service CHEVROLET TRAVERSE 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: TRAVERSE, Model: CHEVROLET TRAVERSE 2010 1.GPages: 448, PDF Size: 6.96 MB

Page 324 of 448

10-16 Vehicle Care

the cooling system is cool before

this is done. SeeCooling Systemon

page 10‑14for more information.

The coolant recovery tank cap has

this symbol on it.

When the engine is cold, the coolant

level should be at or above the

FULL COLD line marked on the

recovery tank.

When the engine is hot, the level

could be higher than the FULL

COLD line. If the coolant is below

the FULL COLD line when the

engine is hot, there could be a leak

in the cooling system.

If the coolant is low, add the coolant

or take the vehicle to a dealer for

service.

How to Add Coolant to the

Recovery Tank

{WARNING

You can be burned if you spill

coolant on hot engine parts.

Coolant contains ethylene glycol

and it will burn if the engine parts

are hot enough. Do not spill

coolant on a hot engine.

Notice: This vehicle has a

specific coolant fill procedure.

Failure to follow this procedure

could cause the engine to

overheat and be severely

damaged.

If coolant is needed, add the proper

DEX-COOL

®coolant mixture at the

coolant recovery tank.

How to Add Coolant to the

Radiator

{WARNING

An electric engine cooling fan

under the hood can start up even

when the engine is not running

and can cause injury. Keep

hands, clothing, and tools away

from any underhood electric fan.

{WARNING

Steam and scalding liquids from a

hot cooling system can blow out

and burn you badly. They are

under pressure, and if you turn

the surge tank pressure

cap —even a little —they can

come out at high speed. Never

turn the cap when the cooling

system, including the surge tank

pressure cap, is hot. Wait for the

(Continued)

Page 326 of 448

10-18 Vehicle Care

8. Start the engine and let it rununtil the upper radiator hose

feels warm. Any time during this

procedure, watch out for the

engine cooling fan(s).

9. If the coolant level inside the radiator filler neck is low, add

more of the proper DEX-COOL

coolant mixture through the filler

neck until the level is back up to

the base of the filler neck.

Replace the pressure cap. Be

sure to secure it tightly. Notice:

If the pressure cap is not

tightly installed, coolant loss and

possible engine damage may

occur. Be sure the cap is properly

and tightly secured.

Engine Overheating

The vehicle has several indicators

to warn of engine overheating.

There is an engine coolant

temperature gauge on the

instrument panel cluster. See

Engine Coolant Temperature Gauge

on page 5‑12.

The vehicle may also display an

ENGINE OVERHEATED IDLE

ENGINE and ENGINE

OVERHEATED STOP ENGINE

message in the Driver Information

Center (DIC). See Warning Lights,

Gauges, and Indicators

on

page 5‑10.

You may decide not to lift the hood

when this warning appears, but

instead get service help right away.

See Roadside Assistance Program

on page 13‑6. If you do decide to lift the hood,

make sure the vehicle is parked on

a level surface.

Then check to see if the engine

cooling fans are running. If the

engine is overheating, both fans

should be running. If they are not,

do not continue to run the engine

and have the vehicle serviced.

Notice:

Engine damage from

running the engine without

coolant is not covered by the

warranty.

Notice: If the engine catches fire

while driving with no coolant, the

vehicle can be badly damaged.

The costly repairs would not be

covered by the vehicle warranty.

See Overheated Engine

Protection Operating Mode

on

page 10‑20for information on

driving to a safe place in an

emergency.

Page 330 of 448

10-22 Vehicle Care

Brakes

This vehicle has disc brakes. Disc

brake pads have built-in wear

indicators that make a high-pitched

warning sound when the brake pads

are worn and new pads are needed.

The sound can come and go or be

heard all the time the vehicle is

moving, except when applying the

brake pedal firmly.

{WARNING

The brake wear warning sound

means that soon the brakes will

not work well. That could lead to

an accident. When the brake

wear warning sound is heard,

have the vehicle serviced.

Notice: Continuing to drive with

worn-out brake pads could result

in costly brake repair. Some driving conditions or climates

can cause a brake squeal when the

brakes are first applied or lightly

applied. This does not mean

something is wrong with the brakes.

