CHRYSLER 300 2006 1.G Owners Manual

Manufacturer: CHRYSLER, Model Year: 2006, Model line: 300, Model: CHRYSLER 300 2006 1.GPages: 392, PDF Size: 6.72 MB

Page 221 of 392

•If there is a need to restart your engine be sure to cycle

the key to the LOCK position before restarting. Trans-

mission engagement may be delayed up to 10 seconds

after restart if the key is not cycled to the LOCK

position first.

•The electronically controlled transmission provides a

precise shift schedule. The transmission electronics are

self-calibrating. Therefore, the first few shifts on a new

vehicle may be somewhat abrupt or soft until after the

break-in period. This is a normal condition, and pre-

cision shifts will develop within a few shift cycles.

WARNING!

It is dangerous to shift the selector lever out of PARK

or NEUTRAL if the engine speed is higher than idle

speed. If your foot is not firmly on the brake pedal,

the vehicle could accelerate quickly forward or in

reverse. You could lose control of the vehicle and hit

someone or something. Only shift into gear when

the engine is idling normally and when your foot is

firmly on the brake pedal.

The selector lever is automatically locked while in the

PARK position. To move the selector lever out of the

PARK position, the brake pedal must be firmly depressed

before the shift lock will release.

Shift the selector lever to the desired position only when

the engine is idling normally and the brake pedal is

applied. Do not release the brake until ready to drive. The

vehicle may otherwise accelerate quickly when the selec-

tor lever is in DRIVE or REVERSE position.

Stopping

For brief stops, leave the transmission in gear and hold

the vehicle with the brake pedal. For longer stops with

the engine idling, shift into the NEUTRAL or PARK

position and hold the vehicle with the parking brake.

When stopping the vehicle uphill, do not hold it with the

accelerator; use the brake. This avoids unnecessary trans-

mission heat build-up.

Maneuvering

To maneuver in tight areas, control the vehicle speed by

gradually releasing the brakes. Accelerate gently and

never abruptly step on the accelerator.

STARTING AND OPERATING 221

5

Page 222 of 392

To rock a vehicle out of soft ground (mud or snow),

alternately shift from forward to reverse, while applying

only slight acceleration. Rocking a vehicle free in this

manner may cause the ABS or traction system malfunc-

tion indicator light to come on. Turn off the engine and

restart the engine to clear the malfunction indication.

Brake Transmission Shift Interlock System

This vehicle is equipped with a brake transmission shift

interlock system (BTSI) that holds the gearshift lever in

the P (Park) position when the ignition switch is in the

LOCK position. To move the gear selector lever out of the

P (Park) position, the ignition switch must be turned to

the ON position, and the brake pedal must be depressed.

Over Temperature Mode

The transmission electronics constantly monitor the

transmission oil temperature. If the transmission exceeds

normal operating temperature, the transmission will

change the way it shifts to help control the condition.

This may result in a slightly different feeling or response

during normal operation in D (Drive) position. After the

transmission cools down, it will return to normal opera-

tion.

AUTOSTICK—If Equipped

Autostick is a driver-interactive transmission that offers

manual gear shifting to provide you with more control.

Autostick allows you to maximize engine braking, elimi-

nate undesirable upshifts and downshifts, and improve

overall vehicle performance. This system can also pro-

vide you with more control during passing, city driving,

cold slippery conditions, mountain driving, trailer tow-

ing, and many other situations.

Autostick Operation

By placing the shift lever in the DRIVE position it can be

moved from side to side. This allows the driver to select

a higher or lower range of gears. Moving the lever to the

left (-) triggers a downshift and to the right (+) an upshift.

The gear position will be shown in the transmission gear

display, located in the instrument cluster.

222 STARTING AND OPERATING

Page 223 of 392

You can shift in or out of the autostick mode at any time

without taking your foot off the accelerator pedal. If you

choose the Overdrive mode, the transmission will oper-

ate automatically; shifting between the five available

gears. When you wish to engage autostick, simply move

the shift lever to the Right or Left (D+/D-) position while

in DRIVE. The transmission will remain in the current

gear until an upshift or downshift is chosen.

