light CHRYSLER 300 2013 2.G Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2013, Model line: 300, Model: CHRYSLER 300 2013 2.GPages: 592, PDF Size: 4.48 MB

Page 500 of 592

Indicator Light (MIL)” is functioning and is not on when

the engine is running, and that the OBD II system is

ready for testing.

Normally, the OBD II system will be ready. The OBD II

system maynotbe ready if your vehicle was recently

serviced, recently had a dead battery or a battery replace-

ment. If the OBD II system should be determined not

ready for the I/M test, your vehicle may fail the test.

Your vehicle has a simple ignition key-actuated test,

which you can use prior to going to the test station. To

check if your vehicle’s OBD II system is ready, you must

do the following:

1. Cycle the ignition switch to the ON position, but do not crank or start the engine.

2. If you crank or start the engine, you will have to start this test over. 3. As soon as you cycle the ignition switch to the ON

position, you will see the MIL symbol come on as part

of a normal bulb check.

4. Approximately 15 seconds later, one of two things will happen:

• The MIL will flash for about 10 seconds and then

return to being fully illuminated until you turn OFF

the ignition or start the engine. This means that your

vehicle’s OBD II system is not readyand you should

not proceed to the I/M station.

• The MIL will not flash at all and will remain fully

illuminated until you turn OFF the ignition or start the

engine. This means that your vehicle’s OBD II system

is ready and you can proceed to the I/M station.

If your OBD II system is not ready,you should see your

authorized dealer or repair facility. If your vehicle was

recently serviced or had a battery failure or replacement,

498 MAINTAINING YOUR VEHICLE

Page 522 of 592

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting or

riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You would not have your full

braking capacity in an emergency.

Master Cylinder – Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the brake system warning light indicates system fail-

ure.

Check the fluid level in the master cylinder when per-

forming underhood services.Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the require-

ments described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the brake

pads wear. However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturer’s recommended brake fluid. Re-

fer to “Fluids, Lubricants, and Genuine Parts” in “Main-

taining Your Vehicle” for further information.

520 MAINTAINING YOUR VEHICLE

Page 526 of 592

All Wheel Drive (AWD) – If Equipped

The all wheel drive system consists of a transfer case and

front differential. The exterior surface of these compo-

nents should be inspected for evidence of fluid leaks.

Confirmed leaks should be repaired as soon as possible.

The transfer case fluid fill/inspection plug is located in

the middle of the rear housing. To inspect the transfer

case fluid level, remove the fill/inspection plug. The

fluid level should be even with the bottom of the hole.

Use this plug to add fluid as required.

The front differential fill plug is located on the outer

cover near the halfshaft attachment. To inspect the differ-

ential fluid level, remove the fill plug. The fluid level

should be even with or slightly below the bottom of the

hole.

Fluid Changes

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Rear Axle

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the axle assembly should be

inspected. If gear oil leakage is suspected inspect the

fluid level. Refer to “Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Vehicle” for further informa-

tion.

Fluid Level Check

Check the fluid level by removing the fill plug on the

axle. The fluid level should be at the bottom of the fill

hole. Add fluid, if necessary, to maintain the proper level.

Refer to “Fluids, Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for further information.

524 MAINTAINING YOUR VEHICLE

Page 531 of 592

WARNING!

Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in

closed areas they may cause respiratory harm.

Cleaning Headlights

Your vehicle is equipped with plastic headlights and fog

lights (if equipped) that are lighter and less susceptible to

stone breakage than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution fol-

lowed by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

Glass Surfaces

All glass surfaces should be cleaned on a regular basis

with MOPAR® Glass Cleaner, or any commercial

household-type glass cleaner. Never use an abrasive type

cleaner. Use caution when cleaning the inside rear win-

dow equipped with electric defrosters or the right rear

quarter window equipped with the radio antenna. Do

not use scrapers or other sharp instrument that may

scratch the elements.

When cleaning the rear view mirror, spray cleaner on the

towel or rag that you are using. Do not spray cleaner

directly on the mirror.

Cleaning Plastic Instrument Cluster Lenses

The lenses in front of the instruments in this vehicle are

molded in clear plastic. When cleaning the lenses, care

must be taken to avoid scratching the plastic.

7

MAINTAINING YOUR VEHICLE 529

Page 538 of 592

CAUTION!