Properly torqued wheel nuts are

necessary to help prevent brake

pulsation. When tires are rotated,

inspect brake pads for wear and

evenly tighten wheel nuts in the

proper sequence to torque

specifications in

Capacities and

Specifications on page 12‑2.

Brake linings should always be

replaced as complete axle sets.

Brake Pedal Travel

See your dealer if the brake pedal

does not return to normal height,

or if there is a rapid increase in

pedal travel. This could be a sign

that brake service might be

required.

Brake Adjustment

Every time the brakes are applied,

with or without the vehicle moving,

the brakes adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is

complex. Its many parts have to be

of top quality and work well together

if the vehicle is to have really good

braking. The vehicle was designed

and tested with top-quality brake

parts. When parts of the braking

system are replaced, be sure to get

new, approved replacement parts.

If this is not done, the brakes might

not work properly. For example,

installing disc brake pads that are

wrong for the vehicle, can change

the balance between the front and

rear brakes —for the worse. The

braking performance expected can

change in many other ways if the

wrong replacement brake parts are

installed.

Page 333 of 448

Vehicle Care 10-25

Starter Switch Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular brake.

See Parking Brake

on

page 9‑28.

Do not use the accelerator

pedal, and be ready to turn off

the engine immediately if it

starts.

3. Try to start the engine in each gear. The vehicle should start

only in P (Park) or N (Neutral).

If the vehicle starts in any other

position, contact your dealer for

service.

Automatic Transmission

Shift Lock Control

System Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle. It should be

parked on a level surface.

2. Firmly apply the parking brake. See Parking Brake

on

page 9‑28.

Be ready to apply the regular

brake immediately if the vehicle

begins to move. 3. With the engine off, turn the

ignition to ON/RUN, but do not

start the engine. Without

applying the regular brake, try to

move the shift lever out of

P (Park) with normal effort. If the

shift lever moves out of P (Park),

contact your dealer for service.

Ignition Transmission

Lock Check

While parked, and with the parking

brake set, try to turn the ignition to

LOCK/OFF in each shift lever

position.

.The ignition should turn to

LOCK/OFF only when the shift

lever is in P (Park).

.The ignition key should come

out only in LOCK/OFF.

Contact your dealer if service is

required.

Page 334 of 448

10-26 Vehicle Care

Park Brake and P (Park)

Mechanism Check

{WARNING

When you are doing this check,

the vehicle could begin to move.

You or others could be injured

and property could be damaged.

Make sure there is room in front

of the vehicle in case it begins to

roll. Be ready to apply the regular

brake at once should the vehicle

begin to move.

Park on a fairly steep hill, with the

vehicle facing downhill. Keeping

your foot on the regular brake, set

the parking brake.

.To check the parking brake's

holding ability: With the engine

running and the transmission in

N (Neutral), slowly remove foot

pressure from the regular brake

pedal. Do this until the vehicle is

held by the parking brake only.

.To check the P (Park)

mechanism's holding ability:

With the engine running, shift to

P (Park). Then release the

parking brake followed by the

regular brake.

Contact your dealer if service is

required.