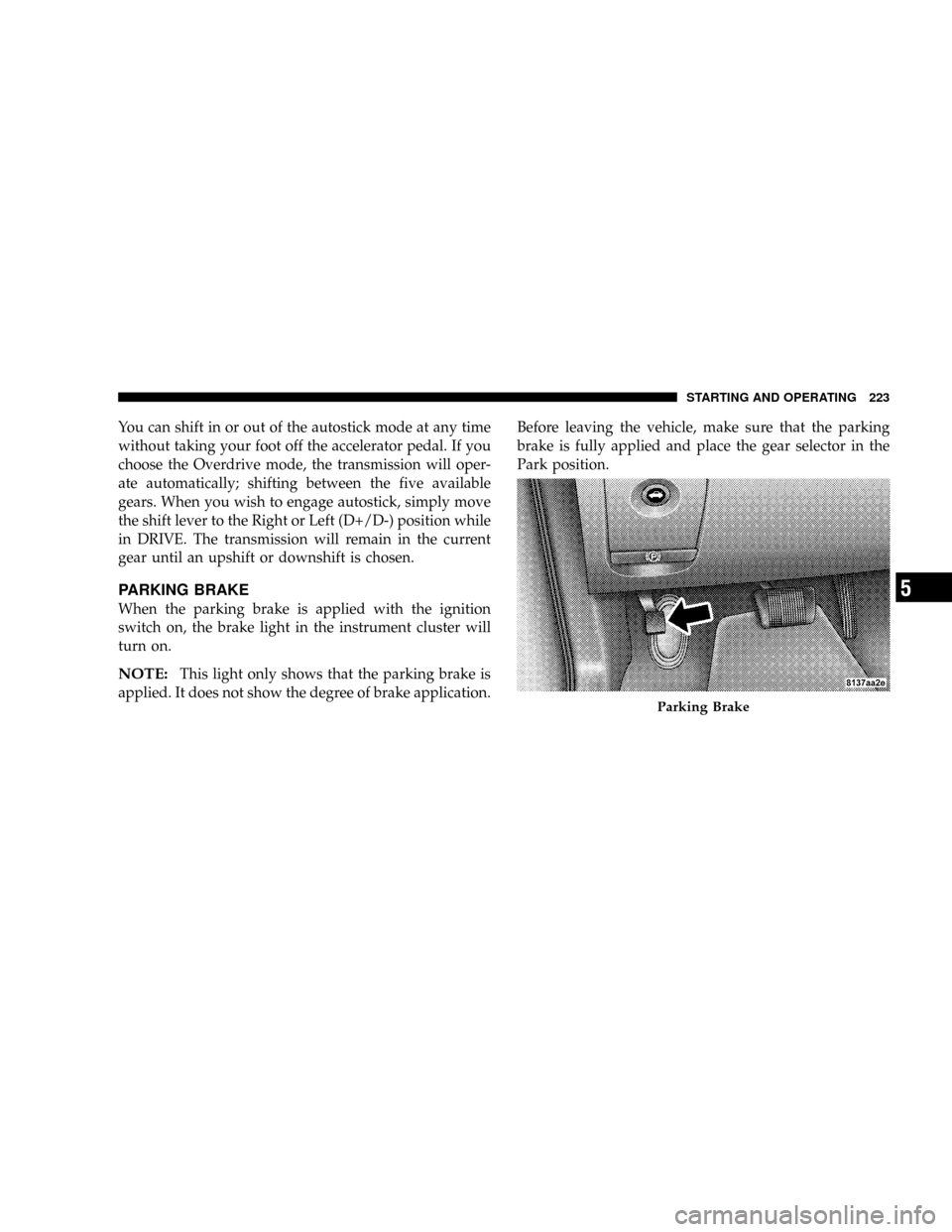

PARKING BRAKE

When the parking brake is applied with the ignition

switch on, the brake light in the instrument cluster will

turn on.

