ignition CHEVROLET TRAVERSE 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: TRAVERSE, Model: CHEVROLET TRAVERSE 2010 1.GPages: 448, PDF Size: 6.96 MB

Page 285 of 448

Driving and Operating 9-33

Using Cruise Control on Hills

How well the cruise control will work

on hills depends upon the vehicle

speed, load, and the steepness of

the hills. When going up steep hills,

you might have to step on the

accelerator pedal to maintain the

vehicle speed. When going

downhill, you might have to brake or

shift to a lower gear to keep the

vehicle speed down. When the

brakes are applied the cruise control

is disengaged.

Ending Cruise Control

There are three ways to end cruise

control:

.Step lightly on the brake pedal.

.Press the[button.

.Press theTbutton.

Erasing Speed Memory

The cruise control set speed

memory is erased when the cruise

control or the ignition is turned off.

Object Detection

Systems

Ultrasonic Parking Assist

For vehicles with the Ultrasonic

Rear Parking Assist (URPA) system,

it operates at speeds less than

8 km/h (5 mph), and assists the

driver with parking and avoiding

objects while in R (Reverse). The

sensors on the rear bumper are

used to detect the distance to an

object up to 2.5 m (8 ft) behind the

vehicle, and at least 25.4 cm (10 in)

off the ground.

{WARNING

The Ultrasonic Rear Parking

Assist (URPA) system does not

replace driver vision. It cannot

detect:

.Objects that are below the

bumper, underneath the

vehicle, or if they are too

close or far from the vehicle

.Children, pedestrians,

bicyclists, or pets.

If you do not use proper care

before and while backing; vehicle

damage, injury, or death could

occur. Even with URPA, always

check behind the vehicle before

backing up. While backing, be

sure to look for objects and check

the vehicle's mirrors.

Page 309 of 448

Vehicle Care 10-1

Vehicle Care

General Information

General Information . . . . . . . . . . 10-2

California Proposition65 Warning . . . . . . . . . . . . . . . . . 10-3

California Perchlorate Materials Requirements . . . . 10-3

Accessories and Modifications . . . . . . . . . . . . . . . 10-3

Vehicle Checks

Doing Your OwnService Work . . . . . . . . . . . . . . . 10-4

Hood . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Engine Compartment Overview . . . . . . . . . . . . . . . . . . . 10-6

