radiator cap CHEVROLET TAHOE 2009 3.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2009, Model line: TAHOE, Model: CHEVROLET TAHOE 2009 3.GPages: 574, PDF Size: 3.06 MB

Page 433 of 574

If no coolant is visible in the surge tank, add coolant as

follows:

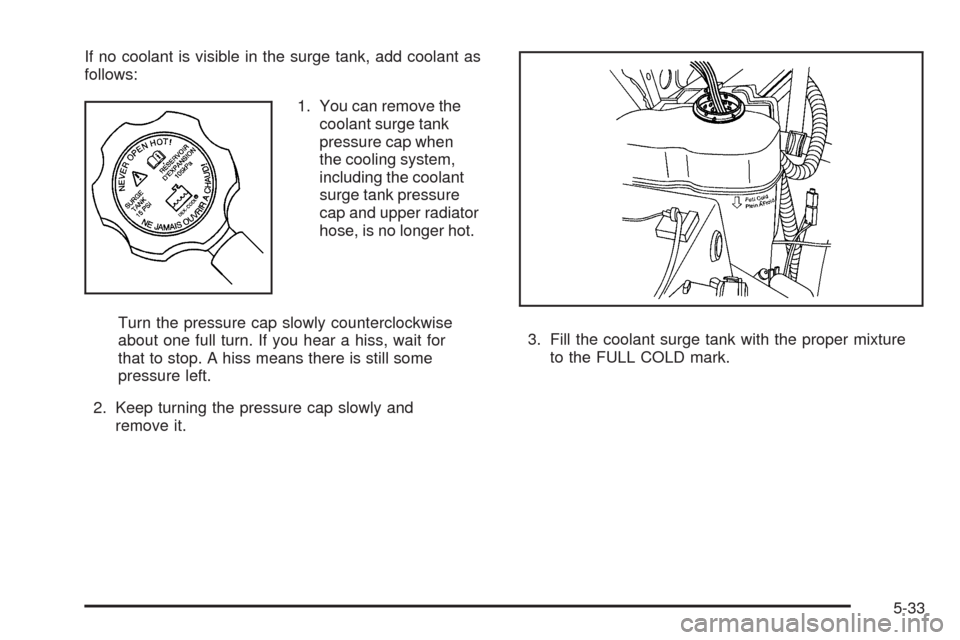

1. You can remove the

coolant surge tank

pressure cap when

the cooling system,

including the coolant

surge tank pressure

cap and upper radiator

hose, is no longer hot.

Turn the pressure cap slowly counterclockwise

about one full turn. If you hear a hiss, wait for

that to stop. A hiss means there is still some

pressure left.

2. Keep turning the pressure cap slowly and

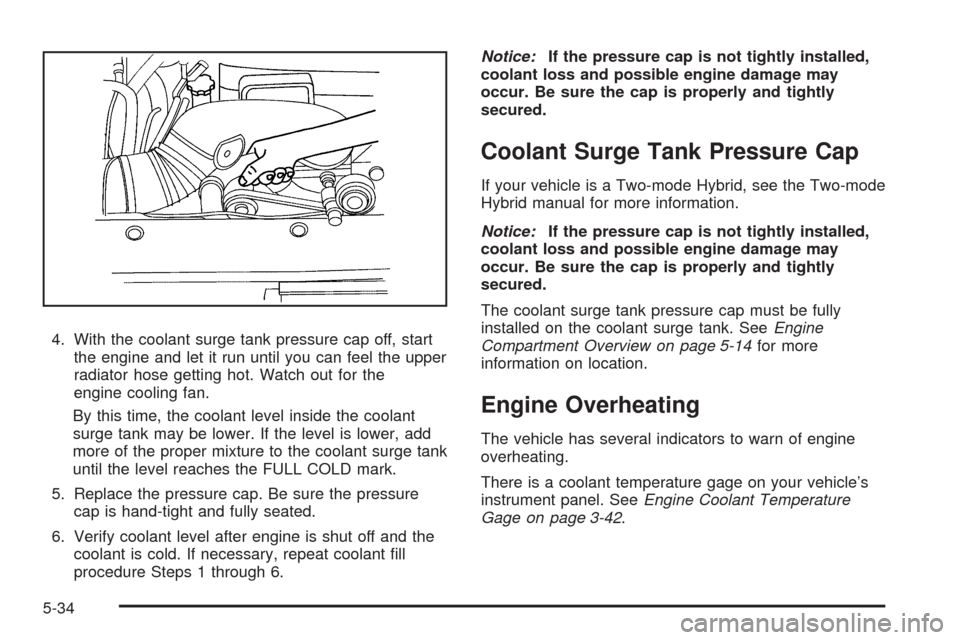

remove it.3. Fill the coolant surge tank with the proper mixture

to the FULL COLD mark.

5-33

Page 434 of 574

4. With the coolant surge tank pressure cap off, start

the engine and let it run until you can feel the upper

radiator hose getting hot. Watch out for the

engine cooling fan.