NOTE:This light only shows that the parking brake is

applied. It does not show the degree of brake application.Before leaving the vehicle, make sure that the parking

brake is fully applied and place the gear selector in the

Park position.

Parking Brake

STARTING AND OPERATING 223

5

Page 224 of 392

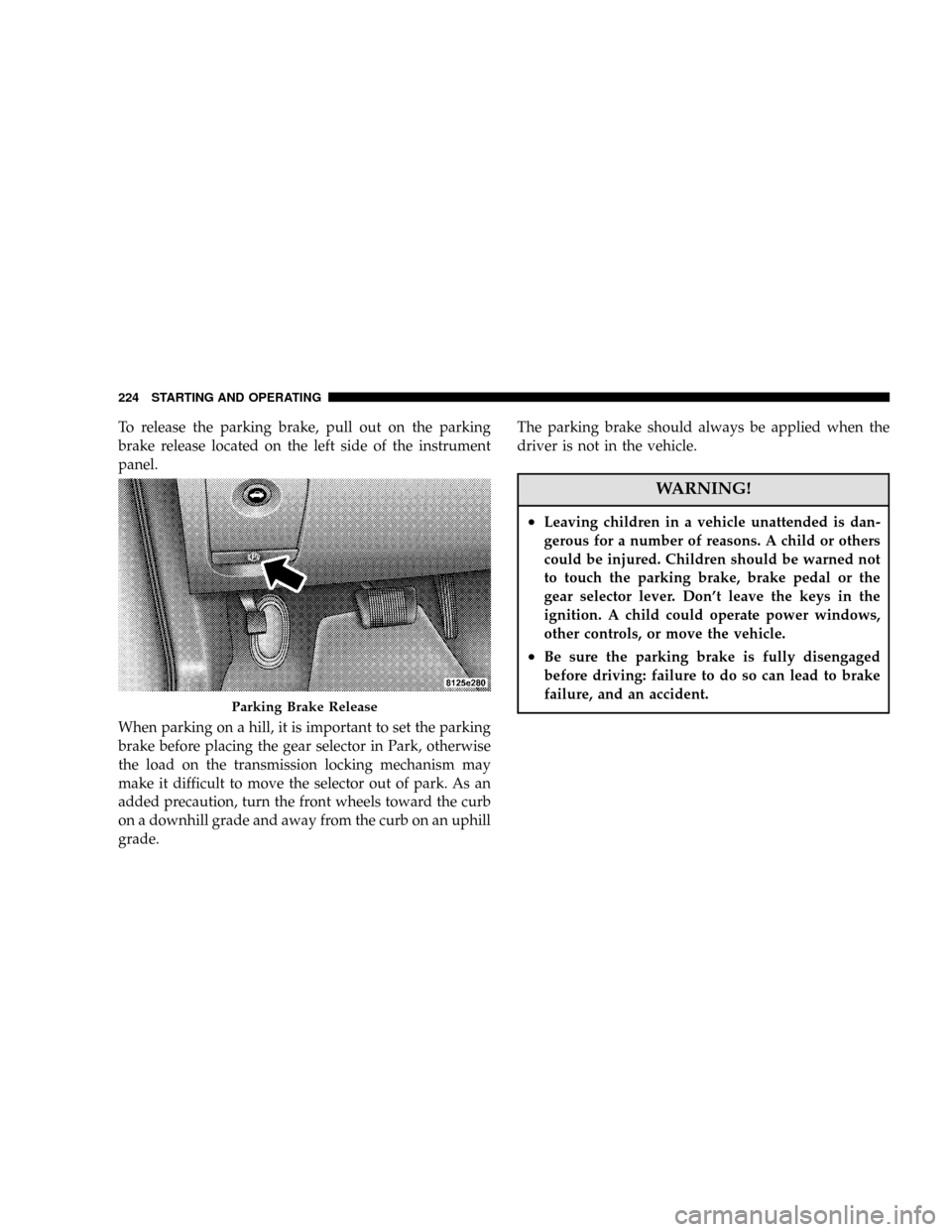

To release the parking brake, pull out on the parking

brake release located on the left side of the instrument

panel.

