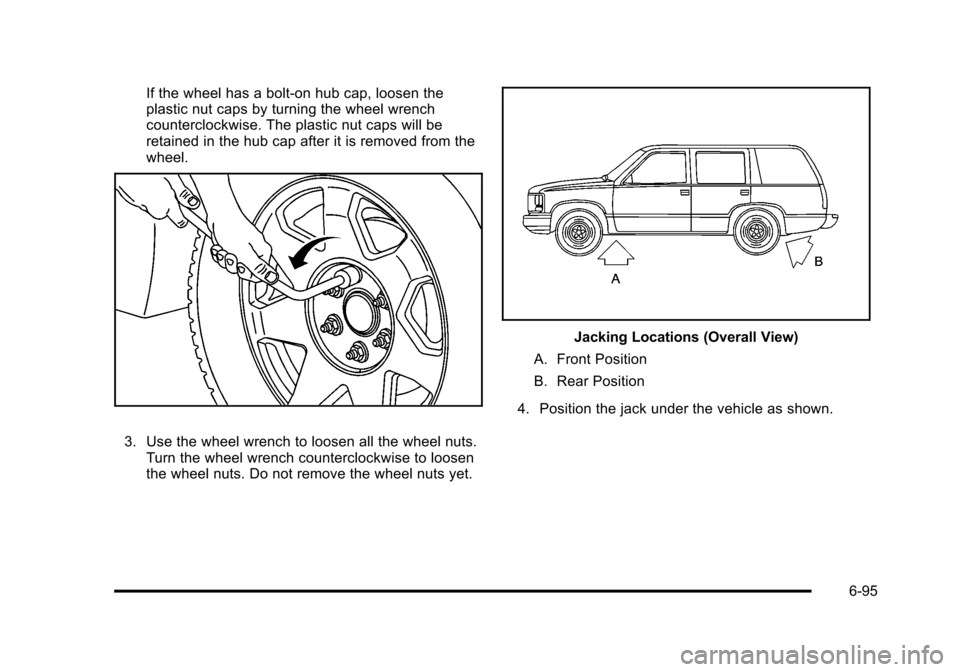

If the wheel has a bolt-on hub cap, loosen the

plastic nut caps by turning the wheel wrench

counterclockwise. The plastic nut caps will be

retained in the hub cap after it is removed from the

wheel.

3. Use the wheel wrench to loosen all the wheel nuts.Turn the wheel wrench counterclockwise to loosen

the wheel nuts. Do not remove the wheel nuts yet.

Jacking Locations (Overall View)

A. Front Position

B. Rear Position

4. Position the jack under the vehicle as shown.

6-95

Page 522 of 608

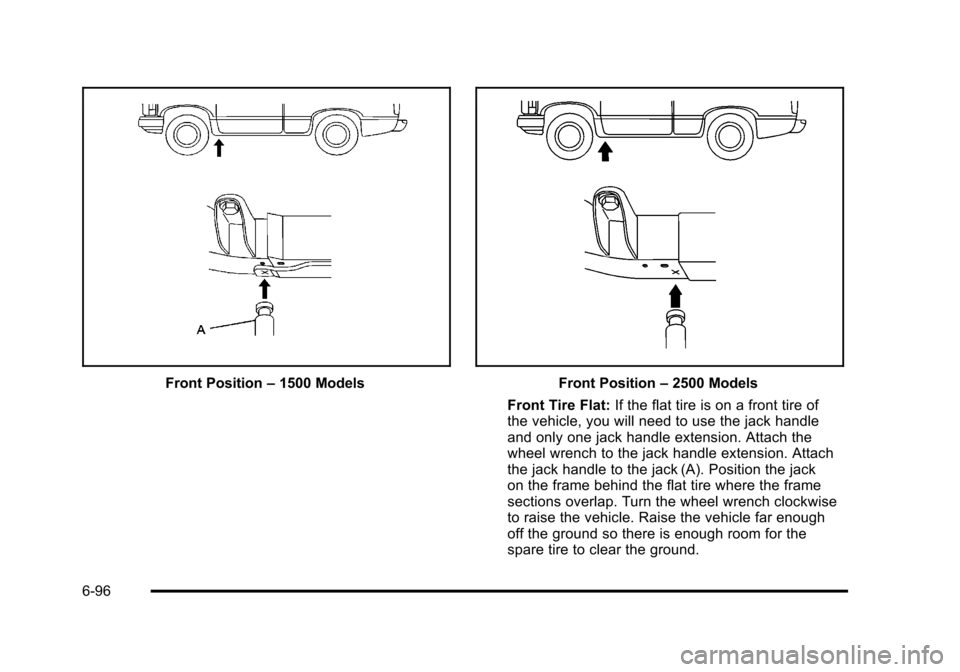

Front Position–1500 ModelsFront Position –2500 Models

Front Tire Flat: If the flat tire is on a front tire of

the vehicle, you will need to use the jack handle

and only one jack handle extension. Attach the

wheel wrench to the jack handle extension. Attach

the jack handle to the jack (A). Position the jack

on the frame behind the flat tire where the frame

sections overlap. Turn the wheel wrench clockwise

to raise the vehicle. Raise the vehicle far enough

off the ground so there is enough room for the

spare tire to clear the ground.

