check engine CHRYSLER 300 2018 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2018, Model line: 300, Model: CHRYSLER 300 2018Pages: 492, PDF Size: 6.67 MB

Page 343 of 492

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will influence

when the “Change Oil” or “Oil Change Required” message

is displayed. Severe Operating Conditions can cause the

change oil message to illuminate as early as 3,500 miles

(5,600 km) since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles (805 km).

The “Oil Change Required” message will be displayed in

the instrument cluster and a single chime will sound,

indicating that an oil change is necessary.

Your authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

your authorized dealer, the message can be reset by

referring to “Instrument Cluster Display” in “Getting To

Know Your Instrument Panel” for further information.NOTE:

Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km), twelve months or 350

hours of engine run time, whichever comes first. The 350

hours of engine run or idle time is generally only a concern

for fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or 350 hours of

engine run time if the vehicle is operated in a dusty and

off-road environment, or is operated predominantly at idle

or only very low engine RPM’s. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before your next scheduled service.

• Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering (if equipped) and

fill as needed.

• Check function of all interior and exterior lights.

8

SERVICING AND MAINTENANCE 341

Page 350 of 492

Checking Oil Level

To assure proper engine lubrication, the engine oil must be

maintained at the correct level. Check the oil level at

regular intervals, such as every month. The best time to

check the engine oil level is about five minutes after a fully

warmed up engine is shut off.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings.

There are three possible dipstick types,

•Crosshatched zone.

• Crosshatched zone marked SAFE.

• Crosshatched zone marked with MIN at the low end of

the range and MAX at the high end of the range.

NOTE: Always maintain the oil level within the crosshatch

markings on the dipstick.

Adding 1 quart (1.0 liters) of oil when the reading is at the

low end of the dipstick range will raise the oil level to the

high end of the range marking.

CAUTION!

Overfilling or underfilling the crankcase will cause

aeration or loss of oil pressure. This could damage your

engine.

Adding Washer Fluid

The windshield washer fluid reservoir is located in the

front of the engine compartment. Be sure to check the fluid

level at regular intervals. Fill the reservoir with windshield

washer solvent (not radiator antifreeze) and operate the

system for a few seconds to flush out the residual water.

When refilling the washer fluid reservoir, apply some

washer fluid to a cloth or towel and wipe the wiper blades

clean. This will help blade performance.

To prevent freeze-up of your windshield washer system in

cold weather, select a solution or mixture that meets or

exceeds the temperature range of your climate. This rating

information can be found on most washer fluid containers.

The fluid reservoir will hold nearly 1 gallon (4 liters) of

washer fluid when the message “Low Washer Fluid”

appears in the instrument cluster.

348 SERVICING AND MAINTENANCE

Page 365 of 492

Coolant Checks

Check engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where appli-

cable). If the engine coolant (antifreeze) is dirty, the system

should be drained, flushed, and refilled with fresh OAT

coolant (conforming to MS.90032) by an authorized dealer.

Check the front of the radiator for any accumulation of

bugs, leaves, etc. If dirty, clean by gently spraying water

from a garden hose vertically down the face of the con-

denser.

Check the coolant recovery bottle tubing for brittle rubber,

cracking, tears, cuts, and tightness of the connection at the

bottle and radiator. Inspect the entire system for leaks. DO

NOT REMOVE THE COOLANT PRESSURE CAP WHEN

THE COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could lead to

severe internal engine damage. If any coolant is needed to

be added to the system please contact an authorized dealer.

If the engine coolant (antifreeze) is dirty or contains visible

sediment, have an authorized dealer clean and flush with

OAT coolant (antifreeze) (conforming to MS.90032).

Refer to the “Maintenance Plan” in this section for the

proper maintenance intervals.

Selection Of Coolant

Refer to “Fluids And Lubricants” in “Technical Specifica-

tions” for further information.

8

SERVICING AND MAINTENANCE 363

Page 368 of 492

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze) is a regu-

lated substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for your

community. To prevent ingestion by animals or children,

do not store ethylene glycol-based coolant in open contain-

ers or allow it to remain in puddles on the ground. If

ingested by a child or pet, seek emergency assistance

immediately. Clean up any ground spills immediately.