By this time, the coolant level inside the coolant

surge tank may be lower. If the level is lower, add

more of the proper mixture to the coolant surge tank

until the level reaches the FULL COLD mark.

5. Replace the pressure cap. Be sure the pressure

cap is hand-tight and fully seated.

6. Verify coolant level after engine is shut off and the

coolant is cold. If necessary, repeat coolant �ll

procedure Steps 1 through 6.Notice:If the pressure cap is not tightly installed,

coolant loss and possible engine damage may

occur. Be sure the cap is properly and tightly

secured.

Coolant Surge Tank Pressure Cap

If your vehicle is a Two-mode Hybrid, see the Two-mode

Hybrid manual for more information.

Notice:If the pressure cap is not tightly installed,

coolant loss and possible engine damage may

occur. Be sure the cap is properly and tightly

secured.

The coolant surge tank pressure cap must be fully

installed on the coolant surge tank. SeeEngine

Compartment Overview on page 5-14for more

information on location.

Engine Overheating

The vehicle has several indicators to warn of engine

overheating.

There is a coolant temperature gage on your vehicle’s

instrument panel. SeeEngine Coolant Temperature

Gage on page 3-42.

5-34

Page 530 of 574

Maintenance Footnotes

†The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

#Lubricate the front suspension, steering linkage, and

parking brake cable guides. Control arm ball joints on

2500 series vehicles require lubrication but should not be

lubricated unless their temperature is 10°F (−12°C) or

higher, or they could be damaged. Control arm ball joints

on 1500 series vehicles are maintenance-free.

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, chafing, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect other brake parts, including calipers,

parking brake, etc.(b)Visually inspect front and rear suspension and

steering system for damaged, loose, or missing parts,

signs of wear, or lack of lubrication. Inspect power

steering lines and hoses for proper hook-up, binding,

leaks, cracks, chafing, etc. Visually check constant

velocity joints, rubber boots, and axle seals for leaks.

(c)Visually inspect hoses and have them replaced if

they are cracked, swollen, or deteriorated. Inspect all

pipes, fittings, and clamps; replace with genuine parts as

needed. To help ensure proper operation, a pressure test

of the cooling system and pressure cap and cleaning the

outside of the radiator and air conditioning condenser is

recommended at least once a year.

(d)Inspect wiper blades for wear, cracking, or

contamination. Clean the windshield and wiper blades, if

contaminated. Replace wiper blades that are worn or

damaged. See Windshield Wiper Blade Replacement on

page 5-60 and Windshield, Backglass, and Wiper

Blades on page 5-110 for more information.

(e)Make sure the safety belt reminder light and safety

belt assemblies are working properly. Look for any other

loose or damaged safety belt system parts. If you see

anything that might keep a safety belt system from doing

its job, have it repaired. Have any torn or frayed safety

belts replaced. Also see Checking the Restraint Systems

on page 1-98.

6-8

Page 531 of 574

(f)Lubricate all key lock cylinders, hood latch assembly,

secondary latch, pivots, spring anchor, release pawl,

rear compartment hinges, outer liftgate handle pivot

points, rear door detent link, roller mechanism, liftgate

handle pivot points, latch bolt, fuel door hinge, cargo door

hinge, locks, and folding seat hardware. More frequent

lubrication may be required when exposed to a corrosive

environment. Applying silicone grease on weatherstrips

with a clean cloth will make them last longer, seal better,

and not stick or squeak.

(g)Check vent hose at transfer case for kinks and proper

installation. Check to be sure vent hose is unobstructed,

clear, and free of debris. During any maintenance, if a

power washer is used to clean mud and dirt from the

underbody, care should be taken to not directly spray the

transfer case output seals. High pressure water can

overcome the seals and contaminate the transfer case

fluid. Contaminated fluid will decrease the life of the

transfer case and should be replaced.

(h)Change automatic transmission fluid and filter if the

vehicle is mainly driven under one or more of these

conditions:

�In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

�In hilly or mountainous terrain.

�When doing frequent trailer towing.

�Uses such as found in taxi, police, or delivery

service.(i)Drain, flush, and refill cooling system. This service can

be complex; you should have your dealer/retailer perform

this service. See Engine Coolant on page 5-29 for what to

use. Inspect hoses. Clean radiator, condenser, pressure

cap, and filler neck. Pressure test the cooling system and

pressure cap.

(j)A fluid loss in any vehicle system could indicate a

problem. Have the system inspected and repaired and

the fluid level checked. Add fluid if needed.

(k)Inspect system. Check all fuel and vapor lines and

hoses for proper hook-up, routing, and condition. Check

that the purge valve works properly, if equipped.

Replace as needed.

(l)If driving regularly under dusty conditions, inspect the

filter at each engine oil change.

(m)Visually inspect belt for fraying, excessive cracks, or

obvious damage. Replace belt if necessary.

(n)Severe Service: Change transfer case fluid if the

vehicle is mainly used for trailer towing or driven in city

traffic, wet environment, or high ambient temperatures.

6-9