6-96

Page 523 of 608

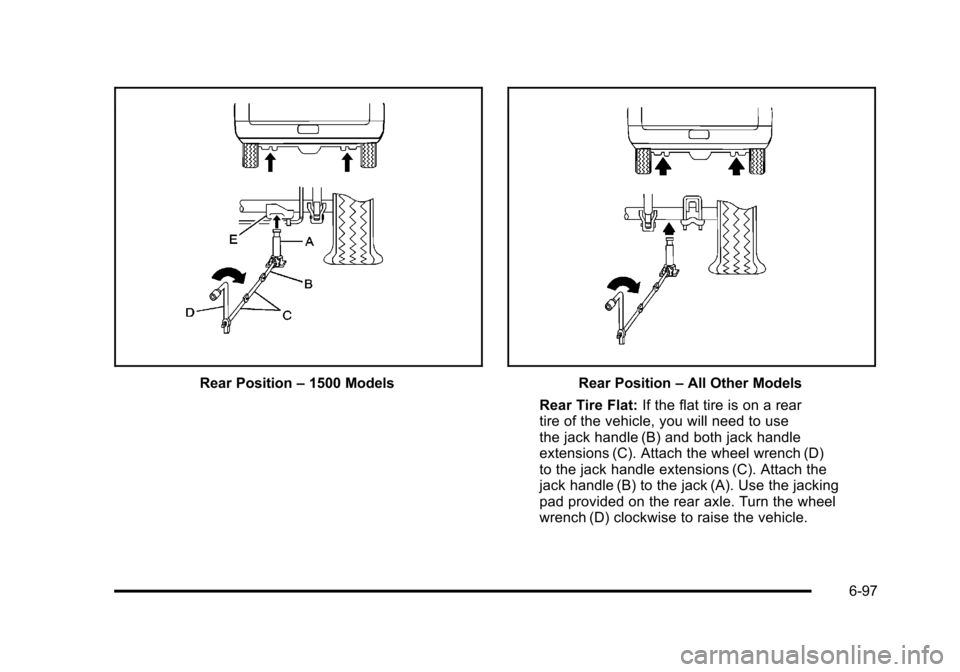

Rear Position–1500 ModelsRear Position –All Other Models

Rear Tire Flat: If the flat tire is on a rear

tire of the vehicle, you will need to use

the jack handle (B) and both jack handle

extensions (C). Attach the wheel wrench (D)

to the jack handle extensions (C). Attach the

jack handle (B) to the jack (A). Use the jacking

pad provided on the rear axle. Turn the wheel

wrench (D) clockwise to raise the vehicle.