Coolant Level

The coolant bottle provides a quick visual method for

determining that the coolant level is adequate. With the

engine OFF and cold, the level of the engine coolant

(antifreeze) in the bottle should be between the ranges

indicated on the bottle.

The radiator normally remains completely full, so there is

no need to remove the radiator/coolant pressure cap

unless checking for engine coolant (antifreeze) freeze point

or replacing coolant. Advise your service attendant of this.

As long as the engine operating temperature is satisfactory,

the coolant bottle need only be checked once a month.

When additional engine coolant (antifreeze) is needed to

maintain the proper level, only OAT coolant that meets therequirements of FCA Material Standard MS.90032 should

be added to the coolant bottle. Do not overfill.

Points To Remember

NOTE:

When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor coming

from the front of the engine compartment. This is normally

a result of moisture from rain, snow, or high humidity

accumulating on the radiator and being vaporized when

the thermostat opens, allowing hot engine coolant (anti-

freeze) to enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

• Do not overfill the coolant expansion bottle.

• Check the coolant freeze point in the radiator and in the

coolant expansion bottle. If engine coolant (antifreeze)

needs to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

• If frequent engine coolant (antifreeze) additions are

required, the cooling system should be pressure tested

for leaks.

366 SERVICING AND MAINTENANCE

Page 369 of 492

•Maintain engine coolant (antifreeze) concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corrosion pro-

tection of your engine which contains aluminum com-

ponents.

• Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

• Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install ONLY

the correct type thermostat. Other designs may result in

unsatisfactory engine coolant (antifreeze) performance,

poor gas mileage, and increased emissions.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically. Refer

to the “Maintenance Plan” in this section for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure and possi-

bly a collision. Driving with your foot resting or riding

on the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible

brake damage. You would not have your full braking

capacity in an emergency.

Fluid Level Check — Brake Master Cylinder

Check the fluid level in the master cylinder immediately if

the brake system warning light indicates system failure.

Check the fluid level in the master cylinder when perform-

ing underhood services.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

8

SERVICING AND MAINTENANCE 367

Page 370 of 492

Add enough fluid to bring the level up to the requirements

described on the brake fluid reservoir. With disc brakes,

fluid level can be expected to fall as the brake pads wear.

However, low fluid level may be caused by a leak and a

checkup may be needed.

Use only brake fluid that has been recommended by the

manufacturer, and has been kept in a tightly closed con-

tainer to avoid contamination from foreign matter or

moisture.

Refer to “Fluids And Lubricants” in “Technical Specifica-

tions” for further information.

WARNING!

•Use only manufacturer’s recommended brake fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. Using the

wrong type of brake fluid can severely damage your

brake system and/or impair its performance. The

proper type of brake fluid for your vehicle is also

identified on the original factory installed hydraulic

master cylinder reservoir.

(Continued)

WARNING! (Continued)

•To avoid contamination from foreign matter or mois-

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master cylin-

der reservoir cap secured at all times. Brake fluid in

a open container absorbs moisture from the air

resulting in a lower boiling point. This may cause it

to boil unexpectedly during hard or prolonged brak-

ing, resulting in sudden brake failure. This could

result in a collision.

• Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

• Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

368 SERVICING AND MAINTENANCE

Page 371 of 492

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission fluid to

ensure optimum transmission performance and life. Use

only the manufacturer’s specified transmission fluid. Refer

to “Fluids And Lubricants” in “Technical Specifications”

for fluid specifications. It is important to maintain the

transmission fluid at the correct level using the recom-

mended fluid.

NOTE:No chemical flushes should be used in any trans-

mission; only the approved lubricant should be used.

CAUTION!

Using a transmission fluid other than the manufactur-

er ’s recommended fluid may cause deterioration in

transmission shift quality and/or torque converter

shudder. Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for fluid specifications.

Special Additives

The manufacturer strongly recommends against using any

special additives in the transmission. Automatic Transmis-

sion Fluid (ATF) is an engineered product and its perfor-

mance may be impaired by supplemental additives. There-

fore, do not add any fluid additives to the transmission.

Avoid using transmission sealers as they may adversely

affect seals.

