clock CHEVROLET TRAX 2024 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2024, Model line: TRAX, Model: CHEVROLET TRAX 2024Pages: 328, PDF Size: 7.3 MB

Page 264 of 328

Chevrolet TRAX Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

17041293) - 2024 - CRC - 12/6/22

Vehicle Care 263

4. Attach the air only hose (10) to thesealant canister inlet valve (1) by turning

it clockwise until tight.

5. Slide the base of the tire sealantcanister (3) into the slot on the top of

the compressor (6) to hold it upright.

Make sure the tire valve stem is

positioned close to the ground so the

hose will reach it.

6. Remove the valve stem cap from the flat tire by turning it counterclockwise.

7. Attach the sealant/air hose (2) to the tirevalve stem by turning it clockwise until

tight.

8. Plug the power plug (9) into the accessory power outlet in the vehicle.

Unplug all items from other accessory

power outlets. See Power Outlets082. If the vehicle has an accessory power

outlet, do not use the cigarette lighter.

If the vehicle only has a cigarette lighter,

use the cigarette lighter.

Do not pinch the power plug cord in the

door or window.

9. Start the vehicle. The vehicle must be running while using the air compressor.

10. Press the on/off button (5) to turn the tire sealant and compressor kit on.

The compressor will inject sealant and air

into the tire.

The pressure gauge (8) will initially show

a high pressure while the compressor

pushes the sealant into the tire. Once

the sealant is completely dispersed into

the tire, the pressure will quickly drop

and start to rise again as the tire inflates

with air only.

11. Inflate the tire to the recommended inflation pressure using the pressure

gauge (8). The recommended inflation

pressure can be found on the Tire and

Loading Information label. See Tire

Pressure 0248.

The pressure gauge (8) may read higher

than the actual tire pressure while the

compressor is on. Turn the compressor

Page 265 of 328

Chevrolet TRAX Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

17041293) - 2024 - CRC - 12/6/22

264 Vehicle Care

off to get an accurate pressure reading.

The compressor may be turned on/off

until the correct pressure is reached.

Caution

If the recommended pressure cannot be

reached after approximately 25 minutes,

the vehicle should not be driven farther.

The tire is too severely damaged and the

tire sealant and compressor kit cannot

inflate the tire. Remove the power plug

from the accessory power outlet and

unscrew the inflating hose from the tire

valve. SeeRoadside Assistance Program

0 300.

12. Press the on/off button (5) to turn the tire sealant and compressor kit off.

The tire is not sealed and will continue

to leak air until the vehicle is driven and

the sealant is distributed in the tire.

Therefore, Steps 13–21 must be done

immediately after Step 12.

Be careful while handling the tire sealant

and compressor kit as it could be warm

after usage.

13. Unplug the power plug (9) from the accessory power outlet in the vehicle. 14. Turn the sealant/air hose (2)

counterclockwise to remove it from the

tire valve stem.

15. Replace the tire valve stem cap.

16. Remove the tire sealant canister (4) from the slot on top of the compressor (6).

17. Turn the air only hose (10) counterclockwise to remove it from the

tire sealant canister inlet valve (1).

18. Turn the sealant/air hose (2) clockwise onto the sealant canister inlet valve (1)

to prevent sealant leakage.

19. Return the air only hose (10) and power plug (9) back to their original storage

location.