When parking on a hill, it is important to set the parking

brake before placing the gear selector in Park, otherwise

the load on the transmission locking mechanism may

make it difficult to move the selector out of park. As an

added precaution, turn the front wheels toward the curb

on a downhill grade and away from the curb on an uphill

grade.The parking brake should always be applied when the

driver is not in the vehicle.

WARNING!

•Leaving children in a vehicle unattended is dan-

gerous for a number of reasons. A child or others

could be injured. Children should be warned not

to touch the parking brake, brake pedal or the

gear selector lever. Don’t leave the keys in the

ignition. A child could operate power windows,

other controls, or move the vehicle.

•Be sure the parking brake is fully disengaged

before driving: failure to do so can lead to brake

failure, and an accident.

Parking Brake Release

224 STARTING AND OPERATING

Page 225 of 392

BRAKE SYSTEM

In the event power assist is lost for any reason (for

example, repeated brake applications with the engine

off), the brakes will still function. The effort required to

brake the vehicle will be much greater than that required

with the power system operating.

Your vehicle is equipped with dual hydraulic

brake systems. If either of the two hydraulic

systems lose normal capability, the remaining

system will still function. There will be some

loss of overall braking effectiveness. This may be evident

by increased pedal travel during application, greater

pedal force required to slow or stop, and potential

activation of the Brake Warning Light.

Anti-Lock Brake System

The Anti-Lock Brake System provides increased vehicle

stability and brake performance under most braking

conditions. The system automatically“pumps”the

brakes during severe braking conditions to prevent

wheel lock-up.The electronic brake force distribution (EBD) prevents the

rear wheels from over-braking and provides greater

control of available braking forces applied to the rear

axle.

WARNING!

Pumping of the Anti-Lock Brakes will diminish

their effectiveness and may lead to an accident.

Pumping makes the stopping distance longer. Just

press firmly on your brake pedal when you need to

slow down or stop.

STARTING AND OPERATING 225

5

Page 226 of 392

WARNING!

•Anti-lock system (ABS) cannot prevent the natu-

ral laws of physics from acting on the vehicle, nor

can it increase braking or steering efficiency be-

yond that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

•The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

•The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user’s safety

or the safety of others.

The ABS light monitors the Anti-Lock Brake Sys-

tem. The light will come on when the ignition

switch is turned to the ON position and may stay on for

as long as four seconds.If the ABS light remains on or comes on while driving, it

indicates that the Anti-Lock portion of the brake system

is not functioning and that service is required. However,

the conventional brake system will continue to operate

normally if the BRAKE warning light is not on.

If the ABS light is on, the brake system should be serviced

as soon as possible to restore the benefits of Anti-Lock

brakes. If the ABS light does not come on when the

Ignition switch is turned to the ON position, have the

bulb repaired as soon as possible.

If both the Brake Warning Light and the ABS Light

remain on, the Anti-Lock brakes (ABS) and Electronic

Brake Force Distribution (EBD) systems are not function-

ing. Immediate repair to the ABS system is required.

When the vehicle is driven over 7 mph (11 km/h), you

may also hear a slight clicking sound as well as some

related motor noises. These noises are the system per-

forming its self check cycle to ensure that the ABS system

is working properly. This self check occurs each time the

vehicle is started and accelerated past 7 mph (11 km/h).

226 STARTING AND OPERATING

Page 227 of 392

ABS is activated during braking under certain road or

stopping conditions. ABS-inducing conditions can in-

clude ice, snow, gravel, bumps, railroad tracks, loose

debris, or panic stops.

You also may experience the following when the brake

system goes into Anti-lock:

•The ABS motor running (it may continue to run for a

short time after the stop),

•the clicking sound of solenoid valves,

•brake pedal pulsations,

•and a slight drop or fall away of the brake pedal at the

end of the stop.

These are all normal characteristics of ABS.

WARNING!