•When installing the power distribution center

cover, it is important to ensure the cover is properly

positioned and fully latched. Failure to do so may

allow water to get into the power distribution

center and possibly result in an electrical system

failure.

• When replacing a blown fuse, it is important to use

only a fuse having the correct amperage rating. The

use of a fuse with a rating other than indicated may

result in a dangerous electrical system overload. If

a properly rated fuse continues to blow, it indicates

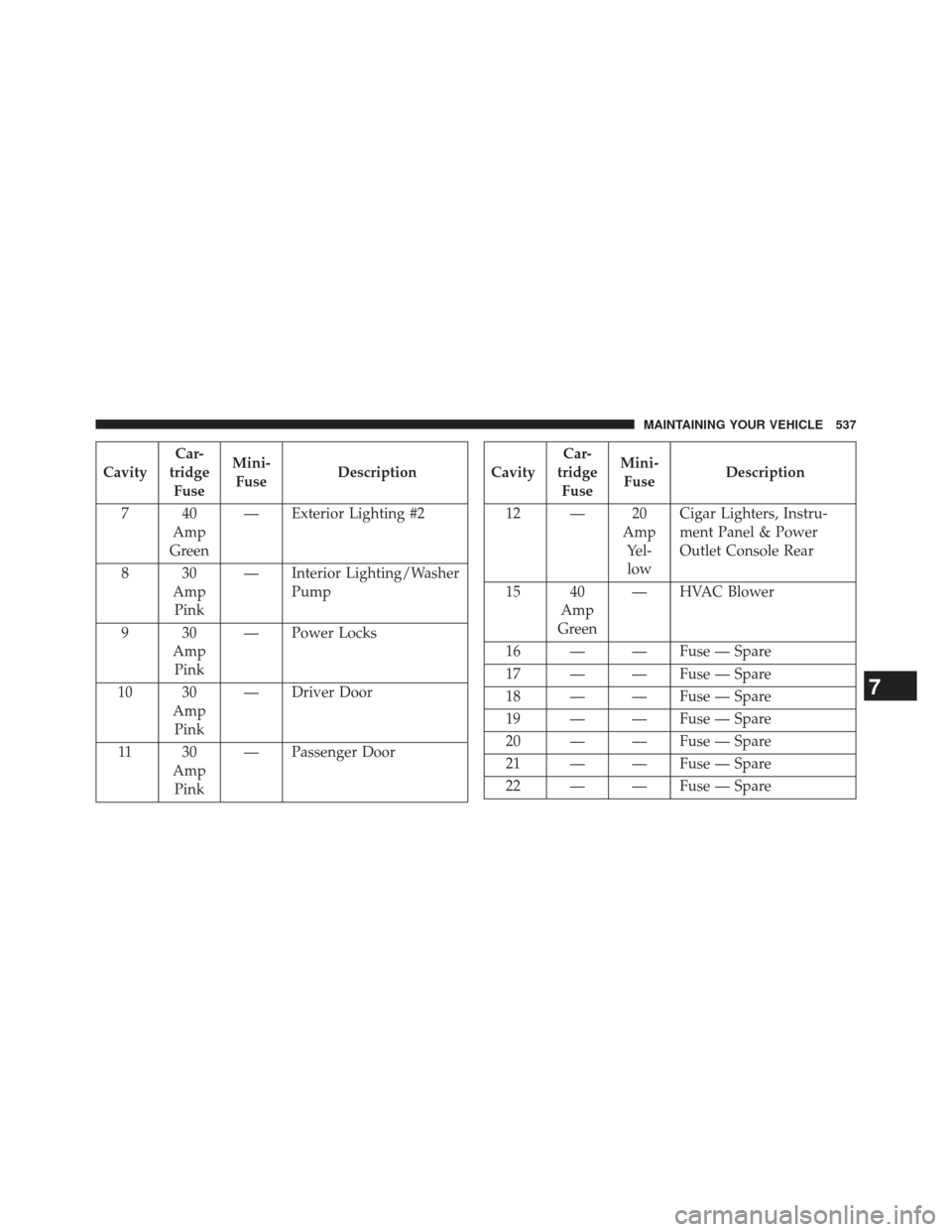

a problem in the circuit that must be corrected.Cavity Car-

tridge Fuse Mini-

Fuse Description

260 AmpYel-low — Front PDC Feed #1

3 — — Fuse – Spare

460 AmpYel-low — Front PDC Feed #2

530 AmpPink — Sunroof

640 Amp

Green — Exterior Lighting #1

536 MAINTAINING YOUR VEHICLE

Page 539 of 592

CavityCar-

tridge Fuse Mini-

Fuse Description

740 Amp

Green — Exterior Lighting #2

830 AmpPink — Interior Lighting/Washer

Pump

930 AmpPink — Power Locks

10 30 AmpPink — Driver Door

11 3 0 AmpPink — Passenger DoorCavity

Car-

tridge Fuse Mini-

Fuse Description

12 — 20 AmpYel-low Cigar Lighters, Instru-

ment Panel & Power

Outlet Console Rear

15 40 Amp

Green — HVAC Blower

16 — — Fuse — Spare

17 — — Fuse — Spare

18 — — Fuse — Spare

19 — — Fuse — Spare

20 — — Fuse — Spare

21 — — Fuse — Spare