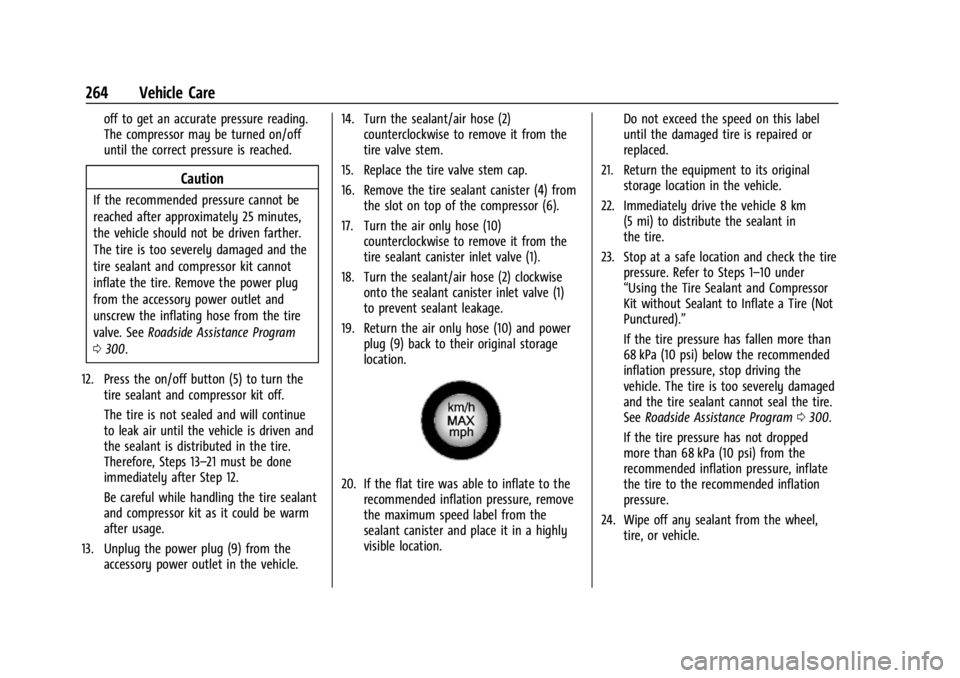

20. If the flat tire was able to inflate to therecommended inflation pressure, remove

the maximum speed label from the

sealant canister and place it in a highly

visible location. Do not exceed the speed on this label

until the damaged tire is repaired or

replaced.

21. Return the equipment to its original storage location in the vehicle.

22. Immediately drive the vehicle 8 km (5 mi) to distribute the sealant in

the tire.

23. Stop at a safe location and check the tire pressure. Refer to Steps 1–10 under

“Using the Tire Sealant and Compressor

Kit without Sealant to Inflate a Tire (Not

Punctured).”

If the tire pressure has fallen more than

68 kPa (10 psi) below the recommended

inflation pressure, stop driving the

vehicle. The tire is too severely damaged

and the tire sealant cannot seal the tire.

SeeRoadside Assistance Program 0300.

If the tire pressure has not dropped

more than 68 kPa (10 psi) from the

recommended inflation pressure, inflate

the tire to the recommended inflation

pressure.

24. Wipe off any sealant from the wheel, tire, or vehicle.

Page 266 of 328

Chevrolet TRAX Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

17041293) - 2024 - CRC - 12/6/22

Vehicle Care 265

25. Dispose of the used tire sealantcanister (4) at a local dealer or in

accordance with local state codes and

practices.

26. Replace it with a new canister available from your dealer.

27. After temporarily sealing a tire using the tire sealant and compressor kit, take the

vehicle to an authorized dealer within

161 km (100 mi) of driving to have the

tire repaired or replaced.

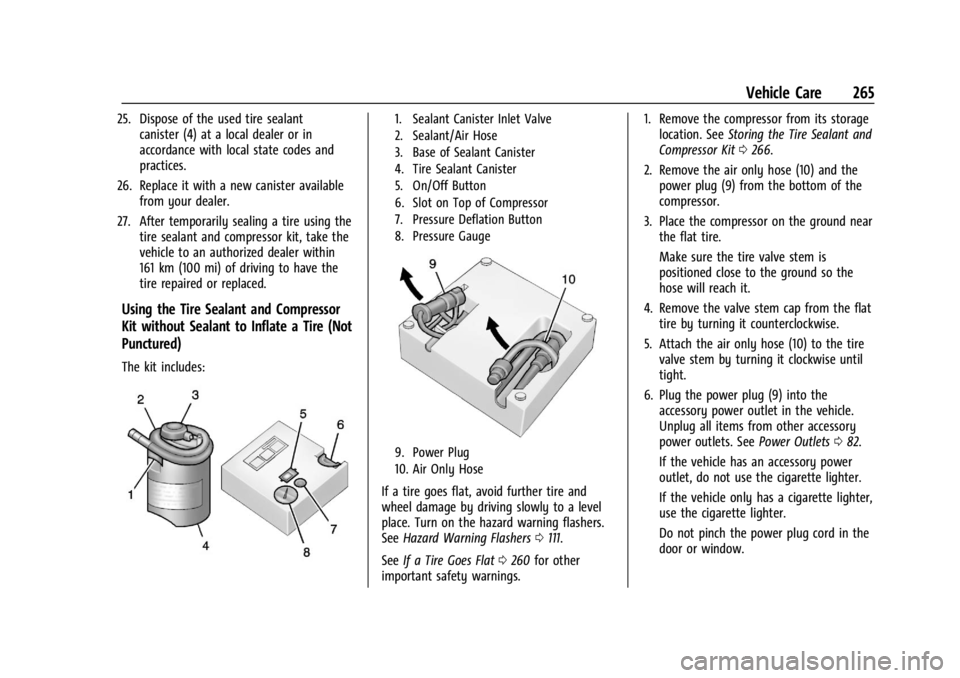

Using the Tire Sealant and Compressor

Kit without Sealant to Inflate a Tire (Not

Punctured)

The kit includes:

1. Sealant Canister Inlet Valve

2. Sealant/Air Hose

3. Base of Sealant Canister

4. Tire Sealant Canister

5. On/Off Button

6. Slot on Top of Compressor

7. Pressure Deflation Button

8. Pressure Gauge

9. Power Plug

10. Air Only Hose

If a tire goes flat, avoid further tire and

wheel damage by driving slowly to a level

place. Turn on the hazard warning flashers.