Engine Cover . . . . . . . . . . . . . . . . 10-7

Engine Oil . . . . . . . . . . . . . . . . . . . 10-8

Engine Oil Life System . . . . . 10-10

Automatic Transmission Fluid . . . . . . . . . . . . . . . . . . . . . . 10-11

Engine Air Cleaner/Filter . . . . 10-12

Cooling System . . . . . . . . . . . . 10-14

Engine Coolant . . . . . . . . . . . . . 10-14

Engine Overheating . . . . . . . . 10-18 Overheated Engine

Protection

Operating Mode . . . . . . . . . . . 10-20

Power Steering Fluid . . . . . . . 10-20

Washer Fluid . . . . . . . . . . . . . . . 10-21

Brakes . . . . . . . . . . . . . . . . . . . . . 10-22

Brake Fluid . . . . . . . . . . . . . . . . . 10-23

Battery . . . . . . . . . . . . . . . . . . . . . 10-24

Starter Switch Check . . . . . . . 10-25

Automatic Transmission Shift Lock Control System

Check . . . . . . . . . . . . . . . . . . . . . 10-25

Ignition Transmission Lock Check . . . . . . . . . . . . . . . . . . . . . 10-25

Park Brake and P (Park) Mechanism Check . . . . . . . . 10-26

Wiper Blade Replacement . . . . . . . . . . . . . . 10-26

Headlamp Aiming

Headlamp Aiming . . . . . . . . . . 10-27

Bulb Replacement

Bulb Replacement . . . . . . . . . . 10-27

Halogen Bulbs . . . . . . . . . . . . . . 10-27

Taillamps, Turn Signal,Sidemarker, and

Stoplamps . . . . . . . . . . . . . . . . 10-28

Replacement Bulbs . . . . . . . . . 10-29

Electrical System

High Voltage Devices and

Wiring . . . . . . . . . . . . . . . . . . . . . 10-29

Electrical System Overload . . . . . . . . . . . . . . . . . . 10-29

Fuses and Circuit

Breakers . . . . . . . . . . . . . . . . . . 10-30

Engine Compartment Fuse Block . . . . . . . . . . . . . . . . . . . . . 10-30

Instrument Panel Fuse Block . . . . . . . . . . . . . . . . . . . . . 10-33

Wheels and Tires

Tires . . . . . . . . . . . . . . . . . . . . . . . . 10-36

Tire Sidewall Labeling . . . . . . 10-36

Tire Designations . . . . . . . . . . . 10-38

Tire Terminology andDefinitions . . . . . . . . . . . . . . . . 10-39

Tire Pressure . . . . . . . . . . . . . . . 10-42

Tire Pressure Monitor System . . . . . . . . . . . . . . . . . . . 10-43

Tire Pressure Monitor Operation . . . . . . . . . . . . . . . . . 10-44

Tire Inspection . . . . . . . . . . . . . . 10-48

Tire Rotation . . . . . . . . . . . . . . . 10-48

When It Is Time for New Tires . . . . . . . . . . . . . . . . . . . . . . 10-49

Buying New Tires . . . . . . . . . . . 10-50

Page 318 of 448

10-10 Vehicle Care

Engine Oil Life System

When to Change Engine Oil

This vehicle has a computer system

that indicates when to change the

engine oil and filter. This is based

on engine revolutions and engine

temperature, and not on mileage.

Based on driving conditions, the

mileage at which an oil change is

indicated can vary considerably. For

the oil life system to work properly,

the system must be reset every time

the oil is changed.

When the system has calculated

that oil life has been diminished, it

indicates that an oil change is

necessary. A CHANGE ENGINE

OIL SOON message comes on.

Change the oil as soon as possible

within the next 600 miles (1 000 km).

It is possible that, if driving under

the best conditions, the oil life

system might not indicate that an oil

change is necessary for over a year.

However, the engine oil and filter

must be changed at least once a

year and at this time the systemmust be reset. Your dealer has

trained service people who will

perform this work using genuine

parts and reset the system. It is also

important to check the oil regularly

and keep it at the proper level.

If the system is ever reset

accidentally, the oil must be

changed at 3,000 miles (5 000 km)

since the last oil change.

Remember to reset the oil life

system whenever the oil is changed.

How to Reset the Engine Oil

Life System

The Engine Oil Life System

calculates when to change the

engine oil and filter based on

vehicle use. Whenever the oil is

changed, reset the system so it can

calculate when the next oil change

is required. If a situation occurs

where the oil is changed prior to a

CHANGE ENGINE OIL SOON

message being turned on, reset the

system.

If the vehicle does not have Driver

Information Center (DIC) buttons:

1. Turn the ignition to ON/RUN,

with the engine off. The vehicle

must be in P (Park) to access

this display. Press the trip

odometer reset stem until OIL

LIFE REMAINING displays.

2. Press and hold the trip odometer reset stem until OIL LIFE

REMAINING shows “100%.”

Three chimes sound and the

CHANGE ENGINE OIL SOON

message goes off.

3. Turn the key to LOCK/OFF. If the CHANGE ENGINE OIL

SOON message comes back on

when the vehicle is started, the

engine oil life system has not

reset. Repeat the procedure.

Page 319 of 448

Vehicle Care 10-11

If the vehicle has Driver Information

Center (DIC) buttons:

1. Turn the ignition to ON/RUN,with the engine off.

2. Press the vehicle information button until OIL LIFE

REMAINING displays.

3. Press and hold the set/reset button until “100%”is displayed.

Three chimes sound and the

CHANGE ENGINE OIL SOON

message goes off.

4. Turn the key to LOCK/OFF.

If the CHANGE ENGINE OIL SOON

message comes back on when the

vehicle is started, the engine oil life

system has not reset. Repeat the

procedure.What to Do with Used Oil

Used engine oil contains certain

elements that can be unhealthy for

your skin and could even cause

cancer. Do not let used oil stay on

your skin for very long. Clean your

skin and nails with soap and water,

or a good hand cleaner. Wash or

properly dispose of clothing or rags

containing used engine oil. See the

manufacturer's warnings about the

use and disposal of oil products.