22 — — Fuse — Spare

7

MAINTAINING YOUR VEHICLE 537

Page 542 of 592

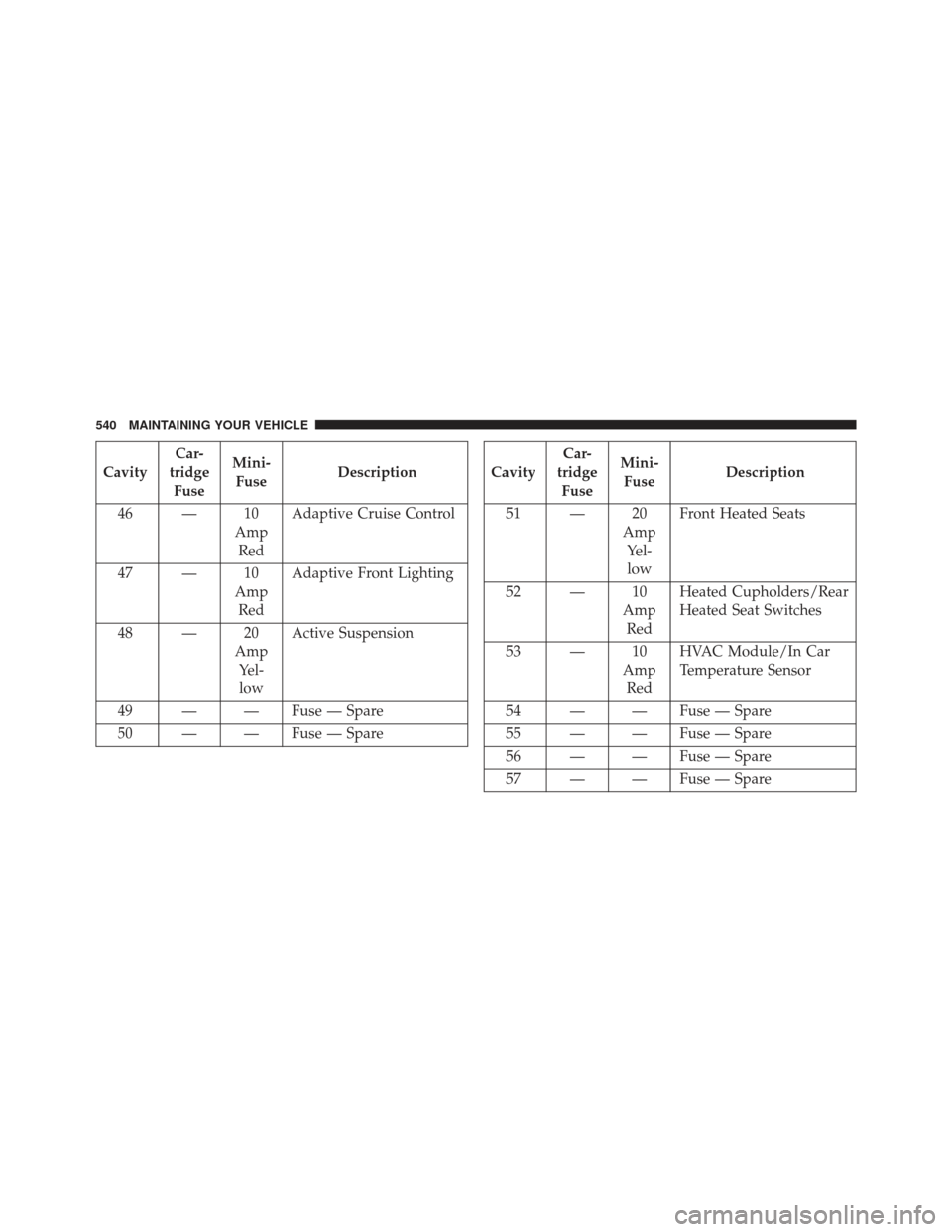

CavityCar-

tridge Fuse Mini-

Fuse Description

46 — 10 AmpRed Adaptive Cruise Control

47 — 10 AmpRed Adaptive Front Lighting

48 — 20 AmpYel-low Active Suspension

49 — — Fuse — Spare

50 — — Fuse — SpareCavity Car-

tridge Fuse Mini-

Fuse Description

51 — 20 AmpYel-low Front Heated Seats

52 — 10 AmpRed Heated Cupholders/Rear

Heated Seat Switches

53 — 10 AmpRed HVAC Module/In Car

Temperature Sensor

54 — — Fuse — Spare

55 — — Fuse — Spare

56 — — Fuse — Spare

57 — — Fuse — Spare

540 MAINTAINING YOUR VEHICLE

Page 544 of 592

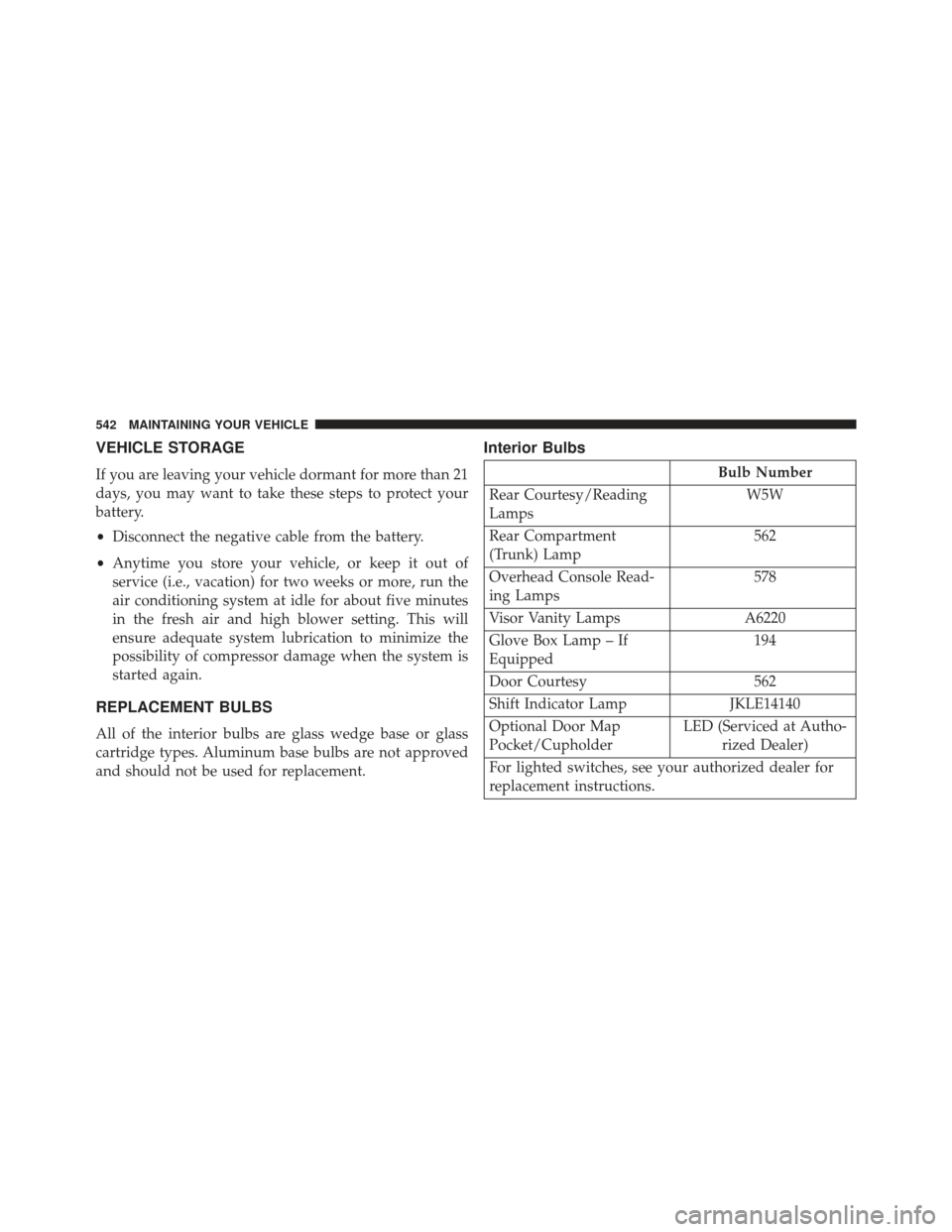

VEHICLE STORAGE

If you are leaving your vehicle dormant for more than 21

days, you may want to take these steps to protect your

battery.

•Disconnect the negative cable from the battery.

• Anytime you store your vehicle, or keep it out of

service (i.e., vacation) for two weeks or more, run the

air conditioning system at idle for about five minutes

in the fresh air and high blower setting. This will

ensure adequate system lubrication to minimize the

possibility of compressor damage when the system is

started again.

REPLACEMENT BULBS

All of the interior bulbs are glass wedge base or glass

cartridge types. Aluminum base bulbs are not approved

and should not be used for replacement.