SeeHazard Warning Flashers 0111.

See If a Tire Goes Flat 0260 for other

important safety warnings. 1. Remove the compressor from its storage

location. See Storing the Tire Sealant and

Compressor Kit 0266.

2. Remove the air only hose (10) and the power plug (9) from the bottom of the

compressor.

3. Place the compressor on the ground near the flat tire.

Make sure the tire valve stem is

positioned close to the ground so the

hose will reach it.

4. Remove the valve stem cap from the flat tire by turning it counterclockwise.

5. Attach the air only hose (10) to the tire valve stem by turning it clockwise until

tight.

6. Plug the power plug (9) into the accessory power outlet in the vehicle.

Unplug all items from other accessory

power outlets. See Power Outlets082.

If the vehicle has an accessory power

outlet, do not use the cigarette lighter.

If the vehicle only has a cigarette lighter,

use the cigarette lighter.

Do not pinch the power plug cord in the

door or window.

Page 267 of 328

Chevrolet TRAX Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

17041293) - 2024 - CRC - 12/6/22

266 Vehicle Care

7. Start the vehicle. The vehicle must berunning while using the air compressor.

8. Press the on/off button (5) to turn the tire sealant and compressor kit on.

The compressor will inflate the tire with

air only.

9. Inflate the tire to the recommended inflation pressure using the pressure

gauge (8). The recommended inflation

pressure can be found on the Tire and

Loading Information label. See Tire

Pressure 0248.

The pressure gauge (8) may read higher

than the actual tire pressure while the

compressor is on. Turn the compressor

off to get an accurate pressure reading.

The compressor may be turned on/off

until the correct pressure is reached.

Caution

If the recommended pressure cannot be

reached after approximately 25 minutes,

the vehicle should not be driven farther.

The tire is too severely damaged and the

tire sealant and compressor kit cannot

inflate the tire. Remove the power plug

from the accessory power outlet and

(Continued)

Caution (Continued)

unscrew the inflating hose from the tire

valve. See Roadside Assistance Program

0 300.

10. Press the on/off button (5) to turn the tire sealant and compressor kit off.

Be careful while handling the compressor

as it could be warm after usage.

11. Unplug the power plug (9) from the accessory power outlet in the vehicle.

12. Turn the air only hose (10) counterclockwise to remove it from the

tire valve stem.

13. Replace the tire valve stem cap.

14. Return the air only hose (10) and power plug (9) back to their original storage

location.

15. Return the equipment to its original storage location in the vehicle.

The tire sealant and compressor kit has

accessory adapters located in a

compartment on the bottom of its housing

that can be used to inflate air mattresses,

balls, etc.

Storing the Tire Sealant and

Compressor Kit

The van model is equipped with a tire

sealant and compressor kit, which is stored

under the load floor in the rear

storage area.

To access the tire sealant and

compressor kit: 1. Open a rear door.

2. Lift the load floor using the handle, or if equipped with sliding load floor, open

the lift gate, release the latch on the

load floor tray, and slide the load floor

toward the rear of the vehicle. See Cargo

Management System 076.

3. Remove the tire sealant and compressor kit from its storage location.

To store the tire sealant and compressor kit,

reverse the steps.