The Anti-Lock Brake System contains sophisticated

electronic equipment that may be susceptible to

interference caused by improperly installed or high

output radio transmitting equipment. This interfer-

ence can cause possible loss of anti-lock braking

capability. Installation of such equipment should be

performed by qualified professionals.

All vehicle wheels and tires must be the same size and

type and tires must be properly inflated to produce

accurate signals for the computer.

STARTING AND OPERATING 227

5

Page 228 of 392

POWER STEERING

The standard power steering system will give you good

vehicle response and increased ease of maneuverability

in tight spaces. The system will provide mechanical

steering capability if power assist is lost.

If for some reason, the power assist is interrupted, it will

still be possible to steer your vehicle. Under these condi-

tions you will observe a substantial increase in steering

effort, especially at very low vehicle speeds and during

parking maneuvers.

NOTE:Increased noise levels at the end of the steering

wheel travel are considered normal and does not indicate

that there is a problem with the power steering system.

Upon initial start-up in cold weather, the power

steering pump may make noise for a short period of

time. This is due to the cold, thick fluid in the steering

system. This noise should be considered normal, and

does not in any way damage the steering system.

WARNING!

Continued operation with reduced power steering

assist could pose a safety risk to yourself and others.

Service should be obtained as soon as possible.

CAUTION!

Prolong operation of the steering system at the end

of the steering wheel travel will increase the steering

fluid temperature and should be avoided when

possible. Damage to the power steering pump may

occur.

228 STARTING AND OPERATING

Page 229 of 392

MULTI DISPLACEMENT SYSTEM (MDS) - 5.7L

Engine Only

This feature offers improved fuel economy by shutting

off four of the engine’s eight cylinders during light load

and cruise conditions. The system is automatic with no

driver inputs or additional driving skills required.

NOTE:The MDS system may take some time to return

to full functionality after a battery disconnect.

ALL WHEEL DRIVE—IF EQUIPPED

This feature provides full time All Wheel Drive (AWD)

with Antilock Brake System (ABS)/Traction Control. The

front wheels provide 38% of the torque, and the rear

wheels provide 62% of the torque. The system is auto-

matic with no driver inputs or additional driving skills

required.

CAUTION!

All wheels must have the same size and type tires.

Unequal tire sizes must not be used. Unequal tire

size may cause failure of the front differential and/or

the transfer case.

SELF–SEALING TIRES—IF EQUIPPED

A non-hardening viscous sealant applied to the inner

liner of each tire fills punctures up to 0.19 in. (5 mm) to

minimize the loss of air pressure. This contributes to the

safety of the vehicle by significantly reducing the prob-

ability of a roadside stop due to a flat tire.

STARTING AND OPERATING 229

5

Page 230 of 392

TIRE PRESSURE MONITOR SYSTEM—IF

EQUIPPED

Tire Pressure Monitoring—Base System

The Tire Pressure Monitor System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels (EXCLUDING THE SPARE

TIRE). Sensors, mounted to each wheel as part of the

valve stem, transmit tire pressure readings to the Re-

ceiver Module.

NOTE:It is particularly important, for you to check the

tire pressure in all of your tires regularly and to maintain

the proper pressure.

The Tire Pressure Monitoring Telltale Light will

illuminate in the instrument cluster, and an au-

dible chime will be activated when one or more

tire pressures is low. The Tire Pressure Monitoring Tell-

tale Light will flash on and off for 10 to 60 seconds when

a system fault is detected. The flash cycle will repeat

every ten minutes or until the fault condition is removed

and reset.The Tire Pressure Monitoring System consists of the

following components:

•Receiver Module

•4 Wheel Sensors

•Tire Pressure Monitoring Telltale Light

NOTE:For vehicles with optional wheel/tire sizes and

significantly different tire placard pressures, the placard

pressure value and the low-pressure threshold value is

re-programmable at your authorized dealer to accommo-

date the customer selected wheel/tire combinations rec-

ommended by DaimlerChrysler.

230 STARTING AND OPERATING