Used oil can be a threat to the

environment. If you change your

own oil, be sure to drain all the oil

from the filter before disposal. Never

dispose of oil by putting it in the

trash, pouring it on the ground, into

sewers, or into streams or bodies of

water. Recycle it by taking it to a

place that collects used oil.

Automatic Transmission

Fluid

It is not necessary to check the

transmission fluid level.

A transmission fluid leak is the only

reason for fluid loss. If a leak

occurs, take the vehicle to the

dealer and have it repaired as soon

as possible.

Change the fluid at the intervals

listed in Scheduled Maintenance

on

page 11‑2, and be sure to use the

transmission fluid listed in

Recommended Fluids and

Lubricants on page 11‑7.

Notice: Use of the incorrect

automatic transmission fluid may

damage the vehicle, and the

damages may not be covered by

the vehicle's warranty. Always

use the automatic transmission

fluid listed in Recommended

Fluids and Lubricants

on

page 11‑7.

Page 333 of 448

Vehicle Care 10-25

Starter Switch Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular brake.

See Parking Brake

on

page 9‑28.

Do not use the accelerator

pedal, and be ready to turn off

the engine immediately if it

starts.

3. Try to start the engine in each gear. The vehicle should start

only in P (Park) or N (Neutral).

If the vehicle starts in any other

position, contact your dealer for

service.

Automatic Transmission

Shift Lock Control

System Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle. It should be

parked on a level surface.

2. Firmly apply the parking brake. See Parking Brake

on

page 9‑28.

Be ready to apply the regular

brake immediately if the vehicle

begins to move. 3. With the engine off, turn the

ignition to ON/RUN, but do not

start the engine. Without

applying the regular brake, try to

move the shift lever out of

P (Park) with normal effort. If the

shift lever moves out of P (Park),

contact your dealer for service.

Ignition Transmission

Lock Check

While parked, and with the parking

brake set, try to turn the ignition to

LOCK/OFF in each shift lever

position.

.The ignition should turn to

LOCK/OFF only when the shift

lever is in P (Park).

.The ignition key should come

out only in LOCK/OFF.

Contact your dealer if service is

required.