Page 269 of 328

Chevrolet TRAX Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

17041293) - 2024 - CRC - 12/6/22

268 Vehicle Care

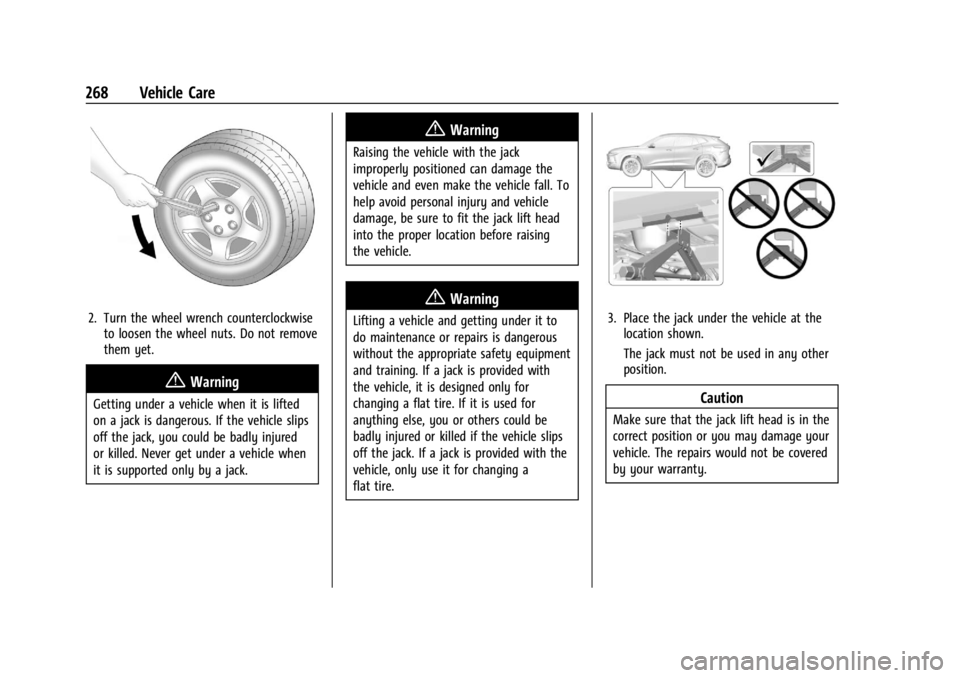

2. Turn the wheel wrench counterclockwiseto loosen the wheel nuts. Do not remove

them yet.

{Warning

Getting under a vehicle when it is lifted

on a jack is dangerous. If the vehicle slips

off the jack, you could be badly injured

or killed. Never get under a vehicle when

it is supported only by a jack.

{Warning

Raising the vehicle with the jack

improperly positioned can damage the

vehicle and even make the vehicle fall. To

help avoid personal injury and vehicle

damage, be sure to fit the jack lift head

into the proper location before raising

the vehicle.

{Warning

Lifting a vehicle and getting under it to

do maintenance or repairs is dangerous

without the appropriate safety equipment

and training. If a jack is provided with

the vehicle, it is designed only for

changing a flat tire. If it is used for

anything else, you or others could be

badly injured or killed if the vehicle slips

off the jack. If a jack is provided with the

vehicle, only use it for changing a

flat tire.3. Place the jack under the vehicle at thelocation shown.

The jack must not be used in any other

position.

Caution

Make sure that the jack lift head is in the

correct position or you may damage your

vehicle. The repairs would not be covered

by your warranty.

Page 270 of 328

Chevrolet TRAX Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

17041293) - 2024 - CRC - 12/6/22

Vehicle Care 269

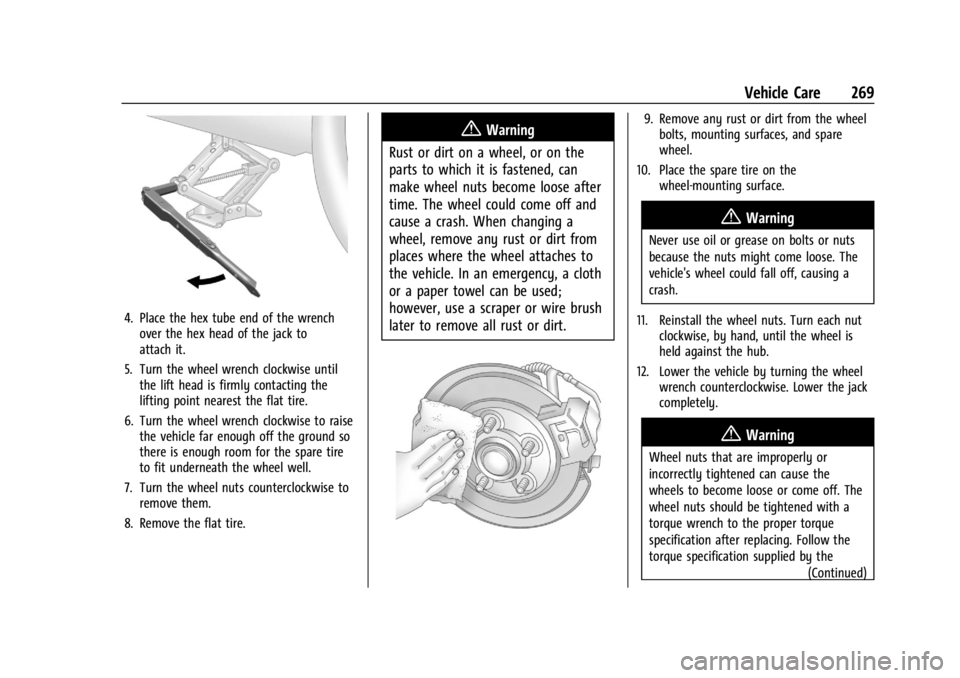

4. Place the hex tube end of the wrenchover the hex head of the jack to

attach it.