6-97

Page 526 of 608

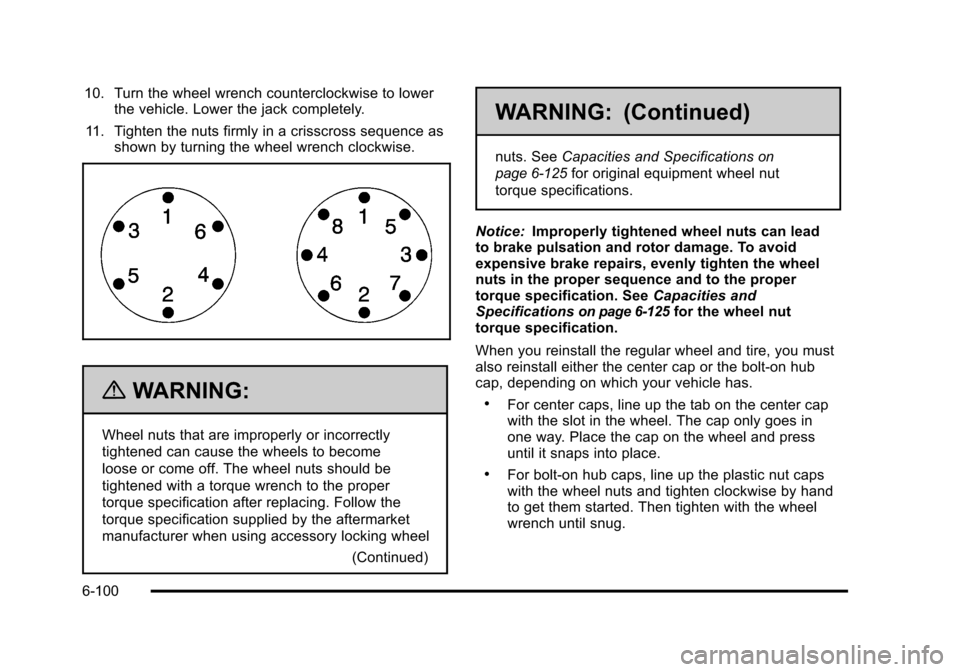

10. Turn the wheel wrench counterclockwise to lowerthe vehicle. Lower the jack completely.

11. Tighten the nuts firmly in a crisscross sequence as shown by turning the wheel wrench clockwise.

{WARNING:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become

loose or come off. The wheel nuts should be

tightened with a torque wrench to the proper

torque specification after replacing. Follow the

torque specification supplied by the aftermarket

manufacturer when using accessory locking wheel

(Continued)

WARNING: (Continued)

nuts. SeeCapacities and Specificationson

page 6‑125

for original equipment wheel nut

torque specifications.

Notice: Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification. See Capacities and

Specifications

on page 6‑125for the wheel nut

torque specification.

When you reinstall the regular wheel and tire, you must

also reinstall either the center cap or the bolt-on hub

cap, depending on which your vehicle has.

.For center caps, line up the tab on the center cap

with the slot in the wheel. The cap only goes in

one way. Place the cap on the wheel and press

until it snaps into place.

.For bolt-on hub caps, line up the plastic nut caps

with the wheel nuts and tighten clockwise by hand

to get them started. Then tighten with the wheel

wrench until snug.

6-100

Page 527 of 608

Secondary Latch System

Your vehicle has an underbody-mounted tire hoist

assembly equipped with a secondary latch system.

It is designed to stop the spare tire from suddenly falling

off your vehicle. For the secondary latch to work, the

spare must be installed with the valve stem pointing

down. SeeStoring a Flat or Spare Tire and Tools

on

page 6‑104.

{WARNING:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

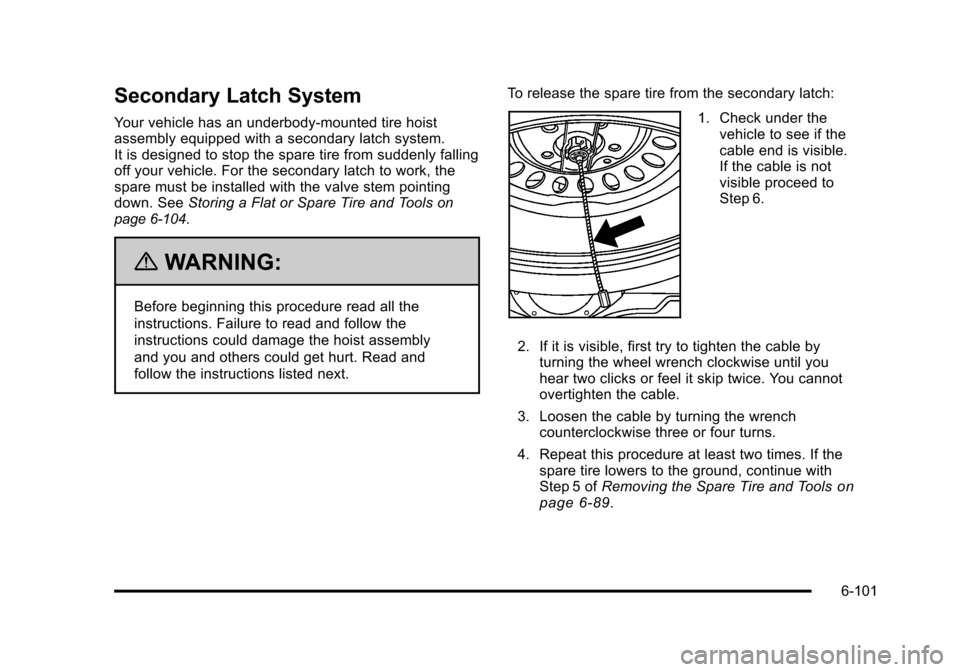

follow the instructions listed next. To release the spare tire from the secondary latch:

1. Check under the

vehicle to see if the

cable end is visible.

If the cable is not

visible proceed to

Step 6.

2. If it is visible, first try to tighten the cable by turning the wheel wrench clockwise until you

hear two clicks or feel it skip twice. You cannot

overtighten the cable.

3. Loosen the cable by turning the wrench counterclockwise three or four turns.

4. Repeat this procedure at least two times. If the spare tire lowers to the ground, continue with

Step 5 of Removing the Spare Tire and Tools

on

page 6‑89.

6-101