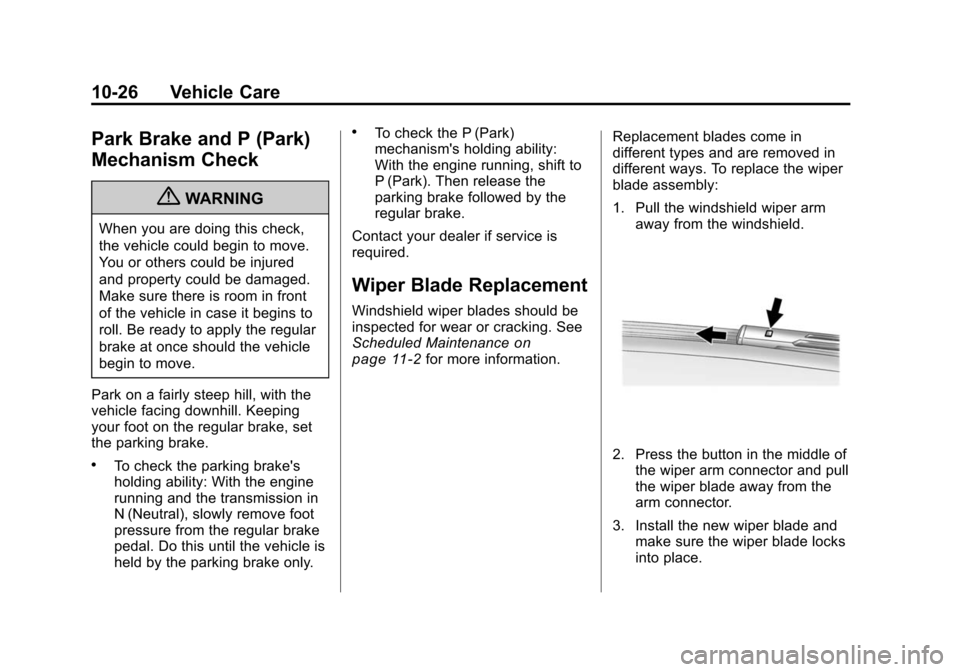

Wiper Blade Replacement

Windshield wiper blades should be

inspected for wear or cracking. See

Scheduled Maintenance

on

page 11‑2for more information. Replacement blades come in

different types and are removed in

different ways. To replace the wiper

blade assembly:

1. Pull the windshield wiper arm

away from the windshield.

2. Press the button in the middle ofthe wiper arm connector and pull

the wiper blade away from the

arm connector.

3. Install the new wiper blade and make sure the wiper blade locks

into place.

Page 335 of 448

Vehicle Care 10-27

For the proper size and type see

Maintenance Replacement Partson

page 11‑9.

Backglass Wiper Blade

To replace the backglass wiper

blade:

1. Pull the wiper blade assembly away from the backglass.

The backglass wiper blade will

not lock in a vertical position so

care should be used when

pulling it away from the vehicle.

2. Rotate the wiper blade assembly, hold the wiper arm in

position, and push the blade

away from the wiper arm.

3. Replace the wiper blade.

4. Return the wiper arm and blade assembly to the rest position on

the glass.

Headlamp Aiming

Headlamp aim has been preset at

the factory and should need no

further adjustment.

However, if your vehicle is damaged

in a crash, the headlamp aim may

be affected. Aim adjustment to the

low-beam headlamps may be

necessary if oncoming drivers flash

their high-beam headlamps at you

(for vertical aim).

If the headlamps need to be

re-aimed, it is recommended that

you take the vehicle to your dealer

for service.

Bulb Replacement

For the proper type of replacement

bulbs, see Replacement Bulbson

page 10‑29.

For any bulb changing procedure

not listed in this section, contact

your dealer.

Halogen Bulbs

{WARNING

Halogen bulbs have pressurized

gas inside and can burst if you

drop or scratch the bulb. You or

others could be injured. Be sure

to read and follow the instructions

on the bulb package.

Page 337 of 448

Vehicle Care 10-29

9. Push the taillamp assembly backinto its original location.

When reinstalling the taillamp

assembly, make sure the pin on

the taillamp assembly lines up

and is inserted correctly into the

opening of the vehicle.