5. Turn the wheel wrench clockwise until the lift head is firmly contacting the

lifting point nearest the flat tire.

6. Turn the wheel wrench clockwise to raise the vehicle far enough off the ground so

there is enough room for the spare tire

to fit underneath the wheel well.

7. Turn the wheel nuts counterclockwise to remove them.

8. Remove the flat tire.

{Warning

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose after

time. The wheel could come off and

cause a crash. When changing a

wheel, remove any rust or dirt from

places where the wheel attaches to

the vehicle. In an emergency, a cloth

or a paper towel can be used;

however, use a scraper or wire brush

later to remove all rust or dirt.9. Remove any rust or dirt from the wheel bolts, mounting surfaces, and spare

wheel.

10. Place the spare tire on the wheel-mounting surface.

{Warning

Never use oil or grease on bolts or nuts

because the nuts might come loose. The

vehicle's wheel could fall off, causing a

crash.

11. Reinstall the wheel nuts. Turn each nut clockwise, by hand, until the wheel is

held against the hub.

12. Lower the vehicle by turning the wheel wrench counterclockwise. Lower the jack

completely.

{Warning

Wheel nuts that are improperly or

incorrectly tightened can cause the

wheels to become loose or come off. The

wheel nuts should be tightened with a

torque wrench to the proper torque

specification after replacing. Follow the

torque specification supplied by the

(Continued)

Page 319 of 328

Chevrolet TRAX Owner Manual (GMNA-Localizing-U.S./Canada/Mexico-

17041293) - 2024 - CRC - 12/2/22

318 Index

CargoCover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Management System . . . . . . . . . . . . . . . . . . . 76

Caution, Danger, and Warning . . . . . . . . . . . . . .2

Center Console Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chains, Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Charging

System Light . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Wireless . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Check Engine Light (Malfunction

Indicator) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Child Restraints Infants and Young Children . . . . . . . . . . . . . 56

Lower Anchors and Tethers forChildren . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Older Children . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68, 70

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Child Safety Locks . . . . . . . . . . . . . . . . . . . . . . . . .22

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Cleaning Exterior Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Interior Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Climate Control Systems . . . . . . . . . . . . . . . . . .158

Air Conditioning . . . . . . . . . . . . . . . . . . . . . . . 158

Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Cluster, Instrument . . . . . . . . . . . . . . . . . . . 86, 87

Collision Alert

Forward (FCA) System . . . . . . . . . . . . . . . . . 203

Collision Damage Repair . . . . . . . . . . . . . . . . . 302

Compact Spare Tire . . . . . . . . . . . . . . . . . . . . . . . 271

Compartments Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Compass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Compressor Kit, Tire Sealant . . . . . . . . . . . . . 261

Connected Services Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Connections Connected Services . . . . . . . . . . . . . . . . . . . . 313

Control Traction and Electronic Stability . . . . . . . 188

Control of a Vehicle . . . . . . . . . . . . . . . . . . . . . 167

Controls Steering Wheel . . . . . . . . . . . . . . . . . . . . 117, 136

Convex Mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Coolant Engine Temperature Gauge . . . . . . . . . . . . . 90

Engine Temperature Warning Light . . . . . 98

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158, 160

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Courtesy Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 Courtesy Transportation Program . . . . . . . . 301

Cover

Cargo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 190 Adaptive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Cupholders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Customer Assistance

Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Text Telephone (TTY) Users . . . . . . . . . . . . 299

Customer Information

Publications Ordering Information . . . . . 304

Customer Satisfaction Procedure . . . . . . . . . 297

Cybersecurity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

D

Damage Repair, Collision . . . . . . . . . . . . . . . . . 302

Danger, Warning, and Caution . . . . . . . . . . . . . .2

Dashboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Data Collection OnStar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Data Recorders, Event . . . . . . . . . . . . . . . . . . . 307

Daytime Running Lamps (DRL) . . . . . . . . . . . .110

Defensive Driving . . . . . . . . . . . . . . . . . . . . . . . . 166

Delayed Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Diagnostics Connected Services . . . . . . . . . . . . . . . . . . . . 315