CAUTION!

Do not use chemical flushes in your transmission as

the chemicals can damage your transmission compo-

nents. Such damage is not covered by the New Vehicle

Limited Warranty.

Fluid Level Check

The fluid level is preset at the factory and does not require

adjustment under normal operating conditions. Routine

fluid level checks are not required; therefore the transmis-

sion has no dipstick. An authorized dealer can check your

transmission fluid level using special service tools. If you

notice fluid leakage or transmission malfunction, visit an

authorized dealer immediately to have the transmission

8

SERVICING AND MAINTENANCE 369

Page 407 of 492

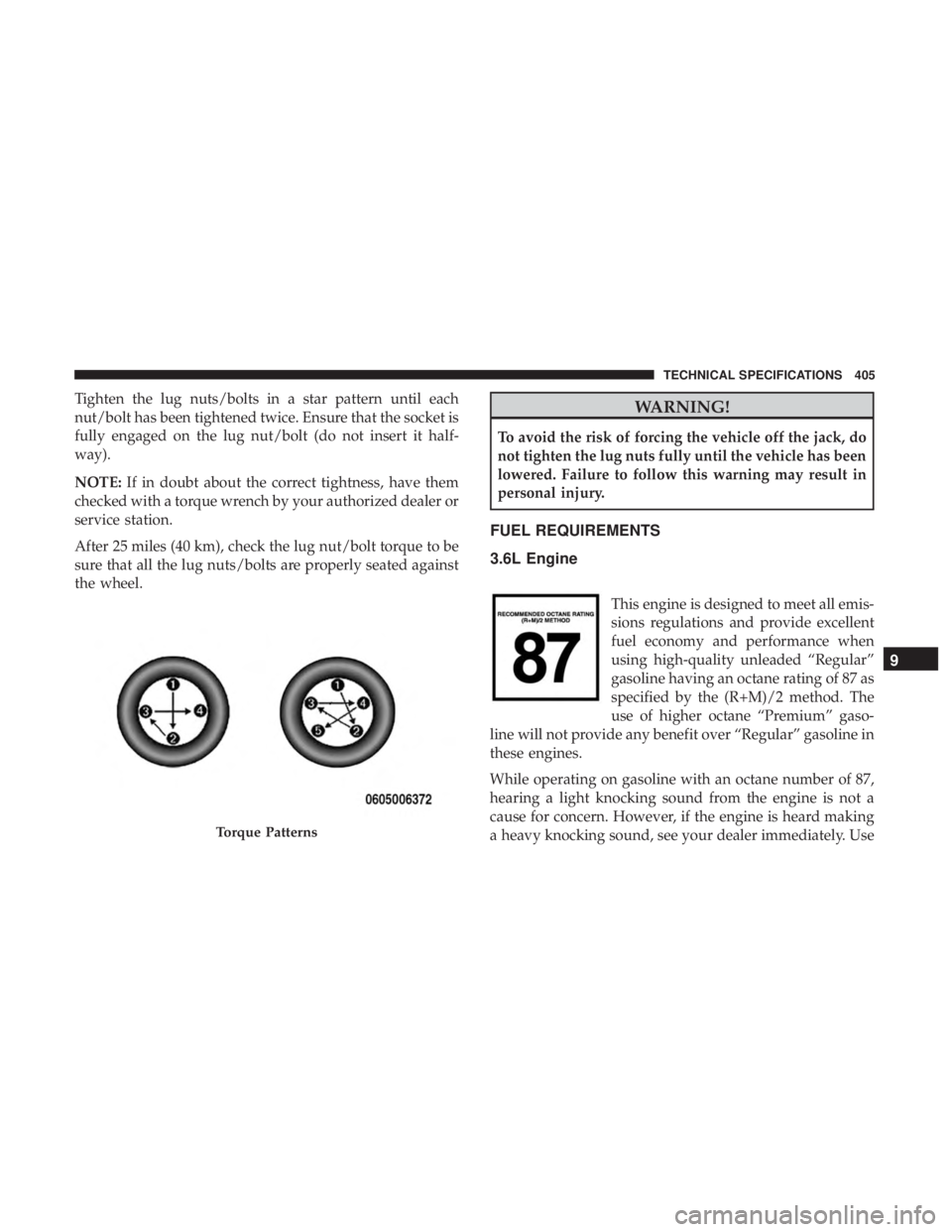

Tighten the lug nuts/bolts in a star pattern until each

nut/bolt has been tightened twice. Ensure that the socket is

fully engaged on the lug nut/bolt (do not insert it half-

way).