10. Reinstall the two nuts that hold the taillamp assembly in place.

11. Reinstall the two taillamp nut covers.

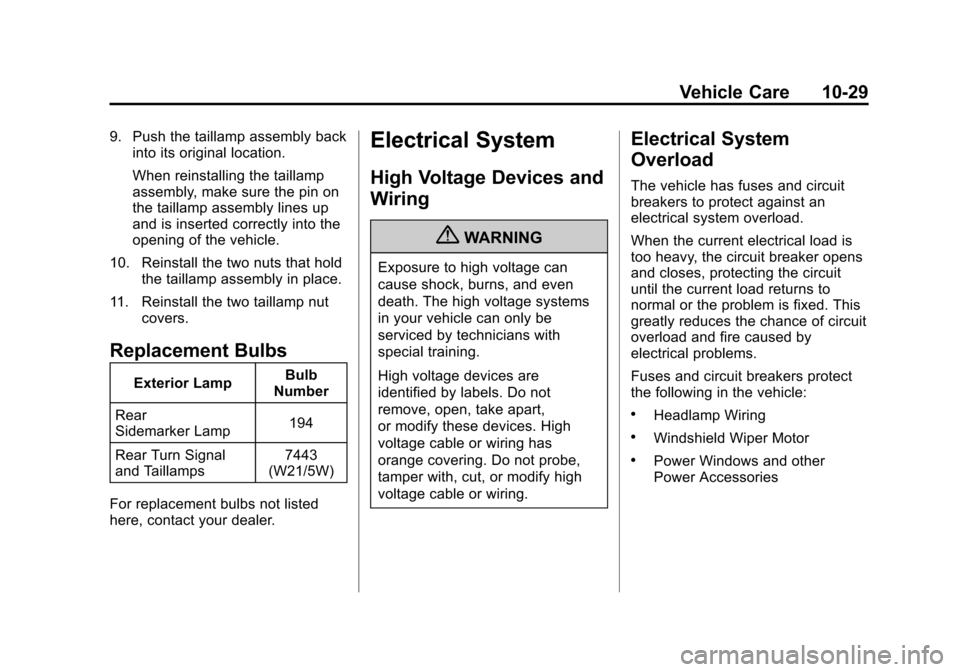

Replacement Bulbs

Exterior Lamp Bulb

Number

Rear

Sidemarker Lamp 194

Rear Turn Signal

and Taillamps 7443

(W21/5W)

For replacement bulbs not listed

here, contact your dealer.

Electrical System

High Voltage Devices and

Wiring

{WARNING

Exposure to high voltage can

cause shock, burns, and even

death. The high voltage systems

in your vehicle can only be

serviced by technicians with

special training.

High voltage devices are

identified by labels. Do not

remove, open, take apart,

or modify these devices. High

voltage cable or wiring has

orange covering. Do not probe,

tamper with, cut, or modify high

voltage cable or wiring.

Electrical System

Overload

The vehicle has fuses and circuit

breakers to protect against an

electrical system overload.

When the current electrical load is

too heavy, the circuit breaker opens

and closes, protecting the circuit

until the current load returns to

normal or the problem is fixed. This

greatly reduces the chance of circuit

overload and fire caused by

electrical problems.

Fuses and circuit breakers protect

the following in the vehicle:

.Headlamp Wiring

.Windshield Wiper Motor

.Power Windows and other

Power Accessories

Page 340 of 448

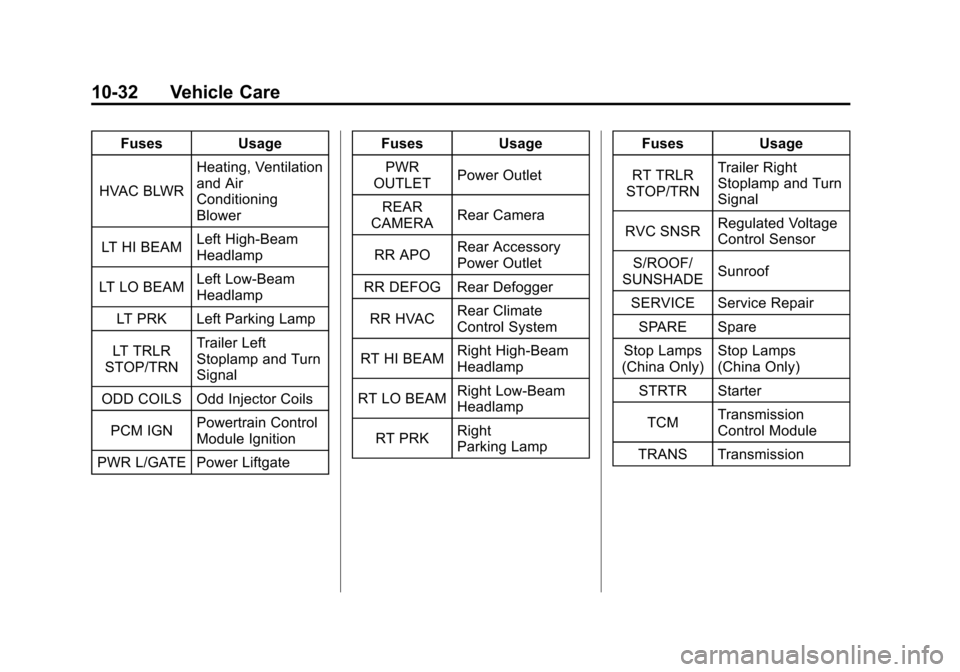

10-32 Vehicle Care

FusesUsage

HVAC BLWR Heating, Ventilation

and Air

Conditioning

Blower

LT HI BEAM Left High-Beam

Headlamp

LT LO BEAM Left Low‐Beam

Headlamp

LT PRK Left Parking Lamp

LT TRLR

STOP/TRN Trailer Left

Stoplamp and Turn

Signal

ODD COILS Odd Injector Coils

PCM IGN Powertrain Control

Module Ignition

PWR L/GATE Power Liftgate Fuses

Usage

PWR

OUTLET Power Outlet

REAR

CAMERA Rear Camera

RR APO Rear Accessory

Power Outlet

RR DEFOG Rear Defogger

RR HVAC Rear Climate

Control System

RT HI BEAM Right High‐Beam

Headlamp

RT LO BEAM Right Low‐Beam

Headlamp

RT PRK Right

Parking Lamp Fuses

Usage

RT TRLR

STOP/TRN Trailer Right

Stoplamp and Turn

Signal

RVC SNSR Regulated Voltage

Control Sensor

S/ROOF/

SUNSHADE Sunroof

SERVICE Service Repair SPARE Spare

Stop Lamps

(China Only) Stop Lamps

(China Only)

STRTR Starter

TCM Transmission

Control Module

TRANS Transmission

Page 344 of 448

10-36 Vehicle Care

Wheels and Tires

Tires

Your new vehicle comes with

high-quality tires made by a

leading tire manufacturer. If you

ever have questions about your

tire warranty and where to

obtain service, see your vehicle

Warranty booklet for details. For

additional information refer to

the tire manufacturer.

{WARNING

Poorly maintained and improperly

used tires are dangerous.

.Overloading your tires can

cause overheating as a result

of too much flexing. You

could have an air-out and a

serious accident. SeeVehicle

Load Limits on page 9‑12.

(Continued)

WARNING (Continued)

.Underinflated tires pose the

same danger as overloaded

tires. The resulting accident

could cause serious injury.

Check all tires frequently to

maintain the recommended

pressure. Tire pressure

should be checked when your

tires are cold. See Tire

Pressure on page 10‑42.

.Overinflated tires are more

likely to be cut, punctured

or broken by a sudden

impact —such as when you

hit a pothole. Keep tires at

the recommended pressure.

.Worn, old tires can cause

accidents. If your tread is

badly worn, or if your tires

have been damaged,

replace them.

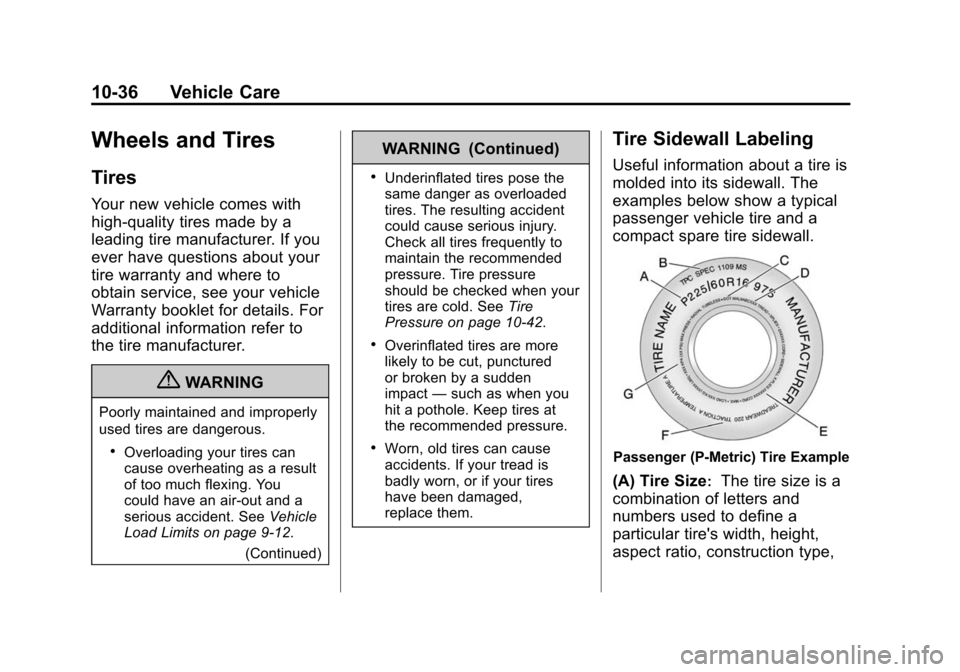

Tire Sidewall Labeling

Useful information about a tire is

molded into its sidewall. The

examples below show a typical

passenger vehicle tire and a

compact spare tire sidewall.