Page 340 of 448

10-32 Vehicle Care

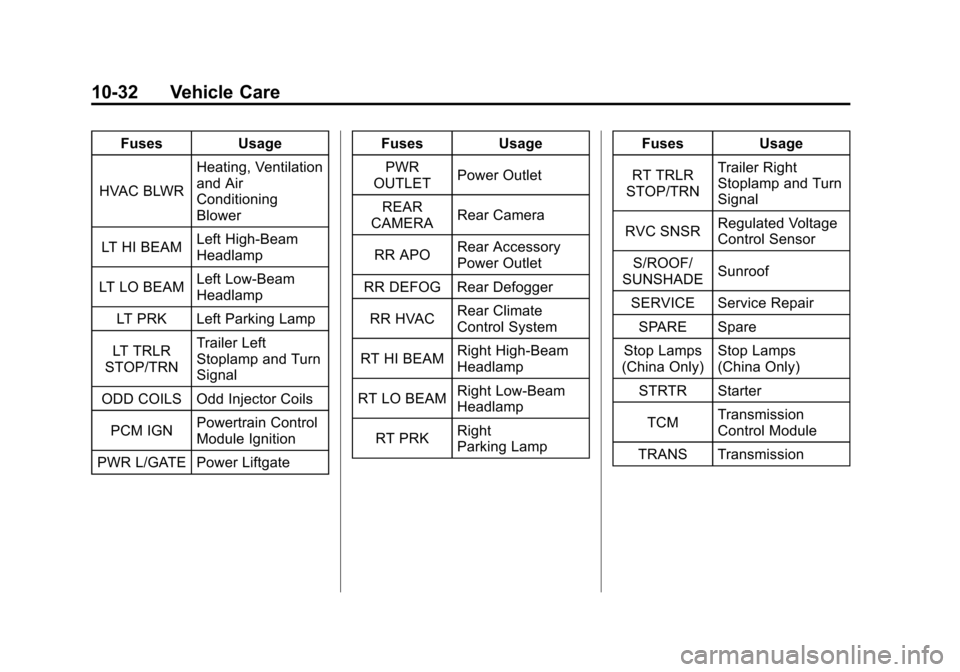

FusesUsage

HVAC BLWR Heating, Ventilation

and Air

Conditioning

Blower

LT HI BEAM Left High-Beam

Headlamp

LT LO BEAM Left Low‐Beam

Headlamp

LT PRK Left Parking Lamp

LT TRLR

STOP/TRN Trailer Left

Stoplamp and Turn

Signal

ODD COILS Odd Injector Coils

PCM IGN Powertrain Control

Module Ignition

PWR L/GATE Power Liftgate Fuses

Usage

PWR

OUTLET Power Outlet

REAR

CAMERA Rear Camera

RR APO Rear Accessory

Power Outlet

RR DEFOG Rear Defogger

RR HVAC Rear Climate

Control System

RT HI BEAM Right High‐Beam

Headlamp

RT LO BEAM Right Low‐Beam

Headlamp

RT PRK Right

Parking Lamp Fuses

Usage

RT TRLR

STOP/TRN Trailer Right

Stoplamp and Turn

Signal

RVC SNSR Regulated Voltage

Control Sensor

S/ROOF/

SUNSHADE Sunroof

SERVICE Service Repair SPARE Spare

Stop Lamps

(China Only) Stop Lamps

(China Only)

STRTR Starter

TCM Transmission

Control Module

TRANS Transmission

Page 341 of 448

Vehicle Care 10-33

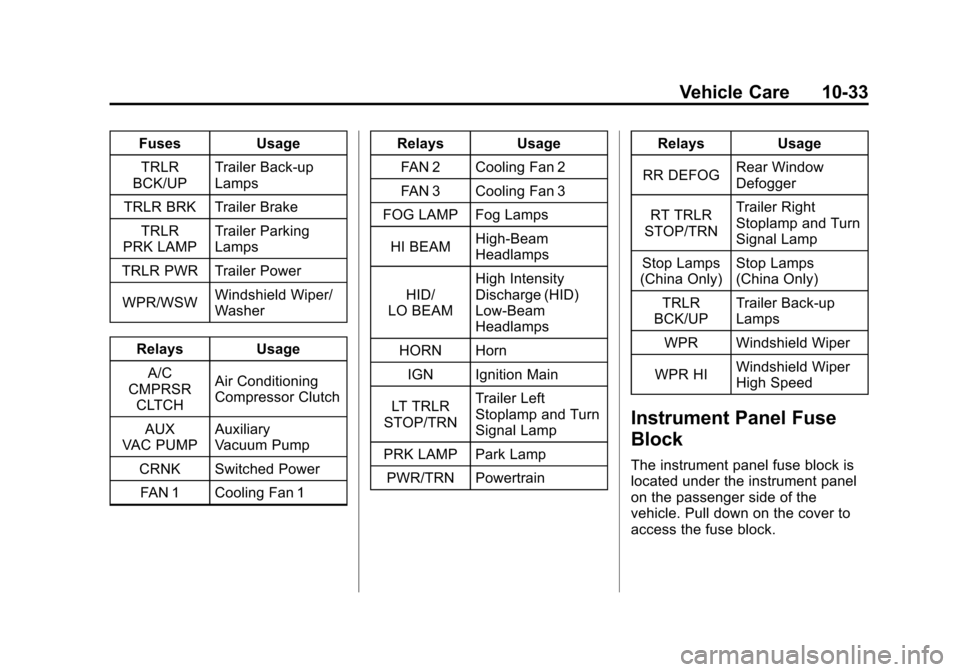

FusesUsage

TRLR

BCK/UP Trailer Back‐up

Lamps

TRLR BRK Trailer Brake TRLR

PRK LAMP Trailer Parking

Lamps

TRLR PWR Trailer Power

WPR/WSW Windshield Wiper/

Washer

Relays Usage

A/C

CMPRSR CLTCH Air Conditioning

Compressor Clutch

AUX

VAC PUMP Auxiliary

Vacuum Pump

CRNK Switched Power FAN 1 Cooling Fan 1 Relays

Usage

FAN 2 Cooling Fan 2

FAN 3 Cooling Fan 3

FOG LAMP Fog Lamps

HI BEAM High‐Beam

Headlamps

HID/

LO BEAM High Intensity

Discharge (HID)

Low‐Beam

Headlamps

HORN Horn IGN Ignition Main

LT TRLR

STOP/TRN Trailer Left

Stoplamp and Turn

Signal Lamp

PRK LAMP Park Lamp PWR/TRN Powertrain Relays

Usage

RR DEFOG Rear Window

Defogger

RT TRLR

STOP/TRN Trailer Right

Stoplamp and Turn

Signal Lamp

Stop Lamps

(China Only) Stop Lamps

(China Only)

TRLR

BCK/UP Trailer Back-up

Lamps

WPR Windshield Wiper

WPR HI Windshield Wiper

High Speed

Instrument Panel Fuse

Block

The instrument panel fuse block is

located under the instrument panel

on the passenger side of the

vehicle. Pull down on the cover to

access the fuse block.