Interior Bulbs

Bulb Number

Rear Courtesy/Reading

Lamps W5W

Rear Compartment

(Trunk) Lamp 562

Overhead Console Read-

ing Lamps 578

Visor Vanity Lamps A6220

Glove Box Lamp – If

Equipped 194

Door Courtesy 562

Shift Indicator Lamp JKLE14140

Optional Door Map

Pocket/Cupholder LED (Serviced at Autho-

rized Dealer)

For lighted switches, see your authorized dealer for

replacement instructions.

542 MAINTAINING YOUR VEHICLE

Page 546 of 592

this, you should not attempt to service a headlamp bulb

yourself. If a headlamp bulb fails, take your vehicle to

an authorized dealer for service.

WARNING!

A transient high voltage occurs at the bulb sockets of

HID headlamps when the headlamp switch is turned

ON. It may cause serious electrical shock or electro-

cution if not serviced properly. See your authorized

dealer for service.

NOTE: On vehicles equipped with HID headlamps,

when the headlamps are turned on, there is a blue hue to

the lights. This diminishes and becomes more white after

approximately 10 seconds, as the system charges.

Standard Low Beam And High Beam Headlamp

1. Open the hood.

NOTE: Removal of the air cleaner filter housing may be

necessary prior to replacing bulbs in the headlamp

assembly on the driver side of the vehicle.

2. Twist the appropriate bulb and socket assembly coun- terclockwise, and then pull it out of the headlamp

assembly.

3. Disconnect the bulb from the socket assembly and install the replacement bulb.

4. Reinstall the bulb and socket assembly into the head- lamp assembly, and then turn it clockwise.

544 MAINTAINING YOUR VEHICLE

Page 555 of 592

NOTE:Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km) or twelve months,

whichever comes first.

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual

wear or damage

• Check the fluid levels of the coolant reservoir, brake

master cylinder, power steering and transmission as

needed

• Check function of all interior and exterior lights

Required Maintenance Intervals.

Refer to the maintenance schedules on the following

page for the required maintenance intervals.At Every Oil Change Interval As Indicated By Oil Change Indicator System:

•Change oil and filter

• Rotate the tires. Rotate at the first sign of irregu-

lar wear, even if it occurs before the oil indicator

system turns on.

• Inspect battery and clean and tighten terminals as

required

• Inspect automatic transmission fluid if equipped

with dipstick

• Inspect brake pads, shoes, rotors, drums, hoses

and park brake

• Inspect engine cooling system protection and

hoses

• Inspect exhaust system

• Inspect engine air cleaner if using in dusty or

off-road conditions

8

M

A I

N T

E

N

A

N

C E

S

C

H E

D

U L

E

SMAINTENANCE SCHEDULES 553