NOTE:If in doubt about the correct tightness, have them

checked with a torque wrench by your authorized dealer or

service station.

After 25 miles (40 km), check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly seated against

the wheel.WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts fully until the vehicle has been

lowered. Failure to follow this warning may result in

personal injury.

FUEL REQUIREMENTS

3.6L Engine

This engine is designed to meet all emis-

sions regulations and provide excellent

fuel economy and performance when

using high-quality unleaded “Regular”

gasoline having an octane rating of 87 as

specified by the (R+M)/2 method. The

use of higher octane “Premium” gaso-

line will not provide any benefit over “Regular” gasoline in

these engines.

While operating on gasoline with an octane number of 87,

hearing a light knocking sound from the engine is not a

cause for concern. However, if the engine is heard making

a heavy knocking sound, see your dealer immediately. Use

Torque Patterns

9

TECHNICAL SPECIFICATIONS 405

Page 424 of 492

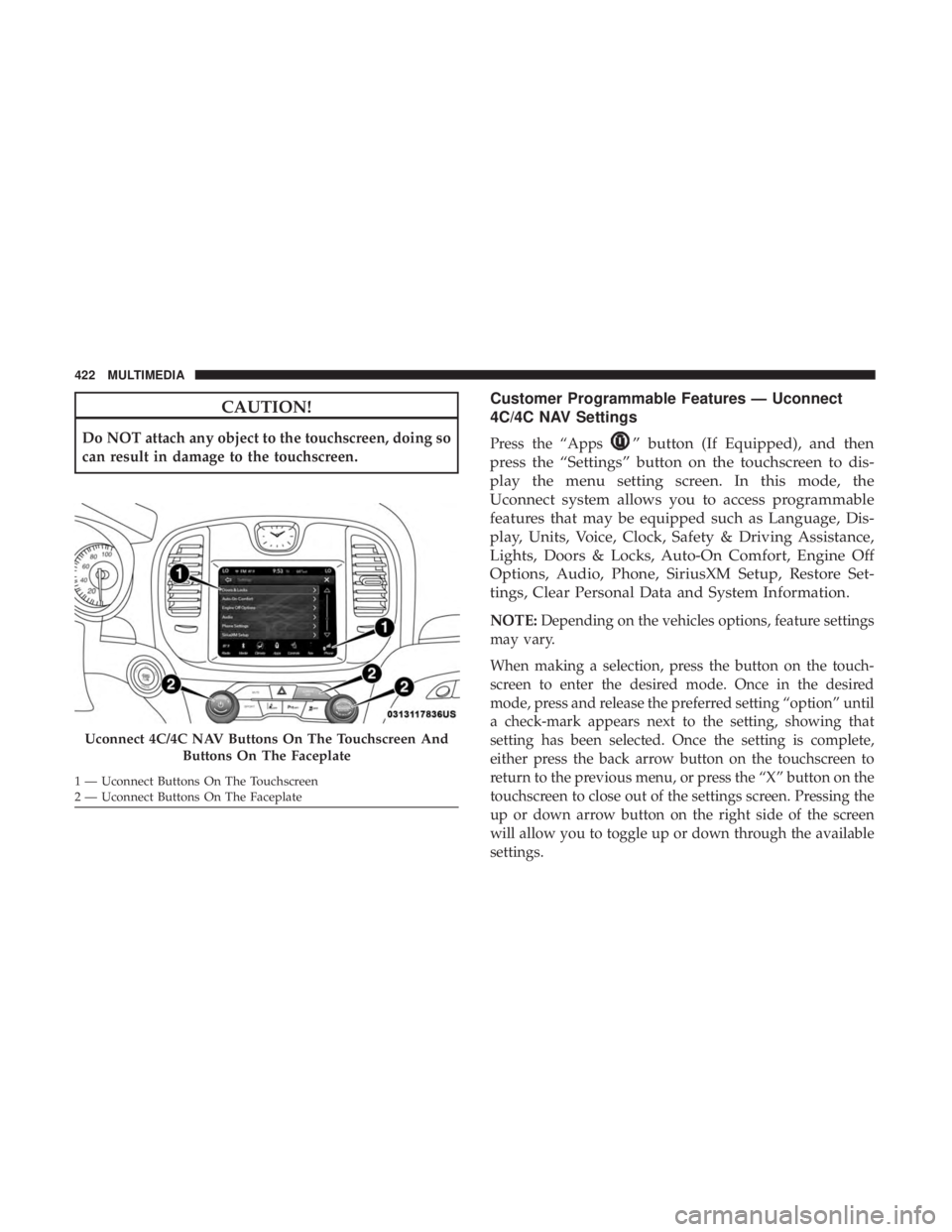

CAUTION!

Do NOT attach any object to the touchscreen, doing so

can result in damage to the touchscreen.

Customer Programmable Features — Uconnect

4C/4C NAV Settings

Press the “Apps” button (If Equipped), and then

press the “Settings” button on the touchscreen to dis-

play the menu setting screen. In this mode, the

Uconnect system allows you to access programmable

features that may be equipped such as Language, Dis-

play, Units, Voice, Clock, Safety & Driving Assistance,

Lights, Doors & Locks, Auto-On Comfort, Engine Off

Options, Audio, Phone, SiriusXM Setup, Restore Set-

tings, Clear Personal Data and System Information.

NOTE: Depending on the vehicles options, feature settings

may vary.

When making a selection, press the button on the touch-

screen to enter the desired mode. Once in the desired

mode, press and release the preferred setting “option” until

a check-mark appears next to the setting, showing that

setting has been selected. Once the setting is complete,

either press the back arrow button on the touchscreen to

return to the previous menu, or press the “X” button on the

touchscreen to close out of the settings screen. Pressing the

up or down arrow button on the right side of the screen

will allow you to toggle up or down through the available