Page 353 of 448

Vehicle Care 10-45

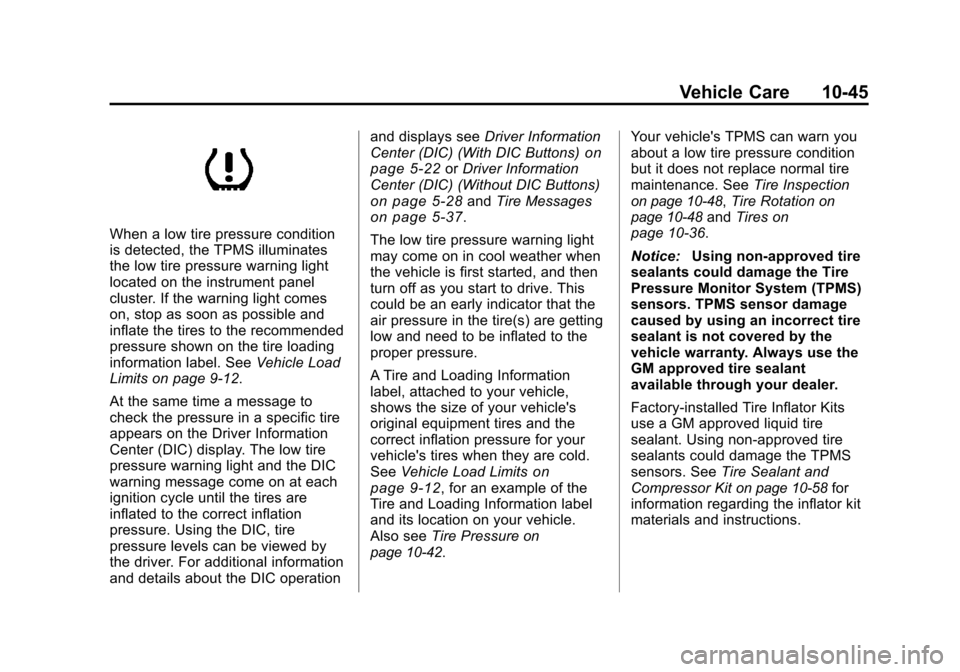

When a low tire pressure condition

is detected, the TPMS illuminates

the low tire pressure warning light

located on the instrument panel

cluster. If the warning light comes

on, stop as soon as possible and

inflate the tires to the recommended

pressure shown on the tire loading

information label. SeeVehicle Load

Limits on page 9‑12.

At the same time a message to

check the pressure in a specific tire

appears on the Driver Information

Center (DIC) display. The low tire

pressure warning light and the DIC

warning message come on at each

ignition cycle until the tires are

inflated to the correct inflation

pressure. Using the DIC, tire

pressure levels can be viewed by

the driver. For additional information

and details about the DIC operation and displays see

Driver Information

Center (DIC) (With DIC Buttons)

on

page 5‑22or Driver Information

Center (DIC) (Without DIC Buttons)

on page 5‑28and Tire Messageson page 5‑37.

The low tire pressure warning light

may come on in cool weather when

the vehicle is first started, and then

turn off as you start to drive. This

could be an early indicator that the

air pressure in the tire(s) are getting

low and need to be inflated to the

proper pressure.

A Tire and Loading Information

label, attached to your vehicle,

shows the size of your vehicle's

original equipment tires and the

correct inflation pressure for your

vehicle's tires when they are cold.

See Vehicle Load Limits

on

page 9‑12, for an example of the

Tire and Loading Information label

and its location on your vehicle.

Also see Tire Pressure

on

page 10‑42. Your vehicle's TPMS can warn you

about a low tire pressure condition

but it does not replace normal tire

maintenance. See

Tire Inspection

on page 10‑48,Tire Rotationon

page 10‑48and Tires on

page 10‑36.