Passenger (P‐Metric) Tire Example

(A) Tire Size:The tire size is a

combination of letters and

numbers used to define a

particular tire's width, height,

aspect ratio, construction type,

Page 345 of 448

Vehicle Care 10-37

and service description. See the

“Tire Size”illustration later in this

section for more detail.

(B) TPC Spec (Tire

Performance Criteria

Specification)

:Original

equipment tires designed to

GM's specific tire performance

criteria have a TPC specification

code molded onto the sidewall.

GM's TPC specifications meet or

exceed all federal safety

guidelines.

(C) DOT (Department of

Transportation)

:The

Department of Transportation

(DOT) code indicates that the

tire is in compliance with the

U.S. Department of

Transportation Motor Vehicle

Safety Standards.

(D) Tire Identification Number

(TIN)

:The letters and numbers

following the DOT (Department

of Transportation) code is the Tire Identification Number (TIN).

The TIN shows the

manufacturer and plant code,

tire size, and date the tire was

manufactured. The TIN is

molded onto both sides of the

tire, although only one side may

have the date of manufacture.

(E) Tire Ply Material

:The type

of cord and number of plies in

the sidewall and under the tread.

(F) Uniform Tire Quality

Grading (UTQG)

:Tire

manufacturers are required to

grade tires based on three

performance factors: treadwear,

traction, and temperature

resistance. For more information

see Uniform Tire Quality

Grading

on page 10‑52.

(G) Maximum Cold Inflation

Load Limit

:Maximum load that

can be carried and the

maximum pressure needed to

support that load.

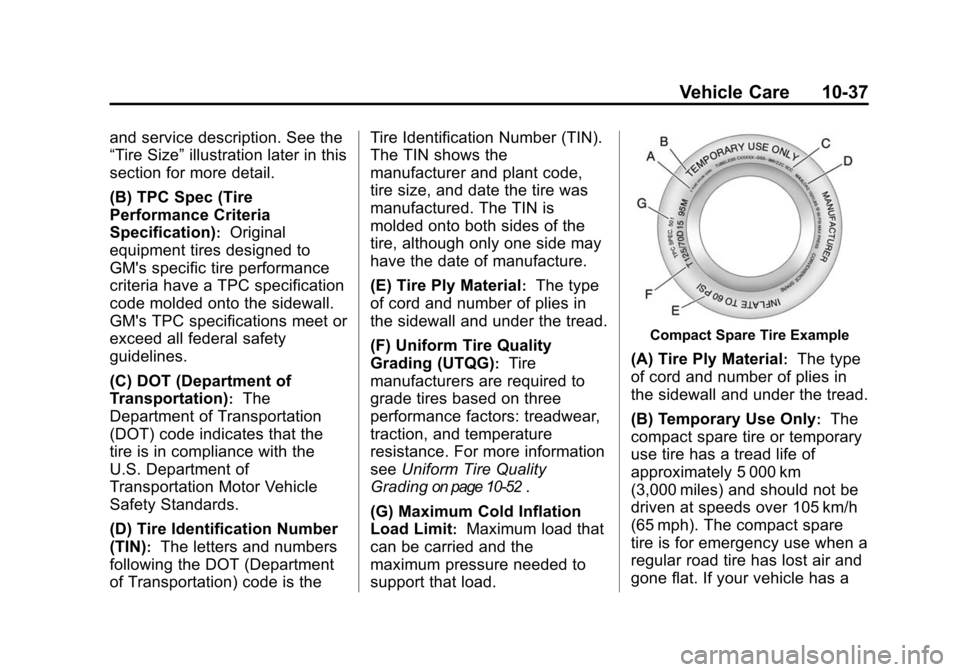

Compact Spare Tire Example

(A) Tire Ply Material:The type

of cord and number of plies in

the sidewall and under the tread.

(B) Temporary Use Only

:The

compact spare tire or temporary

use tire has a tread life of

approximately 5 000 km

(3,000 miles) and should not be

driven at speeds over 105 km/h

(65 mph). The compact spare

tire is for emergency use when a

regular road tire has lost air and

gone flat. If your vehicle has a