settings.

Uconnect 4C/4C NAV Buttons On The Touchscreen And

Buttons On The Faceplate

1 — Uconnect Buttons On The Touchscreen

2 — Uconnect Buttons On The Faceplate 422 MULTIMEDIA

Page 476 of 492

Brightness, Interior Lights.....................70

Bulb Replacement ......................... .304

Bulbs, Light .......................... .212, 304

Camera, Rear ............................ .277

Capacities, Fluid .......................... .412

Caps, Filler Oil (Engine) ........................ .346, 352

Radiator (Coolant Pressure) .................365

Carbon Monoxide Warning ................209, 409

Cargo Vehicle Loading ......................... .281

Cargo Area Cover ...........................93

Cargo Compartment .........................93

Car Washes .............................. .397

Cellular Phone ........................... .447

Certification Label ......................... .281

Chains, Tire ............................. .392

Changing A Flat Tire ....................... .371

Chart, Tire Sizing .......................... .373

Check Engine Light (Malfunction Indicator Light). . . .137

Checking Your Vehicle For Safety ...............208

Checks, Safety ............................ .208

Child Restraint ........................... .191Child Restraints

Booster Seats ........................... .195

Child Seat Installation .....................205

How To Stow An unused ALR Seat Belt ........202

Infant And Child Restraints .................193

Lower Anchors And Tethers For Children .......197

Older Children And Child Restraints ...........194

Seating Positions ........................ .196

Child Safety Locks ..........................39

Clean Air Gasoline ........................ .406

Cleaning Wheels ............................... .391

Climate Control ............................75

Automatic ..............................75

Coin Holder ............................. .103

Cold Weather Operation ..................... .220

Compact

Disc (CD) Maintenance ................464

Compact Spare Tire ........................ .389

Console, Floor ............................ .103

Contract, Service .......................... .468

Cooling Pressure Cap (Radiator Cap) ............365

Cooling System ........................... .362

Adding Coolant (Antifreeze) .................364

Coolant Capacity ........................ .412

Coolant Level ....................... .363, 366

474 INDEX