Notice: Using non‐approved tire

sealants could damage the Tire

Pressure Monitor System (TPMS)

sensors. TPMS sensor damage

caused by using an incorrect tire

sealant is not covered by the

vehicle warranty. Always use the

GM approved tire sealant

available through your dealer.

Factory-installed Tire Inflator Kits

use a GM approved liquid tire

sealant. Using non-approved tire

sealants could damage the TPMS

sensors. See Tire Sealant and

Compressor Kit

on page 10‑58for

information regarding the inflator kit

materials and instructions.

Page 354 of 448

10-46 Vehicle Care

TPMS Malfunction Light and

Message

The TPMS will not function properly

if one or more of the TPMS sensors

are missing or inoperable. When the

system detects a malfunction, the

low tire warning light flashes for

about one minute and then stays on

for the remainder of the ignition

cycle. A DIC warning message is

also displayed. The low tire warning

light and DIC warning message

come on at each ignition cycle until

the problem is corrected. Some of

the conditions that can cause the

malfunction light and DIC message

to come on are:

.One of the road tires has been

replaced with the spare tire,

if your vehicle has one. The

spare tire does not have a

TPMS sensor. The TPMS

malfunction light and DIC

message should go off once you

re‐install the road tire containing

the TPMS sensor.

.The TPMS sensor matching

process was started but not

completed or not completed

successfully after rotating the

vehicle's tires. The DIC message

and TPMS malfunction light

should go off once the TPMS

sensor matching process is

performed successfully. See

“TPMS Sensor Matching

Process”later in this section.

.One or more TPMS sensors are

missing or damaged. The DIC

message and the TPMS

malfunction light should go off

when the TPMS sensors are

installed and the sensor

matching process is performed

successfully. See your dealer for

service.

.Replacement tires or wheels do

not match your vehicle's original

equipment tires or wheels. Tires

and wheels other than those

recommended for your vehicle

could prevent the TPMS from

functioning properly. See Buying

New Tires on page 10‑50.

.Operating electronic devices or

being near facilities using radio

wave frequencies similar to the

TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning it

cannot detect or signal a low tire

condition. See your dealer for

service if the TPMS malfunction

light and DIC message comes on

and stays on.

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. Any time you

rotate your vehicle's tires or replace

one or more of the TPMS sensors,

the identification codes will need to

be matched to the new tire/wheel

position. The sensors are matched

to the tire/wheel positions in the

following order: driver side front tire,

passenger side front tire, passenger

side rear tire, and driver side rear

tire using a TPMS diagnostic tool.

See your dealer for service.

Page 355 of 448

Vehicle Care 10-47

The TPMS sensors can also be

matched to each tire/wheel position

by increasing or decreasing the

tire's air pressure. If increasing the

tire's air pressure, do not exceed

the maximum inflation pressure

indicated on the tire's sidewall.

To decrease air-pressure out of a

tire you can use the pointed end of

the valve cap, a pencil-style air

pressure gauge, or a key.

You have two minutes to match the

first tire/wheel position, and

five minutes overall to match all four

tire/wheel positions. If it takes longer

than two minutes, to match the first

tire and wheel, or more than

five minutes to match all four tire

and wheel positions the matching

process stops and you need to

start over.

The TPMS sensor matching process

is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the engine off. 3. Press the Remote Keyless Entry

(RKE) transmitter's LOCK and

UNLOCK buttons at the same

time for approximately

five seconds. The horn sounds

twice to signal the receiver is in

relearn mode and TIRE

LEARNING ACTIVE message

displays on the DIC screen.

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem. Activate the

TPMS sensor by increasing or

decreasing the tire's air pressure

for five seconds, or until a horn

chirp sounds. The horn chirp,

which may take up to

30 seconds to sound, confirms

that the sensor identification

code has been matched to this

tire and wheel position.

6. Proceed to the passenger side front tire, and repeat the

procedure in Step 5. 7. Proceed to the passenger side

rear tire, and repeat the

procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the procedure in

Step 5. The horn sounds two

times to indicate the sensor

identification code has been

matched to the driver side rear

tire, and the TPMS sensor

matching process is no longer

active. The TIRE LEARNING

ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Tire

and Loading Information label.

11. Put the valve caps back on the valve stems.